Download 02-03 Honda Civic Si Service Manual

Transcript

BodyElectrical

\

Body Electrical

SpecialTools

GeneralTroubleshooting

tntorrnaiion.'......

22,3

RelayandControlUnit Locations.....22-7

Connectors

and Harnesses

22-13

Fuse/Relay

Boxes...............................

22-44

PowerDistribution.............................

22-46

GroundDistribution...........................

22-4A

Under-dash

Fuse/Relay

Box ..............

22-49

Battery ..............

Relays................

*lgnitionSwitch ..............

22-50

22-51

22-53

*Gauges

C o m p o n e nLto c a t i o Inn d e x . . . . . . . . . . . . . . . . 22-54

.......

S e l f - d i a g n o sPt irco c e d u r .e. . . . . . . . . . . . . . . . . 22-56

........

CircuitDiagram

22-54

G a u g eB u l bR e p l a c e m e n. .t . . . . . . . . . . . . . . . .22

. . . .63

....

GaugeAssemblyReplacement

22-64

CoolantTemperature

......

G a u g eT r o u b l e s h o o t i n.g. . . . . . . . . . . . . . . . 22-64

VehicleSpeedSignalCircuit

Troubleshooting

22-65

VSSReplacement

22 61

ExteriorLights

C o m p o n e nLto c a t i oInn d e x . . . . . . . . . . . . . . . . 22-68

.......

C i r c u iD

t iagram

22--71

DaytimeRunningLightsControi

U n i tI n p u tT e s t( C a n a d a .) . . . . . . . . . . . . . . . .22-7

. . . . .6. .

H e a d l i g hAtd , u s t m e n .t . . . . . . . . . . . . . . . . . . 22-74

H e a d l i g hRr e p l a c e m e n. .t. . . . . . . . . . . . . . . . . . .22-79

.........

CombinationLightSwitch

Test/Replacement

22-AO

B u l bR e p l a c e m e n t

22-41

T a i l l i g hRt e p l a c e m e n. .t . . . . . . . . . . . . . . . . . . . .22-82

....

HighMountBrakeLightReplacement......22-42

LicensePlateLightReplacement..............

22-43

S i d eM a r k e L

r i g h tR e p l a c e m e n. .t. . . . . . . . . .22-43

....

BrakePedalPositionSwitchTest ..............

22-44

SideTurn SignalLightReplacement........22-84

Turn Signal/Hazard

Flasher System

C o m p o n e nLto c a t i o Inn d e x . . . . . . . . . . . . . . . . 22-85

.......

C i r c u iD

t iagram

22 A6

Turn Signal/Hazard

RelaylnputTest ........22-87

HazardWarningSwitchTest

22-88

Entry Lightscontrol system

ComponentLocationIndex .......................

22-89

C i r c u iD

t iagram

. . . . . . . 2. .2 9 0

lgnitionKeySwitchTest .....................,......

22-9'l

l g n i t i o nK e yL i g h tT e s t . . . . . . . . . . . . . . . . . . . . . 2

. .2. .-.9. .1. . .

C o n t r oUl n i tI n p u tT e s t . . . . . . . . . . , . . . . . . . . . . 2

. .2. .9. 2

.....

InteriorLights

ComponentLocationIndex .......................

22-94

CircuitDiagram

.........22-95

CeilingLighVSpotlights

T e s V R e p l a c e m e. n

. .t. . . . . . . . . . . . . . . . . . . . .2. .2. -. .9.6. . . . .

RearCeilingLightTesVReplacem

ent ........22-96

CargoAreaLightTest/Replacem

ent .........22-97

HatchLatchSwitchTest ..,..,.......................

22-97

*Audio System

ComponentLocationIndex .......................

22-98

CircuitDiagram

.........22,99

AudioUnit Removal/lnstallation

...............

22-1OO

Audio Unit ConnectorReplacement.........22-101

SpeakerReplacement................................

22-102

RoofAntennaRep1acement

....................-..

22-103

Rear Window Defogger

ComponentLocationIndex ...........

22-104

C i r c u iD

t i a s r a m. . . . . . . . . . . . . . . . . . . . . : : : : : . : :22-105

.::.

FunctionTest

D e f o g g eW

r i r eR e p a i r. . . . . . . . . . . . . . . . . . . . . . .22-106

..........

N o i s eC o n d e n s eCra p a c i t y T e s. t. . . . . . . . . . .22-107

....

Moonroof

C o m p o n e nLto c a t i o Inn d e x . . . . . . . . . . . . . . . . 2. .2. .-.1. .O B

CircuitDiagram

.........22-109

MoonroofControlUnitInputTest .............

22-'l10

S w i t c hT e s V R e p l a c e m e. n

. .t. . . . . , . . . . . , . . .2. .2. .- .11. .2.

MotorTest

.................

22-112

LimitSwilchTest

......22-'l'13

Auto-stopSwitchTest ................................

22-113

PowerMirrors

ComponentLocationIndex .......................

22-114

CircuitDiagram

.........22-115

FunctionTest

.............

22-116

P o w e rM i r r o rS w i t c hT e s t . . . . . . . . . . . . . . . . . . 2. .2. .-.l .l .7.

PowerMirrorActuatorTest .......................

22-117

PowerMirrorActuatorReplacement........22-11A

* Horns

ComponentLocationIndex .......................

22-120

CircuitDiagram

.........22-121

H o r nT e s V R e p l a c e m e. n

. .t. . . . . . . . . . . . . . . . .2. .2. -. .1. 2. -2.

HornSwitchTest

.,....22-122

\

PowerWindows

22 124

ComponentLocationIndex ..........

::::.:

c i r c u i tD i a g r a m. . . . . . . . . . . . . .......... . . . . : . : : : : .22-125

M a s t eS

r w i t c hI n p u tT e s t . . . . . . . . . . . . . . . . . . .22-126

........

22-128

MasterSwitchTest

......

D r i v e r 'W

s i n d o wM o t o rT e s t . . . . . . . . . . . . . . .22-129

Passenger's

WindowSwitchlnputTest ... 22- t30

Passenger's

WindowSwitchTest .............

22-132

22 132

Passenger's

WindowMotorTest ..............

22-133

lMaster

SwitchReplacement......................

Passenger's

WindowSwitch

22-133

Replacement

Wipers/Washers

22-134

ComponentLocationIndex .......................

C i r c u iD

t iagram

RearWindowWiperIntermiftent

........

C o n t r oU

l n i tI n p u tT e s t . . . . . . . . . . . . . . . . . . .22-138

Wiper/Washer

Switch

22-140

TesVReplacement

..

C o n t r oU

l n i tI n p u tT e s t . . . . . . . . . . . . . . . . . . . . . .2.2. .-.1. .4. 1

WiperMotorTest

22-143

22-144

WasherMotorTest

WasherFluidLevelSwitchTesV

.......

R e p l a c e m e(nCt a n a d a.l . . . . . . . . . . . . . . . . . .22-144

WindshieldWiperMotor Replacement.... 22-145

RearWindowWiperMotor

Replacement

22-146

....

W a s h eR

r e s e r v oR

i r e p l a c e m e n. .t. . . . . . . . . .22-146

. . . 147

...

W a s h eTr u b e sB e p l a c e m e n. .t. . . . . . . . . . . . . .22

Accessory Power Socket

.........22-149

CircuitDiagram

AccessoryPowerSocket

. .t. . . . . . . . . . . . . . . . . . . . .2. .2. .- .14. .9. . . .

T e s V R e p l a c e m e. n

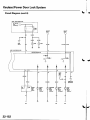

Keyless/Power Door Lock System

22-150

ComponentLocationIndex .......................

.........22-151

CircuitDiagram

22-153

KeylessReceiver

Unit InputTest ...............

22-155

ControlUnit InputTest ...............................

D o o rL o c k A c t u a t o r T e s. .t. . . . . . . , . . . . . . . , . .2, 2. ,-.1. .5. .8

. .5. .9

H a t c hL o c k A c t u a t o r T e s. .t. . . . . . . . . . . . . . . . .2. .2. -. 1

22-160

DoorLockKnobSwitchTest ......................

22-160

DoorLockSwitchTest ................................

.......22-161

TransmitterTest

T r a n s m i t t ePrr o g r a m m i n .g. . . . . . . . . . . . . . . . .2. 2. .-.1. .6. 1

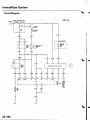

lmmobilizerSystem

22-162

componentLocationIndex ...........

...

S y s t e mD e s c r i p t i o .n. . . . . . . . . . . . . . . :. . . : . . : . :22-163

22-164

CircuitDiagram

Troubleshooting

lmmobilizerControlUnit

- R e c e i v eRre p l a c e m e n. .t. . . . . . . . . . . . . . . . .22-167

........

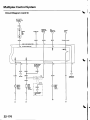

Multiplex ControlSystem

22,164

ComponentLocationIndex ...........

:.:..:.::.:

c i r c u i tD i a g r a m. . . . .... . . . . . . . . . . . . . . . . . . . . . . :22-169

22-17'l

SvstemDescriDtion

22,112

Troubleshooting

M u l t i o l eC

x o n t r oUl n i tI n D uTt e s t . . . . . . . . . . .2.2. - 1 7 5

BodyElectrical

SpecialTools

Ref. No.

Q)

o)

o

Tool Number

07wAz-001010A

O7LAJ-PT3O2OA

07TAz-001020A

Description

MPCSServiceConnector

Test Harness

BackProbeAdaotet

1

1

1

@

22-2

Otv

GeneralTroubleshootingInformation

Tipsand Precautions

Before Troubleshooting

1. Checkapplicablefuses in the appropriatefuse/relay

oox.

Some connectorshave a clip on their side used to

attachthem to a mount bracketon the body or on

a n o t h e rc o m p o n e n tT. h i sc l i p h a sa p u l lt y p e l o c k .

