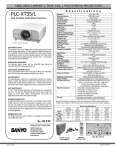

Download SERVICE MANUAL PLC

Transcript