Download SERVICE MANUAL AU-A129E AH-A129E - Wiki Karat

Transcript

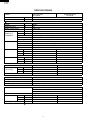

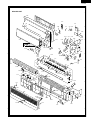

AH-A129E AU-A129E SERVICE MANUAL S2918AHA129E/ SPLIT SYSTEM ROOM AIR CONDITIONERS INDOOR UNIT MODELS AH-A129E OUTDOOR UNIT AU-A129E In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original condition and only parts identical to those specified should be used. TABLE OF CONTENTS Page SPECIFICATIONS ............................................................................................................................................ 2 EXTERNAL DIMENSIONS ................................................................................................................................ 3 WIRING DIAGRAMS ......................................................................................................................................... 4 ELECTRICAL PARTS ....................................................................................................................................... 5 MICROCOMPUTER CONTROL SYSTEM ........................................................................................................ 8 FUNCTIONS ..................................................................................................................................................... 9 REFRIGERATION CYCLE .............................................................................................................................. 13 PERFORMANCE CURVE ............................................................................................................................... 15 DISASSEMBLING PROCEDURE ................................................................................................................... 16 TROUBLESHOOTING OF THE CONTROL CIRCUIT .................................................................................... 21 REPLACEMENT PARTS LIST ........................................................................................................................ 24 SHARP CORPORATION 1 AH-A129E AU-A129E SPECIFICATIONS ITEMS Cooling capacity kW Moisture removal Liters/h Electrical data Phase – Rated frequency Hz Rated voltage range V Rated voltage V Rated current Cool A Rated input Cool W Compressor Type Model Oil charge Refrigerant system Evaporator Condenser Control Refrigerant volume Capillary tube size Outer dia. mm Inner dia. mm Lenght mm Q'ty Noise level High dB(A) Med. dB(A) Low dB(A) Fan system Drive Air flow quantity High m3/min. (at cooling) Med. m3/min. Low m3/min. Fan Connections Refrigerant coupling Refrigerant tube size Gas, Liquid Refrigerant pipe sets No. Drain piping mm(Inches) Others Safety device INDOOR UNIT AH-A129E 3.45 1.3 OUTDOOR UNIT AU-A129E Single 50 198 to 264 220 - 240 5.3 - 5.1 1150 - 1180 Hermetically sealed rotary type RH207VXET 520cc (DIAMOND MS56)) Louver fin and Grooved tube type(7mm tube) Louver fin and Grooved tube type(7mm tube) Capillary tube 940g – 2.7 – 1.6 – 700 – 1 42 48 40 – 36 – Direct drive 9.3 8.4 7.0 Cross flow fan Direct drive 26 – – Propeller fan Flare type 1/2", 1/4" AZ-24T7F; 7m(23ft) O.D ø 18(45/64) Compressor: Overload protector(Internal) Fan motors: Thermal fuse Fuse, Micro computer control Air filters Polypropylene net (Washable) Net dimensions Width mm 897 720 Height mm 297 535 Depth mm 186 236 Net weight kg 10 35 Note: The condition of star( ) marked item are 'IEC378'. 