Some mountedconnectorscannot be disconnected

unlessyou first releasethe lock and removethe

connectorfrom its mount bracket(A).

2. Checkthe batteryfor damage.stateof charge,and

cleanand tight connections.

. Do not quick-chargea batteryunlessthe battery

ground cable has been disconnected,otherwise

you will damagethe alternatordiodes.

. Do not attemptto crankthe enginewith the

batteryground cable looselyconnectedor you

w i l l s e v e r e l yd a m a g et h e w i r i n g .

Handling Connectors

. Make surethe connectorsare clean and have no

l o o s ew i r e t e r m i n a l s .

. Make sure multiplecavity connectorsare packedwith

dielectricgrease(exceptwatertight connectors).

. All connectorshave push-downreleasetype locks(A).

Nevertry to disconnectconnectorsby pulling on their

wires; pull on the connectorhalvesinstead.

Alwavs reinstallDlasticcovers,

Beforeconnectingconnectors,make sure the

terminals(A) are in placeand not bent.

(cont'd)

22-3

BodyElectrical

GeneralTroubleshootingInformation(cont'd)

Checkfor looseretainer(A)andrubberseals(B).

The backsof some connectorsare packedwith

dielectricgrease.Add greaseif necessary.lf the

greaseis contaminated,replaceit.

HandlingWires and Harnesses

. Securewires and wire harnessesto lhe frame with

their respectivewire ties at the designatedlocations.

. Removeclips carefully;don't damagetheir locks(A).

S l i p p l i e r s( A ) u n d e rt h e c l i p b a s ea n dt h r o u g ht h e

hole at an angle,then squeezethe expansiontabs to

r e l e a s et h e c l i p .

J

lnsertthe connectorall the way and make sure it is

securelvlocked.

Positionwires so that the open end of the cover faces

oown.

After installingharnessclips, make sure the harness

doesn't interferewith any moving pans.

Keepwire harnessesaway from exhaustpipes and

other hot parts,from sharp edgesof bracketsand

holes,and from exposedscrewsand bolts.

Seatgrommets in their grooves properly{A). Do not

leavegrommets distorted(B).

| . , ./ f

.ll

----E;

'l/ F.

I

22-4

t/

lwtl"//

\--------\

tflr'---'..-

It

Testingand Repairs

. Do not usewires or harnesseswith brokeninsulation.

Replacethem or repairthem by wrappingthe break

withelectricaltape.

. After installingparts,make surethat no wires are

o i n c h e du n d e rt h e m .

. When using electricaltestequipment,followthe

manufacturer'sinstructionsand those describedin

t h i sm a n u a l .

. l f p o s s i b l ei ,n s e r t t h ep r o b eo f t h e t e s t e r f r o m t h ew i r e

side (exceptwaterproofconnector).

UsebackDrobeadaotor07TM-0010204.

Referto the instructionsin the HondaTerminal Kit for

identificationand reolacementof connectorterminals.

( c o n td )

22-5

BodyElectrical

GeneralTroubleshootingInformation(cont'dl

Five-stepTroubleshooting

'1.

Verify The Complaint

T u r n o n a l l t h e c o m p o n e n t si n t h e p r o b l e mc i r c u i t

to verify the customercomplaint.Note the

symptoms.Do not begin disassemblyor testing

until you have narroweddown the problem area.

2. AnalyzeThe Schematic

Look up the schematicfor the problem circuit.

Determinehow the circuit is supposedto work by

tracingthe currentpathsfrom the power feed

through the circuitcomponentsto ground. lf

severalcircuitsfail at the same time, the fuse or

g r o u n di s a I i k e l yc a u s e .

Basedon the symptoms and your understandingof

the circuitoperation,identifyone or more possible

causesof the problem.

3. lsolateThe ProblemBy TestingThe Circuit

Make circuitteststo checkthe diagnosisyou made

i n s t e p2 . K e e pi n m i n d t h a t a l o g i c a ls, i m p l e

procedureis the key to efficienttroubleshooting.

Testfor the most likelycauseof failure first, Try to

make tests at pointsthat are easilyaccessible.

4. Fix The Problem

Oncethe specificproblem is identified.make the

repair.Be sure to use propertools and safe

proceoures.

5. Make Sure The CircuitWorks

Turn on all componentsin the repairedcircuit in all

modes to make sure you've fixed the entire

problem.lf the problemwas a blown fuse, be sure

to test all of the circuitson the fuse. Make sure no

n e w p r o b l e m st u r n u p a n d t h e o r i g i n a p

l roblem

does not recur.

22-6

Wire Color Codes

The following abbreviationsare usedto identifywire

colors in the circuitschematics:

w H T . . . . . . . . . . . . . . . . . . . . , . , . White

............

Y E L . . . . . . . . . . . . . . . . . . . . . . , , .Y. .e.l.l .o. w

,......

B 1 K . . . . . . . . . . . . . . . . . . . . . . . . . . .B

. .l.a. .c. k. . . . .

B L U. . . . , . . . . . . . . . . . . . . . . . . . . . . .B. .l.u. .e. . . .

G R N . . . . . . . . . . . . . . . . . . . . . . . .G

. .r.e. .e.n. . . . . . .

R E D. . . . . . . . . . . . . . . . . . . . . . . . . . . .Red

........,

o R N . . . . . . . . . . . . . . . . . . . . . . . . Orange

.............

P N K . . . . . . . . . . . . . . . . . . . . . . . .P

. .i,n. k. . . . . . . . .

B R N . . . . . . . . . . . . . . . . . . . . . . . .Brown

.............

G R Y . . . . . . . . . . . . . . . . . . . . . . . .Gray

............,

P U R . . . . . . . . . . . . . . . . . . . . . . . .P

. .u. .r .p.l.e. . . . . .

1 T 8 1 U . . . . . . . . . . . . . . . . . . . . . Light

. . . . . ,Blue

.....

1TGRN....................L

. .i.g. h

. .G

t. ,r.e. .e n

The wire insulationhas one color or one color with

anothercolor stripe.The secondcolor is the stripe.

Relayand Control Unit Locations

EngineCompartment

BLOWERMOTORRELAY

RADIATORFAN

RELAY

HORNRELAY

CONDENSERFAN

RELAY

ELDUNIT

UNDER-HOOD

FUSE/RELAY

BOX

\...

,-:1-'...

22-7

Relayand GontrolUnit Locations

Dashboard

RUNNINGLIGHTSEELAYlCanada)

_DAYTIME

lWirecolorsrRED,RED/YEL,I

andRED/8LU

LRED/BLK

I

BEAMCUTRELAYlcanada) _

_LOW

REDMHT,

RED/BLK,

colors:

lWire

I

andRED/BLU

LBEDA/EL

I

KEYLESSRECEIVER

UNIT

CRUISECONTROLUNIT

'

':

'-.:-

..? ;,

POWERWINOOW RELAY

TURN SIGNAL/HAZARDRELAY

TAILLIGHTRELAY

;

.[:_- -

-l:r

UNDER.DASH

FUSE/RELAY

BOX

--

MULTIPLEXCONTROLUNIT

22-8

(cont'd)

22-9

Relayand Control Unit Locations

a

Dashboard(cont'd)

L

\

SRSUNIT

EPSCONTROLUNIT

AIR/FUEL

RATIOSENSOR

RELAY

[WirecolorsrWHT,WHT/RED, I

OBNandBLK/ORN

I

22-10

PGM.FIMAINRELAY1

lWirecolors:YEUBLK,

WHT/BLKand RED/YEL

LWHT/BLK,

PGM.FIMAN RELAY2

fwirecolors:YEUBLK,

I

YEUBLKand GRN/YELI

LYEUGRN,

Rearand Roof

OPENRELAY MOONROOF

Wirecolors:GRNI/EL,

GRN, I

BLKandYEL/GRNI

LRED/YEL,

MOONROOF

CLOSERELAY

GRN, l

fwire colors:GRN/BLK,

BLKand YEL/GRNI

IGRN,AtVHT,

REARWINDOWWIPERINTERMITTENT

CONTBOL

UNIT

22-11

Relayand ControlUnit Locations

Door and Seat

Driver'sDoor:

l\:

].\

POWERWINDOWMASTERSWITCH

lHasbuilt-incontrolunit)

Passenger's

Seat:

22-12

Gonnectors

and Harnesses

a

GonnectorIndex

"G" for ground

ldentification

numbershavebeenassigned

to in-lineconnectors.

The numberis preceded

by the letter"C" for connectors,

terminalsor "T" for non groundterminals.

Hamess

Location

EngineCompartment

Dashboard

Others{Floor,Door,

Trunk.and Roo{l

Not€s

Startersubharness

C 1 0 2a n dC 1 0 3

T1 andT2

T 1 0 1a n dT 1 0 2

(seepage22-15)

Batterygroundcable

T3

G'l and ( T4

{seepage22-l!)

