Download v - Ansaldo STS | Product Support

Transcript

SERVICE MANUAL 5793

WEIGH RAIL

TYPE IV

September, 1975

B-10/84-100-1138-2

PRINTED IN USA

UNION SWITCH & SIGNAL DIVISION

AMERICAN STANDARD INC./ SWISSVALE, PA 15218

SERVICE MANUAL 5793

WEIGH RAIL

TYPE IV

September, 1975

B-10/84-100-1138-2

PRINTED IN USA

UNION SWITCH &SIGNAL DIVISION

AMERICAN STANDARD INC./ SWISSVALE, PA 15218

m

UNION SWITCH & SIGNAL

TABLE OF CONTENTS

SECTION

I

II

III

IV

v

VI

VII

PAGE

DESCRIPTION AND OPERATION

1.1 GENERAL DESCRIPTION

1.1.1 Main Rail Section (UM377531)

1.1.2 Deflection Multiplication

System

1.1.3 Side Plates (UR451060-1201 and

UM349734) .

.

1.2 OPERATION

1.1.1 Operation Sequence

1. 2 .~ 2 Contacts

1

2

2

2

INSTALLATION

2.1 GENERAL INSTRUCTIONS

5

5

ADJUSTMENT

3.1 CONTACTS

3.1.1 Standard Contact Settinqs

3.1.2 Five Weight Catagories

3.1.3 Master Adjustment Screw

3.1.4 External Parts

6

6

6

1

1

1

7

9

9

LUBRICATION

4.1 WEIGHT RAIL DISASSEMBLY

4.2 WEIGHT RAIL LUBRICATION

4.3 WEIGHT RAIL ASSEMBLY

10

10

10

11

LUBRICATION SPECIFICATIONS

5.1 SPECIFICATION NO. M-7680-2

(UJ41593)

5.2 SPECIFICATION UA41229

5.3 SPECIFICATION M-7611-01 (UA41099)

5.4 SPECIFICATION NO. M-7450-01

(UA41097}

12

GENERAL MAINTENANCE IN~TRUCTIONS

6.1 WEIGHT RAIL

6.2 CONTACTS

6.3 HEATER

14

14

14

14

APPENDICES

15

ii

12

12

12

13

UNION SWITCH & SIGNAL

m

SECTION I

DESCRIPTION AND OPERATION

1.1 GENERAL DESCRIPTION

The weigh rail is a special rail section used in automated

classification yards to determine the weiqht ranqes of cars

about to be processed. This weight information is used to

set the ceiling pressures in a retarder durinq automatic

operation.

The specially designed weigh rail is ·seven feet four inches

long and has a horizontal milled slot at its midpoint. The

milled slot contains a lever mechanism, sensitive to the

weight exerted by passing car wheels.

The main components of the weigh rail are as follows:

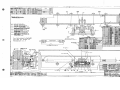

(Refer to Dwg. F451059-Sh. 2, listed in the appendices of this manual}.

1.1.1

Main Rail Section (UM377531)

The weigh rail is rectangular in cross section and will bolt

directly to 140 pound RE rail. The weigh rail can be fitted

to any size standard rail sections by means of compromise

joints.

The steel used in the rail.section is a special heat treated

alloy which will perform satisfactorily under severe service.

1.1.2

Deflection Multiplication System

The multiplication mechanism consists of two levers, a suooort

bracket and four contact actuating screws (see Figure 1).

Its purpose is to multiply rail deflection caused by the

weight of the car wheel and indicate this weiqht bv ooeratinq

the proper contact.

The lever mechanism is attached to the side plate and protected

by the controller box. The side plate is dowel fitted to the

stationary {lower) part of the rail. One end of the primary

lever is always in contact and thus moves with the vertical

deflection of the rail head. The opposite end of the primarv

lever positions the secondary lever through the master

adjusting screw. Four individual adjusting screws (figure 2)

are set in the opposite end of the secondary lever. These

screws operate four contacts which are provided for liqht,

medium, heavy, and extra heavy weight cars. As one faces the

open controller box, reading from left to riqht, are the extra

heavy contact, the light contact, the medium contact, and

finally the heavy contact.

1.1.3

Side Plates (UR451060-1201 and UM349734)

The slot cut through the center of the rail is covered by side

plates which are bolted directly to the rail section.

5793, p. 1

UNION SWITCH & SIGNAL

The side plates protect the slot and internal lever mechanism

from dirt and other foreign elements. a-rings are installed

between the side plates and rail section to further increase

protection of the internal mechanism.

The controller box houses the controller mechanism, a terminal

. block and a heater. The heater prevents frost from interfering

with the contact movement. A toggle switch in the junction

box adjacent to the weigh rail provides on-off control of the

heater.

The weigh rail is shipped from the factory with all internal

wiring connections completed.· The external wiring connections

between the controller box and junction box, are made at the

time of installation with control cable UN451060-1901, which

is shipped with the equipment.

1. 2

OPERATION

As shown in figure 1, the weigh rail has a horizontal milled

slot at its midpoint. As a car wheel passes over the rail

section, the rail portion above the slot deflects in relation

to the lower rail section. Maximum deflection occurs when

the wheel is at the center of the slot where the lever

mechanism is located. The deflection of the rail section

above the slot is directly proportional to the weight of the

passing car.

