Download Handbook Best practice DroppeD oBject ManageMent

Transcript

Handbook Best practice Dropped Object Management Rev. 02 www.samarbeidforsikkerhet.no abbreviations / terms • HSE–Health,safetyandenvironment • DO–Droppedobject,anuncontrolledmovementof anobjectfromoneleveltoanother • CCTV–(Closed-circuittelevision)surveillance camera. • Documented training–trainingwherebypersons usinganequipmenthavereceiveddocumentable practicaltrainingandtheoreticaltuitionthathas providedthemwithknowledgeof:Structure/ composition,operation,propertiesandareasofuse, aswellasmaintenanceandcontrol,allincompliance withthesafe-useandoperatingrequirementsinthe applicableregulationsandinstructionsforuse. • Competent person–Apersonthatcandocument practicalandtheoreticalknowledgeinthediscipline area,forexampleintheformofanexamination certificateoracertificateofcompetence. • SfS–SamarbeidforSikkerhet(“WorkingTogether forSafety”)Atripartitecooperationwithinthefieldof health,safetyandtheenvironment(HSE)intheoil and-gasindustry. 2 Dropped Object Management introduction Fallingobjectsrepresentasignificant safetychallengeinouroperations. Studieshaveshownthatourgreatestchallenges areconnectedtoworkprocessesandinadequately securedequipment.Asacorrectiveaction WorkingTogetherforSafety(SfS)hasdecidedto publishthishandbook,whichsummarizesrelevant requirementsforsecuringfixedandlooseequipment. ThishandbookwasfirstestablishedbyStatoil togetherwiththeircontractorsandusers. Ouraimbypublishingthishandbookisto communicateBestPracticetotheindustry. Themainobjectiveistoavoiddroppedobjects. Toachievethisweneedtoknowhowtosecure equipment.Usethishandbookactively tobetterunderstandandestablishnecessary barriers.Alsomakesurethatthesebarriersare maintained. SfSwouldliketoexpresssincerethanks toStatoilHydrofortheirwillingnesstosheartheirBest Practicewiththerestofourindustry. ErikWiig LeaderSfS Dropped Object Management 3 table of contents Purpose of the handbook......................................... 6 Barriers....................................................................... 8 Fall energy and fall factor........................................ 10 Galvanic corrosion................................................... 12 Bolted connections.................................................. 14 -Specialbolts........................................................ 16 -Boltedconnections.............................................. 18 Correct use of cotter pins....................................... 26 Securing pins/ safety pins....................................... 28 Securing devices...................................................... 30 Correct installation of wire clamps......................... 32 Securing of personnel.............................................. 34 Derrick evacuation equipment................................ 36 Securing of tools at hight........................................ 38 -Handtools<5kg............................................... 38 -Tools5-25kg...................................................... 40 -Securingofotherportableequipment................ 42 -Toolcabinetsforwork......................................... 44 Securing of permanently attached equipment..... 46 Walkways -Grating................................................................. 46 -Pipeworkandequipmentfeedthroughs.............. 48 -Railings............................................................... 50 -Toeboards.......................................................... 52 -Swinggates........................................................ 54 -Ladders............................................................... 56 4 Dropped Object Management Electroandinstrument -Floodlights........................................................... 58 -Lightingfixtures................................................... 60 -Navigationlights................................................. 62 -CCTVcamera..................................................... 64 -Craneboomcamera........................................... 68 -Loudspeakers..................................................... 70 -Junctionboxesandcabinetsinstalledaloft........ 72 -Cabletraysandcableladders............................ 74 Structures -Windwalls.......................................................... 76 -Signs................................................................... 78 Otherequipment -Valvehandlesandwheelsinstalledatheight..... 80 -Locksoninsulationcladding.............................. 82 -Temporary/permanentstorageofgascylinders.. 84 -Snatchblocks.................................................... 86 -Umbilicalrollersheaves..................................... 88 -Loophoses......................................................... 90 -Loadcarriers...................................................... 92 -Correctuseofshackles...................................... 94 -Correctuseofeyebolts/eyenuts....................... 96 Racks and storage..................................................... 98 Unnecessary equipment aloft.............................. 100 Securing of parts, equipment and material during work aloft ................................................... 102 Post inspection/ final check of the work site...... 104 Observation techniques........................................ 106 Dropped Object Management 5 purpose of the handbook Thisdocumentisintendedtohelpeliminatetheriskof droppedobjects.Itappliesbothtoequipmentprocure andtoequipmentalreadyinusein/onyourownandhired installations.Inmanycases,thefunctionalrequirements thatareestablishedfortheequipmentinthisdocument willsetanewstandardforouractivities.Thedefinition ofbarriersthatpreventdroppedobjects,deployedinthe procurement,useandmaintenanceofequipment,has beenanimportantgoal.Whenprocuringnewequipment, wemustendeavourtouseintegratedsolutionsinrespect tobarriers.Inordertominimizethedangerofcollision,we mustalwaysevaluatetheriskassociatedwiththechosen locationofequipment.Equipmentmustbedesignedand installedtoprovidethesafestpossibleaccessformaintenance,ref.NORSOK,PSA,OLFandtheNorwegian LabourInspectionAuthority. Thefunctionalrequirementssetforthinthishandbook mustbecompliedwithinthewholevaluechain: - design - procurement - installation - operation - maintenance Bycomplyingwiththeserequirementsyouwillhelp SfSachievethegoalofzerodroppedobjects Who is responsible? – Everyone in the value chain (see next page). 6 Dropped Object Management Dropped Object Management 7 Barriers • Barriersarefunctionsandmeasuresdesignedto breakaspecifiedundesirablechainsofevents. Inotherwords,theirfunctionistopreventadanger frommanifestingitselfortolimitthedamageby breakinganundesirablechainofevents. 