Download 2004 LEGACY SERVICE MANUAL QUICK REFERENCE INDEX

Transcript

2004 LEGACY SERVICE MANUAL

QUICK REFERENCE INDEX

TRANSMISSION SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reassembling, inspection and adjustment of

components and diagnostics for guidance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

CONTROL SYSTEMS

CS

AUTOMATIC TRANSMISSION

4AT

AUTOMATIC TRANSMISSION

(DIAGNOSTICS)

4AT(diag)

AUTOMATIC TRANSMISSION

5AT

AUTOMATIC TRANSMISSION

(DIAGNOSTICS)

5AT(diag)

MANUAL TRANSMISSION AND

DIFFERENTIAL

5MT

CLUTCH SYSTEM

CL

All information, illustration and specifications contained in this manual are

based on the latest product information

available at the time of publication

approval.

FUJI HEAVY INDUSTRIES LTD.

G2320GE5

AUTOMATIC TRANSMISSION

(DIAGNOSTICS)

5AT(diag)

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

Page

Basic Diagnostics Procedure ......................................................................2

Check List for Interview...............................................................................4

General Description ....................................................................................5

Electrical Component Location ...................................................................7

Transmission Control Module (TCM) I/O Signal .......................................12

Subaru Select Monitor...............................................................................16

Read Diagnostic Trouble Code (DTC) ......................................................19

Inspection Mode........................................................................................20

Clear Memory Mode..................................................................................21

Learning Control........................................................................................22

SPORT Indicator Light Display .................................................................23

Diagnostic Procedure for Select Monitor Communication.........................26

List of Diagnostic Trouble Code (DTC) .....................................................30

Diagnostic Procedure with Diagnostic Trouble Code (DTC) .....................34

Diagnostic Procedure without Diagnostic Trouble Code (DTC) ..............138

General Diagnostic Table........................................................................147

Basic Diagnostics Procedure

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

1. Basic Diagnostics Procedure

A: PROCEDURE

1

2

3

4

5

Step

CHECK PRE-INSPECTION.

1) Ask the customer when and how the trouble occurred using the interview checklist.

<Ref. to 5AT(diag)-4, Check List for Interview.>

2) Before performing diagnosis, inspect the

following items which might influence the AT

problems.

• General inspection <Ref. to 5AT(diag)-5,

INSPECTION, General Description.>

• Oil Leakage

• Stall speed test <Ref. to 5AT-31, Stall Test.>

• Line Pressure Test <Ref. to 5AT-34, Line

Pressure Test.>

• Transfer Clutch Pressure Test <Ref. to 5AT36, Transfer Clutch Pressure Test.>

• Time Lag Test <Ref. to 5AT-33, Time Lag

Test.>

• Road Test <Ref. to 5AT-30, Road Test.>

• Inhibitor Switch <Ref. to 5AT-51, Inhibitor

Switch.>

CHECK SPORT INDICATOR LIGHT.

After the ignition switch is turned to “ON”, wait

for at least 2 seconds.

CHECK SPORT INDICATOR LIGHT.

1) Turn the ignition switch to OFF.

2) Check the SPORT indicator light. <Ref. to

5AT(diag)-24, INSPECTION, SPORT Indicator

Light Display.>

3) After the ignition switch is turned to ON,

wait for at least 2 seconds.

CHECK DTC.

Read the DTC. <Ref. to 5AT(diag)-19, OPERATION, Read Diagnostic Trouble Code (DTC).>

Check

Yes

Is the unit that might influence Go to step 2.

the AT problem normal?

No

Repair or replace

each item.

Does the SPORT indicator

light illuminate?

Go to step 4.

Go to step 3.

Does the SPORT indicator

light blink?

Go to step 4.

Go to step 5.

Is DTC displayed?

Go to step 6.

Go to step 5.

NOTE:

If the communication function of the Subaru Select Monitor cannot be executed normally,

check the communication circuit. <Ref. to

5AT(diag)-26, COMMUNICATION FOR INITIALIZING IMPOSSIBLE, Diagnostic Procedure for Select Monitor Communication.>

PERFORM THE GENERAL DIAGNOSTICS. Is DTC displayed?

