Download INSTRUCTION MANUAL - ElectricalManuals.net

Transcript

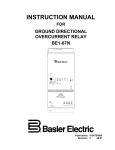

INSTRUCTION MANUAL FOR TEMPERATURE RELAY BE1-49 Publication Number: Revision: 9 1267 00 990 E 11/02 INTRODUCTION This Instruction Manual provides information concerning the operation and installation of the BE1-49 Temperature Relay. To accomplish this, the following is provided. # Specifications # Functional characteristics # Installation # Operational Tests # Mounting Information WARNING! To avoid personal injury or equipment damage, only qualified personnel should perform the procedures presented in this manual. BE1-49 Introduction i First Printing: 1980 Printed in USA © 1980, 1998, 2001, 2002 Basler Electric, Highland, IL 62249 November 2002 CONFIDENTIAL INFORMATION OF BASLER ELECTRIC COMPANY, HIGHLAND, IL. IT IS LOANED FOR CONFIDENTIAL USE, SUBJECT TO RETURN ON REQUEST, AND WITH THE MUTUAL UNDERSTANDING THAT IT WILL NOT BE USED IN ANY MANNER DETRIMENTAL TO THE INTEREST OF BASLER ELECTRIC COMPANY. It is not the intention of this manual to cover all details and variations in equipment, nor does this manual provide data for every possible contingency regarding installation or operation. The availability and design of all features and options are subject to modification without notice. Should further information be required, contact Basler Electric Company, Highland, Illinois. BASLER ELECTRIC ROUTE 143, BOX 269 HIGHLAND, IL 62249 USA http://www.basler.com, [email protected] PHONE 618-654-2341 ii FAX 618-654-2351 BE1- 49 Introduction CONTENTS SECTION 1 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MODEL AND STYLE NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SAMPLE STYLE NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 2 1-1 1-1 1-1 1-3 1-4 CONTROLS AND INDICATORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 SECTION 3 FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Power Supply Status Output (Option 2-S) . . . . . . . . . . . . . . . . . . . . . . . . . . . Constant Current Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Reference Voltage Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Upper and Lower Temperature Comparators . . . . . . . . . . . . . . . . . . . . . . . . . Latch (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Output Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Output Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Target Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 4 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RELAY OPERATING PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DIELECTRIC TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 5 4-1 4-1 4-1 4-1 4-1 4-2 OPERATIONAL TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . POWER SUPPLY STATUS OUTPUT (OPTION 2-S) . . . . . . . . . . . . . . . . . . . . . . OPERATIONAL TEST OF UPPER TEMPERATURE LIMIT TRIP . . . . . . . . . . . . OPERATIONAL TEST OF LOWER TEMPERATURE LIMIT TRIP . . . . . . . . . . . . TRIP POINT SELECTION (EXCEPT OUTPUT OPTIONS L AND M) . . . . . . . . . TRIP POINT SELECTION (OUTPUT OPTIONS L AND M) . . . . . . . . . . . . . . . . . SECTION 6 3-1 3-1 3-2 3-2 3-2 3-2 3-2 3-2 3-3 3-3 3-3 5-1 5-1 5-1 5-4 5-5 5-6 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 SECTION 7 MANUAL CHANGE INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 CHANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 BE1-49 Introduction iii This page intentionally left blank. SECTION 1 • GENERAL INFORMATION GENERAL The BE1-49 Temperature Relay is a solid-state device that monitors the temperature of a remotely located resistive temperature detector (RTD), and provides signals to the protective scheme when the sensed temperature goes above or below predetermined limits. A variety of output options provide a selection of latching or nonlatching types of normally open or closed contacts. DESCRIPTION The Basler Temperature Relay supplies a constant current to a remotely located resistive temperature detector, and senses the temperature of the detector by measuring the voltage across the resistive element. When a preprogrammed temperature limit is reached, the relay energizes its output relay so that the protection scheme may take appropriate action. Programming of the temperature limits is accomplished by adjusting the UPPER TEMPERATURE LIMIT and LOWER TEMPERATURE LIMIT controls on the relay front panel. Each control is adjustable over a range of 60° to 190°C. The effect on the protection scheme of exceeding the control setting limits of the relay is defined by the output option selected. Table 1-1 shows the available output options. The