8 Dropped Object Management Safetybarriersaretechnical,organizationalorother plannedandimplementedmeasuresintendedtobreak anundesirablechainofevents. - Man (humanknowledge,experienceandqualities) - - Technicalsolutionsalonecanserveasbarrier functions,buttheyoftenneedtobecombinedwith organizationaland/orhumansolutions MandOsolutionscannot fillbarrierfunctions alone;theymustalwaysbecombinedwithatleast oneothersolution. Organizational(procedures,specifications, checklistsetc.) t o M Dropped Object Management 9 Fall energy and fall factor Fall factors the “fall factor “describes the severity of a fall. it is an expression of the relationship between the length of the fall and the length of rope available to break the fall. factor0 lanyardwith factor1 factor2 the fall factor is calculated using the formula on next page. lanyardwithout energyabsorber 10 Dropped Object Management Fall energy Fallenergy,measuredinJoules(J)asshowninthe figuretotheleft,isonlyusedinconnectionwiththerisk ofpersonalinjury(inothercasespotentialfallenergy (Ef)iscalculatedusingtheformulaEf=mghwheremis theweightoftheobjectinkg,histheheightfromwhich theobjectisdroppedandgisthegravitationalacceleration=9.8m/s). Alimitof40JhasbeendefinedbyOLFandPSA Norway,asthecriterionforseriouspersonalinjury. Fall factor Thefallfactoristhetotallengthofthefalldividedby thelengthofthesecuringdevicethatabsorbsthefall energy.Theforceapersonorobjectisexposedto, dependsontheenergy-absorbingpropertiesofthe securingdevice(abilitytolengthenwithoutbreaking). Whensecuringpersonsagainstfalling,thefallfactor mustundernocircumstancesexceedfactor2.Itshould preferablybekeptunderfactor1. reference: petzl technical guideline. Dropped Object Management 11 galvanic corrosion Anode(lessnobel) cathode (more nobel) Electrochemical series cathode (protected) more noble graphite titanium silver acid-proof steel a4 – passive stainless steel a2 – passive iconel – passive nickel – passive silver solder Monel copper/nickel alloys Bronze copper Brass iconel – active nickel – active Tin Lead Tinsolder StainlesssteelA4–active StainlesssteelA2–active Caststeel Steelandiron Aluminium2024–T4 Cadmium Aluminium1100 Galvanisedsteel Zinc Magnesiumalloys Magnesium Anode (corrodes) less noble Asabasicrule,onlymetalsofthesameoralmostthesame nobilityshouldbecombinedinacorrosiveenvironment. 12 Dropped Object Management Galvaniccorrosionoccurswhentwodissimilarmetals withdifferentvoltagepotentialsareincontactwitheach otherinthepresenceofanelectrolyte(dampfilmor seawater/freshwater).Whenthishappens,theless noblemetalbecomestheanodeandthemorenoble metalthecathode. Ifasteelscrewisfixedintoacopperplate,thescrew willbetheanodesincecopperisthenoblermetal.The screwwillcorroderapidlyasthedifferenceinpotential isgreat. steel screw current Humidity copper Ifthesamesteelscrewisfixedintoalessnobleplate, e.g.azincplate,thescrewwillbethecathodeandwill notrust.Thezincplatewillcorrode,asitislessnoble thanthescrew. steel screw current Humidity Less noble plate Forthesereasons,itisimportantthatallsecuring devicesareofthestainlesssteeltype.Thisappliesto cotterpins,safetypins,securingwireandlockingwire forthreadingthroughnutsandboltsetc. Dropped Object Management 13 Bolted connections 14 Dropped Object Management Atpresent,boltsarebeingproducedtoatleast85 differentindustrialstandardsandtherequirements forboltedconnectionsvaryforthedifferentsectors dependingonthegivendesign,operationalandmaintenancerequirements. Achievingastableboltedconnectionwilltherefore requireaqualifiedevaluationofthefollowingfactors: • Loaddesign • Choiceofmaterialswithrespecttomechanical propertiesandcorrosionresistance • Whereappropriate,useoflubricant • Pre-tensioninganduseofthecorrecttorque equipment Locking of bolts to secure against loss of torque and pre-tension, is defined as secondary retention. Eighty-fivepercentofalldamagetoboltsetc.isdueto fatigue: –dynamicloadwithinadequatepre-tensioning –overstrainresultinginreducedpre-tensioning Dropped Object Management 15 special bolts BONDURA BOLT www.boltnorge.no Bondurahasaconstructionthatcantakeupmovement andovalitybyusingexpandingtaperedsleevesatboth endsofthebolt.Thereareseveralvariantsofthebolt, bothstraight-throughversionstootherthatarefitted fromoneside.Standardscrewsaretightenedtopress inthecones.Theboltisfixeddirectlytothemachineor equipmentwithlockingscrews.Thispreventsthebolt fromloosening,fallingoutorrotatinginthebolthole. Bonduraboltsmustbefittedandmaintainedin accordancewiththemanufacturer’sspecifications. BonduraiscertifiedincompliancewithAPI8Cand F.E.M.regulations. Areas of use: Forexample,asareplacementforclevisboltsintop drivesandhingeboltsondollies,pipehandling equipmentandcranes. Bondura bolt 6.6 16 Bondura bolt 6.1 Dropped Object Management SUPERBOLT / SUPERNUT www.superbolt.com Superbolt/Supernutareconstructedsuchthatstandardnutsarereplacedby“stretchnuts”withintegrated jackboltsandwashers.Usecanbeverybeneficialin termsofHSEbecauseonlyhandtoolsareneededfor fittinganddismantling.Riggingofheavytorqueequipmentanduseofsledgehammersduringinstallationand disassemblyisavoided.Anadditionalbenefitisthat timeissavedduringtheoperations.Boltsmustbefitted andmaintainedinaccordancewiththemanufacturer’s specifications.BothSuperboltandSupernutisavailable inaspecialcorrosion resistantoffshoreversion. Areas of use: Almostunlimited;available inbothinchandmillimetre dimensionsanddiameters fromM20toM160. Dropped Object Management 17 Bolted connections nord-Lock bolt securing system spiralock 18 Dropped Object Management Dual nuts are not recommended for locking of bolted connections. The following methods are recommended for locking bolted connections. NORD-LOCk BOLT SECURiNG SySTEM www.nordlock.com Whencorrectlyinstalled,theNord-LockBoltsecuring systemprovidesaguaranteedsecureboltedconnection. Lockingisachievedbymeansoftwowashersthatensure theclampingforceismaintainedintheboltedconnection. Nord-LockhasDnV(DetNorskeVeritas)typeapproval. Areas of use: Particularlysuitableforconnectionsexposedtovibrations,e.g.grating,loudspeakers,cabletrays,ladders, guiderailsetc.Butithasanalmostunlimitedrangeof applications. SPiRAL LOCk www.spiralock.com Self-lockisanall-metallocknut/boltandhasaspecially designedthreadedprofilethatlockswhentightened anddistributesthetensionoverthewholelengthof thethread.Thisprovidesbetterloaddistribution,which helpstoimprovethelockingoftheboltconnection. Areas of use: Almostunlimited,frequentlyusedforcriticalbolt connections. Dropped Object Management 19 correct installation of cotter pins in bolts 20 Dropped Object Management CASTLE NUT WiTH COTTER PiN Adoptedfromtheaviationindustry, Castlenutsprovideavisualandreliablemethodfor