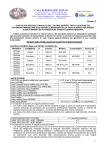

Download SBC1788 User Manual

Transcript