1.2.1

Operation Sequence

The mechanical operating sequence, as a car passes over the

weigh rail, is as follows:

A downward deflection o.f the rail section above the slot

produces a corresponding displacement of the primary lever.

The primary lever pivots on bearing Y, causing an upward

movement of the master adjustment screw on the end of the

primary lever.

The secondary lever pivots on bearing x, producing a downward

movement of the four individual adjustment screws.

The downward movement of the individual adjustment screws

closes the corresponding electrical contacts.

1.2.2

Contacts

Four contacts are provided (liqht, medium, heavy, and extra

heavy). The individual adjustment screws and electrical

contacts are adjusted so that a liqht weiqht car will close

only the light contact. A medium weight car will close

both the light and medium contacts. A car in the heavy weiqht

class will close the light, medium, and heavy contacts.

5793, p. 2

UNION SWITCH & SIGNAL

A

CAR WHEEL

w

RAIL SECTION

0

0

DEFLECTED SHAPE

0

0

0

0

INDIVIDUAL

ADJUSTMENT

SCREW

ORIGINAL

POSITION

NYLON

INSULATION

DEFLECTED

POSITION

, . . . . . . . _ _ _ CONTACT>

-

TO

EXTERNAL

CIRCUIT

SECTION A-A

Figure 1. Weigh Rail Schematic Operation

5793, p. 3

ffi

UNION SWITCH & SIGNAL

And finally, an extra heavy car will close all four contacts.

The spring installed between the secondary lever and the

mounting bracket prevents lost motion in the lever system

and insures the primary lever is always in contact with the

upper surface of the slot.

5793, p. 4

UNION SWITCH & SIGNAL

SECTION II

INSTALLATION

The list of general instructions below should be followed in

the installation of a weigh rail. The detailed instructions

for installing a weigh rail have been illustrated in Dwa.

F452002-Sh. 06 or Sh. 22.

2.1

GENERAL INSTRUCTIONS

1.

The weigh rail must be located on a concrete foundation or

a well tamped road bed. The concrete base is preferred.

2.

~he weigh rail must be placed on top quality ties.

3.

The center of the weigh rail must be accurately placed

over the center of a sixteen inch space between the middle

tie plates.

4.

The track gage should be widened about one quarter to one

half inch in the vicinity of the weigh rail and a guard

rail (straight section not less than six feet in length)

should be installed inside the opposite rail.

s.

The weigh rail must be located in a straight section of

track, preferably at least twenty-five feet from a track

curvature.

6.

The weigh rail must be located on an even grade. Best

performance results when vertical curves are absent for

a distance of twenty-five feet from either end of the

weigh rail.

7.

The weigh rail must be level with adjoining rails.

8.

Joining rails should be equipped with anti-creepers to

prevent unnecessary end load on the weiqh rail.

5793, p. 5

El:)

m

..

UNION SWITCH & SIGNAL

SECTION III

ADJUSTMENT

3.1

CONTACTS

The method of setting contacts by use of a shim qaqe is

illustrated in figure 2. The shim is inserted between the

base of the adjusting screw and top of the upper curved

contact spring.

INDIVIDUAL

ALUMINUM

CASTING

.

ADJUSTMENT~.

SCREW

\

==---------a=i~=====-

~~-

CONTACT

CONTACTS

Fiqure 2.

INSULATION

·

SHIM

/

=~r:~ -

NYLON

SPRINGS

X.H.

L

M

H

Method of Settinq Contacts

NOTE

Never insert the shim between contacts.

Contacts should never be adjusted when

a car wheel is positioned on the weigh

rail.

In addition to the standard contact setting instructions

listed below, each individual application drawinq includes

a detailed adjustment procedure.

Shim gage utilized in setting contacts should be similar to

"Lufkin Thickness Gage #126T". A small one-quarter inch

open end wrench should be used for individual screw adjustment.

3.1.1

Standard Contact Settinqs

To determine circuit continuity in the followinq adjustments,

an analyzer such as an ohmmeter, buzzer (or liqht) and battery

should be used.

Light Weight (L) - 14 to 35 Ton Car Loads

Connect analyzer between the white (common) and green (light

weight) wire leads in the junction box. Insert .015" shim

gage between the "L" adjustment screw and the long contact

spring (see figure 2).

5793, p. 6

UNION SWITCH & SIGNAL

Place the shim flush against the adjustment screw head. With

the shim inserted correctly, turn the "L" adjustment screw

until the circuit is just completed.

Medium Weight (M) - 35 to 52 Ton Car Loads

Connect analyzer between the white and black (medium weiaht)

wire leads in the junction box. Insert .040" shim aaqe

between the "M" adjustment screw and the loner contact sprinq.

Turn the "M" adjustment screw to just make the circuit.

Heavy Weight (H) - 52 to 110 Ton Car Loads

Connect analyzer between the white and red (heavy weiaht) wire

leads in the junction box. Insert .060" shim gaqe between

the "H" adjustment screw and the long contact spring. Turn

the "H" adjustment screw to just make the circuit.

Extra Heavy Weight (XH) - 110 Ton and Up Car Loads

Connect analyzer between the white and blue (extra heavy

weight) wire leads in the junction box. Insert .135" shim

gage between the "XH" adjustment screw and the long contact

spring. Turn the "XH" adjustment screw to just make the

circuit.

3.1.2

Five Weight Catagories

The Type IV Weigh Rail when shipped from the factory is

preadjusted for the standard four weiqht setup. In those

installations using a five weiqht system, the followina

procedure is to be followed.