lockingboltedconnections.Thenuthasradialslotsand islockedbynoncorrosivecotterpinsthatareinserted throughaholeinthebolt. Areas of use: Unlimited, butfrequentlyusedforcriticalboltconnections. Dropped Object Management 21 nyloc lock nut Lock nut with split top Lock nut with deformed top tab washer tab plate 22 Dropped Object Management NyLOC LOCk NUT Nyloclocknutsareextensivelyusedthroughoutthe industry.Nyloclocknutsshouldonlybeusedonce. StandardDin985Nylocnutshaveatemperature ratingfrom-70°Cto+120°C. Areas of use: Thistypeofnutisrecognizedforlockinginconnectionswhereacertaindegreeoflostpre-tensioncanbe accepted. ALL-METAL LOCk NUTS All-metallocknutscanbeusedonallboltdimensions. Thenutlocksbythethreadedsectionortopofthenut deforms/splits,orthroughthenuthavingatoothedring underthecollar.Thisprovidesgreaterfrictionbetween thebolt/underlayandnut,providingasecureconnection.Therearemanyvarietiesandsuppliersonthe market. Areas of use: Thesenutshaveanalmostunlimitedareaofuse. TAB WASHER / TAB PLATE DiN 93/463 Tabwasherscanbeusedonalldimensionsandinany placedesignedfortheuseoftabwashers.Thereare severaltypeswithdifferentareasofuseforlocking eithernutsorbolts.Itisimportanttousetherighttype foreachpurpose. Areas of use: Typicallyinuseonmachinerywhereitisimportantto preventtheboltfromrotating. Dropped Object Management 23 paLnUt (Din 7967) lock nut Lock-wiring of bolts 24 Dropped Object Management PALNUT Palnutlocknut(DIN7967)hasbeenonthemarketfor severaldecadesasanalternativeforlockingofbolted connections.Palnutlocksby“cutting”itselfintothe threadsontheboltwhenitistightened.Intheoffshore contexttheyarenormallyusedforlockingontopof standardnuts. Areas of use: Onthrough-boltsinfixedequipmentanddrillingequipment.Easytoinstallwheresecondaryretentionarenot inplace. LOCk-WiRiNG Lock-wiringofboltsisalockingmethodadoptedfrom theaviationindustry.Inbrief,themethodinvolves threadingaspecialstainlesswirethroughaholeinthe bolthead,twistedandlockedtothenextboltorstructure,thuspreventingthebolttorotateandloosen.The wirecanbeusedtolockamaximumofthreeboltsina row,asshownintheillustration.(Forinfoonthesizeof theholeinthebolthead,seeISO7378). Areas of use: Usedextensivelyforlockingexternalboltedconnectionsondrillingandpipe-handlingequipment.Often usedwheretherearenothrough-boltsand/orthereis aneedforeasyvisualcontrolofthelocking. Dropped Object Management 25 correct use of cotter pins cotter pin in a shacklebolt correct installation of cotter pins in bolts 26 Dropped Object Management Theindustryhasexperiencedproblemswiththecorrect useofcotterpinsandthechoiceofmaterials. Best practice • Cotterpinsmustbebenttopreventthemfrombeing knockedout -Wherethereisadangerofpersonnelexposed,the cotterpinmustbebentasshownintheillustration • Whenhoistingpersonsandloads,alwaysuseshackleswithtwobarriers.Preferably:nutandcotterpin • Linchpins,springtypesplitpinsoranyothertypeof safetypinsthatcanbeknockedoutmustnotbeused forliftingoperations• • Cotterpinsshouldbemadeofstainlesssteel • Forstaticloads,shackleswithtwobarriersarerecommended • Itisarequirementthatcotterpinsasdescribed aboveareinspectedregularlyandreplacedwhen required. references: norsoK r-003, norsoK r-005 and Din-en-iso 1234 Dropped Object Management 27 securing pins/ safety pins 28 Dropped Object Management Withintheindustryvarioustypesofinappropriatesecuringpinsareused.Theseareunsafebecausetheycan easilybeknockedout,forexample;springtypesplitpin. Best practice • NB!Securingpinsofthetypeshowninthepictures must never be usedinliftingappliances • Securingpinsshallprovidesecondaryretention • Securingpinsshallbeofthepropersizeandquality • Securingpinsshallbesecuredbywire(wherethisis appropriate)topreventdrop • Itisarequirementthatsecuringpinsasdescribed aboveareinspectedregularlyandreplacedwhen required. Areas of use: Scaffoldingbolts,securityboltsonremovablerailings, clawcouplingsandsecuringbracketsongascylinder racksetc. references: norsoK r-003 and norsoK r-005 Dropped Object Management 29 securing devices (wires, chains and couplings) Whereverpossible,equipmentinstalledatheightshall haveintegratedsecondaryretention.Ifnotpossible,or whereequipmentisexposedtotheriskofcollision,the equipmentmustbeequippedwithsecondaryretention securelyattachedtothestructure. 30 Dropped Object Management Best practice • Securingdevicesmustbedimensionedinaccordancewiththeequipmentsupplier’scalculations.The qualityofmaterialsusedmustbeconsistentthroughouttheentireassembly • Onlyacid-proofsecuringwire(AISI316,type7x19 IWRC)shallbeused.Wiresmustbelockedwith doublepresslocks(forexampleTaluritlocks).The locksmustbemadeofcopperandtheminimum distancebetweenthelocksmustbeapproximately equaltothelengthofafullycrimpedlock • Allconnectors/snaphooksmustbemadeofacid proofsteel(AISI316)andbeequippedwithlocks. Snaphooksattachedtoshacklesshouldhave eyelets • Chainmustbemadeofacid-proof(AISI316)or galvanizedsteel • Shacklesforusewithsecuringdevicesshouldhave rotatingboltwithnutandcotterpin,markedwith “CE”,“WLL”andtraceability,atleastintheformof batchmarking • Thechainorsecuringwiremustbeasshortas possibletominimizethepotentialfallenergy • Securingdevicesmustbeinstalled,maintained andinspectedinaccordancewiththeinstructions providedintheusermanualormaintenance instructions. references: sfs recommendation 024/2008 and page 10 and 11 in this handbook. Dropped Object Management 31 correct installation of wire clamps correct installation of iron grip wire clamps. 32 WireropeØ Minimumnumber ofwireclamps mm perpiece 3-9 3 10-16 4 17-20 5 21-26 6 27-37 7 Dropped Object Management Corrosionandincorrectinstallationofwireclampsare challengesintheindustry. Best practice • Wireclampsmustbeofthecorrectnumberandsized tothedimensionofthewire • Itisarequirementthatwireclampsareassembled, inspectedandmaintainedinaccordancewiththe manufacturer’susermanual/maintenanceinstructions. Note: Wire clamps of the U-bolt type must not be used in connection with lifting operations. reference: norsoK r-003 and norsoK r-005 Dropped Object Management 33 securing of personnel Documentedtrainingisamandatoryrequirementforall personnelusingfallarrests. Fall strap reel with shock absorber 34 saLa trauma strap Dropped Object Management Best practice • Theestablishedcontrolprocedures,bothbeforeand afteruse,mustbefollowed • Nobodyshallworkaloneorunattended,whenusing fallarrestequipment • Personalusingfallprotectionequipmentmusthave documentedtrainingthatincludesrescuemethods. (Ref.page2) • Necessaryrescueequipmentmustalwaysbeavailableattheworksite • Personalprotectiveequipmentagainstfallsmustbe CEmarked • Theequipmentmustbecheckedatleastevery12 monthsbyacompetentpersonandshallbemarked withthedateforthenextinspection • Abuddycheckofriggingandequipmentmustbe carriedout • Choiceofsecuringequipment,shallbedecidedafter evaluationoftheworksite • Theanchorpointforsuspensionshallbeabletosupportatleast10kN(seerequirementinNS-EN795) • Theharnessshouldpreferablybeequippedwitha safetystrap.