dotted horizontal lines represent hypothetical upper and lower temperature limit settings. The circled numbers represent relay case terminals. A target that indicates when the upper temperature limit has been exceeded is optionally available, and may be either internally operated or current operated. The current operated target requires a minimum of 0.1 A to flow in the trip circuit for proper operation. The internally controlled target MUST be specified if NC output contacts are specified. The relay assembly is mounted in a drawout cradle and enclosed in a standard, utility style case. Individual circuit components are accessible by removing the individual printed circuit boards from the relay cradle and using an extender board (Basler part number 9 1655 00 100) to test or troubleshoot. MODEL AND STYLE NUMBER The electrical characteristics and optional features included in a particular model BE1-49 Temperature Relay are defined by a combination of letters and numbers that make up its style number. The model number, followed by its style number, appears on the front panel, drawout cradle, and inside the case assembly. The style charts represented by Figure 1-1, lists all available options and relates them to the style number system. Upon receipt of a temperature relay, be sure to check relay style number against the requisition and packing list to see that they agree. BE1-49 General Information 1-1 The call-outs in the following figure are referred to in Table 1-1. Table 1-1. Output Characteristics A B C D E OPERATING POWER ON Output Style F. Two Relays, NO H. Two relays, NC J. Two relays, NO, Latching (UTL) L. One relay, NO, Latching M. One relay, NC, Latching N. Two relays: Upper NO Lower NC P. Two relays: Upper NC Lower NO R. Two relays, NC, Latching (UTL) S. Two relays: Upper NO Latching Lower NC T. Two relays: Upper NC Latching Lower NO 1-2 Operating power off or operating power on and temperature is less than LTL Temperature greater than LTL but less than UTL Temperature greater than UTL Temperature drops below UTL Temperature drops below LTL 1 10 2 Open, Closed Closed, Closed Open, Closed Open, Open 1 10 2 Closed, Open Open, Open Closed, Open Closed, Closed 1 10 2 Open, Closed, Closed, Closed Closed, Closed Open, Open 1 10 Open Closed Closed Open 1 10 Closed Open Open Closed 1 10 2 Open, Open Closed, Open Open, Open Open, Closed 1 10 2 Closed, Closed Open, Closed Closed, Closed Closed, Open 1 10 2 Closed, Open Open, Open Open, Open Closed, Closed 1 10 2 Open, Open Closed, Open Closed, Open Open, Closed 1 10 2 Closed, Closed Open, Closed Open, Closed Closed, Open BE1-49 General Information SAMPLE STYLE NUMBER The style number identification chart above illustrates the manner in which a relay's style number is determined. For example, if the style number were P1J-A1E-B0N5F the device would have the following features. (P) (1) (J) (A1) (E) (B) (0) (N) (5) (F) RTD sensing output Designed to be used with copper RTD rated 10 ohms at 25°C Two normally open primary outputs, with the upper temperature limit trip contact latching on closure Instantaneous trip timing Isolated internal operating power obtained from 100/120 Vac or 48/125 Vdc source One current operated target No Option 1 available No Option 2 available SPDT auxiliary contact output Semi-flush mounting Figure 1-1. Style Number Identification Chart BE1-49 General Information 1-3 SPECIFICATIONS Sensing Method Four wire, using a remotely installed 10 ohm copper or 100 ohm platinum resistive temperature detector (RTD) located within the protected machine. Relay supplies constant 40 mA current and senses voltage across the temperature sensitive resistance element. Outputs Output contacts are rated as follows. Resistive 120/240 Vac - make 30 A for 0.2 seconds, carry 7 A continuously, break 7 A. 250 Vdc - make and carry 30 A for 0.2 seconds, carry 7 A continuously, break 0.1 A. 500 Vdc - make and carry 15 A for 0.2 seconds, carry 7 A continuously, break 0.1 A. Inductive 120/240 Vac, 125 Vdc, 250 Vdc - break 0.1 A (L/R = 0.04). Power Supply One of the six types of power supplies listed in Table 1-2 may be selected to provide internal relay operating power. Table 1-2. Power Supply Types And Specifications Type Nominal Input Voltage Input Voltage Range Burden at Nominal B (Mid Range) 48 Vdc 24 to 150 Vdc 4.0 W C (Mid Range) 125 Vdc 120 Vac 24 to 150 Vdc 90 to 132 Vac 4.5 W 10.3 VA D (Low Range) 24 Vdc 12 to 32 Vdc t 4.0 W E (Mid Range) 125 Vdc 120 Vac 24 to 150 Vdc † 90 to 132 Vac 4.5 W 10.3 VA W (Mid Range) 48 Vdc 125 Vdc 24 to 150 Vdc 24 to 150 Vdc 4.0 W 4.5 W X (High Range) 250 Vdc 240 Vac 62 to 280 Vdc 90 to 270 Vac 5.2 W 14.0 