The Automatic Light indicator (0-24 tons) is derived from

track occupancy.· The weigh rail provides the four remaininq

weight indications. The settings are different than for the

standard four weight system.

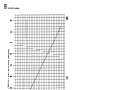

Shown in Fiqure 3 is a araph illustratina the relationship

between the contact gap settina versus the qross car weiqht.

Light Weight (L) 24 to 35 Ton Car Loads

Connect analyzer between the white (common) and green {liaht

weight) wire leads in the junction box. Insert .029" shim

gage between the "L" adjustment screw and the long contact

spring (see figure 2). Place the shim flush aqainst the

adjustment screw head. With the shim inserted correctly,

turn the "L" adjustment screw until the circuit is just

completed.

5793, p. 7

m

UNION SWITCH & SIGNAL

.180

I/

/

.160

/

~'I'

v

.140

I/

/

z

--

~

u,

w

~ .120

v

,..

/

CJ

~

...w

/

.100

i,

u,

a.

c(

I/

CJ .080

...

/

~

z

0

v

v

~

/

0

0

~v

/

en

z

~/

.060

.

I/

v

v

~

"'

/

/'

.040

,/

/

/

/

.020

.ooo

/

v

v

~"

0

Figure 3.

5793, p. 8

20

40

60

80

100

GROSS CAR WEIGHT (TONS)

Contact Setting for Various Car Weights

120

UNION SWITCH & SIGNAL

ffi

Medium Weight (M) - 35 to 55 Ton Car Loads

Connect analyzer between the white and black (medium weiqht)

wire leads in the junction box. Insert • 043'' shim qaqe between

the "M" adjustment screw and the long contact sprinq. Turn

the "M" adjustment screw to just make the circuit.

Heavy Weight (H) - 55 to 90 Ton Car Loads

Connect analyzer between the white and red (heavy weiqht} wire

leads in the junction box. Insert .068" shim qaqe between

the "H" adjustment screw and the long contact sprinq. Turn

the "H" adjustment screw -to just make the circuit.

Extra Heavy Weight (XH} - 90 Ton and Up Car Loads

Connect analyzer between the white and blue (extra heavy

weight) wire leads in the junction box. Insert .110" shim qage

between the "XH" adjustment screw and the long contact sprinq.

Turn the "XH" adjustment screw to just make the circuit.

3.1.3

Master Adjustment Screw

Under normal conditions the master adjustment screw (see Dwq.

F451059-Sh. 02), which is set at the factory, need not be

adjusted. Should there be any difficultv in obtaininq desired

settings of the individual adjustment screws due to extreme

wear of component parts, rail set, etc., a moderate chanqe

in the master adjustment screw setting will return the

individual adjustment screws to their oriqinal settinqs.

Any alteration of the master adjustment screw settinq will

effect all four individual screw settinqs. A clockwise

rotation of the master.adjustment screw will cause a narrowina

(closing) of individual screw contacts while a counterclockwise rotation will cause a wideninq (openinq) of

individual contacts.

A small 7/16" open end wrench should be used for master

screw adjustments.

3.1.4

External Parts

Weigh rail side plate bolts should be checked periodically

(refer to Dwg. F451059-Sh. 02). These bolts should be tiqht

to prevent entrance of foreign matter into the operating

mechanism.

·

The controller box cover should be held tiqhtly in place

insuring compression of the internal qasket.

5793, p. 9

m

UNION SWITCH & SIGNAL

SECTION IV

LUBRICATION

Periodic lubrication of the weigh rail is essential to proner

operation. The weigh rail should be lubricated (at least

once a year), dependinq upon amount of service. The weiqh

rail need not be removed from the track for lubrication. To

prevent damage to components, exercise care in following

the disassembly procedure outlined below.

4.1

WEIGH RAIL DISASSEMBLY (REFER TO.DWG. F451059-SH. 02)

1.

Place the heater switch, at the junction box, to the

OFF position.

2.

Remove the ramp (item 3, Dwg. F452002-SH. 06 or Sh. 22).

3.

Clean both sides of the rail section above and around

the side plates, removing all dirt, grease and corrosion.

Clean the side plates, the top of the rail, etc., to

prevent foreign matter from enterinq the mechanism during

disassembly.

4.

Remove the controller box cover (item 4, Dwg. F451059-Sh. 2).

5.

Measure and record contact gaps (L, M, H, and XH). The

contact settings will be checked (and may be duplicated

if necessary) before the rail is returned to service.

6.

Replace the controller box cover.

7.

Remove the bolts and washers (items 21 and 24) holdinq

the back plate (item 3) to the rail section.

8.

Remove the back plate.

9.

Remove the muslin bag (item 22), containinq VPI crystals

from the slot. If necessary refill with two ounces of

crystals, Specification M-7 450-1.

(See specification

tabulation in "Lubricant Specification" Section).

10.

4.2

1.

Remove the bolts and washers (item 21 and 24) holding

front plate (item 2) to the rail section.

WEIGH RAIL LUBRICATION

The following materials are required for proper

lubrication of the weigh rail.

a. Two (2) a-rings, UJ67134 (17" inner diameter x .139"

cross-section).

5793, p. 10

UNION SWITCH & SIGNAL

b.

0-ring Grease, UJ41593, Specification M-7680-2.*

c.