(E.g.:SALAtraumastrap,whichallows youtorestonyourfeetafterafall,inordertoensure bloodcirculationtothelegs). references: the norwegian Working environment act, the norwegian Labour inspectorate’s regulation - including; nos. 500, 523, 524 and 555. Module o-2.2 training plan for documented safety training; Fall arrest equipment and basic lifting appliances. oLF guidelines for construction of scaffolding (no. 105), oLF guidelines for fall arrest and rescue (no. 113) and sfs recomandation 023/2008 Dropped Object Management 35 Derrick evacuation equipment 36 Dropped Object Management Best practice • Equipmentmustbeprotectedfromwearandharsh environment • Equipmentshouldbestoredincabinet/lockerto protecteditfromUVradiationandweather • EvacuationblocksmustbeCE-marked • Theridingbeltorharnessmustbeattachedtothe evacuationblockortotheguidelinewhereappropriate • Evacuationblock,guideline,attachmentpoint, couplingsandshacklesaredefinedasevacuation equipment/antifallingdevicesandmustbechecked, certifiedandmarkedaccordingly • Anchorpointsforsuspensionmustbeabletosupport atleast10kN • Theequipmentmustbecheckedatleastevery12 monthsbyacompetentpersonandshallbemarked withthenextinspectiondate • Safeaccesstoanduseoftheequipmentmustbe ensured. references: norsoK D-001, norwegian Labour inspectorate’s regulations no. 555, ns en 341 (evacuation Blocks), ns en 362 (connectors) ns en 795 (anchor points) and ns en 813 or 1497 (riding belts) Dropped Object Management 37 securing of tools at height (<5kg) Weaklink tool belt for scaffolder internal securing loops 38 safety wires and connectors securing of tools Dropped Object Management Thereisasignificantpotentialofdroppedobjectswhen usingtoolsatheight. Best practice • Useoftoolsatheightmustberisk-assessed • Wiresandconnectorsmustbeusedbetweenthe tools,beltorbag • Swivelswithsetscrewsshouldnotbeused • Weaklinkshallbeinstalledbetweenthebag/belt andsafetywire • Atoolbagwithinternalloopsshouldbeusedwhen varioustoolsaredeployedatheight • Wriststrapsmustnotbeusedbecauseofpotential personalinjury • Ifanattachmentpointotherthanthebeltorbagis required,useanappropriatepartofthesurrounding structure,preferablyabovetheworklevel • Inlimitedareas,forexamplethederrick,flareboom andcranes,toolsusedatheightmustbeloggedout andintoensurethatnothingisleftbehind. reference: sfs recommendation 024/2008 Dropped Object Management 39 Securing of tools at height (5-25kg) 40 Dropped Object Management Methodsforsecuringheavytoolsandhand-held machineryforuseatheighthavenotbeenadequately defined.Inviewofthemajorpotentialforserious damageifsuchtoolsormachineryaredropped, itisimportanttohaveclearguidelines. Best practice • Alluseofheavytoolsandhand-heldmachineryat heightmustberisk-assessed • Allheavytoolsandhand-heldmachineryusedat heightmustbesecuredagainstdropbothwhenin useandwhilebeingtransported • Securingdevicesmustbedimensionedinaccordancewithverifiablecalculationsanddocumented droptests(seethesectiononsecuringdevices) • Securingpointsfortoolsandmachinerymustbein placeabovetheworksiteandthesecuringdevice mustbeastautaspossible • Inlimitedareas,forexamplethederrick,flareboom andcranes,toolsusedatheightmustbeloggedout andintoensurethatnothingisleftbehind. reference: sfs recommendation 024/2008 Dropped Object Management 41 Securing of other portable equipment at height 42 Dropped Object Management Severalofreporteddroppedobjectincidentsarerelated toradios,pagersandgasdetectors. Best practice • Allportableequipmentusedatheightmustbesecuredagainstbeingdropped • Carryingpouchesmustalwaysbeusedforradios andanyotherportableequipmentthatdon’thave certifiedsecuringpoints -Locksonthepouchesmusthaveadoublesecuring mechanismtopreventunintentionalopening • Beltclipswhichallowequipmenttobecomedetached whenturned180ºshouldnotbeused • Beltswithsnapfastenersarenotrecommendedfor securingofequipmentatheight. reference: sfs recommendation 024/2008 Dropped Object Management 43 tool cabinets for work at height Toolcabinets/lockersforworkatheighthavenowbeen installedatmanyfacilities,offshoreinmostcasesnear thedrillfloor.Unfortunately,anumberofirregularities havebeenobservedregardingsecuring,controland registrationoftools.. 44 Dropped Object Management Best practice • Eachcabinet/lockershallbeequippedwithalistof contentsandbekeptlocked • Adesignatedpersonmustberesponsibleforthecabinettoensurethatalltoolstakenfromandreturnedto thecabinetarelogged • Thecontentsofthetoolcabinetforworkatheight anditsaccompanyinglogbookmustbecheckedat theendofeveryshift • Alltoolsmustbeadequatelyequippedforsecuringat heightandmusthavedocumentedattachmentpoints • Inadditiontothenecessarytools,cabinetsshouldbe equippedwithasufficientnumberof: -correctlydimensionedsafetywireswithapproved swagelocks -connectors/snaphookswithlocking -toolbagswithinternalfasteningdevices -specialbeltsforfasteningoftoolsandbag -weaklinksforfasteningbetweentheharness/belt andsafetywire. reference: sfs recommendation 024/2008 Dropped Object Management 45 securing of permanently attached equipment grating Atpresentthereareanumberofdifferentwaysof fasteninggratingtounderlyingstructuresorframes. Asaresultofvibrationsanddefectivelockingof fastening,thereareincidentsofloosegratingandloose ormissingfasteningclips. 46 Dropped Object Management Best practice • Gratingmustbeadequatelyfixedtounderlying structurestopreventlooseningduetovibrations orloads • Gratingshouldbesecuredagainstmajorsideways displacementinalldirections • Through-boltsorthreadedconnectionswithlocknut, arerecommendedforsecuringtostructure • Openingsinthegratingmustnotexceed20mm wherepersonnelmaytraffictheareabelow,and shouldotherwisenotexceed35mm. reference: norsoK c-002, norsoK s-002, en-iso 14122-2 and the norwegian Labour inspection authority’s regulation no. 170 with guidelines. Dropped Object Management 47 piping and equipment feedthroughs Significantshortcominginpipingandequipmentfeedthroughandmissingholecoveringarefoundthroughout theindustry. 48 Dropped Object Management Best practice • Allpipingandequipmentfeedthroughsindecksand gratingmusthaveatoeboardandmustbecovered tothegreatestextentpossible • Canvasoracladdingmaterialcanbeused.Thisis especiallyimportantinareaswherethereisequipmentrequiringperiodicmaintenance.Doneproperly andpreferablypermanently,itwillbeanefficient measureagainstdroppedobjects. references: norsok D-001, norsoK c-002 and norsoK s-002 Dropped Object Management 49 railings Majordefectsinrailingshavebeenobservedinthe industry,andparticularlyincollapsible,movableand aluminiumrailings. 