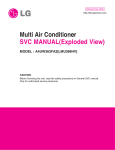

Download STATUS menu

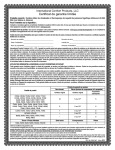

Transcript