Enginegroundcable

{seepage22-14)

Enginewire harness

C l 0 l t h r o u g hC 1 0 4

G1 0 1

Enginecompartment

wire harness G201andG202

{riohtbranchi

Enginecompartment

wire harness G301

(leftbrench)

Enginecompartment

wire harness

(dashboard)

(seepage22 16)

(seepage22 18)

(seepage22 18)

(seepage22-18)

c401

C451and C452

C501throughC503

c551

c851

G402

EPSsubharness

C 1 5 1a n d C 1 5 2

G'151

\seepage22 241

Dashboard

wire harness

A

lleftbranch)

C504throughC510

G501andG503

(seepage22-26)

L e f ts i d et u r n s i g n a l l i g h t

c506

(seepage22-26)

Dashboard

wire harness

A

(rightbranch)

C50lthroughC503

C 5 l l t h r o u g hC 5 1 5

C852andC853

G502

(seepage22-26)

lseepage22-26)

Rightside turn si9nal light

sub harness

Dashboard

wire harnessB

ECMwire harness

(seepage22-30)

C40lthrough

C403

c510

G40l

c101

cl52

C451

through

C453

c511

{seepage22-32}

G451

Floorwireharness(frontside)

C402

andC403

c453

C508

andC509

c512

G551

(see page 22'34)

Floorwire harness(rearside)

C553and C554

(seepage22-34)

Roo{wire harness

Hatchwire harness

Driver'sdoorwire harness

c507

C553andC554

C504andC505

5 1 4a n dC 5 1 5

)552

(seepaqe22-38)

c851 rhrouoh c853

( s e ep a q e 2 2 . 4 3 i

C 5 5 1a n . l C 5 5 ?

P a s s e n q e r ' sd o o r w i . e h a r n e s s

T eh a r n e s s

/C wire harness

( s 6 ep a q e 2 2 ' 3 9 )

(see paqe 22-40)

( s e eo a o e 2 2 - 4 1

(seeoaqe22-42i

22-13

and Harnesses

Connectors

Gonnectorto Harnesslndex

BatteryGroundCable

Connectoror Terminal

Cavities

T3

2

Location

Left side of enqinecompartment

Left side of enginecompartment

Batterv

Connectsto

Notes

Bodygroundviabattery

qroundcar)le

B a t t e r vn e o a t i v et e r m i n a l

EngineGround Cable

r4

Connectoror Terminal

Cavities

5

4

focation

Riohtsideof enoine

Rightsideof enginecompartment

Connec{sto

Bodygroundviaengine

ENGINEGROUNDCABLE

BATTERYGROUNDCABLE

\.....

22-14

Notes

StarterSubharness

Connectoror Terminal

Alternator

Knocksensor

Startersolenoid

c102

Ret

10

8

5

7

Cavities

4

1

1

6

c103

6

1

T1

2

T101

4

1

I

r2

r102

Location

Connoc,ts

to

Right side of eng;necompartment

Front of engine

Middle of enginecompartment

Front of enginecompartment

F r o n t o f e n g a n ec o m p a r t m e n t

L€tt sideof enginecompartment

Middleor enoinecomDanment

Under-hood

fuse/relay

box

Alternator

Batterv

Notes

Enginewire harness(see

page22 16)

Enginewire harness(see

o a a e2 2 - 1 6 )

Underhoodfuse/relay

box

Stanermotor

Battervpositiveterminal

STARTERSUB HARNESS

22-15

Connectorsand Harnesses

Connectorto HarnessIndex(cont'dl

EngineWireHarness

position(CMP)sensor

Camshaft

Lllr sensor

EC[,4connectorA

ECI/lconnectorB

(ECT)

Enginecoolanttemperature

sensor

Engineoil pressure

switch

EVAPcanisterpurgevalve

ldleair control(lAC)valve

lgnitioncoilNo. l

lgnitioncoilNo.2

lgnitioncoilNo.3

lgnitioncoilNo.4

IniectorNo. 1

InlectorNo.2

IniectorNo.3

IniectorNo.4

Intakeairtemperature

{lAT)sensor

2

3

3

24

2

28

18

4

5

6

7

25

24

20

19

12

TDCsensor

Throttleposition(TP)sensor

Vehiclespeedsensor(VSSI

VTCoil controlsolenoidvalve

VTECoil pressureswitch

VTECsolenoidvalve

c 101

8

11

10

27

29

30

3

c102

22

1

2

3

3

3

3

3

2

2

2

2

2

3

3

3

2

2

2

20

Transmission

housing

Leftsideof engine

Rightsideofengine

Underglovebox

Underglovebox

Leftside of engine

BightsideoI engine

Leftside of intakemanifold

Left sideof intakemanifold

Middleof enginecompartment

Middleof enginecompartment

Middleof enginecompartment

Middleof enginecompartment

Middleof enginecompartment

Middleof enginecompartment

Middleof enginecompartment

Middleof enginecompanment

Leftsideof intakemanifold

Leftsideof engine

Left side of intakemanifold

housing

Transmission

Rightsideo{ engine

Rightsideof engine

Rightsideof engine

Underrightsideof dash

Frontof enginecompanment

Frontof enginecompartment

22-16

ECMwire harness{seepage

22-321

(seepage

Startersubharness

22-15)

(seepage

Startersubharness

22 151

....-

10

11

13

14

22-17

Connectorsand Harnesses

Connectorto HarnessIndex{cont'dl

EngineCompartmentWire Harness(Rightbranch)

Connsctoror Terminal

ABSmodulator-control

unit

Bearwasher

motor

RightfrontABSwheelsensor

Rightfrontairbags€nsor

Bightfrontparkinglight

Rightfrontsidemarkerlight

Rightfrontturn signallight

Rightheadlight

Righthorn

wash€rfluidlevelswitch

Windshield

washermotor

G201

G202

Cavitiss

8

12

1

10

11

2

7

6

2

2

2

2

2

2

I

2

2

Location

Bightsideo{ enginecompartment

Behindrightsideof {rontbumper

Rightsideot enginecompartment

Behindrightsideof frontbumper

Behindrightheadlight

Behindrightsideof Jrontbumper

Behindrightheadlight

Behindrightheadlight

Behindfrontbumper

Behindrightsideof trontbumper

Behindriohtsideof frontbumoer

Behindrightsideof trontbumper

Behindrightsideof Jrontbumper

Connectsto

Notes

Canada

Bodygroundvia€ngine

compartment

wtreharness

Bodygroundviaengine

.omnerhent

wire harness

\

22-18

ENGINECOMPARTMENT

WIRE

HARNESS

(cont'd)

22-19

Connectors

and Harnesses

Connectorto HarnessIndex (cont'dl

EngineCompartmentWire Harness(Left branch)

AirJuel(A,,/F)

ratiosensor

Brakefluidlevelswitch

Condenser

fan motor

Cruisecontrolactuator

ELDunit

Foglightconnector

LeftfrontABSwheelsensor

Leftfrontairbagsensor

Leftfrontparkinglight

Leftfrontsidemarkerlight

Leftlrontturnsignallight

Leftheadlight

Lefthorn

Radiatorfan motor

Radiator

fan switch

Secondary

heatedoxygen(SHO2S)

Testtachometer

connector

Windshield

wipermotor

Under'hood

fuse/relay

box

connector

A {seepage22-44)

Under-hood

f use/relay

box

connectorB (seepage22-44)

Underhoodfuse/relay

box

connector

C (seepage22-44)

Underhoodfuse/relay

box

D (seepage22 44)

connector

fuse/relay

Under-hood

box

24

22

2

2

25

1

9

2

2

4

3

,l

3

4

Frontof enginecompanment

Leftsideof enginecompartment

Leftsideof enginecompartment

Leftsideo{ enginecompartment

Frontof enginecompartment

Underrightsideof cowlcover

Under'hood

f use/relay

box

Leftsideof enginecompartment

Leftsideof enginecompanment

Behindleftsideof frontbumper

Behindleftheadlight

Behindleftsideof frontbumper

Eehindleftheadlight

Behindleftheadlight

Behindfrontbumper

Leftsideof enginecompartment

Frontof enginecompartment

Leftsideof enginecompartment

11

7

2

5

2

Leftsideof enginecompanment

L.Jnder

leftsideof cowlcover

L.Jnder

hoodfuse/relay

box

I

5

L.Jnder

hoodfuse/relay

box

10

12

L.Jnder'hood

f use/relay

box

12

17

13

20

21

23

l

2

2

2

2

2

3

l

2

2

5

underhoodfuse/relay

box

6

fuse/relay

Under-hood

box

\

22-20

l'

\-

ENGINECOMPARTMENTWIRE

HARNESS

(conr'd)

22-21

and Harnesses

Connectors

Connectorto HarnessIndex (cont'd)

EngineCompartmentWire Harness(Dashboard)lcont'dl

Connectoror Terminal

Cavities

Location

1

Undermaddle

of dash

12

Underleftsideof dash

Foglightconnector

Under'dash

fuse/relay

box

connector

F (seepage22-45)

Underdash

fuse/relay

box

G (seepage22-45)

connector

Underdash

fuse/relay

box

connector

H (seepage22'45)

fuse/relay

Under-dash

box

connector

| (seepage22'45)

Under-dash

fuse/relay

box

connector

J (seepage22-45)

c151

c401

1

Underrightsideot dash

c451

I

Underrightsideot dash

c452

9

UnderrightsideoJdash

c501

10

'10

UnderrightsideoI dash

c502

6

4

Underrightsideol dash

c502

6

8

UnderrightsideoJdash

5

UnderrightsideoJdash

10

Undermiddleof dash

1

Underrightsideof dash

5

5

10

Underleftsideof dash

3

Underleftsideof dash

2

5

Underleftsideof dash

3

8

Underleftsideol dash

12

2

Underrightsideof dash

c503

c851

'14

G402

1' I

Connectsto

EPSsubharness

{seepage2224)

wire harnessB

Dashboard

(seepage22-30)

ECMwire harness(seepage

22-321

ECMwire harness(seopage

22 32)

Dashboard

wire harnessA

(seepage22-26)

Dashboard

wire harnessA

USA

lsee page 22-261

Dashboard

wire harnessA

Canada

(seepage22-26)

Dashboard

wire harnessA

(seepage22-26)

Floorwireharness(seepage

22-34l'

,VCwire harnesslsee page

22-43\

Eodygroundviaengine

..mdarlma.t

22-22

Notes

Oplion

w,rc harncss

BOX

FUSE/RELAY

UNDER-DASH

WIRE

ENGINECOMPARTMENT

D

'

