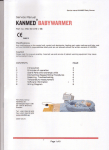

Download SERVICE MANUAL

Transcript