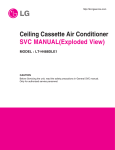

Download Single Packaged Air Conditioner

Transcript