-

' 1_-1.:,

-.,.i

ifa.: ,, ..j

,

. -,,

-g'-.t

';.-a

22-23

Connectorsand Harnesses

Connectorto Harnesslndex (cont'dl

EPSSubharness

Connectoror Terminal

EPScontrolunitconnectorA

EPScontrolunitconnectorB

EPScontrolunitconnector

C

EPSmotor

EPStorquesensor

c151

2

,l

3

1

6

c152

4

G151

5

22-24

Cavities

2

2

20

2

6

2

I

Location

Underrightsideofdash

Underrightsideof dash

Underrighrsideof dash

Middleof enginecompanment

Middleof enginecompartment

Underrightsideof dash

Underrightsideof dash

Connectsto

Enginecompartment

wire

harness(seepage22-18)

ECI\,4

wire harness(seepage

22-321

aodygroundvia EPS

Notes

EPSSUB HARNESS

22-25

Connectorsand Harnesses

Connectorto HarnessIndex (cont'd)

DashboardWire HarnessA {Leftbranchl

Connectoror Terminal

Accessorypower socket

Audioantenna

Brakepedalpositionswitch

Clutchinterlockswitch

Clutchpedalpoistionswitch

Cruisecontrolunit

Cruisemainswitch

Daytimer!nning lightscontrolunit

Daytimerunninglightsrelay

Gaugeassembly

connector

A

GaugeassemblyconnectorB

Hazardwarningswitch

Heatercontrol panelconnectorA

Heatercontrol panelconnectorB

HVACpush switch assembly

Keyless

receiverunit

Low beamcut relay

Optionalsecurityconnector

Powermirrorswitch

Under-dash

fuse/relay

box

connector

K (seepage22-45)

Under'dashfuse/relaybox

L {seepage22-45}

Underdashfuse/relay

box

connectorM lsee page22'45)

Under-dash

fuse/relay

box

connectorN (seepage22-45)

UndeFdash

fuse/relay

box

connector

O (seepage22-45)

UndeFdash

fuse/relay

box

connectorY(seepage22 45)

c504

22

2

26

30

29

6

28

I

8

20

11

18

19

10

5

3

27

,I4

2

2

4

2

2

14

5

14

4

22

22

10

22

'14

10

5

5

16

13

17

Undermiddleof dash

Underleftsideof dash

] Underleftsideof dash

] Underleftsrdeof dash

| Underleftsideof dash

I Underleftsideof dash

Underleftsideof dash

Underlettsideof dash

Underlettsideof dash

I Behindgaugeassembly

i Behindgaugeassembly

Behindhazardwarnningswitch

Behindheatercontrolpanel

Behindheatercontrolpanel

] BehindHVACswitchassembly

I Undermiddleof dash

lUnderleftsideofdash

Underlefrsideof dash

UnderleftsideoI dash

ln the under-dash

fuse/relay

box

l0

In the under-dash

fuse/relay

box

12

ffi

Canada

Canada

In the undeFdash

fuse/relay

box

In the underdashfuse/relay

box

12

11

Inthe under-dash

fuse/relay

box

L

In the under-dash

fuse/relay

box

Underleftsideof dash

c505

Underleftsideot dash

c506

34

Underleftsideof dash

c507

1

Underleftsideof dash

c508

Undermiddleof dash

c509

24

c510

25

G501

1

Undergaugeassembly

G503

21

Underleftsideof dash

Undermiddleof dash

12

Undermiddleol dash

Driver'sdoorwire harness

(seepage22'40)

Driver'sdoorwire harness

(seepage22-40)

Leftsideturo signallight

suonarness

Roofwire harness(seepage

22 3Al

Floorwire harness{seepage

22-341

Floorwire harness(seepage

22 34J

Dashboard

wire harnessB

(seeoaoe22-30)

Body ground via dashboard

Body ground via dashboard

Left Side Turn Signal Light Sub harness

Connectoror Terminal

Leftsideturn signallight

c506

22-26

35

34

Cavities

Location

2

B e h i n d l e f t s i d e t u r n s i g n a ll i g h t

2

Under left side of dash

Connectsto

Dashboard

wire harnessA

Noles

WIRE

DASHBOARD

A

HARNESS

,./

-19

20

34

LEFTSIDETURN SIGNAL LIGHT

SUB HARNESS

I

2s

). \'u

)t

30

(cont'd)

22-27

Connectorsand Harnesses

Connectorto HarnessIndex (cont'd)

DashboardWire HarnessA (Rightbranch)

Connecloror Terminal

Cavities

Location

20

Eehindaudiounit

10

Underrightsideof dash

Audiounitconnector

c501

6

c502

5

4

Underrightsideof dash

c502

5

8

Underrightsideof dash

c503

4

5

tJnderrightsideof dash

c5' 11

c512

c514

ca52

c853

Undermiddleof dash

12

8

Undermiddleof dash

8

2

Underrightsideof dash

9

Underrightsideof dash

10

6

Underrightsideof dash

2

21

Undermiddleofdash

3

'l

G502

Undermiddleof dash

Underrightsideof dash

Connectsto

Enginecompartment

wire

harness(seepage22,18)

Enginecompanmentwire

harness(seepage22-18)

Enginecompartment

wire

harness(seepage22-18)

Enginecompartment

wire

harness(seepage22-18)

ECN4

wire harness(seepage

22-321

Floorwire harness{seepage

22-341

Rightsideturn signallight

suonarness

Passenger's

doorwire

harness(seepage22 4l)

Passenger's

doorwire

harness(seepage22 4'l)

A,/Cwire harness(seepage

22-43)

ly'Cwire harness(seepage

22-431

Eodygroundvia dashboard

Notes

USA

Canada

Right Side Turn Signal Light Sub harness

ConnectororTorminal

Rightsideturn signallight

c5't3

22-28

1

8

Cavities

Location

2

Eehindrightsideturn signallight

2

Underriohtsideof dash

Connectsto

Dashboard

wire harnessA

Not€s

WIBE

DASHBOARO

HARNESS

A

'---/...'

T

I

22-29

Connectors

and Harnesses

Connectorto HarnessIndex(cont'd)

DashboardWire HarnessB

Collqctor or Terminal

C a b l e reel

2

1

17

16

't9

Cavities

Locatiol|

5

In steeringcolumncover

In steeringcolumncover

4

In steeringcolumncover

In steeringcolumncover

1

In steeringcolumncover

1

In steeringcolumncover

4

Undermiddleof dash

18

Undermiddleofdash

14

In steeringcolumncover

5

Underleft sideof dash

Combination

lightswitch

Driver'sairbaginflator

lgnitionkey switch

lgnitionswitch

lmmobilizer

controlunit receiver

Passenger's

airbaginflator

SRSunitconnector

A

Wiper/washerswitch

Underdashfuse/relay

box

connectorAlseepage22,45)

Under dashluse/relaybox

connectorB (seepage22-45)

Under'dash

fuse/relay

box

connectorC (seepage22-45)

Under-dash

fuse/relay

box

connector

S lseepage22-45)

Under'dash

fuse/relay

box

connectorX(seepage22 45)

c401

10

c402

12

10

Undermiddleof dash

c403

11

4

Undermiddleof dash

G510

14

12

Undermiddlesideof dash

G40l

22-30

18

I

3

5

6

6

Underleftsideofdash

14

Underleftsideof dash

1

2

Underlettsideof dash

8

8

Under left sideof dash

Underrightsideof dash

Undergaugeassembly

Connectsto

Enginecompartment

wire

harness(seepage22-'18)

Floorwire harness(seepage

22-34J

Floorwire harness(seepage

22-341

Dashboard

wire harnessA

(seeoaoe22-26)

Bodygroundviadashboard

Notes

WIRE

OASHBOARD

HARNESS

B

22-31

Connectors

and Harnesses

Connectorto HarnessIndex(cont'd)

ECMWire Harness

Connectoror TerminiF

Arrruert/vrl ralo sensorretay

Datalinkconnector

EC[/lconnectorE

PGM-Flmainrelay1

PGM-Flmainrelay2

Under-dash

fuse/relay

box

connector

D (seepage22 45)

Underdashfuse/relay

box

connectorE lsee page22-45)

under-dashfuse/relaybox

connectorR lsee page22-45)

c10'1

I Re- lcavities

8

7

6

1

4

4

2

L

Location

Eehindglovebox

Undermiddleof dash

Behindglovebox

Behindglovebox

Behindglovebox

In the under-dash

fuse/relay

box

Inthe under-dash

fuse/relay

box

3

6

In the under-dash

fuse/relay

box

4

20

Underrlghtsideof dash

c152

1' I

8

Underrightsideof dash

c451

I

c452

10

4

Underrightsideot dash

c453

14

6

UndermiddleoI dash

c511

12

G451

22-32

Connectsto

Underrightsideof dash

Undermiddleof dash

Undergaugeassembly

Enginewire harness(see

page22'16)

EPSsubharness(seepage

22-24)

Enginecompanment

wire

harness{seepage22-18)

Enginecompartment

wire

harness{seepage22-18)

Floorwire harness(seepage

22-34)

Dashboard

wire harness

A

{seeoaoe22-26)

Bodygroundvia ECMwire

harness

Notes

ECMWIREHARNESS

22-33

Connectorsand Harnesses

Connectorto Harnesslndex (cont'd)

FloorWire Harness(Frontsidel

Connec-tor

or Terminal

I

Driver'sseatbeltswitch

Driver'ssideairbaginflator

Driver'ssideimpactsensor

Leftside seatbelt buckletensioner

Memoryerasesignal(MES)connector

Parkingbrakeswitch

Passenger's

seatbelt switch

Passenger's

sideairbaginflator

Passenger's

sideimpactsensor

Rightsideseatbeltbuckletensioner

SRSunitconnector

B

SRSunitconnector

C

Under-dashfuse/relaybox

connector

P {seepage22-45)