VA t Type D power supply initially requires 14 Vdc to begin operating. Once operating, the voltage may be reduced to 12 Vdc and operation will continue. † Prior to 1996, Type E power supply accepted only ac input power. See the power supply discussion in Section 3, Functional Description. Target Indicator 1-4 A magnetically latched, manually reset, target indicator is optionally available to indicate that the output has tripped. An internally operated or current operated target may be specified. A current operated target requires 0.2 A in the output trip circuit to actuate, and trip circuit current must not exceed 30 A for 0.2 seconds, 7 A for 2 minutes, and 3 A continuous. A current operated target may be selected only when normally open (NO) output contacts have been specified. BE1-49 General Information Temperature Adjustment Range Two independently adjustable temperature controls, one for upper and one for lower temperature limits, each capable of settings over the range of 60 to 190°C. Pickup Accuracy Relay pickup point will not vary more than +3°C for variations in input power or operating temperature within the operating range. UL UL Recognized under Standard 508, UL File #E97033. Shock In standard tests, the relay has withstood 15 g in each of three mutually perpendicular axes without structural damage or degradation of performance. Vibration In standard tests, the relay has withstood 2 g in each of three mutually perpendicular axes swept over the range of 10 to 500 Hz for a total of six sweeps, 15 minutes each sweep, without structural damage or degradation of performance. Isolation In accordance with IEC 255-5 and ANSI/IEEE C37.90, one minute dielectric (high potential) tests as follows: All circuits to ground: Input to output circuits: Surge Withstand Capability 2,121 Vdc 1,500 Vac or 2,121 Vdc. Qualified to ANSI/IEEE C37.90.1 1989 (Transient Immunity and Radiated Susceptibility). Qualified to IEC-255-5 (Impulse requirements) and IEC-2555\6 (Surge requirements). Temperature Operating Range Storage Range –4°F to 149°F (–20°C to 65°C) –58°F to 194°F (–50°C to 90°C) Weight 11 lb (5 kg) net. Case Size S1 (See Section 4, Installation for dimensions.) BE1-49 General Information 1-5 This page intentionally left blank. SECTION 2 • CONTROLS AND INDICATORS INTRODUCTION Figure 2-1 illustrates the controls and indicators of the BE1-49 Temperature Relay. The locators of Figure 2-1 correspond to the locators listed in Table 2-1. Table 2-1 lists and describes each control and indicator. Figure 1BE1-49 Controls and Indicators Table 2-1. BE1-49 Control and Indicator Descriptions Locator Control or Indicator Function A LOWER TEMP LIMIT °C Control Determines the RTD temperature that will be the lower limit for the relay. B UPPER TEMP LIMIT °C Control Determines the RTD temperature that will be the upper limit for the relay. C POWER Indicator A red light emitting diode (LED) lights when the relay power supply is supplying a nominal +12 Vdc to the relay circuitry. BE1-49 Controls and Indicators 2-1 Locator 2-2 Control or Indicator Function D Target Indicator An overtemperature condition, as set by the UPPER TEMP LIMIT °C control, trips the normally black target indicator to red. The target is magnetically latched and may be manually reset by the target reset lever after the overtemperature indication is terminated. Depending on the option supplied, the temperature indication may be terminated when the over temperature condition has ended, or when the RTD temperature has fallen below the lower temperature limit as set by the LOWER TEMP LIMIT °C control on relays with a latching type of output. E Target Reset Lever The target indicator is a magnetically latched device. Therefore, the target must be returned to its normal (black) position after an upper temperature indication is terminated by pushing up on the reset lever that extends through the lower left of the relay case front cover. BE1-49 Controls and Indicators SECTION 3 • FUNCTIONAL DESCRIPTION INTRODUCTION The following paragraphs and Figure 3-1 provide a functional description of the BE1-49 relay. Paddle Operated Shorting Bars POWER SUPPLY SENSOR 11 12 POWER SUPPLY STATUS 17 POWER SUPPLY POWER 3 INPUT 4 OPERATING VOLTAGE CONSTANT CURRENT SOURCE 18 19 AUXILIARY OUTPUTS REFERENCE VOLTAGE SUPPLY 1 TGT 8 UPPER TEMP. LIMIT 9 R T D 1 UPPER SET OPTIONAL TEMPERATURE LATCH COMPARATOR OUTPUT DRIVER (HIGH) UPPER TEMP. OUTPUT 10 RESET AMPLIFIER 2 7 LOWER TEMP. LIMIT 6 LOWER TEMPERATURE COMPARATOR OUTPUT DRIVER (LOW) 10 LOWER TEMP. OUTPUT 1 THE BE1-49 TEMPERATURE RELAY REQUIRES FOUR WIRES FOR THE RTD. ONE PAIR PROVIDES CONSTANT CURRENT AND THE SECOND