1) Inspect using “Diagnostic Procedure without Diagnostic Trouble Code (DTC)”. <Ref. to

5AT(diag)-138, Diagnostic Procedure without

Diagnostic Trouble Code (DTC).>

2) Perform clear memory mode.

3) Perform the inspection mode. <Ref. to

5AT(diag)-20, Inspection Mode.>

4) Display DTC.

5AT(diag)-2

NOTE:

Record all DTC.

Go to step 6.

Inspect using

“General Diagnostic Table”. <Ref. to

5AT(diag)-147,

General Diagnostic Table.>

Basic Diagnostics Procedure

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

6

Step

Check

PERFORM THE DIAGNOSIS.

Is DTC displayed?

1) Inspect using the “Diagnostic Procedure

with Diagnostic Trouble Code (DTC)”. <Ref. to

5AT(diag)-34, Diagnostic Procedure with Diagnostic Trouble Code (DTC).>

NOTE:

For DTC table, refer to “List of Diagnostic Trouble Code (DTC)”. <Ref. to 5AT(diag)-30, List of

Diagnostic Trouble Code (DTC).>

2) Repair the trouble cause.

3) Perform clear memory mode.

4) Perform the inspection mode. <Ref. to

5AT(diag)-20, Inspection Mode.>

5) Display DTC.

5AT(diag)-3

Yes

Inspect using the

“Diagnostic Procedure with Diagnostic Trouble Code

(DTC)”. <Ref. to

5AT(diag)-34,

Diagnostic Procedure with Diagnostic Trouble Code

(DTC).>

No

Inspect using

“General Diagnostic Table”. <Ref. to

5AT(diag)-147,

General Diagnostic Table.>

Check List for Interview

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

2. Check List for Interview

A: INSPECTION

Check the following items when problem has occurred.

NOTE:

Use copies of this page for interviewing customers.

Customer’s name

Date of sale

Date of repair

Trans. model

Odometer reading

Symptom

Frequency

Weather

Place

Ambient air temperature

Vehicle speed

AT warning light (SPORT indicator

light)

Select lever position

Driving condition

Manual mode

TRANSMISSION

V.I.N.

km (miles)

❏ No up-shift

❏ No down-shift

❏ No kick down

❏ Vehicle does not move (❏ Any position ❏ Particular position)

❏ Lock-up malfunction

❏ Noise or vibration

❏ Shift shock or slip

❏ Select lever does not move

❏ Others

(

)

❏ Continuous ❏ Intermittent (

times a day)

❏ Fine ❏ Cloudy ❏ Rainy ❏ Snowy

❏ Others

(

)

❏ Highland ❏ Suburbs ❏ Inner city ❏ Uphill ❏ Rough road

❏ Others

(

)

❏ Hot ❏ Warm ❏ Cool ❏ Cold

km/h (MPH)

❏ Blinks continuously

❏P ❏R ❏N ❏D

❏ Not affected

❏ At racing

❏ When decelerating

❏ ON ❏ OFF

❏ Not blink

❏ Manual mode

❏ At starting

❏ While idling

❏ When accelerating

❏ While cruising

❏ While turning (❏ RH / ❏ LH)

5AT(diag)-4

General Description

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

3. ATF LEVEL

A: CAUTION

Make sure that ATF level is in the specification.

<Ref. to 5AT-27, INSPECTION, Automatic Transmission Fluid.>

CAUTION:

• All airbag system wiring harnesses and connectors are colored yellow. Do not use an electric test equipment on these circuits.

• Be careful not to damage the airbag system

wiring harness when performing diagnostics

and servicing the TCM.

• Measurement

When measuring the voltage and resistance of the

ECM, TCM or each sensor, use a tapered pin with

a diameter of less than 0.64 mm (0.025 in) in order

to avoid poor contact. Do not insert a pin more than

0.65 mm (0.026 in) diameter.

(A)

(C)

F

(D)

(E)

Measure battery voltage and specific gravity of

electrolyte.

Standard voltage: 12 V or more

(B)

(C)

(D)

AT-01450

(A)

(B)

(C)

(D)

(E)

B: INSPECTION

1. BATTERY

COLD

L

• Supplemental Restraint System

The airbag system wiring harness is routed near

the TCM.