50 Dropped Object Management Best practice • Railingmustbe1100mmhighasaminimumand haveintegratedtoeboardsthatareatleast100mm high•Railingmusthaveafunctionaldesignforthe areaitisintendedtosecure,e.g.wiremeshmustbe installedasrequired(lockedareas) • Railingsshallnothavedeformationsorcracksthat affectsthefunctionalityorstrength • Itmustalwaysbepossibletoinsertmovablerailings intothefasteningsandinsertasecuringthrough-bolt • Thesafetyboltmustbeadequatelylockedusinga securingpin,snaphook(witheyelet)oracotterpin (seealsothesectiononsecuringpins) • Boththesafetyboltandlockingmustbesecuredin theimmediatevicinityoftheattachment • Allconnectionsbetweenelementsintherailingmust besecuredwiththrough-boltandlocknut • Useofsetscrewsarenotrecommendedin permanentrailings • Railingsandattachmentpointsforcollapsibleand movablerailingsmustbeinspectedonaregular basistomaintainadequatesecuringandfunctionality. reference: en iso 14122-3, norsoK D-001, norsoK c-002, norsoK s-002 and the norwegian Labour inspection authority’s regulation no. 170 with guidelines Dropped Object Management 51 Toe boards 52 Dropped Object Management Shortageofandincorrectlyinstalledtoeboardsare observedthroughouttheindustry.Commonlythe gapbetweenthetoeboardanddeckareexceeding requirements. Best practice • Decks,gangwaysandplatformsmusthavetoe boardswithaminimumheightof100mm • Onstairways,everystepmusthaveatoeboardwith aminimumheightof50mm • Alllandingsinstairwaysmusthavetoeboardswitha minimumheightof100mm • Thegapbetweenthedeckorgratingandtoeboard mustnotexceed10mm. references: en-iso 14122-3, norsoK D-001, norsoK s-002, norsoK c-002 and the norwegian Labour inspection authority’s regulation no. 170 with guidelines Dropped Object Management 53 Swing gates 54 Dropped Object Management Onmanyswinggatesthehingesarefittedwithout therequiredmaterialqualityordesignstrengthto servetheintendedfunction.Manyoldergatesalsolack integratedtoeboards. Best practice • Gatesmustbeofthesamestrengthasthe surroundingrailings • Gatesmustbesecuredinordertoprevent disengaging. • Gatesmustopen/swinginwardstotheplatform ordeck • Gatesmustbedesignedtoautomaticallyreturn toandremaininclosedposition. • Onfloatingrigs/installationsitisrecommended tofitalatchtosecuredthegateinclosedposition. • Toeboardsmustbeintegratedingates • Whereverpossible,thehingesshouldbeanintegral partofthegate • Swinggatesmustbeinspectedandmaintainedon aregularbasistoensureadequatefunction. references: norsoK D-001, norsoK c-002, norsoK s-002 and en-iso 14122-3 Dropped Object Management 55 Ladders Damagedladdersandsafetycageshavebeen observedintheindustry.Crackshavebeenfoundin bothladdersandcages,especiallyinderricksandare asarulecausedbycollisionwithmovingequipment/ objects. 56 Dropped Object Management Best practice • Laddershigherthan9mmusthaveincorporateda restplatformevery6thmorbeequippedwithafixed fallarrestdevice(ref.NORSOK) • Laddershigherthan6mshouldhavearestplatform, incompliancewithTheNorwegianLabourInspection Authority’srecommendations • Safetycagesmustbeinstalledonladdersofmore than3mandonshorterladderswherethereisarisk offallingtoalowerlevel • Thesafetycagemuststartatamaximumof2.2m abovethedeck/floor.Minimizethedistancebetween theupperpartoftherailingandthelowerpartofthe cage,byusingextraprotectionasappropriatewhere thereisariskoffallingtoalowerlevel • Thesafetycagemustextendtoatleast1.1mabove thetoplevel • Thediameterofthesafetycagemustbeatleast 70-80cm • Alldamageanddeformationmustbereportedand correctedassoonaspossible • Laddersandsafetycagesmustbeinspectedona regularbasistouncovercracksordamage. reference: norsoK D-001, norsoK s-002, en-iso 14122-1, en-iso 14122-4 and the norwegian Labour inspection authority’s regulation no. 170 with guidelines Dropped Object Management 57 Floodlights 58 Dropped Object Management Floodlightsarerarelyadequatelysecuredagainstdrop causedbyhitsfrommovingequipment. Best practice • Floodlightsmustbepositionedtopreventbeinghitby equipment/loads • Ifthereisapotentialofthefloodlightsbeinghitby mobileequipment/loads,theymusteitherbeprotectedwithreinforcedcagesorbefittedwithsafetywires • Floodlightsmustbeequippedwithtwoindependent barriers.Theattachmentpointsshouldbeintegrated, forexamplewitheyeboltsthreadedintothefloodlight housing • Calculationsmustbeavailableforattachmentpoints andsecuringdevicesrelatedtotherelevantfallenergies • Fasteningdevicesforsecuringofequipmentto bracketorstructureshouldbefittedwithsecondary retention • Hatchesforreplacementoflightbulbsmustbe hingedorsecuredwithwiretothefloodlighthousing/ frame • Fornewinstallationsorforinstallingsecuringdevices onexistingequipment,ausermanual/maintenance instructionsshouldbeavailable.Theinstructions shouldalsocoversecuringdevices. references: norsoK D-001, norsoK s-002 and sfs recommendation 024/2008 Dropped Object Management 59 Lighting fixtures 60 Dropped Object Management Therehavebeenseveralseriousincidentswhereboth thecoverandthecasinghavedropped. Best practice • Lightingfixturesmustbepositionedtopreventbeing hitbymobileequipment/loads • Lightingfixturesandbracketsshouldbefittedwith secondaryretention • Safetywiresattachmentpointsshouldbeintegrated inbothendsofthefixture • Batterypacksmustbefittedwithsecondaryretention • Theearthingwireshouldbeattachedinternallyto functionasasecondaryretention • Abovewalkwaysandothertraffickedareasfixtures withpowercableinfromonesideonly,requiresthat theoppositeendissecuredwithasafetywire • Thecovershouldhavehingesthatcanbefittedon eitherside • Thecomponentrailshouldbehingedandmustallow foradequatesecuringintheclosedposition • Strengthofattachmentpointsandsecuringdevices, relatedtotherelevantfallenergiesmustbeevaluated • Fornewinstallationsorwheninstallingsecuring devicesonexistingfixtures,usermanuals/maintenanceinstructionsshouldbeavailable. Theinstructionsmustalsocoversecuringdevices. references: norsoK D-001, norsoK s-002 and sfs recommendation 024/2008 Dropped Object Management 61 Navigation lights 62 Dropped Object Management Best practice • Theboltsusedtoattachnavigationlightstobrackets andstructuresshouldbeequippedwithsecondary retention • Attachmentbracketsmusthaveholesforattachment ofsafetywires • Coverforelectricalconnectionsmustbehingedor securedwithwire • Strengthofattachmentpointsandsecuringdevices, relatedtotherelevantfallenergimustbeeva-luated • Navigationlightswithslidinggroovesforboltattachmenttothestructure,arenotrecommended • Fornewinstallationsorwheninstallingsecuring devicesonexistingequipment,ausermanual/maintenanceinstructionsshouldbeavailable. Theinstructionsmustalsocoversecuringdevices. references: norsoK D-001 and sfs recommendation 024/2008 Dropped Object