Under-dash

fuse/relay

box

connectorO (seepage22,45)

c402

c403

Ref

uavftres

11

l0

13

12

19

9

5

3

7

4

20

21

11

3

2

2

4

2

1

3

2

2

4

18

8

18

'r8

8

22

23

c453

10

4

Location

I Underdriver'sseat

i Underdriver'sseat

I Leftside offloor

Underdriver'sseat

Underdashfuse/relay

box

1Middleoffloor

Underpassenger's

seat

Underpassenger's

seat

Rightsideoffloor

Underpassenger's

seat

I Undermiddleof dash

Undermiddleof dash

Underdashfuse/relay

box

Underdashfuse/relay

box

]

I

Undermiddleof dash

Undermiddleof dash

6

Undermiddleof dash

c508

2

4

Undermiddleof dash

c509

14

6

Undermiddleofdash

c512

1

8

10

6

G551

22-34

I

4

connects to

Undermiddleof dash

I

Undermiddleof dash

] Unaermiddleof aasn

L,nderpassenger's

seat

Dashboard

wire harnessB

{seepage22 30)

Dashboard

wire harnessB

(seepage22-30)

ECMwire harness(seepage

22-321

Dashboard

wire harnessA

(seepage22-26)

Dashboard

wire harnessA

\see page 22-26)

Dashboard

wire harnessA

{seepage22-26)

Enginecompartment

wire

harness(seepage22 18)

OPDSunitharness(seepage

22-421

Bodygroundviafloorwire

Nol6s

- 10

11

FLOORWIREHARNESS

( c o n t ' d)

22-35

Gonnectors

and Harnesses

a

Connectorto HarnessIndex (cont'dl

Floor Wire Harness {Rear side}(cont'dl

Cargoarea

Driver'sdoorswitch

EVAPemissionbypasssolenoidvalve

EVAPemissioncontrolcanistervent

shutvalve

Fuelpump/sending

unit

Fueltankpressure

sensor

Left back-uplight

Left rearABS wheel sensor

Leftrearsidemarkerlight

Left rear speaker

Leftrearturn signallight

Leftsideseatbelttensioner

LefttaillighVbrake

light

(rearwindow

Noisecondenser

defogger)

(rearwindowwiper)

Noisecondenser

Passenger's

door switch

Rearwindowwiperintermiftent

controlunit

Rightback-uplight

Righttaillighvbrake

tight

Rightrearturn signallight

BightrearABSwheelsensor

Rightrearsidemarkerlight

Rightrearspeaker

Rightsideseatbelttensioner

c554

6

2

24

2

1

2

2

LeftB pillar

Fueltank

Fueltank

I

3

25

1

26

4

2A

5

27

'13

5

3

2

2

2

2

2

2

3

2

Fueltank

Fueltank

Lefttaillight

Left rear offloor

Behindleftsideof rearbumper

Leftquarterpanel

Lefttaillight

LeftB-pillar

Lefttaillight

Rightquarterpanel

18

10

11

2

1

20

Rightquarterpanel

R i g hB

t pillar

Rightq uarterpanel

22

20

21

15

19

12

11

7

2

3

2

2

2

2

2

12

Righttai ight

Righttaillight

Righttaillight

Rightsideof cargoarea

Behindrightsideof rearbumper

Rightquanerpanel

RightB-pillar

Rightquanerpanel

I

12

Rightquanerpanel

side of cargo area

rearseal bdcl

Rightsideof cargoarea

22-36

H a t c hw i r e h a r n e s s( s e ep a g e

22 39)

H a t c hw i r e h a r n e s s( s e e p a g e

Bodv ground vta

Bodygroundviafloorwire

FLOORWIREHARNESS

22-37

Connectors

and Harnesses

Connectorto HarnessIndex(cont'd)

RoofWire Harnsss

Connectoror Terminal

Moonroofclose

relay

Moonrool control unit

Moonroofmotor

Moonrootopenrelay

Moonroofpositionsensor1

N4oonroofpositionsensor2

Moonroofswitch

Rearceilinglight

SpotlighVceiling

light

c507

22-38

6

I

7

8

5

1

2

10

Cavities

5

5

2

5

2

4

5

3

4

8

tocation

Middleof roof

Middleof roof

Middleof roof

Middleof roof

MiddleoI roof

Middleof roof

Frontof roof

N4iddleof roof

Frontof roof

Underleftsideof dash

Connectsto

Dashboard

wire harnessA

(seeoaoe22-261

Notes

HatchWire Harness

Connectoror Torminal

Hatchlatchswitch

Hatchlockactuator

Highmountbrakelight

Licenseplatelight connectorA

Licenseplatelight connectorB

Rearwindowde{ogger

connector

A

I

3

Cavities

2

2

2

2

2

1

B

Bearwindowdetoggerconnector

10

1

LeftC-pillar

Bearwindowwipermoto.

c553

6

2

4

12

Middleof hatch

Rightquanerpanel

c554

l

2

Rightquanerpanel

( )

7

8

Location

Middleo{ hatch

Middleof hatch

Behindhighmountbrakelight

Middleof hatch

Middleof hatch

RightC-pillar

Connects to

Notes

Floorwire harness(seepage

22-341

Floorwire harness(seepage

)2-34\

22-39

Connectors

and Harnesses

Connectorto Harnesslndex (cont'd)

\,

Driver'sDoorWire Harness

Connectoror Terminal

Driver'sdoor lockactuator

Driver'sdoorlockknobswitch

Driver'sdoor lockswitch

Driver'sdoorspeaker

Driver'spowerwindow motor

Left power mirror actuator

Left tlveeter

Powerwindow masterswitch

c504

c505

ReI

9

10

1

7

2

3

Cavities

2

3

3

2

Location

8

5

20

Driver'sdoor

Driver'sdoor

Driver'sdoor

Driver'sdooa

Driver'sdoor

Driver'sdoor

Driver'sdoor

Driver'sdoor

Underleftsideof dash

6

't3

Underleftsideof dash

6

2

DRIVER'SOOORWIREHABNESS

22-40

Connectsto

A

Dashboard

wire harness

\seepage22-261

A

Dashboard

wire harness

Notes

Passenger'sDoor Wire Harness

Connectoror Terminal

Passenger's

doorlockactuator

Passenger's

doorspeaker

powerwindowmotor

Passenger's

powerwindowswitch

Passenger's

Rightpowermirroractuator

Righttweeter

c514

Rel

6

I

5

1

4

3

2

Cavities

2

2

2

5

6

2

13

Passenger's

door

Passenger's

door

Passenger's

door

Passenger's

door

Passenger's

door

Passenger's

door

Underrightsideof dash

1

6

Underrightsideof dash

Location

Connectsto

Notes

Dashboard

wire harnessA

(seepage22'26)

Dashboard

wire harnessA

lsee oeoe 22-26\

PASSENGER'S

DOORWIREHABNESS

22-41

and Harnesses

Gonnectors

Connectorto Harnesslndex {cont'dl

OPDSUnit Harness

ConnoctororTorminal

OPDSunit

Cavitios

2

1

I

Location

In frontpassenger's

seat

Underfrontpassenger's

seat

FLOORWIBEHARNESS

22-42

Connectsto

Floorwareharness(seepage

22-34)

Notes

A/C Wire Harness

Connoctoror Terminal

Air mix controlmotor

Blowermotor

Evaporator

temperature

sensor

Modecontrol motor

Powertransistor

Recirculation

controlmotor

c851

Rel

I

2

8

3

4

1

1

Cavities

5

2

2

10

5

1

Undermaddle

of dash

Underrightsideof dash

Undermiddleof dash

Underrightsideof dash

Underrightsideof dash

Underrightsideof dash

Undermiddleol dash

c852

6

21

Undermiddleofdash

c853

5

,]

Undermiddleo{ dash

Location

Connec'tsto

Notes

Enginecompartment

wire

harness(seepage22-18)

Dashboard

wire harnessA

{seepage22 26i

Dashboard

wire harnessA

lsee oaoe 22-261

22-43

Fuse/Relay

Boxes

Connectorto Fuse/RelayBox Index

Under-hoodFuse/RelayBox

Socket

Ref

14

2

Ay'Ccompressorclutch relay

B

Blower motor relay

c

15

9

C o n d e n s efra n r e l a y

D

E

E L Du n i t

H e a d l i g hrte l a y1

Headlightrelay 2

Horn relay

Radiatorfan relay

Rearwindow defoqqerrelay

T1 (Batterv)

T101 (Alternator)

-

I

L'

-

1'

11

to

5

6

10

'l

J

|

||

-

-

-

T---r .-:-

t L _ _| . 1 I

t

t

t

L

"

"

tr

T

T

tTt Tr

,/^-------lFr

-/1-l

szl:!)

lrt

lview of tront sidel

22-44

Startersubharness(seeoaqe22-15)

Startersubharness{seeoaoe22-'15}

8

7

a-------) |

-

4

4

4

t t-l t t_l t tIl L l L l t l ' " . -

""""-l-

r^l

tt

Terminal

Connects to

2

Enginecompartmentwire harness(seepage 22-18)

4

5

Enginecompartmentwire harness(seepage22-18)

4

Enginecompartmentwire harness(seepage 22-18)

4

14

Enginecompartmentwire harness(seepage 22-18)

7

E n g i n ec o m p a r t m e nwt i r e h a r n e s s( s e ep a g e2 2 - 1 8 )

3

Enginecompartmentwire harness{seepage 22-18)

4

{View of back side)