L

F

HOT

3. General Description

Level gauge

Check position when “HOT”

Upper level

Lower level

Check position when “COLD”

4. FRONT DIFFERENTIAL OIL LEVEL

Make sure the front differential oil level is in the

specification. <Ref. to 5AT-29, INSPECTION, Differential Gear Oil.>

Specific gravity: More than 1.260

2. TRANSMISSION GROUND

L

F

Make sure that the ground terminal bolt is tightened

securely.

• Chassis side

(A)

(B)

Tightening torque:

13 N⋅m (1.3 kgf-m, 9.4 ft-lb)

AT-00317

(A) Upper level

(B) Lower level

5. OPERATION OF SHIFT SELECT LEVER

Make sure there is no abnormal noise, dragging or

contact pattern in each select lever range.

AT-01464

WARNING:

Stop the engine while checking operation of the

select lever.

5AT(diag)-5

General Description

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

• LHD model

• RHD model

AT-01465

AT-02048

C: PREPARATION TOOL

1. SPECIAL TOOL

ILLUSTRATION

TOOL NUMBER

24082AA230

DESCRIPTION

CARTRIDGE

REMARKS

Troubleshooting for electrical system.

22771AA030

SUBARU SELECT

MONITOR KIT

Troubleshooting for electrical system.

• English: 22771AA030 (Without printer)

• German: 22771AA070 (Without printer)

• French: 22771AA080 (Without printer)

• Spanish: 22771AA090 (Without printer)

ST24082AA230

ST22771AA030

2. GENERAL TOOL

TOOL NAME

Circuit tester

Oscilloscope

REMARKS

Used for measuring resistance, voltage and current.

Used for measuring sensor.

5AT(diag)-6

Electrical Component Location

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

4. Electrical Component Location

A: LOCATION

1. CONTROL MODULE

• LHD model

(1)

(3)

(4) (2)

(5)

AT-02049

(1)

(2)

Engine control module (ECM)

SPORT indicator light (AT warning

light)

(3)

Transmission control module

(TCM)

(4)

(5)

Data link connector

Body integrated unit

• RHD model

(3)

(2) (4)

(5)

(1)

AT-01467

(1)

(2)

Engine control module (ECM)

SPORT indicator light (AT warning

light)

(3)

Transmission control module

(TCM)

5AT(diag)-7

(4)

(5)

Data link connector

Body integrated unit

Electrical Component Location

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

• LHD model

(1)

(2)

AT-01470

AT-02051

(4)

(3)

AT-02053

AT-02052

(5)

AT-02054

• RHD model

(1)

(2)

AT-01468

5AT(diag)-8

AT-01470

Electrical Component Location

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

(4)

(3)

AT-01469

AT-01471

(5)

AT-01472

2. SENSOR

• LHD model

(3)

(5),(8)

(1) (2)

(6),(9)

(7)

(4)

AT-02050

5AT(diag)-9

Electrical Component Location

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

• RHD model

(1)

(3)

(5),(8)

(6),(9)

(2)

(7)

(4)

AT-01443

(1)

(2)

(3)

Accelerator position sensor

Front vehicle speed sensor

Inhibitor switch

(4)

(5)

(6)

Rear vehicle speed sensor

Turbine speed sensor 1

ATF temperature sensor 1

(7)

(8)

(9)

Lateral G sensor

Turbine speed sensor 2

ATF temperature sensor 2

(2)

(1)

AT-00375

AT-01447

(5)

(4)

(3)

AT-01445

5AT(diag)-10

AT-01448

Electrical Component Location

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

(7)

(6)

AT-01446

AT-01475

(9)

(8)

AT-01759

AT-01760

3. SOLENOID

(3)

(2)

(4)

(7)

(8)

(6)

(5)

(1)

(9)

AT-01449

(1)

(2)

(3)

High & low reverse clutch solenoid

Direct clutch solenoid

Front brake solenoid

(4)

(5)

(6)

Input clutch solenoid

Line pressure solenoid

Lock up solenoid

5AT(diag)-11

(7)

(8)

(9)

Transfer solenoid

Low coast brake solenoid

Memory box

Transmission Control Module (TCM) I/O Signal

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

5. Transmission Control Module (TCM) I/O Signal

A: ELECTRICAL SPECIFICATION

B55

B54

1 2 3 4

10 11 12 13

19 20 21

5 6

14 15

7

16

22

1 2 3 4

10 11 12 13

19 20 21

8 9

17 18

23 24

5 6 7

14 15 16

22

8

17

23

9

18

24

AT-01451

NOTE:

The measurement should perform after warming up.