Management 63 CCTV camera 64 Dropped Object Management Withintheindustry,itisidentifiedthatCCTVcameras havebeeninadequatelysecured. Best practice (integrated solution) • CCTVcameralocationmustbeevaluatedtoprevent riskofbeinghitbymovingequipment/loads • Inareaswherethereiscraneactivity,cameras shouldbeshieldedbyprotectivecages • Thecameracasingmustbefastenedtothebracket andstructurewithadequatelockingofattachment bolts • Theattachmentpointforsecuringdevicesshould formanintegratedpartofthecameracasingand bracket • Strengthofattachmentpointsandsecuringdevices, relatedtotherelevantfallenergiesmustbeevaluated • Fornewinstallationorwheninstallingsecuring devicesonexistingequipment,ausermanual/ maintenanceinstructionsshouldbeavailable. Theinstructionsshouldalsocoversecuringdevices. references: norsoK D-001, norsoK s-002 and sfs recommendation 024/2008 Dropped Object Management 65 66 Dropped Object Management Best practice (non-integrated solution) • CCTVcameralocationmustbeevaluatedtoprevent riskofbeinghitbymovingequipment/loads • Wherethereisdangerofthecamerabeingstruckby mobileequipment/loads,itmusteitherbeprotected byareinforcedcageorbefittedwithsafetywireto structure • Thecamerashouldbefittedwithtwoindependent barriersonthecameracasing,themotorizedpan-tilt zoomunit,thewipermotorandthelenscover • Thecameracasingandmotorizedpan-tilt-zoomunit shouldbeattachedtothebracketandstructurewith adequatelylockedattachmentbolts • Theattachmentpointforthesecuringdevicesshould beintegratedintothecameraparts.Alternatively specialclampscanbeusedasattachmentpoints • Calculationsmustbeavailableforattachmentpoints andsecuringdevices,relatedtotherelevantfall energies • Fornewinstallationsorwheninstallingsecuring devicesonexistingequipment,ausermanual/ maintenanceinstructionsshouldbeavailable. Theinstructionsshouldalsocoversecuringdevices. references: norsoK D-001, norsoK s-002 and sfs recommendation 024/2008 Dropped Object Management 67 Crane boom camera 68 Dropped Object Management Withintheindustrytherehavebeenseveralincidents whereacranecamerahasbeenstruckduringlifting operations. Best practice • Craneboomcamerasmusthavetwoindependent barriers • Boltsusedforattachingthecraneboomcamerato bracketsandstructuresshouldbefittedwithsecondaryretention • Attachmentpointsforthesafetywireshouldbe integratedaspartofthecameracasing.Alternatively, specialclampscanbefittedroundthecameracasing • Thesafetywiremustrunfromthecameracasing throughthecamerabracketandthenthroughthe attachmentbracketbeforebeingattachedsecurelyto thestructureofthecraneboom • Calculationsmustbeavailableforattachmentpoints andsecuringdevices,relatedtotherelevantfall energies • Fornewinstallationsorwheninstallingsecuring devicesonexistingequipment,ausermanual/ maintenanceinstructionsshouldbeavailable. Theinstructionsshouldalsocoversecuringdevices. reference: sfs recommendation 024/2008 Dropped Object Management 69 Loudspeakers 70 Dropped Object Management Best practice • Loudspeakerslocationmustbeevaluatedtoprevent riskofbeinghitbymovingequipment/loads • Ifthereisariskofbeinghitbymobileequipment /loads,loudspeakersmusteitherbeprotectedby reinforcedbracesorequippedwithasafetywire • Boltsusedtofastenloudspeakerstobracketsand thestructureshouldbefittedwithsecondaryretention,asanalternativeasafetywirecanbeattached betweenbracketandstructure • Strengthofattachmentpointsandsecuringdevices, relatedtotherelevantfallenergimustbeeva-luated • Fornewinstallationsorwheninstallingsecuring devicesonexistingequipment,ausermanual/ maintenanceinstructionsmustbeavailable. Theinstructionsshouldalsocoversecuringdevices. references: norsoK D-001, norsoK s-002 and sfs recommendation 024/2008 Dropped Object Management 71 Junction boxes and cabinets installed at hight 72 Dropped Object Management Withintheindustryitisrevealedincorrectpositioning ofjunctionboxesandcabinets,defectivesuspension /fasteningandinadequatesecuringofhatches,doors andcovers. Best practice • Junctionboxesandcabinetsmustbelocatedwhere theydonotobstructpassageways,evacuationroutes ormovingequipment • Thetypeanddesignofattachmentandsafety devicesmustbeinaccordancewithcalculatedloads andknownpotentialexternalstressfactors • Fasteningdevisesforsecuringofequipmentto bracketorstructureshallbefittedwithsecondary retention • Wherethereisdangeroftheequipmentbeingstruck bymovingequipment/loads,itmustbeprotectedbya reinforcedcageorbefittedwithasafetywire • Coversmustbesecuredbyfastenersthataresecuredandlockedtopreventloosening,andmustbe securedwithwireorchain • Hingedhatches/doorsshouldbesecuredagainst unintendedunhookingandlockingdevicesshould befittedwithbarrieragainstopening • Asaminimum,themanufacturer’sinstructionsfor installationandmaintenance(usermanual)must becompliedwith. references: norsoK D-001, norsoK s-002 and sfs recommendation 024/2008 Dropped Object Management 73 Cable trays and cable ladders 74 Dropped Object Management Best practice • Onlyapprovedboltconnectionsshallbeusedfor fasteningandcouplings • Cablefixingclampswithscrewconnectionsareused forsafeandfunctionalsecuringofinstrumentcables • Whenattachingthecablesupportsystemtoastructure,theriskofgalvaniccorrosionmustbeassessed andinsulationconsideredwhereappropriate • Theusermanual/instructionsforusemustalso provideguidelinesforcorrectinstallation,bothinthe jointsandtheattachment • Inaddition,theusermanual/instructionsforuse mustprovideguidelinesfornecessarymaintenance/ retighteningandinspectionofbothelectro-steeland boltandscrewconnections. references: norsoK s-002, sfs recommendation 001/2001 and sfs recommendation 024/2008 Dropped Object Management 75 Wind walls 76 Dropped Object Management Withintheindustrymanydamagedandlooseplates havebeenrevealedinwindwalls.Thisisduebothto faultyinstallationandtoexternalfactors(collisionswith mobileequipmentandharshenvironment). Best practice • Wind-wallpanelsmustbefastenedtoaseparate support/structureandnevertothemainstructure • Wind-wallpanelsmustalwaysbereinforcedusing horizontalsteelbeamsinaccordancewiththedesign loads • Areasthatareexposedtocollisionriskmusthave strongercornermountingssecuredbythrough-bolts andlocknuts • Thepreferredattachmentsolutionisthrough-bolts withwashersandlocknuts • Theusermanual/instructionsmustalsoprovide guidelinesforcorrectinstallationofbothjointsand attachmentpoints • Guidelinesmustbeavailableonessentialmaintenanceandinspectionofwind-wallpanelsandtheir attachmentpoints. reference: norsoK c-002 Dropped Object Management 77 Signs 78 Dropped Object Management Signinstallationmethodshaveinmanycasesbeen foundinadequate. Best practice • TherequirementsoftheNorwegianLabourInspectionAuthorityinrespecttopostingofsignsmustbe followed • Signs,bracketsandframesforsignsmustalwaysbe