Under-dashFuse/RelayBox

Socket

B

c

D

E

F

G

H

Ref

Terminal

2

3

1

5

6

14

5

19

9

I

20

13

12

10

3

J

K

24

22

27

26

7

M

N

o

P

Powerwindow relay

o

6

10

25

14

18

R

S

Startercut relay

T

Taillightrelay

Turn signal/hazardrelay

U

11

1:

.o^

;;

4

8

2

in

a

Floorwire harness(seepage 22-34)

ECMwire harness(seepage 22-32)

Dashboardwire harnessB (seepage 22-30)

Multiplexcontrol unit servicecheckconnector

l

l

17

2

Optionalconnector

Optionalconnector

Floorwire harness(seepage22-34)

28

I

13

{Plugsdirectly into the multiplexcontrol unat)

( P l u q sd i r e c t l vi n t ot h e m u l t i D l e cx o n t r o lunrl)

l5

to

W ( M e m o r ye r a s es i g n a l( M E S )

connector)

X

Y

:

11

'10

Connects to

Dashboardwire harnessB {seepage 22-30)

Dashboardwire harnessB {seepage 22-30)

Dashboardwire harnessB (seepage 22-30)

ECMwire harness(seepage 22-32)

ECI\4wire harness(seepage 22-32)

Enginecompartmentwire harness(seepage 22-'l8l

Enginecompartmentwire harness(see page 22-181

E n g i n ec o m p a r t m e nwt i r e h a r n e s s( s e ep a g e2 2 - 1 8 )

Enginecompartmentwire harness(see page 22-18)

Enginecompartmentwire harness(seepage 22-18)

Dashboardwire harnessA (seepage 22-26)

Dashboardwire harnessA (seepage 22-26)

Dashboardwire harnessA (seepage 22-26)

Dashboardwire harnessA (seepage 22-26)

Dashboardwire harnessA (seepage 22-26)

Floorwire harness(seepage 22-34)

l t

tn--rl

I U LI L.]L.J

h - - n UL]L]UL]

I] L] L] LI L]

!3

12

22-45

PowerDistribution

Fuseto Componentslndex

Under-hoodFuse/RelayBox

Fuse

Number

'I

Amps

204

15A

WireColor

Component(sl or Circuit(s) Protected

BLUI/EL Condenserfan motor

BLU/RED Ay'Ccompressorclutch

WHT/GRN Dashlights,Front parkinglights,Frontside marker lights,Licenseplate

l i q h t ,R e a rs i d em a r k e rl i q h t s T

, ailliqhts

15A

WHT/BLU C a r q oa r e al i q h t ,C e i l i n ql i q h t s l. q n i t i o nK e v l i q h t .S o o t l i o h t s

BLU/BLK Radiatorfan motor

WHT/BLK Turn siqnal/hazardrelav,Turn siqnal liqhts

WHT/BLK CKPsensor,ECM,IACvalve, lmmobilizercontrol unit-receiver,Injectors,

15A

WHT/GRN Brakelights,Brakesignals(to ABS modulator-controlunit, Cruisecontrol

20A

10A

B L U / R E D i1Orns

WHT/GRN ABS modulatorcontrol unit

, a u g ea s s e m b l yl,m m o b i l i z e r

WHT/RED A u d i o u n i t ,D a t al i n kc o n n e c t o(rD L C )G

7.5A

5

204

10A

P G M - Fm

I a i n r e l a v1 a n d 2 . T D Cs e n s o r

7

unit, ECM)

8

9

control unit-receiver,lmmobilizerindicatorlight. Keylessreceiverunil,

lvlultiDlexcontrol unit

10

40A

11

30A

IJ

40A

40A

14

40A

t5

15A

16

17

204

WHT/RED ABSmodulator-control

unit

BLK/YEL Noisecondenser,Rearwindow defoqqer

BLU^^/HT Blower motor

WHT/BLK No. 7 fuse (in the under-dashfuse/relavbox), Powerwindow relav

WHT/RED No.2 and No.3 fuses (in the under-dashfuse/relavbox)

REDI/EL Daytimerunning lightscontrol unit (Canada),Daytimerunning lights relay

{ C a n a d a )H, i o hb e a mi n d i c a t o lri q h t .L e f th e a d l i q h t

18

19

20

15A

60A

WHT

Multiplexcontrol unit

RED

D a v t i m er u n n i n ql i q h t sc o n t r o lu n i t ( C a n a d a )R. i o h th e a d l i o h t

WHTiBLU EPScontrol unit

80A

40A'

50A'?

WHT

Batterv.Power distribution

lgnition switch (BAT)

* 1 :U S A

" 2. Canada

l

l

II

I

E'l

22-46

t4 " t |

t

l

lI

l - - -

E,l E,l r--r r---rt__J i; i6'!/'

E,l E,l E,l

l'lr]n

r L__J,a

,..r^{-------l^-,

n[:]$"Lrt

O: Sparefuse

t

t

" N2,

Eol E l f__--l

|

|

nf

- r^l

Under-dashFuse/RelayBox

Fuse

Number

Amps

1

15A

2

3

204

10A

10A

5

6

7.5A

7

204

I

7.5A

9

10A

10

7.54

11

7.5A

7.5A

12

13

't4

10A

10A

1E

Wire Color

Component(s) or Circuit(s) Protected

BLKA/VHT l g n i t i o nc o i l s

WHT/RED Airlfuelratiosensor,ECM

RED/BLU D a y t i m er u n n i n gI i g h t sc o n t r o lu n i t{ C a n a d a )

BLI(ORN Air/fuel ratio sensorrelay,Alternator,CMP sensor,Cruisecontrol main

switch,Cruisecontrol unit. ELDunit, Evaporativeemission(EVAP)bypass

solenoidvalve, Evaporativeemission(EVAP)canisterpurge valve,

Evaporativeemission(EVAP)canistervent shut valve,SecondaryH02S,

Vehiclespeed sensor

Not used

Y E U G R N Moonroof control unit, Moonroof open and close relay,Powerwindow

relaV

GRN

Moonroof motor

YEURED A u d i o u n i t

GRN

OPDSunit, Rearwindow wiper motor, Rearwindow washer motor, Rear

window wiper intermittentcontrol unit

YEL

Back-uplights,Cruiseindicatorlight, EPScontrol unit, Gaugeassembly,

Keylessreceiverunit, Multiplexcontrol unit, Securitycontrol unit

connector(optional)

BLIVORN ABS modulator-controlunit

YEURED D a y t i m er u n n i n ol i o h t sc o n t r o lu n i t ( C a n a d a )

PNK

S R Su n i t

BLK/YEL A,,/C

compressorclutch relay,Blower motor relay,Condenserfan relay,

Heatercontrol panel,Power mirror actuator,Power mirror defogger

(Canada),Radiatorfan relay,Rearwindow defoggerrelay,Recirculation

control motor

Not used

17

15A

18

19

15A

7.5A

20

21

22

23

24

25

30A

Notused

YEL/BLK E C M ,F u e lp u m p

BLK/YEL >H> Unrr

Y E U G R N Accessorypower socket

Y E U B L K T u r ns i q n a l / h a z a rrde l a v T

, u r ns i q n a l i o h t s

G R N / B L K M u l t i p l e xc o n t r o lu n i t ,W i n d s h i e l dw a s h e rm o t o r .W i n d s h i e l dw i o e r m o t o r

204

20A.

G R N / B L K Passenqer'swindow motor

GRN,A/VHT Driver'swindow motor

lo

Not used

Not used

Notused

_ _ ^ :

Hr tl_l

f at-t

at\t I

r^,rl fl

!!;r -

!f 3 3 9: , i ; s ! ! s

Fnf

|rnITf

22-47

GroundDistribution

Groundto ComponentsIndex

Componentor circuit qrounded

Ground

Batterv,Transmissionhousinq

En g i n e

G1 0 1

G 15' ]

ECM(PGis BLK;LGis BRN/YEL)

BLK:IACvalve,lgnitioncoils,Vehiclespeedsensor,VTECsolenoidvalve

switch

BRNA/EL:

Camshaft

oosition(CMP)sensor.CKPsensor,TDCsensor.VTECoil pressure

EPScontrolunit

G201

ELDunit. Multiplexcontrol inspectionconnector,Multiplexcontrol unit, Powerwindow relay,Rear

window washer motor, Rightfront parkinglight, Rightfront side marker light, Rightfront turn signal

light,Turn signal/hazardrelay,Washerfluid level sensor(Canada), Windshieldwasher motor,

WindshieldwiDer motor

G202

G301

ABSmodulator-control

unit

G401

G402

G4 5 1

G501

G502

G503

G551

G552

22-48

Blower motor relay,Brakefluid level switch,Condensorfan motor, Cruisecontrol actuator,Leftfront

parkinglight, Leftfront side marker light, Leftfront turn signallight, Radiatorfan motor, Radiatorfan

swrtcn

Combinationliqht switch,lqnitlon kev srvitch,Wiper/wasfrersr,virch

Left and riqht airbaqsensors,SRS unit

Datalink connector(DLC)

Clutchinterlockswitchm Clutchpedal positionswitch (for cruisecontrol),Cruisecontrol main switch,

Cruisecontrol unit, Daytimerunning lightscontrol unit (Canada),Driver'sdoor lock knob switch,

Driver'sdoor lockswitch,Driver'spower window motor, Heatercontrol panel,Left power mirror

defogger(Canada),left side turn signal light, Moonroof control unit, Monroof open and close relays,

'1,

Moonroof positionsensor Moonroof seitch,Power mirror switch,Powertransistor,Powerwindow

masterswitch.SDotliqhts

Accessorypower socket,Gaugeassembly,Keylessreceiverunit, lvlultiplexcontrol unit, Right power

m i r r o rd e f o g g e {r C a n a d a )

A u d i ou n i t

Driver'sseat belt switch,Fuelgauge sendingunit, Fuelpump, Memory erasesignal(IMES)connector,

OPDSunit. Riohtseat belt switch

High mount brakelight, Licenseplate lights,Rearwindow defogger,Rearwindow defoggernoise

condenser.Rearwindow wioer motor, Hatchlatch switch

Back-uplights,Brakelights,Rearside marker lights,Rearturn signal lights,Rearwindow wiper noise

condenser,Rearwindow wiper intermittentcontrol unit, Taillights

Under-dashFuse/RelayBox

Removaland Installation

SRScomponentsare locatedin this area.Reviewthe

SRScomponentlocations{seepage 23-13)and

precautionsand procedures(seepage23-14)in the SRS

sectionbeforeperformingrepairsor service.