Item

P/L solenoid output

PVIGN power supply

I/C oil pressure switch

input

Power GND

CAN communication line

(+)

CAN communication line

(−)

ATF temperature sensor

1 input

Connector

No.

B54

Termin

al

No.

9

Measuring conditions

Engine ON, “P” range,

Accelerator OFF, Brake

ON

Manual mode 1st, Accelerator OFF, Brake ON

8

Ignition switch ON

7

Ignition switch ON

B54

Approx. 4.0 —

6.0 V

Approx. 2.0 —

4.0 V

Power supply

voltage

Power supply

voltage

5

B54

4

—

—

—

B54

3

—

—

—

2

Ignition switch ON

5AT(diag)-12

2.5 — 2.9 V

(ATF temperature 20°C

(68°F))

0.8 — 1.0 V

(ATF temperature 80°C

(176°F))

Driving frequency 750 —

850 Hz

—

B54

Approx. 0 V

Remarks

—

6

Always

—

3 — 9 Ω (ATF

temperature

20°C (68°F))

B54

B54

—

Voltage (V)

Measure the

resistance

between terminal and chassis

ground.

—

—

4.0 — 5.0 kΩ

(ATF temperature 20°C

(68°F))

0.7 — 0.9 kΩ

(ATF temperature 80°C

(176°F))

The condition

of I/C oil pressure switch

cannot read by

the tester.

Transmission Control Module (TCM) I/O Signal

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

Item

Battery power supply

I/C solenoid output

H&LR/C solenoid output

Connector

No.

Termin

al

No.

B54

1

B54

B54

Control valve power supply output

B54

LC/B solenoid output

B54

Power GND

Analog GND (Sensor

GND)

LC/B oil pressure switch

input

18

17

16

Measuring conditions

Always

While driving at 1st — 3rd

of manual mode

While driving at 4th or 5th

of manual mode

While driving at 2nd of

manual mode

While driving at 3rd — 5th

of manual mode

Ignition switch ON

B54

14

Ignition switch OFF

While driving at 1st — 2nd

of manual mode

While driving at 3rd — 5th

of manual mode

Always

B54

13

Always

B54

15

12

—

Voltage (V)

Power supply

voltage

Approx. 5.5 —

7.5 V

Approx. 0 V

Approx. 5.5 —

7.5 V

Approx. 0 V

Power supply

voltage

Approx. 0 V

Power supply

voltage

Approx. 0 V

11

Ignition switch ON

PVIGN power supply

relay output

B54

10

Ignition switch ON

0 — 1.5 V

24

While driving at other than

4th of manual mode

While driving at 4th of

manual mode

Approx. 4.5 —

6.5 V

D/C solenoid output

B54

B54

23

22

When lock-up

When not lock-up

While driving at 1st or 5th

of manual mode

While driving at 2nd — 4th

of manual mode

3 — 9 Ω (ATF

temperature

20°C (68°F))

Driving frequency 750 —

850 Hz

—

5 — 17 Ω (ATF

temperature

25°C (77°F))

—

B54

L/U solenoid output

Driving frequency 750 —

850 Hz

Approx. 0 V

ATF temperature sensor

2 input

B54

3 — 9 Ω (ATF

temperature

20°C (68°F))

—

—

Approx. 0 V

Approx. 3.5 —

5.5 V

Approx. 0 V

Approx. 5.5 —

7.5 V

Approx. 0 V

—

The condition

of LC/B oil

pressure switch

cannot read by

the tester.