securelyattachedandtheframesshouldbeofmetal • Wheretheunderlyingmaterialpermits,signframes shouldbeattachedusingthrough-boltswithlocknuts • Fastenersusedforattachmenttobracketsandstructuresshouldbefittedwithsecondaryretention • Identificationtagsthatarepaintedorgluedare recommendedforidentificationofpipingsystems.On hotsurfaces,identificationtagsshouldbeattached withplastic-coatedsteelbands. references: norsoK D-001 and the norwegian Labour inspection authority’s regulation no. 526 -chapter 3 - §§ 10 and 11. Dropped Object Management 79 Valve handles and valve wheels installed at height 80 Dropped Object Management Manycaseshaveoccurredwherevalvewheelsand valvehandlesformanualvalvesarenotadequately secured. Best practice • Valvewheelsandhandlesmustbefittedwithsecondaryretention • Wherepossible,nutsandcotterpinsshouldbeused inthevalvestemonstationaryvalvehandlesand wheels(NordlockandNylocnutscanalsobeused whereappropriate) -Onlargehandlesandwheels,boltsandlocknuts shouldbeusedinsteadofcotterpins • Whenmobilehandlesorwheelsareused,they shouldbesecured -Whennotinuse,handlesandwheelsshouldbe storedinasuitableandsafelocation • IfSeegerringsareusedforlocking/securing, frequentinspections/maintenanceshouldbecarried outtocheckforcorrosionand/ormechanicaldamage • Onwheelsthataresecuredbyasetscrewonly, replacethesetscrewwithathrough-boltandlocknut • Safetywirewithalockablesnaphookmaybean alternativeifthesecuringmethodsmentionedabove cannotbeused. references: sfs recommendations 001/2001 and sfs recommendations 024/2008 Dropped Object Management 81 Locks on insulation cladding 82 Dropped Object Management Therehavebeenmanyinstanceswithintheindustry wherepiecesofinsulationcladdinghavedroppedfrom heightsduetovibrations,corrosionorstrongwinds. Best practice • Insulationcladdingmustbesecurelyfastenedto preventlocksfromlooseningunintentionally • Thelocksshouldbesecuredwithsecondaryretention,eitherbyusingaboltandlocknutorbyinserting astainlesscotterpinthroughthesecuringholesin thelocksorsimilar. • Maintenanceroutinesmustincludeinspectionofthe claddingtoensurethatitisingoodcondition. reference: sfs recommendation 024/2008 Dropped Object Management 83 temporary / permanent storage of gas cylinders storage rack with bolted cylinder brackets temporary storage, secured with chain 84 Dropped Object Management Gascylinderstemporarilystoredareoften poorlysecuredwithropeorcargostraps. Best practice • Storingofgascylindersmustnotobstructpassage • Gascylindersmustbestoredandsecuredsafely • Storingofgascylindersmustberiskassessed • Temporarilystoredgascylindersmustbesecured withachain • Permanentstorageracksmustbeequippedwith securingbrackets/chains. references: norsoK s-001 and norsoK s-002 Dropped Object Management 85 snatch blocks nord lock a set-screw is installed through the nut and into the stem a set-screw is installed through the nut and into the bearing bolt 86 Dropped Object Management Best practice • Blocksmusthavetwobarriersbothinthesuspensionandtheshaft • Amaintenanceprogrammustbeestablishedin accordancewiththeusermanual,includingrequirementforinspectioneverytwelvemonthsofblocks, shacklesandliftinglugsbyacompetentperson -Blocksmustbedismantledattherequestofthe competentpersonorinaccordancewiththemanufacturer’srecommendationsor,inanycase,atleast everyfifthyear • Snatchblocksandsuspensionshacklesshouldpreferablybemarkedwithcolouredtiewrapsusingthe designatedcolourcodeoftheyear. Acompetencematrixmustbedrawnupinaccordance withNORSOKforpersonnelwhomaintainandoperate snatchblocks. references: norsoK r-003, norsoK r-005 and sfs recommendation 014/2004 (snatch blocks). Dropped Object Management 87 Umbilical roller sheaves (Banana sheaves) 88 Dropped Object Management Asaresultofinadequatesecuringofrollersin umbilicalrollersheaves,therehavebeenseveral seriousincidents. Best practice • Anumbilicalrollersheavemusthavemaintenance programandbesubjectedtotestingandinspection everytwelvemonthsinaccordancewiththemanufacturer’sinstructions • Rollersmustbesecuredwithtwoindependentbarriers,forexample,through-boltswithlocknutsor cotterpins • Anumbilicalrollersheavemustbeusedexclusively forthepurposeforwhichitwasdelivered,i.e.itisnot permittedtouseitforsuspendingwires • Theumbilicalmustbeinstalledondeckandthesupportrollersreinstalledandsecured • Ausermanual/maintenanceinstructionsforthe equipmentmustbeavailableTheinstructionsmust coverinstallation,inspectionandmaintenance. Instructionmustalsoincludesecuringdevices • Sheavesandsuspensiondevicesshouldpreferably bemarkedwithcolouredtiewrapsusingthedesignatedcolourcodeoftheyear. references: norsoK r-003 and sfs recommendation 024/2008 Dropped Object Management 89 Loop hoses Faultyinstallationorinadequatemaintenanceofloop hoses,andespeciallyhigh-pressurehoses,isapotential safetyrisk. 90 Dropped Object Management Best practice • Theequipmentmanufacturer’sinstructionsforinstallationandtechnicaldescriptionmustbefollowed • Clampsmustbeattachedandsecurelyfastened wherethehoseismarkedwith;“Attachsafetyclamp here” • Safetychainsmustbeasshortaspossible-and installedasclosetotheverticalaspossible, topreventfallenergyandpendulumeffect • Securingdevicesforhosesmustbedesignedtosupportthemaximumloadsgeneratedbyabursthose. Thedesignbasismustbedocumented • Therequiredresistancetowearandtear,chemicals, heatandUVradiationmustalsobedocumented • Thesecuringsystemforhosesmustbecertifiedand traceable • Thesecuringdevicesmustbecheckedandmarked inaccordancewiththenormforliftingappliances • Inadditiontocorrectinstructionsforinstallation, theusermanual/maintenanceinstructionsshould containguidelinesfornecessarymaintenanceand inspectionofthehosesecuringsystem. Dropped Object Management 91 Load carrier Units (LcU) Severalseriousincidentsrelatedtotheuse- anddispatchofloadcarriershavebeenrevealed. Forklift pockets and roof Forklift pockets, frame, tank and tank top Forklift pockets and frame 92 Dropped Object Management Best practice • Chainslingsmusthavethenecessarycertification,be intactandwithouttwists.Shacklesmustbeequipped withnutsandcotterpins • LCU`smusthavethenecessaryidentificationand certifiedliftinglugs • Liftinglugs,doors,hingesandlocksmustnotbe deformedordamaged • Permittedloadsincontainersandbasketsmustbe welldistributedandadequatelysecuredbystamping, useoflashingandnets(baskets).Lashingmustnot comeincontactwithsharpedges.Paddingshould beusedwhereappropriate.Heavyobjectsmustbe placedatthebottom • OnLCU`swithattachedequipmentsuchaspumps, tanks,winchesetc.,checkandensurethatno equipmentprotrudesfromtheframe • Tanksmusthavesecuredandsealedmanholes/ valves.Allattachedequipment(grids,covers,plates etc.)mustbeadequatelysecured.Thepermittedload mustnotbeexceeded -Itmustbeensuredthattherearenolooseobjectsin theforkliftpocketsorontopoftheLCU`sorinloads -Checkofequipmentmustbedocumentedbya signaturebeforetransporttoorfromalocation. references: DnV 2.7.1, ns-en 12079, norsoK r-003, norsoK r-005, sfs recommendation 024/2008 and oLF guideline no. 116 Dropped Object Management 93 correct use of shackles Load direction on a shackle safe use of shackles. Limitations. Load on shackle bolt illustration for shackles > WLL 8.5 t. on small shackles, the load must be distributed across the whole bolt. example: if a load of WLL 10.5 t is distributed across only 40 per cent of the shackle bolt’s length, WLL is reduced to 10.5 x 0.8 = 8.4 t. WLL x factor = Lifting capacity 94 Dropped Object Management Best practice • Shacklesmustbecertified,CE-markedandapproved, i.e.bemarkedwiththedesignatedcolourcodeofthe year(preferablybyusingcolouredtiewraps). • Shacklesmustbeequippedwithtwobarriers:nutand cotterpin • Shacklesmustonlybeusedfortheirintendedpurposeandmanner • Theusermustbefamiliarwiththeapplicablelimitationsandguidelinesforuse • Shacklesaredesignedtosupporttheloadatthebottomofthehollowtorusandevenlyacrosstheshackle bolt•Ifshacklesareexposedtoloadsinotherplaces, thismustbetakenintoaccountduringuseasitwill reducecapacity • Pointloadsontheshackleboltshouldbekepttoa minimumasitwillreducecapacity • Onshackleswithacapacityofmorethan8.5t,or havelargeopenings,thereductionfactorshownatthe bottomofthefiguremaybeusedtopreventdeformationoftheshacklebolt. references: norsoK r-cr-002, norsoK r-003, and norsoK r-005 Dropped Object Management 95 correct use of eye bolts /eye nuts Before use of grade 80 eye bolts, see designated lifting table 45° 45° stated WLL right Wrong Figure showing correctly and incorrectly installed eye bolts. note: only grade 80 (or better) eye bolts shall be used offshore. 96 Dropped Object Management Best practice • Eyebolts/eyenutsmustbecertified,CE-markedand approved,i.e.bemarkedwiththedesignatedcolour codeoftheyear(preferablybyusingcolouredtie wraps) • Eyebolts/nutsmustonlybeusedfortheirintended purposeandmanner • Theusermustbefamiliarwiththeapplicablelimitationsandguidelinesforuse • Eyebolts/nutsforuseoffshoreshallbeatleast grade80Eyebolts/nutsforuseonshoreshouldbe atleastgrade80 • Grade80eyebolts/nutsarelabelledwiththepermittedloadintheleastadvantageousdirection,i.e.90 degreesonthefasteningbolt • Eyebolts/nutsmustbeadequatelytightenedprior touse • Manufacturerinstalledeyebolts/nutsarenormally appropriateforuseduringinstallation/removalofthe unitstheyareinstalledon,e.g.gearboxes,pumps, motorsandvalves • Eyebolts/nutsmustberemovedafteruse,andthe threadsintheequipmentonwhichtheyhavebeen usedmustbepreservedbyforexample;greaseand aplasticplug. references: norsoK r-cr-002, norsoK s-002, norsoK r-003 and norsoK r-005 Dropped Object Management 97 Racks and storage 98 Dropped Object Management Thedesignofracksforstorageofmaterialand equipmentisoftennotappropriatetoensuresafe storage. Best practice • Ensurethattemporarystorageinmodulesispermittedinacontrolledmannerwithrespecttotype ofgoods,duration,storageareaandhousekeeping • Storagemustnotobstructaccessibilityorevacuation ofthemodule • Ensurethatthestoredmaterialsdonotobstruct accesstoemergencyequipment • Storageracksandstorageareasmustbedesigned toensurethatequipmentcannotaccidentallydropto lowerlevels • Theheaviestequipmentshouldbestoredlowest • Onmobileunits,temporarystoragespace/racks mustbeseafastenedandshelvesshallbeequipped withbaffleplates. references: norsoK s-001 and norsoK s-002 Dropped Object Management 99 Unnecessary equipment at height 100 Dropped Object Management Obsoleteequipmentisoftenfoundatheight. Thisequipmentisoftenexcludedfromestablished inspectionandmaintenanceprocedures,and introducesaconsiderableriskpotential. Best practice • Itismandatoryonregularbasistoevaluatewhat equipmentisrequiredorshouldberemoved. • Theassessmentshouldestablishwhetherequipment shouldberelocatedtoreducetheriskofcollisionwith mobileequipment • Inspectionandmaintenanceproceduresshouldbe revisedregularly,toensureinspectionandmaintenanceofallequipmentinstalledatheight. Finalchecksmustbecarriedoutconsistentlytoensure thatnoequipment/materialsareforgottenatheight. references: sfs recommendation 01/2001 and sfs recommendation 024/2008 Dropped Object Management 101 Securing of parts, equipment and material during work at height 102 Dropped Object Management Thepotentialfordroppedobjectsduringrepairand installationworkatheightissevereandisreflected inasignificantproportionofreportedincidents. Best practice • Allrepairandmaintenanceworkatheightmustbe riskassessed • Allparts,equipmentandmaterialusedatheightmust besecuredagainstdrop • Smallpartsmustbestoredinsuitablestorage containersorsimilar • Inlimitedareas,forexamplethederrick,flareboom andcranes,toolsusedatheightmustbeloggedout andintoensurethatnothingisleftbehind. • Whentheworkiscomplete,afinalcheckmustbe carriedout,toensurethatnomaterialorequipment havebeenleftatheight. reference: sfs recommendation 024/2008 Dropped Object Management 103 post inspection/final check of the work site 104 Dropped Object Management Alwayskeepyourworksitetidy. Best practice • Tools,equipmentandmaterialmustbesecured inasafelocation,attheendofeachshift • Whentheworkisfinished,afinalcheckand inventorycountmustbecarriedouttoensurethat notools,equipmentormaterialisnotleftbehindat height • Theworksitemustbeleftinatidyandcleanstate, andalltools,equipmentandmaterialmustbe returnedtotheirdesignatedstorageplace. reference: sfs recommendation 024/2008 Dropped Object Management 105 observation technique InordertoidentifyPotentiallyDroppedObjects(DO),it isimportanttobetrainedinDOobservationtechniques, suchasDROPSorsimilar. Thetrainingmustincludemethodsforreliablesecuring ofequipment. Best practice inspection: • Ampletime • Limitsizeofthearea • Concentrateonasmallnumberofcategories andinspectinastructuredwaytomaintainan overview • Limitnumberofpersonnelineacharea, tokeepanoverview • Findingsnotinconformitywiththeestablished standardorchecklistarephotographed,given anaccuratedescriptionandsitereference • Inspection,identificationandcategorizationof findingsarethefirststepsinminimizingthe potentialfordroppedobjects • Follow-upandcorrectionoffindingsaredecisive factorsinpreventingdroppedobjects reference: sfs recommendation 024/2008 106 Dropped Object Management Ifyouhavequestionsorcommentsonthe contentsofthishandbook,pleasecontact: [email protected]@psk.no Neverletyour tools COS_080363.February2009 offtheleash! www.samarbeidforsikkerhet.no

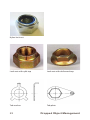

![Manual 08 [colour match]](http://vs1.manualzilla.com/store/data/006024659_1-3bda8edcd573634c82e14bf074c48937-150x150.png)