No-Rust Grease #1, UA41229.*

d.

Instrument Oil UA41099 or liqhtweight hiqh grade

non-gumming machine oil.

·

e.

VPI (vapor phase inhibitor) crystals, UA41087,

Specification M-7450-1.*

2.

The procedure for lubricating the weigh rail is as

follows:

4.3

a.

Remov~ and discard side plate 0-rinqs (item 28).

b.

Using mineral spirits, remove all corrosive material

from the o-ring grooves, the interior side plate

surface and mating rail section surface and the slot.

Wipe dry with a clean lintless cloth.

c.

Apply liberal amounts of o-ring lubricant (UJ41593)

to the new 0-ring (UJ67134) and 0-ring grooves,

then install new 0-rings into the grooves.

d.

Coat the side plates with grease (UA41229).

e.

Apply a few drops of instrument oil (UA41099) to

primary lever bearinq Y (see fiqure 1).

WEIGH RAIL ASSEMBLY (REFER TO DW~. F451059-SH. 02)

1.

Replace back plate (item 3), bolts and washers.

2.

Replace muslin bag containing VPI crvstals in the space

between the end of the slot and retaining bracket

(item 13-).

3.

Using the dowel pin as a guide, replace the front

side plate.

4.

Replace the front plate, bolts and washers.

5.

Remove controller box cover and carefully clean

contacts with a relay contact file or fine emery cloth.

6.

Readjust contacts to agree with oriqinal settings if

necessary.

(See "Adjustments", A. Contacts).

7.

Replace the ramp.

* Specific information covering the above lubricants toqether

with approved eources of supply are listed in "Lubricant

Specifications" section following.

5793, p. 11

m

UNION SWITCH & SIGNAL

SECTION V

LUBRICANT SPECIFICATIONS

5.1

SPECIFICATION NO. M-7680-2 (UJ41593) - NO. 2 SILICONE

GREASE

1.

This grease must conform to MIL-L-4343A.

2.

This grease can be obtained from either u.s.&s. by

ordering the above commodity nun:iJJer or from:

Manufacturer:

Trade Name:

3.

A satisfactory source of supply for this grease in

Canada is:

Manufacturer:

Trade Name:

5.2

1.

This grease can be obtained from either u.s.&s. by

ordering the above commodity number or from:

Trade Name:

5.3

1.

Dow Corning Silicone,LTD.

Toronto, Canada

No. 55 Pneumatic Grease

SPECIFICATION UA41229, RUST PREVENTIVE GREASE

Manufacturer:

2.

Dow Corning Corporation

No. 55 Pneumatic Grease

Gulf Oil Corporation, Gulf Bldq.

Pittsburqh, Pennsylvania

Gulf No-Rust, No. 3

This grease is not stocked in Canada and must be

obtained as indicated above.

SPECIFICATION M-7611-01 (UA41099), INSTRUMENT OIL

The above oil must conform to the followinq

specifications.

a.

5793, p. 12

General Composition - This specification covers

a high quality synthetic lubricating oil suitable

for clock-work mechanisms and delicate instruments

in a temperature range of from 30°F to 150°F. It

is oxidation resistant, has low volatility and

does not creep or spread.

UNION SWITCH & SIGNAL

b.

Properties - The oil shall have the following

typical characteristics:

Gravity, A.P.I

Viscosity, Centistokes

at 320F

at l00°F

Viscosity SUV at l00°F,

seconds

Flash, °F

Pour Point, °F

Color, ASTM, Union

Neutralization Value

ASTM D974, Total Acid No.

2.- This oil can be obtained either from

the above commodity number or from:

Manufacturer:

Trade Name:

3.

5.4

1.

270

28

132

405

-40

1.0

.01

u.s.&s. by

orderinq

Gulf Oil Corporation, ~ulf Bldq.

Pittsburqh, Pa.

Gulf Special Instrument Oil

This oil is not stocked in Canada and must be obtained

as indicated above.

SPECIFICATION NO. M-7450-01 (UA41097), VPI CRYSTALS

These crystals may be obtained from

the above commodity number or from:

Manufacturer:

Trade Name:

2.

21.6

u.s.&s.

by orderinq

Shell Oil Company

VPI Crystals No. 260

A satisfactory source of supply for these crystals

in Canada is:

Manufacturer:

Trade Name:

Shell Oil Company, Toronto,

Canada

VPI Crystals, No. 260

5793, p. 13

m

UNION SWITCH & SIGNAL

SECTION VI

GENERAL MAINTENANCE INSTRUCTIONS

6.1

WEIGH RAIL

1.

6.2

The rail mounting (in track) should be checked

periodically. The center gap of 16 inches must be

maintained. The weigh rail should be held tightly

to the ties and foundation so that there is no

"pumping". Side pla.te bolts s~ould be tight.

CONTACTS

1.· Contacts should be cleaned and settings checked at least

every sixty days.

6. 3

HEATER

1.

The heater should be turned on at temperatures of 40°F

or lower. During freezing weather conditions the

heater should be operated continuously.

2.

The application of external heat such as a torch

to the weigh rail or controller box is not recommended.

Application of external heat hastens the loss of

lubricant and in extreme cases can damage internal

wiring.

5793, p. 14

UNION SWITCH & SIGNAL

ffi

APPENDICES

5793, p. 15

UNION SWITCH & SIGNAL

--,--::---~-

-----~ --~-- -

.... hF.