PAIR MONITORS THE RTD VOLTAGE DROP. THIS CONFIGURATION ELIMINATES MATCHING THE RESISTANCE OF THE LEADS. NO BALANCING OF LEAD RESISTANCE OR REGARD FOR WIRE LENGTH IS NECESSARY AS LONG AS THE TOTAL RESISTANCE OF THE WIRING IN THE RTD CIRCUIT IS LESS THAN 20 OHMS. D2817-08 07-09-98 Figure 3-1. Functional Block Diagram Power Supply Basler Electric enhanced the power supply design for unit case relays. The new design created three, wide- range power supplies that replace the six previous power supplies. Style number identifiers for these power supplies have not been changed so that customers may order the same style numbers that they ordered previously. The first newly designed power supplies were installed in unit case relays with EIA date codes 9638 (third week of September 1996). The new power supply design is indicated by a circuit board part number of 9 2757 XX XXX. The older power supply design is indicated by a circuit board part number of 9 1431 XX XXX. A benefit of the new design increases the power supply operating ranges such that the 48/125 volt selector is no longer necessary. Specific voltage ranges for the three new power supplies and a cross reference to the style number identifiers are shown in Table 3-1. Table 3-1. Wide Range Power Supply Voltage Ranges Power Supply Style Chart Identifiers Nominal Voltage Voltage Range Low Range D 24 Vdc 12 t to 32 Vdc Mid Range B, C, E, W 48, 125 Vdc, 120 Vac 24 to 150 Vdc, 90 to 132 Vac High Range X 125, 250 Vdc, 120, 240 Vac t 14 Vdc is required to start the power supply. 62 to 280 Vdc, 90 to 270 Vac BE1-49 Functional Description 3-1 Relay operating power is developed by the wide-range, isolated, low burden, fly-back switching power supply. Nominal ±12 Vdc is delivered to the relay internal circuitry. Input (source voltage) for the power supply is not polarity sensitive. A red LED lights to indicate that the power supply is functioning properly. NOTE If a relay has an older power supply (as indicated above), the RTD measuring circuit is not isolated from relay input power terminals 3 and 4. If the RTDs are grounded and the relay power supply is the old style, only a Type E power supply may be used. Old style Type E power supplies included an isolation transformer that permitted the RTDs to be grounded. Old style power supplies accepted only ac input power; new style power supplies accept both ac and dc input power. Power Supply Status Output (Option 2-S) The power supply status output relay is energized and its NC output contact is opened when power is applied to the relay. Normal internal relay operating voltage maintains the power supply status output relay continuously energized with its output contact open. If the power supply output voltage falls below the requirements of proper operation, the power supply output relay is de-energized, closing the NC output contact. Constant Current Source The constant current source provides a regulated 40 mA to the external RTD. This circuit is relatively unaffected by changes in the ambient temperature. Since resistance of the RTD varies directly with temperature, 40 mA through the RTD develops a voltage which is proportional to RTD temperature. See Section 5 for a graphical representation. Amplifier The amplifier monitors the voltage across the RTD and provides a voltage level signal to both the upper and lower temperature limit comparator stages. Reference Voltage Supply The reference voltage supply provides a regulated voltage to the UPPER TEMPERATURE LIMIT and LOWER TEMPERATURE LIMIT front panel controls. Each of these controls is a potentiometer and functions as a variable voltage divider. The position of the potentiometer wiper determines a reference voltage for one input of the corresponding comparator circuit. Upper And Lower Temperature Comparators Two similar comparators in the relay each compare the amplified voltage across the RTD with a dedicated reference voltage established by the setting of a front panel control. The upper temperature comparator provides an output current to its associated driver circuit when the RTD voltage exceeds the reference voltage from the UPPER TEMPERATURE LIMIT potentiometer. The lower temperature comparator provides an output current to its associated driver circuit when the RTD voltage is less than the reference voltage from the LOWER TEMPERATURE LIMIT potentiometer. Latch (Optional) A latching function is optionally available for the upper temperature output. When this latch is selected, the upper temperature output will latch in its energized condition when the upper temperature limit is exceeded. The output will then remain latched until the RTD temperature falls below its lower limit (as determined by the lower temperature comparator). 