2 AH-A129E AU-A129E EXTERNAL DIMENSIONS Length unit (mm) 186 297 897 58 182 19.5 Remote controller Figure E-1. INDOOR UNIT 245 58 535 236 228 430 720 775 3 278 143 Figure E-2. OUTDOOR UNIT 20˚ 55 AH-A129E AU-A129E WIRING DIAGRAMS INDOOR UNIT TERMINAL BOARD 2 RE RE WH TRANSFORMER SWITCH CN201 UNIT BCN CN7 RECEIVER & LED UNIT CN101 CN6 THERMISTOR (ROOM TEMP.) THERMISTOR (PIPE TEMP.) LOUVER MOTOR CN4 1 2 3 4 5 6 CN5 BL NR VARISTOR (B) 1 1 TERMINAL BOARD G(Y) G(Y) TERMINAL BOARD 1 G(Y) INTERNAL THERMAL FUSE R.P.M SIGNAL CN3 N SSR (A) (C) 5 3 1 CN2 RE BL GR N BK FUSE T2.5A CN8 BK BL FAN MOTOR CONTROL CAPACITOR BOARD UNIT 2 430V 2µF BR BL L N BR BL POWER EVAPO- SUPPLY RATOR CORD FAN MOTOR BK BL BR GR G(Y) BL : BLACK RE : RED : BLUE WH : WHITE : BROWN : GRAY : GREEN–YELLOW Figure W-1. Wiring Diagram for AH-A129E INDOOR UNIT TERMINAL BOARD 2 OUTDOOR UNIT TERMINAL BOARD G(Y) 1 1 N N TERMINAL BORAD 1 BK BK BL N L CONDENSER RE INTERNAL THERMAL FUSE UNIT TO UNIT CORD WH CONTROL BOARD UNIT 1 RY 250V IN OUT 5 7 1 CN1 2 UNIT TO UNIT CORD THERMAL FUSE OUTDOOR UNIT C COMPRESSOR MOTOR FAN MOTOR S R BL BK BK :BLACK BL :BLUE G(Y) :GREEN-YELLOW RE :RED WH :WHITE MOTOR PROTECTOR FAN MOTOR CAPACITOR 430V 1.5µF BL Figure W-2. Wiring Diagram for AU-A129E 4 WH RE RUNNING CAPACITOR 400V 30µF AH-A129E AU-A129E ELECTRICAL PARTS DESCRIPTION Compressor Indoor fan motor Outdoor fan motor Indoor fan motor capacitor Outdoor fan motor capacitor Running capacitor Transformer Fuse MODEL RH207VXET ML-A525 ML-A593 – – – – REMARKS 220/240V, 50Hz, 1000W 220 - 240V, 50Hz, 220V, 60Hz 220/240V, 50Hz, 220V, 60Hz 430V, 2µF 430V, 1.5µF 400V, 30µF Primary; AC 220/240V, 50Hz SITE AU AH AU AH AU AU AH – Secondary; AC14.5/15.9V, 50Hz 250V, 2.5A AH 5 33µ 3 2 12H / 24H 19 (P41) JP10 X NONE IC1 PIN NO. SYMBOL SET LOUVER MOTOR FUNCTION R6 470 1/2w RY1 5 12V X NONE JP9 17 (P43) OFF/ON X NONE JP7 16 (P44) 3/5min. X NONE JP5 15 (P45) DEICE B 2 2 D. FAN OFF OFF WIDEH CN3 1 2 3 4 1 6 5 BCN R28 680 1 6 5 R26 680 R30 10k R29 330 5V C13 1000P 50v R41 10k 8 IC4 X NONE JP4 14 (P46) DEICE A 9 12V C23 1000P 50v C17 1000P 50v POWER ON R40 10k 5V CN8 5 5 (RED) LED101 SSR 4 4 (YELLOW) LED102 12V 3 12V 2 3 (C102) 0.1µ 25v 2 CN6 1 1 CN101 2 2 1 – 10v + C101 3 3 1 PHOTO DETECTOR UNIT (TEST RUN) AUX. CN7 CN201 5V FREEZE A FREEZE B DE. FAN A DE. FAN B NC JP8 SM8313 19 P06 IC1 JP2 JP1 USE X NONE 5 (P33) OFF/ON 6 (P32) C7 0.1µ 50v WIRELESS CHANG/ NORMAL – + PREHEAT C8 10µ 10v 5V 6 5 4 3 2 1 P33 P50 P51 P52 P53 R9 3.9k(F) 2.7k(F) 3 (P51) FAN M 7 P32 R10 4 (P50) FAN L 8 P31 9 10 11 P30 AGND CK2 CK1 RESET 12 5V 2.7k R8 2 (P52) FAN H R39 10k(F) R38 10k(F) R37 10k(F) R36 10k(F) R35 10k(F) 10k 10k 10k R34 R33 R32 R31 2 1 2 Q1 5V TR 1.2k(F) R12 1 (P53) R11 R12 R8 R9 R10 JP2 JP1 JP3 JP6 12V 2 SWEAT 1 7.32k(F) R11 64 (P54) 5V X NONE JP14 33 (P27) R20 10k X NONE JP13 34 (P26) DE. FAN A C22 1000P 50v C21 1000P 50v R25 1.2k FUSE 2.5A 250V X NONE JP12 35 (P25) C11 10µ C10 10µ X NONE JP11 36 (P24) FREEZE A – 16v + – 16v + FAN MOTOR R17 15kF R18 15kF R19 10k FREEZE B CN5 3 2 1 CN1 5 3 1 THERMAL PROTECTOR R21 10k 12V D9 A C 11 CNR3 5V 13 R5 2.7k R23 33k R24 4.7k DE. FAN B MODEL A MODEL B FAN H FAN M FAN L WIRELESS PREHEAT MODEL A L S201D01 SSR FAN MOTOR CAPACITOR IC5 BZ F C12 0.01µ 250vAC C19 1000p 50v C15 0.1µ 50v 3 NR G RPM PLUSE 5V 3 OCS DEICE B DEICE A 12H/24H D. FAN OFF OFF WIDEH RPM C1 0.1µ 250vAC 8MHz MODEL B 3 1 7 5 CN2 10k JP4 JP5 JP7 JP9 JP10 C18 1000P 50v R7 3.3k 2 1 CN2 Figure L-1. Electronic Control Circuit Diagram USE JP3 7 (P31) RPM PLUSE 1/3 P07 51 P11 48 50 P12 47 P10 P13 49 P14 P16 P15 43 P17 K1 P20 42 41 40 14 13 15 P46 F P45 P22 38 P21 P23 37 39 P44 P24 16 17 18 1 2 R3 22k Q3 BCN 7 3 CN8 7 36 P43 P41 P42 NC 46 X NONE JP6 8 (P30) 5V C14 0.01µ 16v P25 NC 45 SWEAT R4 6.8k C16 0.1µ 50v D4 D3 R2 22k D2 THERMAL FUSE D1 P26 NC 44 ON/OFF NC R22 1k 5 6 7 8 5V – + 35 P27 IC6 CN8 C3 0.22µ 50v C2 2200µ 35v 34 33 4 3 2 NC 1 NC BCN JP11 JP12 JP13 JP14 10V 47µ – 25v IN P05 52 5V 4 IC2 P04 53 4 OUT P03 NC 54 – TEST 32 + C4 GND 29 3 OCS IN 30 P02 NC 55 3 28 P60 P01 NC 56 C5 0.1µ 50v 27 P61 P00 NC 57 IN 26 P62 GND 58 IC3 25 GND VDD 59 GND 24 P63 VR 60 OUT 23 NC P64 P57 61 + 22 NC P65 P56 C6 100µ 10v OCSOUT 31 NC 7812 21 KH P66 P55 62 NOTE : 1. : TEST POINT 2. Not specified