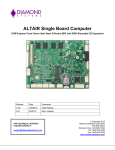

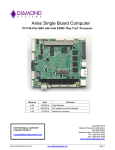

Download PCI/104-Express QSeven™ BASED SINGLE BOARD COMPUTER

Transcript