Download User Manual - Jireh Industries

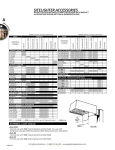

Transcript