._

-····

......... ,~

-a !01

-02G!

-

--

I

--<205

-0207

1--

-0208

--

............ ~

I.M377S31

REJIAJiKS

__. ....

8

o

....

1,;;!Jf.AAX

6

6

111432333

u.on531

W1TH

,52002-06()g_

111.hTH

WITHOOT

SEE NOTE G

WITHOOT

SEE NOTE G

UM34~694

IJM3847f.Z.

8

OIJL'()

11~,·z

111nMot11'

.SIEFIX NO'S. MIIIK£0 ~ARE FOR CIWVERTING

EXISTll«l WEIGH RAILS FRO! TlllEE-IIEIGHT TO

FOUR-IOiHT C~IFICATl<W

NOTE

..

- INSPECT & TEST PER SPEC. EU5005

NOTE A -

:1: ~m:!

~g;iAmM,a,f-hARTs.

NDTE 8 • BEFORE ASSIMILYf COAT BACK OF FR<WT & BACK PLATES.

ITEMS 2 ANO 3 W Tli A HEAVY CMTlll6,«

ITEM 30. OR ITEMe.J

•Y

NDTE

c - m ~ R F . J k ~ i , g JMRtfppttlEf~~~

NOTE

o-

SPECIAL IIISTRIMEHT 9IL (QA41im) AT BEARING& 11

NOTE E i«ITE

lli&~ !Pllt1M'~1«iarcrrro~ -·LA CORO

m

t/Ji~(i

ASSEMILl~iT MINGS, ITEM 28 OR ITEM[)

ITEM Of 0-RING GREASE M-76S0-2,

F• y~'YJ,fclhiij!Mf·

..,...

1~~01iE1rJ~\{M11\!1;POR

CLOSED ANO IIISER!E6 lt(!O SPACE INllCAfEO BY ARRON.

NDTE G • MIST

l~CT

PER !U5005

R Ail:'u\1MENT

SCREW & WEIGHT ADJUSTMENT SC~EWS

TO B strfNPPROx. POSl!IOIIS.

For Adjustment of Rail

for Use in Five Weight

Categories, Refer to

Paragraph 3.1.2

F11, R•'- o,,,!I

t Mei.e.s .. J."

1.112 .,:-.: . ' . cttf'~~;~--,--c-~·~·

V11w "YV1t.w SNOWING Jo1HT BAil 'Dtt.tLl.lHe

G~EEN LEAD~G (I)

·.

44

44

\0

1

i

i

l.J.

Yre

4.

WS:.16M Rtht,,. $ac.TtON(W1T1"' Z.4V,M ....'T . . .) ~ T

TYPE + lfEIGI! RAIL 5_ECTIOII_ _JWITH Ii V. HEii~

VIEll

LOOKING IN!O CCIITlOI. -WllH COVFR RfM>IED

"

--·--'._~

TERIAL KIT, FR<WT PLATE

_J14V.HTR.,

tR<WT PLATE ASSEMBLY WITli CONTROLLER, 14V HEATER, ETC.)

,MATERIAL KIT, FROO PLATE

FR<WT PLATE ASSEMBLY WITh CONTROLLER, 24V, HEATER, ETC.)

TYPE 4 WEIG/t R'IL SECTl<W

(WITH 14V. HEATER)

l'fPE 4 WEIGH RAIL SECTIIW

(!IT!i 24 V. HEATER

OESCR I PT l<W

EB

UNION SWITCH & SIGNAL

WEIGH RA

PC. NO.

COl'I..

c,51059

SH.

I

TR

24-VOLT

14-VOLT

CLI _ ___ .,,.,

H.01..11.s·z·

REMA-.K.S

Wt-rH(~~)

w,rH(s:!..... ) 0090250

24•VOLT

SEii: J,JoTE"'G"

UJJ390.207

24-WLT

SEE NOTE°(;.•

N3,0Z07

UR4'?i5i2.2

Rlt-~GBI

;.

i

·1

.j

~

I'

J

,

•

I

~

;

I

_1r-·1i

. ,

;2

/2_

·,,:j

I~

,

t

I

,

. ...

I

I

I

.L~_JI2).L__Jc;_]_

j

.

/2

11

!

.

I

I ..__Jr·,,

I I

11

bl[lLJ

r== · ------ - --- ·-= .:)

1

I

f,

i

,

.

:

.

;•

,

,

-

u.tl2&183

tlX432351-00I

I(

.

·r-! II .f

I

i~~

•

,·

\

I

!

_J•

'1

'-

!

•

,

•

8

t--.......8 _.:i

1

I

•A·'

1·

·1

•

•

•

.I

j

i

q

j- l

+

:

I

'

•

1'

2.7

I

~·~=1j""-'W

~

-

L ·

.

J

I

_

I

r - -----

..-L-- -

4

I

~

I

·-

f1' (FOR

I

_-.

L------

l"f~fWll\8~ f~ ~lfc.l:U.Jff ~liJF~L~~~EIGH

Nott G

RAIL CALIBRATIOO.

~

,.

L'"

14 TO 3~TON

JNSERT

. • Ol5_~E(SHIM)

c

eE!W~PtTHE

1

l~~~

CAR LOADS

'&y C:USTOMII.R..

COIMCT BUZZER AM> BATTERY TO THE WHITE A11D

.BLACK WIRES IN .AN:TIOO BOX.

r ;

i

• ·1

-.