3.0 — 3.6 kΩ

(ATF temperature 20°C

(68°F))

0.4 — 0.6 kΩ

(ATF temperature 80°C

(176°F))

—

3 — 9 Ω (ATF

temperature

20°C (68°F))

Driving frequency 750 —

850 Hz

3 — 9 Ω (ATF

temperature

20°C (68°F))

Driving frequency 750 —

850 Hz

3 — 9 Ω (ATF

temperature

20°C (68°F))

Driving frequency 750 —

850 Hz

D/C oil pressure switch

input

B54

21

—

—

—

Subaru Select Monitor

communication line

B54

20

—

—

—

5AT(diag)-13

Remarks

—

Approx. 0 V

2.3 — 2.7 V

(ATF temperature 20°C

(68°F))

0.6 — 0.8 V

(ATF temperature 80°C

(176°F))

Fr/B solenoid output

Measure the

resistance

between terminal and chassis

ground.

The condition

of D/C oil pressure switch

cannot read by

the tester.

Transmission Control Module (TCM) I/O Signal

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

Connector

No.

Termin

al

No.

Control GND

B54

19

H&LR/C oil pressure

switch input

B55

8

Item

Front vehicle speed sensor input

Lateral G sensor power

supply

Lateral G sensor signal

input

Inhibitor switch 1 input

Inhibitor switch 2 input

Accessory power supply

B55

7

B55

6

B55

5

B55

4

B55

B55

3

2

Measuring conditions

Always

While driving at 2nd of

manual mode

While driving at 3rd — 5th

of manual mode

While driving at 2nd and

20 km/h (12 MPH) of manual mode

While driving at 4th and 80

km/h (50 MPH) of manual

mode

Approx. 0 V

Power supply

voltage

Ignition switch ON

4.75 — 5.25 V

—

2.0 — 3.0 V

—

Ignition switch ON, Engine

ON, Flat value

Ignition switch ON, “P”

range

Ignition switch ON, “N”

range

Ignition switch ON, “P”

range

Ignition switch ON, “D”

range

Accessory switch ON

Accessory switch OFF

Ignition power supply

B55

Rear vehicle speed sensor input

B55

Fr/B oil pressure switch

input

B55

Turbine speed sensor 1

input

B55

1

18

17

16

Voltage (V)

Measure the

resistance

between terminal and chassis

ground.

—

Ignition switch ON

Ignition switch OFF

While driving at 2nd and

20 km/h (12 MPH) of manual mode

While driving at 4th and 80

km/h (50 MPH) of manual

mode

Ignition switch ON, Engine

ON, While driving at other

than 4th

Ignition switch ON, Engine

ON, While driving at 4th

2nd of manual mode, Turbine speed sensor is

2,000 rpm (Read from

Subaru Select Monitor)

4th of manual mode, Turbine speed sensor is

2,000 rpm (Read from

Subaru Select Monitor)

5AT(diag)-14

Remarks

—

Approx. 0 V

Approx. 140 —

170 Hz

—

Approx. 560 —

680 Hz

4.0 — 5.0 V

—

1.5 V or less

4.0 — 5.0 V

—

1.5 V or less

Power supply

voltage

Approx. 0 V

Power supply

voltage

Approx. 0 V

—

—

Approx. 190 —

230 Hz

—

Approx. 760 —

920 Hz

Approx. 0 V

—

Power supply

voltage

Use an oscilloscope.

Approx. 0 Hz

—

Approx. 1,900

— 2,100 Hz

Use an oscilloscope.

Transmission Control Module (TCM) I/O Signal

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

Item

Range lock solenoid output

Inhibitor switch 3 input

Inhibitor switch 4 input

Control valve communication line

Connector

No.

Termin

al

No.

Ignition switch ON, While

stopping at “D” range

B55

B55

B55

B55

15

14

13

12

Back-up light relay output

B55

11

Ignition power supply

B55

10

AWD solenoid output

Turbine speed sensor 2

input

B55

B55

23

22

Control GND

B55

21

Inhibitor switch 3 open

circuit monitor input

B55

20

PN signal output

Measuring conditions

B55

19

Ignition switch ON, Vehicle

speed at least 20 km/h (12

MPH)

Ignition switch ON, “R”

range

Ignition switch ON, “D”

range

Ignition switch ON, “P”

range

Ignition switch ON, “D”

range

Voltage (V)