is 1/5w 12V 20 P40 P54 63 6 64 5V 5V IN PIPE TEMP. X NONE JP8 40 (P20) ON/OFF 15k(25˚C) ROOM TEMP. TH2 1 N POWER SUPPLY OUTDOOR UNIT NEUTRAL LINE EARTH LINE GREEN/YELLOW TERMINAL BOARD 3P 15k(25˚C) OUT TEST TH1 POWER ON CN4 6 5 4 3 2 1 RY1 B L N AH-A129E AU-A129E 7 FUSE Figure L-2. Printed Wiring Board (FAN MOTOR) CN2 DIP C16 1 1 IN CN4 C5 6 GND 3 JP32 OUT IC3 C19 JP35 AUX 1 CN201 SW102 SW101 3 C21 C22 C18 (THERMISTOR) C10 C11 R19 R18 R17 R15 C9 Q3 1 R16 QPWBFA891JBE0 TEST RUN DPWBFA047JBK0 D7 From louver CN3 From fan motor R25 To Fan motor capacitor (C) F.M. GRAY CAP 1 C1 (RPM) 250V 2.5AT 5 JP16 CN5 5 ( LOUVER ) MOTOR (F) BROWN C12 (B) N CN7 BZ 3 1 1 12V BLUE 1 D9 N BROWN L L NR (G) JP19 JP18 From Terminal board " L " OUT RY1 F.M. CAP (A) BLUE 7 BCN R14 R13 CT Q2 C6 32 R4 R24 D6 From Terminal board " 1 " 1 R6 5V CN8 JP20 R5 33 20 JP36 3 (E) R40 3 R28 R29 JP21 GND JP22 R41 CN6 1 SWEET 12V JP29 7 JP23 C4 (D) CNR2 ORANGE JP31 JP17 1 3 JP25 JP24 5 R.P.M. IC4 16 C13 1 C17 OSC JP15 1 JP28 JP27 JP26 51 19 3 IC5 1 JP12 JP11 JP8 9 8 52 IC1 2 POWER ON CN1 R30 (TRANSFORMER) 1 64 1 JP33 QPWBFB253JBE0(C) REEZE B REEZE A 2 PURPLE RY2 RY3 C23 Q1 C20 3 R26 C8 R39 JP30 QPWBFB 126JBE0 C101 PHOTO DETECTOR UNIT LED101(RED) M.B. JP14 JP13 DEF FAN A To Fan motor capacitor 7 C3 C2 OUT IC2 F.H. C7 GND IN CN101 M.A. RECEIVER 1 R8 R12 LED102 (YELLOW) DPWBF A092 JBK0 R37 From Transformer QPWBFB253JBE0(P) 5 R38 R22 JBK0(P) R11 DE FAN B DPWBFA F.M. D3 D1 WIREL IC6 DIP OFF WIDEH R2 R3 PREH. D4 D2 R31 JP6 R32 JP3 R33 JP1 R34 JP2 JP35 R10 R36 R9 JP7 JP9 D. FAN OFF D5 C15 CNR1 JP34 2 DEICE A R21 SSR DEICE B JBK0(C) 13 JP5 JP4 R23 R7 C14 1 TIMER DPWBFA CNR3 JP10 R20 7 DSGY-A878JBK0 From Thermistor AH-A129E AU-A129E AH-A129E AU-A129E MICROCOMPUTER CONTROL SYSTEM Microcomputer (IC1) The microcomputer is a CMOS, one chip, 8-bit microcomputer. Microcomputer port allocation is as follows. Pin No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 Terminal Name P53 P52 P51 P50 P33 P32 P31 P30 AGND CK2 CK1 RESET F R46 R45 R44 R43 R42 R41 R40 KH P66 P65 P64 P63 GND P62 P61 P60 OSC OSC TEST Input Output IN IN IN IN IN IN IN IN IN IN IN IN OUT IN IN IN IN IN IN IN IN IN IN IN IN IN IN OUT IN IN OUT IN Pin No. 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 Function MODEL B FAN H FAN M FAN L WIRELESS PREHEAT PRM PLUSE SWEAT 0V OSILLATION OSILLATION RESET BUZZER DEICE A DEICE B COMP. OFF WIDTH DEHUM. FAN OFF TEST 1 – – PRM SIGNAL – – – AC CLOCK 0V – EEPROM CLOCK EEPROM DATA – – – 8 Terminal Name P27 P26 P25 P24 P23 P22 P21 P20 KI P17 P16 P15 P14 P13 P12 P11 P10 P07 P06 P05 P04 P03 P02 P01 P00 GND VDD VR P57 P56 P55 P54 Input Output IN IN IN IN IN IN IN IN IN OUT OUT OUT OUT OUT OUT OUT OUT OUT OUT OUT OUT OUT OUT OUT OUT IN IN IN IN IN IN IN Function MODEL 4 MODEL 3 MODEL 2 MODEL 1 SWITCH AUX. SWITCH TEST RUN – POWER ON WIRELESS SIGNAL LED OPERATION LED TIMER – – (VALVE COIL) (OUT DOOR FAN) RY1 SSR LOUVER MOTOR LOUVER MOTOR LOUVER MOTOR LOUVER MOTOR – – – – 0V 5V 5V (CURRENT LEVEL) TH1 TH2 MODEL A AH-A129E AU-A129E FUNCTIONS 2. Operation modes 2-1 COOL operation The compressor turns on or off, at the thermostat lines C3 and C4. The outdoor fan motor is also controlled with the compressor. 34.5 C1 33.5 C2 32.5 C3 31.5 C4 States 1 & 3 : Compressor ON State 2 : Compressor OFF Room temperature Room temperature( C) 1. Temperature control characteristic 1-1 COOL operation In the “COOL” mode, the thermostat circuit is controlled by four thermostat lines (C1 thru C4). 20.5 19.5 C3 Room temperature transition 18.5 2 17.5 18 32 Preset temperature(˚C) Preset temperature Figure H-3 Figure H-1 2-2 DRY operation In the “DRY” mode, the thermostat circuit is controlled by three thermostat lines (D1 thru D3). 