3-2 BE1-49 Functional Description Output Drivers Two Darlington amplifiers are provided as output drivers in the relay. Each amplifier receives the output current from an associated comparator and amplifies it to provide sufficient current to drive the selected output device. An inverter is provided in the input to the lower limit output driver to cause it to energize the output relay when the lower limit is exceeded. Output Relay A wide variety of relay contact arrangements are available. The contact arrangement is specified by the OUTPUT letter in the relay style number. Refer to Figure 1-1 for a list of all of the available output options. Target Indicator An optional target indicator on the front panel is tripped and magnetically latched when the upper temperature limit is exceeded. It may be reset manually after the upper temperature limit output is de-energized. BE1-49 Functional Description 3-3 This page intentionally left blank. SECTION 4 • INSTALLATION GENERAL When not shipped as part of a control or switchgear panel, the relays are shipped in sturdy cartons to prevent damage during transit. Immediately upon receipt of a relay, check the model and style number against the requisition and packing list to see that they agree. Visually inspect the relay for damage that may have occurred during shipment. If there is evident damage, immediately file a claim with the carrier and notify the Regional Sales Office, or contact Customer Service at Basler Electric, Highland, Illinois. In the event the relay is not to be installed immediately, store the relay in its original shipping carton in a moisture and dust free environment. When the relay is to be placed in service, it is recommended that the following operational test be performed prior to installation. RELAY OPERATING PRECAUTIONS Before installation or operation of the relay, note the following precautions: 1. A minimum of 0.2 A in the output circuit is required to ensure operation of current operated targets. 2. The relay is a solid-state device. If a wiring insulation test is required, remove the connecting plugs and withdraw the cradle from its case. 3. When the connecting plugs are removed the relay is disconnected from the operating circuit and will not provide system protection. Always be sure that external operating (monitored) conditions are stable before removing a relay for inspection, test, or service. Also, be sure that connecting plugs are in place before replacing the front cover. 4. Be sure the relay case is hard wired to earth ground using the ground terminal on the rear of the unit. Use a separate ground lead to the ground bus for each relay. DIELECTRIC TEST In accordance with IEC 255-5 and ANSI/IEEE C37.90, one minute dielectric (high potential) tests as follows: All circuits to ground: Input to output circuits: 2,121 Vdc 1,500 Vac or 2,121 Vdc. MOUNTING Relay outline dimensions and panel drilling diagrams are supplied in Figures 4-1 through 4-10. CONNECTIONS Incorrect wiring may result in damage to the relay. Be sure to check model and style number against the options listed in the Style Number Identification Chart before connecting and energizing a particular relay. Connections should be made with 14 AWG stranded wire or better. Typical external connections are shown in Figure 4-11 . For internal connections refer to Section 3, Functional Description. NOTE Be sure the relay case is hard-wired to earth ground with no smaller than 12 AWG copper wire attached to the ground terminal on the rear of the relay case. When the relay is configured in a system with other protective devices, always use a separate lead to the ground bus from each relay. BE1-49 Installation 4-1 To prevent an inductive overload of the relay contacts, it is necessary to break the trip circuit externally through the 52a contacts. (see Figure 4-11). Terminals 3 and 4 are external relay power supply voltage inputs and are not polarity sensitive. Terminals 6 and 8 are the constant current supply to the RTD. CAUTION If a relay built before mid 1996 is used with grounded RTDs, the relay must use a Type E power supply. Refer to the power supply discussion in Section 3, Functional Description. Terminals 7 and 9 are the voltage sensing inputs to the relay. To achieve the rated temperature accuracy for the relay, a wire should be connected from each of terminals 6, 7, 8, and 9 to the RTD. Each of the four wires should have less than 20 ohms of resistance. If less than rated temperature accuracy is acceptable, terminals 6 and 7 may be jumpered together and terminals 