About Power

Supply Voltage

− 1.2 V

Ignition switch ON

Ignition switch OFF

Engine ON, “P” range or

“N” range, Accelerator

OFF

Engine ON, “D” range,

Accelerator OFF, Brake

ON

2nd of manual mode, Turbine speed sensor is

2,000 rpm (Read from

Subaru Select Monitor)

4th of manual mode, Turbine speed sensor is

2,000 rpm (Read from

Subaru Select Monitor)

Always

Ignition switch ON, “D”

range

Ignition switch ON, “R”

range

Ignition switch ON, Other

than “P” range or “N”

range

Ignition switch ON, “P”

range or “N” range

5AT(diag)-15

Remarks

7 — 21 Ω

Approx. 0 V

4.0 — 5.0 V

—

1.5 V or less

4.0 — 5.0 V

—

1.5 V or less

—

Ignition switch ON, “R”

range

Ignition switch ON, Other

than “R” range

Measure the

resistance

between terminal and chassis

ground.

—

1.5 V

Power supply

voltage

Power supply

voltage

Approx. 0 V

Approx. 0 V

Approx. 2.0 —

3.0 V

—

Approx. 90 —

110 Ω (ATF temperature 25°C

(77°F))

—

3 — 9 Ω (ATF

temperature

20°C (68°F))

Approx. 1,300

— 1,500 Hz

Driving frequency 750 —

850 Hz

Use an oscilloscope.

Approx. 1,900

— 2,100 Hz

—

Approx. 0 V

—

Use an oscilloscope.

4.0 — 5.0 V

—

Less than 1.5 V

Power supply

voltage

—

0 — 1.0 V

—

ECM should

connected correctly

Subaru Select Monitor

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

6. Subaru Select Monitor

A: OPERATION

1. READ DIAGNOSTIC TROUBLE CODE

(DTC)

NOTE:

Do not connect scan tools except for Subaru Select

Monitor.

5) Turn ignition switch to ON (engine OFF) and turn

on the Subaru Select Monitor.

1) Prepare the Subaru Select Monitor kit.

(A)

AT-00341

AT-00338

2) Connect the diagnosis cable to Subaru Select

Monitor.

3) Insert the cartridge to Subaru Select Monitor.

<Ref. to 5AT(diag)-6, PREPARATION TOOL, General Description.>

AT-00339

4) Connect the Subaru Select Monitor to data link

connector.

(1) Data link connector is located in the lower

portion of the instrument panel (on the driver’s

side).

(1)

AT-01712

(1) Data link connector

(2) Connect the diagnosis cable to data link

connector.

(A) Power switch

6) On the «Main Menu» display screen, select the

{Each System Check} and press the [YES] key.

7) On the «System Selection Menu» display

screen, select the {Transmission} and press the

[YES] key.

8) Press the [YES] key after the information of

transmission type is displayed.

9) On the «Transmission Diagnosis» display

screen, select the {Diagnosis Code(s) Display} and

press [YES] key.

NOTE:

• For details concerning operation procedure, refer to the “SUBARU SELECT MONITOR OPERATION MANUAL”.

• For details concerning DTCs, refer to the List of

Diagnostic Trouble Code (DTC). <Ref. to 5AT(diag)-30, List of Diagnostic Trouble Code (DTC).>

2. READ CURRENT DATA

1) On the «Main Menu» display screen, select the

{Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display

screen, select the {Transmission} and press the

[YES] key.

3) Press the [YES] key after the information of

transmission type is displayed.

4) On the «Transmission Diagnosis» display

screen, select the {Current Data Display & Save}

and press the [YES] key.

5) On the «Transmission Diagnosis» display

screen, select the {Data Display} and press the

[YES] key.

6) Using the scroll key, scroll the display screen up

or down until the desired data is shown.

5AT(diag)-16

Subaru Select Monitor

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

• A list of the support data is shown in the following table.