33.5 D1 32.5 D2 31.5 D3 19.5 18.5 17.5 18 Preset temperature(˚C) 32 DRY operation On the switch on, the compressor always starts to operate for 2 minutes with fan speed “D” (slower than “UL”). The microcomputer measures the room temperature 2 minutes after this first compressor operation. This room temperature is set as the preset temperature automatically. The preset temperature ranges from 18˚C to 32˚C. When the room temperature is below 18˚C, the preset temperature is set to 18˚C, and when the room temperature is over 32˚C, the preset temperature is set to 32˚C Dry operation is divided into three zones (Cooling zone, Dehumidifying zone and Circulating zone) by thermostat lines (D1 to D3), and the compressor and the fan motor are controlled in each zone as shown in Table H-1. States 1 & 5 : Cooling zone States 2 & 4 : Dehumidifying zone States 3 : Circulating zone Figure H-2 D1 Room temperature Room temperature( C) 1-2 C4 3 1 D2 5 D3 1 4 2 3 Room temperature transition Preset temperature Figure H-4 9 AH-A129E AU-A129E Table H-1 7. Timer 7-1 24-HOUR PROGRAMMABLE ON/OFF TIMER ON-TIMER or OFF-TIMER can be independently programmed. When the unit operates during one hour after the OFF-time is set, thermostat setting is automatically shifted (+1˚C in cool operation and dry operation, -3˚C in heat operation, but, 16˚C set temperature at the lowest). When the ON-timer is set in heat operation and cool operation, operation starts before 0 to 30 minutes(depends on the room temperature) so that preset temperature is obtaind at set time. Compressor Fan speed Cooling zone ON "UL" Dehumidifying zone ON "D" Circulating zone OFF "D" or OFF 2-3 Fan only operation The indoor fan motor always turns on. 3. Fan speed Fan speeds are given by the indoor fan motor, “H”, “M”, “L” and “UL”, which are available in the following operation mode. 7-2 ONE-HOUR TIMER When ONE-HOUR timer is set, the unit turns off automatically after one hour. The one hour timer operation has priority over other time operation, such as the TIMER ON and TIMER OFF. If the ONE-HOUR TIMER button is pressed again during operation, the unit will operate additionally for another one hour. Table H-2 FAN Switch HIGH LOW SOFT COOL M L UL FAN ONLY M L UL 8. Automatic air conditioning When automatic air conditioning is selected, the operation mode and preset temperature are set automatically according to the room temperature on starting operation. 4. Anti-sweating When the operation continues 30 minutes in cooling zone or dehumidifying zone during dry operation or in continuous compressor operation during cool operation, the fan speed of indoor fan motor shifts up, from “UL” to “L” or from “D” to “UL”. Table H-3 Room temp. of operation start 5. Freeze preventive When the indoor pipe temperature falls below -1˚C during cool operation or dry operation, the compressor is stopped. Above 28˚C 26˚C to 28˚C 24˚C to 26˚C Below 24˚C 6. Test run If the “TEST RUN” button in the unit is pushed during suspension of operation, cool test operation starts. At this time, the fan speed is set to “AUTO”. If this button is pushed during operation, the test operation starts in current operation mode. The operation LED (red) flickers during test run. During cool operation and heat operation, the compressor is kept on but in dry operation it is set in the dehumidifying zone. In fan only mode the indoor fan motor runs continuously. Operation start COOL DRY Preset temp. 26˚C 25˚C 24˚C Room temp. at operation start 9. Automatic fan speed When the automatic fan speed is selected in cool or heat operation, the fan speed is automatically changed by the thermostat lines C1 to C3 in cool operation and H1 to H4 in heat operation. Room temperature States 1 & 5 :"M" States 2 & 4 : "L" States 3 : "UL" 5 C2 C3 1 4 2 3 Room temperature transition Preset temperature Figure H-5 10 C1 AH-A129E AU-A129E 10.Power on start If the connecting wire "POWER ON" is cut on the PWB ass’y, when the power is supplied by turning on a circuit breaker, the air conditioner automatically starts of operation in “AUTO” mode. (Refer to Figure L-2. Printed Wiring Board.) 