Removal

1. Make sure you have the anti-theftcode for the radio,

then write down the frequenciesfor the radio's

presetbuttons.

5. Removethe mounting bolt, and slidethe underdash fuse/relaybox (A) down from the bracket{B).

6. Disconnectthe backside from connectorsfrom the

back of the under-dashfuse/relaybox, and remove

the fuse/relaybox.

N O T E : T h eS R Sc o n n e c t o irs a s p r i n g - l o a d eldo c k

type (seepage 23-11).

lnstallation

2. Disconnectthebatterynegativecable,then

disconnectthe positivecable,and wait at least

three minutes.

1. Installthe under-dashfuse/relaybox in the reverse

order of removal and connectall connectorsto the

under-dashfuse/relaybox.

3. Removethe driver'sdashboardlower cover (see

page 20-59).

2 . I n s t a l l t h ed r i v e r ' sd a s h b o a r dl o w e rc o v e r .

4. Disconnectthe connectorsfrom the fuse side of the

under-dashfuse/relaybox.

3. Connectboth the negativecable and positivecable

to the battery.

4. Enterthe anti-theftcode for the radio,then enter

the customer'sradio stationpresets.

5. Confirmthat all systemswork properly,

6 . D o t h e e n g i n ec o n t r o lm o d u l e( E C M )i d l e l e a r n

p r o c e d u r e( s e ep a g e1 1 - 1 3 9 ) .

22-49

Battery

Battery Test

A batterycan explodeif you do not follow the

proper procedure,causingseriousinjury to anyone

nearby.Follow all procedurescarefullyand keep

sparksand open flames away from the battery.

Use eithera JCI or BearARBSTtester,and follow the

manufacturer'sprocedures.lf Vou don't have one of

these computerizedtesters,follow this conventional

test procedure:

1. Be sure the temperatureof the electrolyteis

between70'F (21"C)and 100'F(38'C).

2. Inspectthe batterycasefor cracksor leaks.

. l f t h e c a s ei s d a m a g e d r, e p l a c e t h eb a t t e r y . l

. lf the case looksOK, go to step 3.

3. Checkthe indicatorEYE.

. lf the EYEindicatesthebafteryischarged,goto

step 4.

. l f t h e E Y Ei n d i c a t e s al o w c h a r g e ,g o t o s t e p 7 .

4. Apply a 300 amp load for 15 secondsto removethe

surfacecharge.

5, Wait 15 seconds,then apply a test load of 280 amps

for 15 seconds.

6. Recordbatteryvoltage.

. l f v o l t a g ei s a b o v e 9 . 6 v o l t s , t h e

b a t t e r yi s O K . l

. l f v o l t a g ei s b e l o w 9 . 6 v o l t sg, o t o s t e p T .

7 . C h a r g et h e b a t t e r yo n H i g h( 4 0a m p s )u n t i lt h e E Y E

shows the batteryis charged,plus an additional30

minutes.lf the batterychargeis very low, it may be

necessaryto bypassthe charger'spolarity

protectioncircuitry.

. l f t h e E Y Ei n d i c a t e s t h eb a t t e r yi s c h a r g e d w i t h i n

3 hours,the batteryis OK.l

. lf the EYEindicatesthebatteryis notcharged

within 3 hours,replacethe battery.l

22-50

{

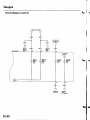

Relays

PowerRelayTest

Usethischanto identifythetypeof relay,thendo the

testlistedfor it.

type 1:

NOTE:Turnsignal/hazard

relayinputtest(seepage2287).

Relay

A'lCcomoressor

clutchrelav

Airlfuel ratio sensorrelav

Condenserfan relay

H e a d l i o hrte l a v1

H e a d l i q hrte l a v2

H o r nr e l a v

Powerwindow relay

R a d i a t oIra n r e l a y

Reverserelav

Startercut relav

T a i l l i q h rt e l a V

D a y t i m er u n n i n gl i g h t sr e l a y

{ C a n a d)a

Test

Normally-open

type A

type 2:

P G M - FmI a i nr e l a v1

P G M - Fm

l a i n r e l a v2

Blower motor relav

Rearwindow defoqoerrelav

Moonroofclose relay

Moonroof oDenrelav

Low beam cut relav {Canada)

Normally-open

tvpe B

F i v et e r m i n a l

type

Normally-open

type A:

PGM-FImain relay 1

PGM-FImain relay 2

type 1:

Checkfor continuitvbetweenthe terminals.

. Thereshould be continuitybetweenthe No. 1 and

N o , 2 t e r m i n a l sw h e n p o w e ra n d g r o u n da r e

connectedto the No. 3 and No. 4 terminals.

. Thereshould be no continuitybetweenthe No. 1 and

N o . 2 t e r m i n a l sw h e n p o w e ri s d i s c o n n e c t e d .

type 2:

(cont'd)

22-51

Relays

PowerRelayTest (confdl

Normally-open

type B:

Five-terminal

type

Checkfor continuitybetweenthe terminals.

C h e c kf o r c o n t i n u i t yb e t w e e nt h e t e r m i n a l s .

. Thereshould be continuitybetweenthe No. 1 and

N o . 3 t e r m i n a l sw h e n p o w e ra n d g r o u n da r e

connected

t o t h e N o .2 a n d N o . 4 t e r m i n a l s .

' Thereshould be no continuitybetweenthe No, 'l and

No. 3 terminalswhen power is disconnected.

. T h e r es h o u l db e c o n t i n u i t yb e t w e e nt h e N o . 1 a n d

N o . 2 t e r m i n a l sw h e n p o w e ra n d g r o u n da r e

c o n n e c t e tdo t h e N o . 3 a n d N o . 5 t e r m i n a l s .

. T h e r es h o u l db e c o n t i n u i t yb e t w e e nt h e N o . 1 a n d

N o . 4 t e r m i n a l sw h e n p o w e ri s d i s c o n n e c t e d .

tF-gr

tJ 1l

Rearwindow defonn* *O,

type 1:

6:)

rc*V

.r{{

(n F, t )\

\

s3.

Blower motor relay

type 1:

type2:

type 2;

22-52

lgnitionSwitch

Test

SRScomponentsare locatedin this area.Reviewthe

S R Sc o m p o n e n lto c a t i o n s( s e ep a g e2 3 - 1 3 a

) nd

precautionsand procedures{seepage 23-'l4)in the SRS

sectionbefore performingrepairsor service.

1, Removethe driver's dashboardlower cover {see

page 20-59).

2. Disconnectthe 5P connectorfrom the under-dash

fuse/relaybox.

WHT/RED

Wiresideof

f e m a l tee r m i n a l s

BLK/YEL

BLK/WHT

BLK/RED

Checkfor continuitybetweenthe terminalsin each

switch positionaccordingto the table.

\

Terminal WHT/

BLK/ BLK/ BLK/

RED WHT YEL RED WHT

p.J,i""-\ (ACC)

(BAT) flGl) trc2t (sr)

o (LocK)

| (ACC)

o- --o

_H

[ (oN)

c)III (START)

o _H

lf the continuitychecksdo not agreewith the table,

replacethe steeringlock assembly(seepage'17-121.

22-53

Gauges

\-

ComponentLocationIndex

PARKINGBRAKESWITCH

p a g e1 9 - 1 0

FUELGAUGESENDING

p a g e1 1 - 1 5 6

SWITCH

ENGINEOILPRESSURE

page8-4

GAUGEASSEMBLY

Procedure,page22-56

SelJ-diaqnostic

page22 63

Gauqedulb Replacement,

Rep6cement,page22-64

CoolantTemperatureGauge

page22'64

TroLrbleshooting,

VEHICLESPEEDSENSOR{VSS)

page22-65

Troubleshooting,

Beplacement,page22-67

BRAKEFLUIDLEVELSWITCH

p a g e1 9 - 1 0

\

22-54

CONNECTOR

B

lgreenJ

CONNECTORA

(bluel

SPEEDOMETER

VehicleSpeedSignalCircuit

page22-65

Troubleshooting,

TACHOMETEB

\7

t----/

\

_ / \

i . . _ ODO/TRIPMETER

FUELGAUGE

Test,page11-156

22-55

Gauges

v

Self-diagnosticProcedure

The gaugeassemblyhas a self-diagnosisfunction.

. T h e B e e p e rD r i v eC i r c u i C

t heck

. The IndicatorDrive CircuitChecL

. The LCDSegmentsCheck

. The GaugesDrive CircuitCheck(Speedometer,Tachometer,Fuelgauge,Coolanttemperaturegauge)

. T h e C o m m u n i c a t i oLni n eC h e c k( t h ec o o l a n t t e m p e r a t u rsei g n a l i n e b e t w e e nt h e g a u g ea n d E C M )

NOTE:Indicatorsare also controlledvia the communicationline.

Enteringthe self-diagnosis

f unction:

Beforedoing the self-diagnosisfunction,checkthe No. 9 (10A)fuse in the under-hoodfuse/relaybox and No. 10 {7.5A)

fuse in the under'dashfuse/relaybox.

1. Pushand hold the trip/resetbutton.

2 . T u r nt h e l i g h t i n gs w i t c hO N .

