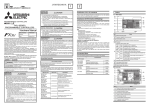

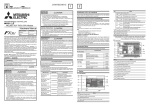

Download MELSEC iQ-F FX5 User`s Manual (Startup)

Transcript