11.Auto restart Power failure occurs during operation, the unit will restart in the same operation mode as before after power recovery. (Refer to Figure L-2. Printed Wiring Board.) 12.Outputs in each operation mode Table H-4 COOL DRY Compressor Outdoor Fan motor Indoor Fan motor Cooling ON ON ON Circulating OFF OFF ON Cooling ON ON L/UL Dehumidifying ON ON UL/D Circulating OFF OFF D/OFF OFF OFF ON FAN ONLY 13.Diagnosis procedure When indoor fan motor is out of order or compressor lock occurs, the compressor, inddor fan motor, outdoor fan motor, and louver are all stopped and the operation LED(red) turns on or off syncronously with the timimg of the timer LED. When the thermistor for room temperature or pipe temperature is open or short state, the operation LED turns on or off syncronously with the timing of the timer LED by pushing continously for more than three seconds both "TEST" button and "AUX." button. 1sec. Timer LED Indoor fan motor Operation LED Comp.-lock Operation LED 1sec. ON 4sec. OFF ON OFF ON OFF Thermistor short state Operation LED ON Thermistor open state Operation LED ON OFF OFF Timing chart of Timer LED and Operation LED of DIAGNOSIS PROCEDURE. When "OI" button the remote controller or "AUX." button in the unit is pushed, the unit is free from DIAGNOSIS PROCEDURE. 11 AH-A129E AU-A129E 14.Test mode 14-1 TEST 1 (For control circuit operation checking) Make terminals 1 and 2 of connector CN4 short-circuited and supply power. The timer's periods become shorter i.e. a 3 minute cycle is carried out in 3 seconds, except for ; The operation LED flicker's period in Test run The protector timer The defrost timer not shortened 14-2 TEST 2 (For output of each operation checking) Test mode is for checking output of each operation. Keep pushing both the buttons, "AUX." and "TEST RUN", and supply the power, the system will go to the test 2 mode. In this mode, the output of operation is switched by the "TEST RUN" button in the unit or the "OI" button in the remote controller. Use the "AUX." button to back to step 1. Normal outputs are shown in Table H-5. Table H-5 Lamps Step Output for outdoor unit RED YELLOW Indoor Fan motor Louver 1 OFF 1 2 OFF OPEN 2 ON Flickering ON D OFF 3 OFF ON OFF M OFF 4 OFF ON ON L CLOSE 5 OFF ON OFF D OFF 6 OFF OFF OFF UL OFF 7 OFF OFF OFF H OFF 8 OFF OFF ON M OFF 9 OFF ON ON L OFF 10 OFF OFF ON OFF OFF 11 OFF ON OFF OFF OFF 12 OFF OFF ON OFF OFF 13 OFF OFF OFF OFF OFF 14 OFF ON ON OFF OFF 15 OFF ON OFF OFF OFF 16 OFF OFF OFF OFF OFF 17 OFF ON ON OFF OFF 18 OFF OFF OFF OFF OFF 19 OFF ON OFF OFF OFF 20 OFF ON ON OFF OFF 21 OFF ON ON OFF OFF 22 OFF OFF OFF OFF OFF 23 OFF OFF OFF OFF OFF 3 (Back to step 1) 1 : 7˚C : 7˚C Room temp. 42˚C (Room temp.) or (Room temp.) 2 : –2˚C : –2˚C Pipe temp. 42˚C (Pipe temp.) or (Pipe temp.) ON OFF 42˚C ON OFF 42˚C 3 : ON in the case of Power on start 12 AH-A129E AU-A129E REFRIGERATION CYCLE Indoor unit Evaporator 3 Flare coupling Flare coupling Service port Outdoor unit Flare coupling Flare coupling Compressor Capillary tube 1 Accumulator 4 Condenser 2 S Strainer Figure R-1. Refrigeration Cycle S Figure R-2. Flow of Refrigerant 13 AH-A129E AU-A129E Cycle temperature and service port pressure (ISC Cooling) NO. Condition 1 2 3 4 Service port pressure Cooling 81˚C 39˚C 13˚C 9˚C 0.53MPa Gauge pressure ISO Cooling T1 condition Cooling Indoor side Temperature (˚C) Relative humidity (%) 27 47 Dimension of Capillary tube Capillary tube O.D. ø 2.7 I.D. ø 1.6 L 700 14 Outdoor side Temperature (˚C) Relative humidity (%) 35 40 AH-A129E AU-A129E PERFORMANCE CURVES 4.5 13600 4.0 11900 (KW) 15300 3.5 3.0 8500 2.5 1500 Input(W) 10200 1000 500 15 14 Outlet air temp.