-

. --- 1

• M•

(isTo52TOO

L

I

• ~---

•

~-=J.

_j

i_

·

T

"'T

-....

I

I

·

'<I\>

...__ ---,

!!!

~t.---,

' ;

r - - ------ · - - -·. - - - - 1

I

~

INSTALL RAIL & RAMP IN TRACK AS SHOIN. SPOT HEAVY CAR

8

r.Gw:~..u~~,U\ifME~M~~Tro,.c~~M 0o~

PU.CE 00 POST•

•

,ECT BUZZER AM) BATTERY TO THE WHITE

AM> GREEN WIRES IN JlliCTIOO BOX.

I- -

~il

.

I i

.

LJ

NOTE F -

Y,Utti.tt RAH. '&y CuS'TOMe.111. T'o S.u,T

l'ltn..L.U•~ 1..a .J'ou,JT '&~tt. SuPP\.\'I.D

:1

u.s.&S.

NOTE C - VICINITY

TRACK GAGEOFTOBE

WIDENED

1/4soTOGUARD

1/2 INCH

WEIGHING

DEVICE

RAILSINWILL

BE EFFECTIVE IN PREVENTING WHEEL FLANGE !ATERAL

PRESSURE 00 WEIGH RAI~.

NOTE D - SPACER BLOCKS SHOULD BE WELDED TO TIE PU.TES BEFOlE

INSTALLING WEIGH RAIL. SEE SECTIOO A-A.

NOTE E - BOTTCJ.1 OF JlliCTION BOX FLUSH WITH TOP OF TIE.

NOTE. ..G·- Hoi.e.s'Z7ltU "DltlLLED IN £.l't.CH E.~o Of'

ff

PLATE, TIE(! X 5 X 6FT, 5-1/4

GUARD RAIL TO BE CENTERED OPPOSITE CENTER LINE OF

WEIGHING DEVICE. STRAIGHT PORTIOO PREFERRED AS

LOOG AS WEIGH RAIL {7 FT .-4) BUT IN Alfi CASE NOT

LESS THAN 66 INCHES.

RE.F. OliLY)

..

1

a-

'DR11.1..(41HoLE.s 1..i R1u,•P(l:Tii.J1113)

®

I

'

•

f

NOTE

ITT .

.

1 r>mt; ·r,rn x s x ,

2

NOTE A - PARTS SHOIN IN FULL LINES FURNISHED BY

To 'l>UIT C.oN1'1TION'ii

IN TMI<. Fll!LO

•

I

I

2

J ::;

Lcc .. Tr.o

(111I

_J_'

L

. . ..

.

·-1,-..-.--- - - - · - - - ·

,

~

CONTACT 51'111"'5

1--

,

RAMP

BLOCK SPACER

BLOCK SPACER

OOTLET

(

/.

•

'-'

; ___ -- 7,t''f,'

~

- -if,-

GI

G--1

I

I

, •

• It - •

•.

•

.

I:"'~ __l_ _ _L_

I

-·t,f' W•19hu19 .Dwtv,t:ezfi Co,,,~~,•fe r;~ndar,o

__ L __L -

,·

,

,,

+----. - - - - .

+-

•

6

9

5

5

2

FURNISH THE FOLLCWING ITEMS FOl EACH

RETARDER YARD INSTALLATIOO

Lt1326557

I A2586 I TSSI WRENCH

21

1'1]s1'I

1·

I'I1 \.,.~.) •

•

~

I

r- - -----;-___:_::__-;------:--=-:..--=-===i'

r. •=3j,

n-r-rr-r:1

1-_j

.

,.

.

.

I

11

r- -::----- · . I

~. j ! -- ! ;_. _i ! ! - !

__L

I ,(

-$,----.I

L' .

•

,

I

-..,----r

.

.

.

i( '

("'\

!•

I. I -+

I- - -.11-. -

I

.

02

~_.1( __ 6 LAG

j )

·,_.

I

I

I

.--- ~ - - - .- - - - -

-~-·

STANOAR' TIES CJ! P,\WS'I'

•

. i !)j

i_.-=r- [CJ!

j

'

OESCR IPTIOO

RAIL •EIGH

BOX JlliCTION

SH.

THE FOLLCWING ITEMS ARE FOR REFERENCE OOLY

lM'.376133

17913

I 52 I BOLT. l'OtmAnoo

UJ47509

!WASHER, I STL. PLATE(CAD. PL.)

STL. HEX. (CAO. PL.)

;'2-1

u····:

•

sm,orEF I

I

I

jsf£'N07E ,B

f IIa I.I,-·1.II ·-· I:r·11l·-'

7J

~--,ci,

·J

,

r

r"'\

J

,

NOTE1

~EIGH

A~BI

ROAD

:;

--.- -

-~-

(sEE ntll)

lM3264B2

-·1°1JLJi

iJur

u:1~J=:4ru1-rFT·{·iu:~T-lil

lI.

I ·' I ! ' ' j

I ! '. j.

I

~/%1 ~ ~

r7{-l 1 ~

~"~l I I ; ~

_ _ _1 __

!!

+.

__J_

-,

DWG.

F451059

066316

FBOOIJ

C50002

C50002

066316

0

i

ll- -1.::--

I

1

,l: 11 __ j~~I

-L.

r~

.I ~·UIiEl

L

·~ir~·~;:~J?~f·~ _" :l1iw;'

Ull3'4'-.SG81

""

PC, NO.