Item

Engine speed signal

Battery voltage

Accelerator Position Sensor

Front vehicle speed sensor signal

Gear position

Turbine speed sensor signal

Rear vehicle speed sensor signal

Lateral G sensor

ATF Temperature Sensor 1 Signal

ATF Temperature Sensor 2 Signal

Turbine speed sensor 1 signal

Turbine speed sensor 2 signal

High & Low Reverse Clutch Solenoid Indicator Current

Direct Clutch Solenoid Indicator Current

Front Brake Solenoid Indicator Current

Input Clutch Solenoid Indicator Current

Line Pressure Solenoid Indicator Current

Lock-up Solenoid Indicator Current

Transfer Solenoid Indicator Current

High & Low Reverse Clutch Solenoid Target Oil Pressure

Direct Clutch Solenoid Target Oil Pressure

Front Brake Solenoid Target Oil Pressure

Input Clutch Solenoid Target Oil Pressure

Line Pressure Solenoid Target Oil Pressure

Lock-up Solenoid Target Oil Pressure

Transfer Solenoid Target Oil Pressure

Ignition switch

Tip signal

Cruise control On signal

Tip Down Shift Signal

Stop light switch signal

Tip Up Shift Signal

Drive range signal

Reverse range signal

Diagnosis Light Output Signal

Shift lock solenoid signal

Parking range signal

P/N Range Output Signal

Neutral range signal

Inhibitor Switch 1 Input Signal

Inhibitor Switch 2 Input Signal

Inhibitor Switch 3 Input Signal

Inhibitor Switch 4 Input Signal

Inhibitor Switch 3 Monitor Input Signal

Backup light relay output signal

High & Low Reverse Clutch Oil Pressure Switch Input Signal

Direct Clutch Oil Pressure Switch Input Signal

Front Brake Oil Pressure Switch Input Signal

Input Clutch Oil Pressure Switch Input Signal

Display

Engine speed

Battery Voltage

Acceleration opening angle

Front Wheel Speed

Gear Position

Turbine Revolution Speed

Rear Wheel Speed

Lateral G sensor

ATF Temp.

ATF Temp. 2

Turbine Revolution Speed 1

Turbine Revolution Speed 2

H&LR/C Solenoid Current

D/C Solenoid Current

F/B Solenoid Current

I/C Solenoid Current

P/L Solenoid Current

L/U Solenoid Current

AWD Solenoid Current

H&LR/C Solenoid Target Pressure

D/C Solenoid Target Pressure

F/B Solenoid Target Pressure

I/C Solenoid Target Pressure

P/L Solenoid Target Pressure

L/U Solenoid Target Pressure

AWD Solenoid Target Pressure

Ignition SW

Tip Mode SW

Cruise Control Signal

Down SW

Stop Light SW

Up SW

D Range

R Range

Diagnosis Lamp

Shift lock solenoid

P range

P/N Signal

N range

Inhibitor SW1

Inhibitor SW2

Inhibitor SW3

Inhibitor SW4

Inhibitor SW3 Monitor

Back-up light relay

H&LR/C Oil Pressure SW

D/C Oil Pressure SW

Fr/B Oil Pressure SW

I/C Oil Pressure SW

5AT(diag)-17

Unit of measure

rpm

V

%

km/h

—

rpm

km/h

V

°C

°C

rpm

rpm

A

A

A

A

A

A

A

kPa

kPa

kPa

kPa

kPa

kPa

kPa

ON Input or OFF Input

ON or OFF

ON or OFF

ON or OFF

ON or OFF

ON or OFF

ON or OFF

ON or OFF

ON or OFF

ON or OFF

ON or OFF

ON or OFF

ON or OFF

High or Low

High or Low

High or Low

High or Low

High or Low

ON or OFF

ON or OFF

ON or OFF

ON or OFF

ON or OFF

Subaru Select Monitor

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

Item

Low Coast Brake Oil Pressure Switch Input Signal

Low Coast Brake Solenoid Input Signal

Display

LC/B Oil Pressure SW

LC B Solenoid

NOTE:

For details concerning operation procedure, refer

to the “SUBARU SELECT MONITOR OPERATION

MANUAL”.

3. CLEAR MEMORY MODE

NOTE:

To clear the previous DTC, use {Clear Memory},

and to clear the learned value, use {Clear Memory

2}.

1) Check that the select lever is in “P” range.

2) On the «Main Menu» display screen, select the

{Each System Check} and press the [YES] key.