(˚C) Cooling capacity (BTU/h) Indoor air temp. : 27˚C Indoor humidity : 47RH% Indoor fan speed : Hi Power source : 1ø 220V 50Hz 13 12 11 10 9 8 7 30 31 32 33 34 35 36 37 38 39 40 Outside air temp.(˚C) Figure P-1. At Cooling 15 AH-A129E AU-A129E DISASSEMBLING PROCEDURE INDOOR UNIT CAUTION: DISCONNECT THE UNIT FROM THE POWER SUPPLY BEFORE ANY SERVICING 1. Remove the 3 screw covers in the front panel. 4. Close the open panel softly, and then press B and C of it securely. Remove the front panel ass’y as to lift up. B B C 2. Remove 3 fixed screws. 5. Loose a cord clamp screw and take it out. 3. Pull the open panel at A toward you. Remove a fixed screw. A 6. Loose 3 screws on the terminal board and take out the unit-to-unit cord from it. A 16 AH-A129E AU-A129E 7. Take the thermistor holder from evaporator. 11.Loose 6 screws fixing control box and take out control ass’y. 8. Take out the thermistor from evaporator. 12.Loose 2 screws fixing drain pan ass’y. (Left side) 9. Disconnect fan motor connectors and others. 13.Loose a screw fixing drain hose. 10.Loose 2 screws for a pipe cover and take it out. Loose the earth screw. 14.When assembling, make sure that O ring is fitted to the drain hose. O-ring Drain hose O-ring (Section) 17 AH-A129E AU-A129E 15.Take out the drain pan ass’y. 19.Take out the fan bearing ass’y. 16.Loose a screw fixing cross flow fan to motor. 20.Take out the cross flow fan while slightly lifting the evaporator. 17.Slide the cross fan leftward to depart from the motor shaft and take out fan motor. 18.Loose 2 screws fixing evaporator. 18 AH-A129E AU-A129E FOR OUTDOOR UNITMODEL AU-A129E CAUTION:DISCONNECT THE UNIT FROM THE POWER SUPPLY BEFORE ANY SERVICING 1 2 Remove the three(3) screws holding the right side cover and take it out. Remove the three(3) screws holding the left side cover and take it out. 3 Remove the another screws holding the cabinet and take it out. NOTE: Number as shown in following figure is the re moval order. 2 Left side cover Condenser Compressor Bulkhead Fan motor Propeller fan Cabinet Right side cover 1 3 Fan guard Figure D-1. OUTDOOR UNIT 19 AH-A129E AU-A129E TROUBLESHOOTING OF A CONTROL CIRCUIT The machine does not function at all with remote controller and switches on the indoor unit. Using a meter, measure the voltage between anodes of D1 and D2 on the PWB ass'y 1. Is the measured value approx. 20.6 Vac ? measure the secondary voltage of transformer. NO YES Replace the PWB with a new one. Is the 2.5A fuse open circuit ? NO YES Replace the fuse and varistor with new ones. 20 Replace the transformer with a new one. AH-A129E AU-A129E The machine does not function at all with remote controller Push button "O/I" on the wireless remote controller. Is transmitting indicator of the remote controller active ? NO Are batteries of the wireless remote controller good ? YES Does beep sound from the indoor unit ? NO Replace the batteries with new ones. YES Replace the wireless remote controller. YES NO Does connector CN103 connect in place ? Is indicator lamp of indoor unit proper ? NO YES PWB is normal. Inspect the outdoor unit. NO YES Using a tester, measure the voltage between terminals of resistor R30 on the PWB ass'y. Connect the connector properly. Replace the PWB with a new one. When the signal is received, does the voltage change ? YES Push the button "O/I". Replace the PWB with a new one. 21 NO Replace the display unit with a new one. AH-A129E AU-A129E CHARACTERISTIC OF TH1 & TH2 K 180 The room is not cooled. The compressor does not operate. 160 140 120 Push the button "TEST" on the indoor unit, and wait 3 minutes. 100 80 10˚C 30K 60 Using a meter, measure voltage at the terminals on the terminal board. 40 20 0 -10 Is there a voltage between terminal "N" and "1" of the terminal board the power supply voltage ? 