3 . T u r nt h e i g n i t i o ns w i t c hO N ( l l ) .

4 . W i t h i n5 s e c . ,t u r n t h e l i g h t i n gs w i t c hO F F ,t h e n O N a n d O F Fa g a i n .

5. Within 5 sec.,releasethe trip/resetbutton,then push and releasethe buttonfour times reDeatedlv.

NOTE:

. While in the self-diagnosismode, the dash lights brightnesscontrolleroperatesnormally.

'Whileintheself-diagnosismode,thetrip/resetbuttonisusedtostartthebeeperdrivecircuitcheckandthegauge

drive cicuit check.

. lf the vehiclespeedexceeds1.2 mph 12km/h)orthe ignition switch is tu rned OFF,the self,diagnosis mode ends.

oN flrl

lgnition

OFF

Switch

Lighting

Switch

Trip/Reset

Switch

->

5 sec.

Move to selt-diagnosis mode.

5 sec.

The BeeperDriveCircuitCheck:

When enteringthe self-diagnosismode, the beepersoundsfive times

TheIndicatorDriveCircuitCheck:

When enteringthe self-diagnosismode,the following indicatorsblink.

Seatbelt indicator,Door/hatchindicator,Brakesystem,Lowfuel indicator,Maintenancerequiredindicator(USA),

) , i l p r e s s u r el i g h t .

W a s h e rf l u i d l e v e li n d i c a t o (r C a n a d a O

22-56

\

The LCDSegmentCheck:

W h e ne n t e r i n gt h e s e l f - d i a g n o s m

i s o d e ,t h e o d o / t r i ps e g m e n tb l i n k sf i v et i m e s .

TheGaugeDriveCircuitCheck:

W h e ne n t e r i n gt h e s e l f - d i a g n o s m

i s o d e ,t h e s p e e d o m e t e trh, e t a c h o m e t e rt ,h e f u e l g a u g e ,a n d t h e c o o l a n t

g a u g en e e d l e ss w e e pf r o m t h e m i n i m u mp o s i t i o nt o m a x i m u mp o s i t i o nt,h e n r e t u r nt o t h e m i n i m u m

temperature

posrtron.

NOTE:After the beeperstops soundingand the needlesreturnto the minimum position,pushingthe trip/resetbutton

s t a r t st h e b e e p e rd r i v ec i r c u i tc h e c k( o n eb e e p )a n d t h e g a u g ed r i v ec i r c u i tc h e c ka g a i n .

T h e c h e c kc a n n o tb e s t a r t e du n t i l t h en e e d l e sr e t u r nt o t h e m i n i m u mp o s i t i o n .

Self-diagnosis

mode

ON

OFF

Trip/Reset

switch

9loFF _---

causeneedlesXl"

Beeper

ON

;;

r

n =--llJL--

f---U---------l

r-r r-r r-r .-1 r-r

r-r

lll u u l_lL__l

I

@,

[-----l

l-l

The needlessweepfrom the

minimum positionto the

maximum position,then return

t o t h e m i n i m u mp o s i t i o n -

5 sec

The Communication Line Check:

In the self-diagnosismode, after the odo/trip LCDsegmentscheck,the self-diagnosisstartsthe communicationline

cnecK.

l f a l l s e g m e n t sc o m e so n , t h e c o m m u n i c a t i o lni n e i s O K .

" E r r o r "i s i n d i c a t e d ,

l f t h ew o r d

t h e r ei s a m a l f u n c t i o ni n t h e c o m m u n i c a t i o lni n e b e t w e e nt h e g a u g ea s s e m b l yt.h e

m u l t i D l e cx o n t r o lu n i t .a n d t h e E C M .

Faulty:

Normal:

iD

:-l!:!!JlJ!J

t l

i-

f l

O i -

,-

t

--

-

,-

r-

i-

,

| | | t t f

i-

r-

Endingthe self-diagnosisfunction:

T u r nt h e i g n i t i o ns w i t c hO F F .

N O T E lrf t h e v e h i c l es p e e de x c e e d s1 . 2m p h { 2 k m / h ) t, h e s e l f d i a g n o s i sf u n c t i o ne n d s .

22-57

Gauges

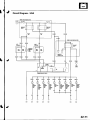

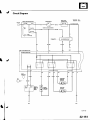

CircuitDiagram

'

UflOEN fiOOOFUSE/8ILAY

8OX

ECM/PCM

V

I

-r'

r--l

l J ,

I

I 8|

COOLANI

TEMPfNAIUFT

SPIEDOMEIENTACHOMEIIR FUTLGAUGI GAUGE

Norll0AlFUSE

8L(

-o-

22-58

ii-ciorurnn

coNNECron

N o 2 0 i o A: lU S A

ti) l To mxr I

MAi{IIiIANCE

ft0unlD

[{0tcaTo8

LIGH]

(LEDI

(cont'd)

22-59

Gauges

I

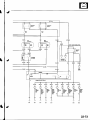

CircuitDiagram(cont'dl

No2il5AlFUSE

ilnlh.undi hooq

llu!./rcl.ybox r

DASH

LGHTS

Yt

Yl

t

'-

l

-t

WASHEF

Itut0

I!VEL

6t0tc ToR

UGHT

(tDl

J

ls?2

I

BLUIYEL

I

J

cSutsE

m n0L

a

22-60

'-

./

ib-n'rnoL

UNIT

tNGniEorL

PRESSUBE

swtTcH

lCld.d Eisin.3topp.d

l

iopd Ersin.runni.s

i

I

!

i

I

I

L

--t

DAYTIME

BUNN|NG

LIGHTS

@NTROL

UNII

I

;

I

-.-..

I

i

icmadd

(cont'd)

22-61

Gauges

CircuitDiagram(cont'dl

\"

GRNIfiED

I

\""'7

V

GAUGIASSEi|BLY

LEFTTUN

SIGI'IAL

II'{DICATOR

LTCHTS

HIGHSEAM

-|.

IMMOBITIZER

ltDtcATon r/: \ tilucaToB

f,il

CoME|NAT|ON

LtctlTswtTclt

vll9i,]

\,

tMf,tOBtUZEn

@l\tTRoL

UN|I ftCtIVER

J

22-62

GaugeBulb Replacement

LIGHT{1.4WI

RIGHTTURNSIGNALINDICATOR

CRUISE

HIGHBEAMINOICATOR

LIGHT{1.4W)

ITORLIGHT{I.4W)

LEFTTURNSIGNALINDICATORLIGHTl1.il wl

GAUG€LIGHT{1.4WI

GAUGELIGHT{1.4W}

IMMOBILIZENINDICATOR

LTGHT

{1.4Wl

22-63

Gauges

GaugeAssemblyReplacement

CoolantTemperature

Gauge

Troubleshooting

1 . Removethe instrumentpanel (seepage 20-59),

t h e n r e m o v et h e u p p e rc o l u m nc o v e r{ s e ep a g e1 7 -

2. P l a c ea c l e a ns h o pt o w e l ( A )u n d e rt h e g a u g e

assemblyto preventscratchingthe steering

c o l u mn o r d a s hp a n e l .

Beforetesting,checkthe No. I { 10A)fuse in the underhood fuse/relaybox and the No. '10(7.5A)fuse in the

under dash fuse/relaybox.

1. Startthe engine,and checkthe malfunction

i n d i c a t o lra m p ( M l L ) .

3 . Removethe screwsfrom the gauge assembly(B).

Does the MIL come on?

YES- Troubleshootthe causeof the ECM DTC(see

p a g e11 - 5 7 )a, n d r e c h e c k .

NO-Go to step 2.

2. Checkfor a multiplexcontrol unit DTC(seepage

22,168).

ls a DTC indicated?

YES Troubleshootingthe causeof the multiplex

control unit DTC{seepage 22-168),and recheck.

NO Go to step 3.

4. Disconnectthe connectors(C),and removethe

g a u g ea s s e m D r y .

I n s t a l l t h eg a u g ea s s e m b l yi n t h e r e v e r s eo r d e ro f

removal.

3 . D o t h e c o m m u n i c a t i o lni n ec h e c kw i t h t h e s e l f diagnosisprocedure(seepage 22-56).

ls the word "Error" indicated on the odo/ttip

d isplay ?

YES The gaugecannot receivethe signalfrom the

multiplexcontrol unit and the ECI\,4.

Checkfor an

open in the WHT/GRNwire (gaugeconnector

t e r m i n a lB1 3 ) .l f n o o p e ni s f o u n d ,g o t o s t e p5 .

NO Go to step 4.

4. Do the gaugedrive circuitcheckwith the selfd i a g n o s i sp r o c e d u r e( s e ep a g e2 2 - 5 6 ) .

Does the temperaturegauge needle sweep lrom

the minimum position to the maximum, then tetutn

to the minimumposition?

YES Go to step 5.

NO Replace

t h e g a u g ea s s e m b l y . l

5. Substitutea known-goodECM and recheck.

Did the symptom/ ind ication go away?

YES Replace

theECM.

NO Substitutea known good gaugeassembly.lf

the symptom/indicationgoes away, replacethe

g a u g ea s s e m b l y . l

22-64

I

VehicleSpeedSignalCircuitTroubleshooting

Special Tools Required:

Test Harness07LAJ-PT3020A

5. Connectthe WHT test harnesscliD(B)to the

positiveprobe of a voltmeter,and connectthe RED

test harnessclip (C)to the negativeprobe.

Beforetesting,inspectthe No. 4 (10A)and No. 10 (7.5A)

fuses in the under-dashfuse/relaybox.

1. Disconnectthe 3P connectorfrom the vehicle

speedsensor(VSS){A).

T u r nt h e i g n i t i o ns w i t c hO N ( l l ) .

le thara