8 and 9 jumpered together. The relay circuitry is connected to the case terminals by removable connecting plugs (1 for 10 terminal cases, 2 for 20 terminal cases). Removal of the connecting plug(s) opens the NO trip contact circuit and shorts the NC trip contact circuit before opening the power and sensing circuits. ADJUSTMENTS The relay has been calibrated at the factory and it is strongly recommended that the calibration adjustments not be disturbed. If, however, relay pickup accuracy is suspect for any reason, remove the relay from service and check the temperature settings using the procedures given in Section 5 of this manual. D1427-01.VSD 12-04-01 Figure 4-1. S1 Case, Outline Dimensions, Front View 4-2 BE1-49 Installation D2856-23 06-15-99 Figure 4-2 . S1 Case, Single-Ended, Semi-Flush Mounting, Outline Dimensions, Side View BE1-49 Installation 4-3 CASE DETAIL A-A SHOWING THE ADDITION OF WA OVER THE BOSS TO TIGHTEN RELAY AGAINST THE PANE D1427-28 12-04-01 Figure 4-3 . S1 Case, Single-Ended, Projection Mount, Outline Dimensions, Side View 4-4 BE1-49 Installation D1427-27 12-04-01 Figure 4-4 . S1 Case, Double-Ended, Semi-Flush Mounting, Outline Dimensions, Side View BE1-49 Installation 4-5 CASE DETAIL A-A SHOWING THE ADDITION OF WASH OVER THE BOSS TO TIGHTEN T RELAY AGAINST THE PANEL P0002-17 01-30-01 Figure 4-5 . S1 Case, Double-Ended, Projection Mount, Outline Dimensions, Side View 4-6 BE1-49 Installation 5.56 (141.3) D1427-25 12-06-01 8.38 (212.9) 9 10 1 2 Figure 4-6 . S1 Case, Single-Ended, Projection Mount, Outline Dimensions, Rear View BE1-49 Installation 4-7 5.56 (141.3) D142702 7-993 19 20 11 12 8.68 (220.7) 9 10 1 2 Figure 4-7. S1 Case, Double-Ended, Projection Mount, Outline Dimensions, Rear View 4-8 BE1-49 Installation Figure 4-8 . S1 Case, Panel Drilling Diagram, Semi-Flush Mounting BE1-49 Installation 4-9 Figure 4-9 . S1 Case, Single-Ended, Projection Mount, Panel Drilling Diagram, Rear View 4-10 BE1-49 Installation Figure 4-10 . S1 Case, Double-Ended, Projection Mounting, Panel Drilling Diagram, Rear View BE1-49 Installation 4-11 Figure 4-11. DC Connection Diagram 4-12 BE1-49 Installation SECTION 5 • OPERATIONAL TEST INTRODUCTION Operational test procedures are provided in this section for use in verifying operation of the temperature relay and for selecting desired upper and lower temperature limit trip points. Temperature calibrations performed on the bench may be affected by the resistance of the relay-to-RTD wiring in the field installation. This effect is minimized by using the 4-wire sensing connection shown in Figure 4-11. These variations will be on the order of 1.5°C or less, provided the field wiring is held at 20 ohms or less per lead. For greater accuracy, it is suggested that a resistance equivalent to that of the RTD current supply wiring be inserted in the test setup. If a relay fails an operational test, refer to Section 6. Alternatively, the relay may be returned to the factory for repair. When returning the relay to the factory, ship the entire relay cradle assembly, preferably in the case. Some of the steps in the following procedures call for observations that are dependent on the output option supplied. A table of observable results is provided with those steps. CAUTION Before performing the following tests, refer to the relay operating precautions in Section 4, Installation. POWER SUPPLY STATUS OUTPUT (OPTION 2-S) Step 1. With the unit in a powered-up condition, verify that the power supply status output contact is energized open (terminals 11 and 12). Step 2. Remove input power and verify that the status output contact closes. Restore input power. OPERATIONAL TEST OF UPPER TEMPERATURE LIMIT TRIP Step 1. Connect the relay as shown in Figure 5-1. Step 2. Set the resistor decade box for minimum resistance. Step 3. Set LOWER TEMP LIMIT °C control to 60. Step 4. Set UPPER TEMP LIMIT °C control to 190. Step 5. With relay connecting plug(s) in place, apply appropriate operating power to relay. Step 6. Observe that the test setup indicators are ON or OFF as listed in the chart which follows. Test Setup Indicators, Step 6 OUTPUT OPTION C D F H J L M N P R S T ON OFF ON ON OFF ON OFF ON ON OFF DS1 OFF OFF OFF ON OFF OFF DS2 OFF OFF OFF ON OFF - - ON OPTION 3 0 1 2 5 DS3 --- --- ON ON DS4 --- OFF --- OFF BE1-49 Operational Test 5-1 DS3 DS4 4 19 17 18 UPPER TEMP. TRIP CIRCUIT AUXILIARY CONTACTS LOWER TEMP. TRIP CIRCUIT 2 RTD CURRENT SOURCE POWER SUPPLY TEMP. SENSING RTD SENSE 1 9 10 7 8 5 6 3 1 4 2 } D.C. + DS2 3 APPROPRIATE AC OR DC POWER SOURCE 7 6 5 RESISTOR DECADE BOX 8 D2817-10 07-09-98 DS1 1 Relay ground stud. 2 Not present in Options L and M. 3 DC source supplies a maximum of 250 Vdc. 4 DS3 and DS4 not required when Option 3 is 0. DS3 required when Option 3 is 2. DS4 required when Option 3 is 1 or 3. 