{SEE TAB)

ISEE TAB

i

r--- ·

. ---,

!

.

I

i .

._.__j

c:JJ

)

(r

±'

~

,I

J

CAR LOADSC!HIECT BUZZER ANO BATTERY TO IH£ WHITE AM)

RED WIRES IN JlliCTIOO BOX.

•

NSERT ,..o,gp GAGE (SHIMl BElllEEN THE

.. H

AOJUSIM:NT SCREW ANO THE OiG C<M'ACT

!52 TO 110 TOO PRING. TURN THE AOJUSTMEfd SCREW TO

CAR LOADS

T MAKE THE CIRCUIT,

'

~OIMCT BUZZER AM> BATTERY TO IH£ WHITE

ANO BLUE WIRES IN Jt.NCTIOO BOX,

I

,

_--- - .

--- .

·~RT .135 GAGE

~ml BETWEEN THE

..,,,

110-;gr oo ~oor:8Fs=.~URN THET~~NT

CAR LOSOS SCREW TO ,U;T MAKE THE CIRCUIT,

~

1·

~11-S.~"·

{\J

i1

j

L

0 .g

00

m:Z:

J

('J.

For Adjustment of R~il

for Use in Five Weight

Categories, Refer to

Paragraph 3 .1. 2

i

..tdl

""

-:

l~

I _..r~" ~

X.45ZOOZ-K04

/ 'wc·,{/Zll/1//;

,

.

'

.., .L BET•EtN

I_

~

"3zSPACER BLOCKS

I i,,k1&,I RAIL_, ,..,OUN rE"D ON CON'CAC1'£

F'OchlDATIOH(U~NG ZfV. Htll~

!lQ4!;2002-0601

f ~EIGH_RAIL, M(l(P.ITtO ON CONCRETE FOlNlATIOO {USING 24 V. HEATER)

PARI NlMlER _I_

OESCRIPTIOO

___.J

BEFD!lE INSTALLING

MEiio~ RAIL (SEE NOTE D)

2

1

.'!, •

.e

..... i.:r,,:~~=~t"'">..::t-

·-------

,- d '% "'

-iI

·----11'-=----- ..

----i

I/4 FI ~T WELD (BOTH ENOS)

4 :; In% .. '(

~~ r;!.Eo::J::::·

Moo.aTE't> ow Co,.ctt.E.TE f'ouun"T1ow(osuac.24V.H~~~~"'o."'

WElllll-RA!I., t.«lltlTED <Jl_cONCRETE ~TIOO (USIMl 14 v. HEAJER)

~El~H RA1~ 1

1 :1;J;

!ti~~~:1---e::~~:;.:,:

:e;;?:; 11:

! Jr:

,i·~;. ... r,·

~if!~~if1;E~·.;·;·

i_ •

~!: ! ~?.~:;::~~!',

!it. f.'.,

,• w

UNION

-----

~ -!:..-.i-

----~--------- - l .

. __________,._ -

SW.'J..!;.,H.. a

SIGNAL

--::::~~!!':y~~.~

1t "-

l"'k1h'31:"Q~ ..

·•

m

01(1/irl,.,RL APPltOV~L-

I

Jfld,a:-ll-17-U

UNION SWITCH & SIGNAL

PC. NO.

CO,f>L.

I

j F451059

_j 511..,j HEATER

24-VOLT

14-VOLT

'(1"45200%·Z2C3 lrJA1..SIO"-atc8lo2

-

.,Q«;flll'f 6UA tt}

wrrr.H RAii Col

I 24·VoLT

Hol.ll$"Z"

, _. . h

w1TH (As s"'°"'") 0090207

f#/ITH (AS"'°11111) 0090250

5&.E NOT& ..6.

U>l390207

3

RA""P

FROOl'°!J

s...

6

6

UR349t.8t

9

ll~g

Ult349C.81

UA4357%~

'

11 1

le

'

~l

ltEMAltlC.S

l'Dlwt."L"

..

) Fut•- MlilO"' F•-. W4W R...... o 1'e.U.w.11- Y•.

/e

I

~

FtR5T MAO• Foa. Tllr, p Ry.C..LAWC:At,Talll'iD.

.~-:

Im

I

if~~;

I•

I

---1

u.-

,F..

•

I-

ii

~ - --(',-

=========t=::-~--:'::::·-=====-:-:~=-==.

- ----F-r-,j

-

r-- --------- -

•

p

__

r

~~==-'--'=.::..:-_=!:=_

-----

II

I c:c::.

"

•,

e 1r

L..J

____~=:'i

- 11

b~

n

11 -

i!r-d

!I

b.-..di •

-

.•

-- -1

---.:::::::.J

..

IL

I

~

"-'.._=11

i.k-...:::5

{

.

_ •

I:>

~

0\

l

b=.

II

F"

i

r-:-; r·, ·H _l!__tl __.___,

a

- <d=- ____

'11

t

'

. .

'I

:

(

L

-

,

--r .

,.

- - - - -- -

-·,----

-!

.:..=..:...._

·

-

J'

- - ~ -,.,-__________

-

.]

I

I

- -----

/.::

·1

- - - •"<- ·

-----

TE SLAB

0

J&~~l~LV1st&fflav£AN)IMY11£

TO AGREE WITH LOCAL BEO CINllllONS.