0 10 20 Fig. 1 30 40˚C NO Replace the PWB ass'y with a new one. YES Measure resistances of TH1 and TH2. Are the resistances correct Fig. 1 ? NO Replace the thermistor ass'y with a new one. YES The control circuit is normal. The compressor may be defective. The running capacitor may be defective. Refrigerant may have leaked. The outdoor fan motor may be defective. The outdoor fan motor capacitor may be defective. 22 AH-A129E AU-A129E REPLACEMENT PARTS LIST [AH-A129E] REF. NO. PART NO. DESCRIPTION Q'TY CODE CABINET AND UNIT PARTS 1- 1 1- 2 1- 3 1- 4 1- 5 1- 6 1- 7 1- 8 1- 9 1-10 1-11 1-12 1-13 1-14 1-15 1-16 1-17 1-18 1-19 1-20 1-21 1-22 1-23 1-24 1-25 1-26 1-27 1-28 1-29 1-30 1-31 1-32 1-33 1-34 1-35 1-36 1-37 1-38 1-39 1-40 1-41 1-42 1-43 1-44 1-45 1-46 1-47 1-48 CMOT-A271JBK0 NFANCA041JBE0 CSRA-A445JBK0 MJNTPA035JBFF MLOV-A115JBFE MLOV-A116JBFF MLOV-A171JBFE PHOS-A015JBE0 PPACGA002JBE0 LHLD-A279JBF0 GGAD-A042JBEA LHLD-A092JBFZ RMOT-A073JBE0 CHLD-A067JBK0 PFPFPB038JBE0 LHLDW0365JBE0 PGUMMA056JBE0 PGUMMA082JBE0 DCHS-A356JBK0 DWAK-A780JBK0 PFILMA065JBEF HDEC-B021JBEA GCOVAA006JBFE HBDG-A059JBEA HPNL-A119JBTB MARMPA006JBFA MARMPA007JBFA GWAK-A178JBFC LHLD-A194JBF0 MARMPA008JBFA MARMPA009JBFA PGUMSA113JBE0 PCOV-A207JBE0 PFPFPA905JBE0 PFPFPA774JBE0 PGUMSA135JBE0 CPNL-A307JBK0 PCUS-A026JBE0 LHLD-A278JBE0 LHLD-A181JBFA LHLD-A161JBF0 QW-VZC636JBE0 PSEL-B778JBE0 PSEL-B779JBE0 PSEL-B780JBE0 PSEL-B863JBE0 TSPC-C986JBRA TLABCB257JBR0 Fan motorr sub ass’y Cross flow fan Drain pan ass’y Louver link Horizontal adjustment louver A Horizontal adjustment louver B Horizontal louver Drain hose O ring Shaft holder Wire guard Louver holder Louver motor Bearing ass’y Seal Wire holder Motor cushion Motor cushion Cabinet ass’y Panel ass’y Air filter Decoration panel Front panel cover Badge Open panel Open arm L Open arm R Front panel Panel center holder Arm L Arm R Damper rubber Drain cover Panel insulator A Cabinet insulator Damper rubber Open panel ass’y Cushion 12 Guard holder Pipe holder Pipe holder Fan motor lead Aluminum tape Aluminum tape Aluminum tape Aluminum tape Name label Wiring diagram 2- 1 2- 2 2- 3 2- 4 2- 5 2- 6 2- 7 2- 8 2- 9 2-10 2-11 2-12 2-13 2-14 2-15 2-16 2-17 2-18 2-19 2-20 2-21 2-22 2-23 DSGY-A878JBK0 DPWBFA047JBK0 QACC-A194JBE0 QTAN-A127JBE0 QTAN-A088JBE0 DPWBFA154JBK0 PSEL-B777JBE0 RTRN-A182JBE0 RC-HZA286JBE0 RTHM-A296JBE0 LHLD-A095JBF0 PBOX-A133JBF0 HPNLCA564JBF0 HPNLCA565JBEA LHLD-A141JBFA PSEL-B859JBE0 PSHE-A072JBE0 PSHE-A095JBE0 LHLD-A224JBFE RH-IXA519JBE0 RH-IZA149JBE0 RIC--A022BDE0 RIC--A025BDE0 Display unit Switch board unit Power supply cord Terminal board(3p) Terminal board(3p) COntrol board unit Aluminun tape Transformer Fan motor capacitor Thermistor Thermistor holder Control box Control cover Operation panel Cord holder Aluminun tape Protect paper Protect sheet Cord clamp Microcomputer(IC1) Integrated circuit(IC2) TIntegrated circuit(IC3) Integrated circuit(IC4) 1 1 1 3 9 3 1 1 1 1 1 2 1 1 1 1 1 1 1 1 2 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 1 1 4 1 1 1 1 1 1 1 1 1 BN BG BN AE AB AD AN AL AA AC AN AC AU AL AB AA AN AD BD AZ AN AL AD AF AX AC AC AX AC AC AC AE AC AA AC AB AY AC AD AC AD AG AC AB AD AC AD AD 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 AS AP AU AN AP BN AC AY AY AN AC AG AG AG AC AC AB AB AG AX AE AE AE CONTROL BOX PARTS 23 AH-A129E AU-A129E REF. NO. PART NO. DESCRIPTION 2-24 2-25 2-26 2-27 2-28 2-29 2-30 2-31 RH-IZA140JBE0 RH-IZA337DRE0 VHRS201D01/-6 RRLYJA032JBE0 RFIL-A042JBE0 RH-VZA025JBE0 RC-QZA096JBE0 QFS-AA050JBE0 Integrated circuit(IC5) Integrated circuit(IC6) Solid state relay(SSR) Relay Coil(L) Varistor(NR) Capacitor(C1) Fuse 3- 1 3- 2 CPIPCA402JBK0 PEVA-A248JBE0 Pipe assembly Evaporator 4- 1 4- 2 4- 3 4- 4 4- 5 4- 6 4- 7 4- 8 4- 9 4-10 LX-NZ0247JBE0 CRMC-A490JBE0 TINS-A565JBR0 TINSEA221JBR0 PPLTNA020JBW0 FCOV-A013JBFA XTTSD45P30000 LX-BZA106JBE0 TLABPA175JBR0 TINS-A566JBR0 Special nut Wireless remote controller Installation manual Operation manual Mounting angle Screw cover Tapping screw Special screw Louver label Installation manual 6- 1 6- 2 6- 3 LX-BZA075JBE0 XREUW50-06000 XZPSD40P14000 Special screw Ring Special tap screw Q'TY CODE 1 1 1 1 1 1 1 1 AE AK AK AU AM AD AE AD 1 1 BB BT 7 1 1 1 1 3 6 1 1 1 AB BG AF AR AP AB AA AD AB AD 1 2 4 AA AB AA CYCLE PARTS ACCESSORY PARTS SCREWS AND NUTS HOW TO ORDER REPLACEMENT PARTS To have your order filled prompty and correctly, please furnish the following information. 