5 1/4 W Resistor is 10 ohms for copper RTD, 100 ohms for platinum. 6 If relay has current operated target, obtain minimum trip current by adding parallel resistance to DS1 and DS2. Omit DS2 when testing relays equipped with output options L or M. 7 8 Figure 5-1. Temperature Relay Test Setup 5-2 Range of decade box is zero to 10 ohms for copper RTD; zero to 100 ohms for platinum. BE1-49 Operational Test Step 7. Set UPPER TEMP LIMIT °C control to the upper temperature limit to be tested. Step 8. Adjust resistor decade box for greater resistance until an upper temperature limit trip indication (DS1) is observed. The chart below presents the trip indication for all relay output options. On relays with target option A, target will also indicate trip. On relays with target option B, target will indicate trip if current through terminal 1 is at least 0.2 A. Trip Indications, Step 8 OUTPUT OPTION C D F DS1 ON ON ON H J OFF ON L ON M N OFF ON OPTION 3 0 1 2 5 DS3 --- --- OF F OF F DS4 --- ON --- ON P R S OFF OFF ON T OFF Step 9. Read resistance from decade box. Refer to Figure 5-2, Temperature/Resistance, to verify the temperature at which the trip occurred. Step 10. Adjust UPPER TEMP LIMIT °C as necessary and repeat steps 8 and 9 until upper temperature limit trip occurs at desired temperature. Step 11. On relays with output options J, L, M, R, S, and T, adjust resistor decade box for 0.96 ohms. For all other relays determine the resistance that corresponds to a level 10°C below the upper limit setting (using Figure 5-2), then adjust resistor decade box for the resistance value obtained. Observe that relay resets per indication chart below. Reset Indications, Step 11 OUTPUT OPTION DS1 C D F OFF OFF OFF BE1-49 Operational Test H ON J L M OFF OFF ON N P R S T OFF ON ON OFF ON OPTION 3 0 1 2 5 DS3 --- --- ON ON 5-3 180 170 160 150 R) 130 90 (1 0 PL AT IN UM 100 0O R 110 HM (1 0 + R) OH M + 120 CO PP E TEMPERATURE IN DEGREES CELSIUS 140 80 70 60 50 40 COPPER 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 PLATINUM 10.0 15.0 20.0 25.0 30.0 35.0 40.0 45.0 50.0 55.0 60.0 65.0 70.0 D2817-12 07-07-98 RESISTANCE (IN OHMS) ABOVE 10 OHMS (COPPER), OR ABOVE 100 OHMS (PLATINUM) Figure 5-2. RTD Temperature/Resistance Graph OPERATIONAL TEST OF LOWER TEMPERATURE LIMIT TRIP NOTE The operational test for the lower temperature limit trip is not required on relays with output options L and M. (The lower trip on these relays is given in Step 3, page 5-1.) Step 1. Connect the relay as shown in Figure 5-1. Step 2. Set the resistor decade box for 0.0 ohms. Step 3. Set LOWER TEMP LIMIT °C control to 60. Step 4. Set UPPER TEMP LIMIT °C control to 190. Step 5. With relay connecting plug(s) in place, apply appropriate operating power to relay. Step 6. Observe states of test setup indicators as listed in the following chart. 5-4 BE1-49 Operational Test Test Setup Indicators, Step 6 OUTPUT OPTION C D F H J L M N P R S T ON OFF ON ON OFF ON OFF ON ON OFF DS1 OFF OFF OFF ON OFF OFF DS2 OFF OFF OFF ON OFF - - ON OPTION 3 0 1 2 5 DS3 --- --- ON ON DS4 --- OFF --- OFF Step 7. Set LOWER TEMP LIMIT °C control to the lower temperature limit to be tested. Step 8. Gradually increase the decade box resistance until a lower temperature limit trip indication (DS2) is observed. The chart below presents the trip indications for all relay output options. Trip Indications, Step 8 OUTPUT OPTION C D F DS2 ON ON ON H J OFF ON L M N P R S T - - OFF ON ON OFF ON Step 9. Read resistance from decade box. Refer to Figure 5-2, Temperature/ Resistance, to verify the temperature at which the trip occurred. Step 10. Adjust LOWER TEMP LIMIT °C as necessary and repeat steps 8 and 9 until lower temperature limit trip occurs at desired temperature. Step 11. Determine the resistance that corresponds to a level 10°C below the lower limit setting from Figure 5-2, then adjust resistor decade box for resistance value obtained. Observe relay resets by the indication in chart below. Reset Indication, Step 11 OUTPUT OPTION DS2 C D F OFF OFF OFF H J L M N P R S T ON OFF - - ON OFF ON ON OFF TRIP POINT SELECTION (EXCEPT OUTPUT OPTIONS L and M) This procedure provides a method for selecting the upper and lower temperature limit trip points. The lower trip point is selected first. If only the upper trip selection is desired, perform steps 1, 3, 9, 10 and 11. Step 1. Connect the relay as shown in Figure 5-1. Step 2. Set the LOWER TEMP LIMIT °C control to at least 10°C above the intended lower temperature limit