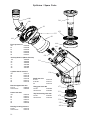

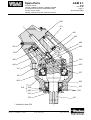

Download Hydraulic Motor/Pump Series V14

Transcript