1. MODEL NUMBER 3. PART NO. 2. REF. NO. 4. DESCRIPTION 24 AH-A129E AU-A129E 1 2 3 4 5 6 INDOOR UNIT A A 1-35 4-2 4-5 4-4 B 1-40 4-7 4-8 4-1 B 1-41 4-3 4-10 1-15 2-13 2-2 2-17 2-12 2-10 3-2 C 1-19 2-7 2-14 C 3-1 2-18 2-9 2-7 2-11 2-10 1-38 1-32 2-8 6-1 1-46 2-15 2-16 D 1-39 1-33 1-36 D 2-4 1-11 2-1 1-3 2-3 2-5 2-19 1-10 1-16 1-14 1-5 1-6 1-2 E E 4-9 1-12 1-42 1-4 1-7 1-8 1-12 1-1 1-18 1-17 1-9 1-30 1-23 1-21 F 1-13 1-43 F 6-3 1-31 1-26 1-29 1-25 1-48 G G 6-2 1-45 1-28 1-20 1-27 1-44 1-34 1-24 1-37 1-47 4-6 1-22 H H 1 2 3 4 25 5 6 AH-A129E AU-A129E REPLACEMENT PARTS LIST [AU-A129E] REF. NO. PART NO. DESCRIPTION Q'TY CODE 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 1 1 1 BQ AW AP AX AR AH AR BA AY AK AZ AE AC BH AK AK AK AK AE 1 1 1 1 1 1 1 1 1 AD AC AP BC AX AF AC AF AR 1 1 1 1 1 1 1 1 1 1 1 1 3 3 1 1 1 1 1 1 1 CH CA BB AE AG AB BF AH AD AD AP AG AK AB AH AD AD AE AC AE AD 4 1 1 2 4 2 1 AB AA AB AA AA AB AD CABINET AND UNIT PARTS 1- 1 1- 2 1- 3 1- 4 1- 5 1- 6 1- 7 1- 8 1- 9 1-10 1-11 1-12 1-13 1-14 1-15 1-16 1-17 1-18 1-19 CMOTLA593JBE0 NFANPA020JBEA PANGKA018JBP0 PSKR-0106JBP0 GPLTPA014JBFA GFTA-A387JBF0 GBOX-A007JBFA GCAB-A105JBTA GGADFA030JBTA PSEL-A346JBE0 PSPF-A696JBE0 TSPC-C984JBR0 TLABBA029JBRA CCHS-A661JBTA PSPF-A277JBE0 PSEL-A347JBE0 PSEL-A344JBE0 PSEL-A345JBE0 LBSHCA022JBE0 Fan motor Propeller fan Motor stay angle Bulkhead Left side cover Terminal cover Right side cover Cabinet Fan guard Bulkhead seal Compressor cover Name label Sharp badge Base pan ass'y Angle seal Angle seal Condenser seal Cabinet seal Bushing CONTROL BOX PARTS 222222222- 1 2 3 4 5 6 7 8 9 TLABCB257JBR0 TLABPA182JBE0 QW-VZD440JBF0 RC-HZA389JBE0 RC-HZA154JBE0 QTAN-A153JBE0 LHLD-0227JBM0 PCOV-A455JBP0 PCOV-A471JBP0 Wiring diagram Badge Comp. wire ass'y Runnning capacitor Fan motor capacitor Terminal board Cord holder Capacitor cover Terminal cover 3- 1 3- 2 3- 3 3- 4 3- 5 3- 6 3- 7 3- 8 3- 9 3-10 3-11 3-12 3-13 3-14 3-15 3-16 3-17 3-18 3-19 3-20 3-21 PCMPRA290JBE0 PCON-A410JBP0 DVLV-A189JBK0 LX-NZ0133JBE0 LX-NZA081JBE0 PCAP-A006JBF0 DVLV-A286JBK0 LX-NZ0255JBE0 LX-NZA034JBE0 PCAP-0045JBE0 DCPY-A185JBK0 LX-NZA037JBE0 GLEG-A085JBE0 LX-NZA048JBE0 PCOV-A378JBE0 LX-NZA152JBE0 PSEL-B172JBE0 PSEL-B722JBE0 PGUMSA205JBE0 PSEL-B765JBE0 PSEL-B770JBE0 Compressor Condenser 2-way valve unit Flare nut Bonnet Nut bonnet 3-way valve unit Flare nut Service nut Nut bonnet Capillary tube ass'y Valve cap Compressor cushion Special nut Terminal cover Special nut Terminal gasket Rubber washer Damper rubber Insulator Insulator CYCLE PARTS SCREWS AND NUTS 6666666- 1 2 3 4 5 6 7 LX-BZA078JBE0 LX-BZA075JBE0 LX-NZA030JBE0 LX-CZA038WRE0 LX-BZA076JBE0 XTTUW40P16000 LX-WZA019JBE0 Special Special Special Special Special Tapping Washer screw screw nut screw screw screw HOW TO ORDER REPLACEMENT PARTS To have your order filled prompty and correctly, please furnish the following information. 1. MODEL NUMBER 3. PART NO. 2. REF. NO. 4. DESCRIPTION 26 AH-A129E AU-A129E 1 2 3 4 5 6 OUTDOOR UNIT A A 1-5 3-2 1-14 1-17 B B 3-16 3-18 3-15 3-17 3-11 6-2 C C 3-19 3-20 1-19 1-16 1-10 1-15 1-3 D 3-14 3-10 3-7 3-9 3-1 1-4 6-1 6-1 3-5 D 6-1 3-12 1-11 3-21 6-7 6-1 3-8 3-13 1-16 1-2 3-3 3-4 3-6 1-1 E E 6-3 1-8 1-7 2-8 F 6-4 6-5 2-4 2-5 2-1 2-9 2-6 1-21 2-7 G 1-9 1-13 F 6-4 6-6 G 1-6 6-6 1-12 2-2 H H 1 2 3 4 27 5 6 AH-A129E AU-A129E 28 '99 SHARP CORP. (2U0.85E) Printed in Netherlands