trip point. Step 3. Set UPPER TEMP LIMIT °C control to 190. BE1-49 Operational Test 5-5 Step 4. Set resistor decade box for minimum resistance. Step 5. With relay connecting plug(s) in place, apply appropriate operating power to relay. Step 6. Refer to Figure 5-2, Temperature/Resistance, to obtain resistance value for lower trip point. Step 7. Set decade box for resistance value obtained in step 6. Step 8. Slowly adjust LOWER TEMP LIMIT °C control counter-clockwise until trip indication in chart below is observed. The lower temperature limit trip point is now selected. Lower Temperature Limit Trip Point Selection, Step 8 OUTPUT OPTION C D F H J N P DS1 ON ON ON OFF ON OFF ON R S T OFF OFF ON Step 9. Refer to Figure 5-2, Temperature/Resistance to obtain resistance value for upper temperature limit trip point. Step 10. Set resistor decade box for resistance obtained in Step 9. Step 11. Slowly adjust UPPER TEMP LIMIT °C control counter-clockwise until trip indication in chart below is observed. The upper temperature limit trip point is now selected. Upper Temperature Limit Trip Point Selection, Step 11 OUTPUT OPTION C D F H J N DS1 ON ON ON OFF ON ON P R OFF OFF S T ON OFF TRIP POINT SELECTION (OUTPUT OPTIONS L AND M) Step 1. Connect the relay as shown in Figure 5-1. Step 2. Set the UPPER TEMP LIMIT °C control to at least 5°C above the intended upper temperature limit trip point. Step 3. Set LOWER TEMP LIMIT °C control to 60. Step 4. Refer to Figure 5-2, Temperature/Resistance, to obtain resistance value for upper trip point. Step 5. Set decade box for the resistance obtained in step 4. Step 6. Slowly adjust UPPER TEMP LIMIT °C control counter-clockwise until appropriate trip is observed. For option L, DS1 should go on; for option M, DS1 should go off. The upper temperature limit trip point is now selected. Step 7. Refer to Figure 5-2, Temperature/Resistance, to obtain resistance value for lower temperature limit trip point. Step 8. Set decade box for resistance obtained in step 7. Step 9. Slowly adjust LOWER TEMP LIMIT °C control counterclockwise until appropriate indication is observed. For option L, DS1 should go off; for option M, DS1 should go on. The lower temperature limit trip point is now selected. 5-6 BE1-49 Operational Test SECTION 6 • MAINTENANCE GENERAL Basler relays are static devices which require no preventive maintenance other than a periodic operational check. The operational test procedure of Section 5 provides an adequate check to verify proper operation of the relay. If the relay fails to function properly, contact the Technical Support Services Department of Basler Electric for a return authorization number before returning the relay for service. STORAGE This protective relay contains aluminum electrolytic capacitors which generally have a life expectancy in excess of 10 years at storage temperatures less than 40°C. Typically, the life expectancy of an electrolytic capacitor is cut in half for every 10°C rise in temperature. Storage life can be extended if, at one year intervals, power is applied to the relay for a period of 30 minutes. BE1-49 Maintenance 6-1 This page intentionally left blank. SECTION 7 • MANUAL CHANGE INFORMATION CHANGES This section contains information concerning changes to current and previous editions of the manual. The substantive changes are summarized in Table 7-1. Table 7-1. Instruction Manual Revisions Revision Change ECO/Date C Deleted reference to Service Manual 9 1267 00 620. Updated the Dielectric Test information. Changed Input Voltage Range and Burden Data in Power supply table in Specifications, Section 1. Corrected Style Chart by changing power supply type X from “230 Vac” to “240 Vac”. Added new power supply information to Section 3 in Power Supply paragraph starting with “Basler Electric enhanced the power supply design...”. Added new dimension figures to include all options available (S1 Single-Ended and Double-Ended, and both mounting positions). Added power supply status and terminal connections to Connection Diagram. Changed the symbol for case ground in Figure 5-1. Changed the format of the manual. 16871/07-98 D Updated the figures in Section 4 to reflect new covers. Corrected error in Figure 1-1: option 3 choices were changed from 0, 1, 2, and 3 to 0, 1, 2, and 5. 15559/12-01 E Additions to the manual clarified that pre-1996 relays with Type E power supplies and all post-1996 relays are compatible with grounded RTDs. 19417/11-02 BE1-49 Manual Change Information 7-1 This page intentionally left blank. ROUTE 143, BOX 269 HIGHLAND, IL 62249 USA http://www.basler.com, [email protected] PHONE +1 618-654-2341 FAX +1 618-654-2351