J

~

TO 1/2 11«:H IN

50 GUARD RA I LS

INi WHEEL FLANiE

)L,

• ,.

I

_:..l

------------:-:;:,:t-------------

We19hm9 .I)ev,c• ( Concrefe ('<>undahon

,;f

~

'----lfJlT:r~~H~

r.GE!J

C...

t

r~GHl~

--:..:..=i

• ;•

6

NOTE O - SPACER BLOCKS SHOULD BE WELOEO TO TIE PLATES

BEFORE INSTALLINi WEIGH RAIL. SEE SECTION A-A.

NOTE E - BOTT!J,! OF JIH:TION BOX FLUSH WITH TOP OF TIE.

:,irr:~~tG~~'LgLr~v,l:.'RA'L 0 c

Mo"l'ie,.··

~

"'.I) R •LI.

Loc.AiT!,.l),

.•

Z

~-

..---~---~-7rl~-l-------~-~~-i

~---~-+-----·ff-~---...i

t,to1..1i.1> .. C." lo Bft

'Dtt.u.. i..e.l>

tN

E.l\t..t END

,~

CAR LOADS

13,y CosTo...,aR..

1t11~.:ossmY

1F---~- _ ---.~~~~

C(M£CT BUZZER ANO BATTERY TO THE WHITE ANO BLACK

!'IRES IN JtH:TION BOX.

---=-=~

--===f·

- - - - - - - -,~..,.J

L

.-

i--1

I'

'--~

c_:J

11

l4-TOLlS TCJ.4

WE.tGt,,\ R.lh\.. 'Sy CusTe>MltR. TO Su,,.

J:>R.ll-'-lNG lN J"ou,.aT "BAii.. Su1"P1..1&1)

J

r·-

~

i.,T~LL~&«it,~.JrLT~cMM't~ rJm~ri:R,

ANOTIGHTENNUTS. IMCABLE INTOJIH:TIONBOX,

BUT oJO NOT PLACE ctl POST.

("t) Hoc.E.S IN R "'MP (1:'TE:"\ 3)

TO ~ I T CotJl)1"';IOtJS

IN THE F'IEI.O

.

u.s.&S.

NOTE B - WJ;O RAIL TO BE CENTEREO OPFOSITE CENTER lltiE OF

.~,~~C[lllswifl!.~B1W1ll:~E~ ~T

LESS Ttl<N 66 INCHES,

F-r~,-,::_~

II

.

Ir----"=_

r

- - -==-----.

,I

~i

--===-=11'1] - n -1i

11

NOTE A - PARTS 5IIO'IN IN FULL LltiES FURNISHEO 6Y

·-.

------,

I

/1

r-----I

<:~~ff:

"M"

3STO 5"Z. TON

CAR LQl.05

5. TURN THE

TO JUST MIIKE THE

TltE

"HM

5'2.TO 110 TON

CAR L0,.05

--·---.:

i

-·-"· ~-J

CAUTION

For Adjustment of Rail

for Use in Five Weight

Categories, Refer to

Paragraph 3.1.2

~!!;.

UX45200Z-2203

U0452_CIQ?_-ZZ02

U0452002-ZZOI

REV

PART NlMI_ER

~--p,..~_ _ _

__,-,;:-,_.,---:-----:-____:_----,;;i~·~--;.s~

C~~~~~~~=::~F...E:::..::-.::2.:::.:::j;~-:Jriij

- -· . -~

... .;:;;-.::::--,=.::~=·12

-

lSO.LE. -

'"· - ' " "

-,.,.=--

~

..~-l

~ l t , . . f f - L Y... ~

uN10N. iw1TcH

a

sidklt'i

122'1 I

~--'.

EB

UNION SWITCH & SIGNAL DIVISION

AMERICAN STANDARD INC. I SWISSVALE, PA 15218

Sales Offices

2409 Treelodge Parkway

Atlanta, GA 30338

(404) 399-3577

Montreal

1115 Dorchester Blvd.

Suite 1003

Montreal, PO, Canada H3B2J2

(514) 866-3677

Roanoke

4718 Hickory Hill Drive

Salem, VA 24153

(703) 989-8400

Chicago

216 Lancaster Lane

Bolingbrook, IL 60439

(312) 759-3577

New York

40 W. 40th St., Rm. 1105

New York, NY 10018

(212) 840-5438

San Francisco

903 Sneath Lane, Suite 230

San Bruno, CA 94066

(415)588-6788/588-6789

Huntington, WV

Omaha

6122 Gideon Road

Huntington, WV 25705

(304) 736-2629

16326 Oak Circle

Omaha, NE 68130

(402) 334-1516

St. Louis

500 Northwest Plaza

Box 1267

St. Ann, MO 63074

(314) 291-7400

Atlanta

Phlladelphla

Jacksonville

P.O. Box 8609

Jacksonville, FL 32211

(904) 724-2607

Honeywell Center

111 Presidential Blvd.

Suite 206

Bala Cynwyd, PA 19004

(215) 667-7072

Pittsburgh

1789 Braddock Avenue

Pittsburgh, PA 15218

(412) 273-4300

Mall all orders to:

Order Entry Department

Union Switch & Signal Division

American Standard Inc

Swissvale, PA 15218

St. Paul

402 McColl Building

5th and Jackson

St. Paul, MN 55101

(612) 222-7562