3) On the «System Selection Menu» display

screen, select the {Transmission} and press the

[YES] key.

4) Press the [YES] key after the information of

transmission type is displayed.

5) On the «Transmission Diagnosis» display

screen, select the {Clear Memory} and press the

[YES] key.

NOTE:

If {Clear Memory 2} is selected and performed,

DTC may not be cleared.

6) When the ‘Done’ are shown on the display

screen, turn off the Subaru Select Monitor and turn

the ignition switch to OFF. To turn the ignition

switch ON again, wait for more than 10 seconds.

NOTE:

For details concerning operation procedure, refer

to the “SUBARU SELECT MONITOR OPERATION

MANUAL”.

5AT(diag)-18

Unit of measure

ON or OFF

ON or OFF

Read Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

7. Read Diagnostic Trouble

Code (DTC)

A: OPERATION

Refer to “Subaru Select Monitor” for information

about how to obtain and understand the DTC.

<Ref. to 5AT(diag)-16, OPERATION, Subaru Select Monitor.>

NOTE:

DTC can not be read by SPORT indicator light.

5AT(diag)-19

Inspection Mode

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

8. Inspection Mode

A: PROCEDURE

WARNING:

Observe the traffic law during actual driving.

1) Shift the select lever to “D” range, and then drive

the vehicle with changing the gear from 1st to 5th.

2) When driving the vehicle at 5th speed of “D”

range, set the gear to manual mode and drive the

vehicle with shifting down using “−” of steering

switch or “−” of select lever from 5th → 4th, 4th →

3rd, 3rd → 2nd, 2nd → 1st.

NOTE:

At shifting down, drive the vehicle at least 10 seconds in each speed.

3) Shift the select lever to “R” range and drive the

vehicle for more than 2 seconds.

5AT(diag)-20

Clear Memory Mode

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

9. Clear Memory Mode

A: OPERATION

Use “Subaru Select Monitor” to clear DTC. <Ref. to

5AT(diag)-18, CLEAR MEMORY MODE, OPERATION, Subaru Select Monitor.>

NOTE:

DTC cannot be cleared without using Subaru Select Monitor.

5AT(diag)-21

Learning Control

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

10.Learning Control

A: GENERAL DESCRIPTION

Be sure to perform the {Clear Memory 2} only when

the following services are performed. And when the

shifting shock is occurred in total check with vehicle

driving, perform the learning with following procedures. <Ref. to 5AT(diag)-18, CLEAR MEMORY

MODE, OPERATION, Subaru Select Monitor.>

• Replacement of TCM

• Replacement of transmission assembly

• Replacement of TCM and transmission assembly

CAUTION:

When {Clear Memory 2} is executed, DTC may

not be cleared.

B: PROCEDURE

1) Turn the ignition switch to OFF.

2) Turn the air conditioner switch to OFF.

3) Turn the headlight switch to OFF.

4) Turn the rear defogger switch to OFF.

5) Start the engine.

6) Connect the Subaru Select Monitor to the vehicle.

7) Drive the vehicle for 5 — 10 km (3 — 6 miles) to

warm up ATF temperature more than 70 °C (158

°F).

8) With the throttle opening angle on SUBARU select monitor indicates between 10%±2%, shift the

gear from 1st → 2nd, 2nd → 3rd, 3rd → 4th, 4th →

5th while driving the vehicle at “D” range. <Ref. to

5AT(diag)-16, READ CURRENT DATA, OPERATION, Subaru Select Monitor.>

9) Repeat the step 8) until reducing of shifting

shock was felt.

10) Reducing of shifting shock was not felt though

the procedure was repeated 5 cycle, recheck that

the learning conditions (throttle opening angle, ATF

temperature, etc.) are specified and recheck that

other parts are normal.

5AT(diag)-22

SPORT Indicator Light Display

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

11.SPORT Indicator Light Display

A: OPERATION

When any on-board diagnostics item is malfunctioning, the display on the SPORT indicator light blinks from

the time the malfunction is detected after starting the engine until the ignition switch is turned OFF. The malfunctioning part or unit can be determined by a DTC during the on-board diagnostics operation. Problems

which occurred previously can also be identified through the memory function. If the SPORT indicator light

does not show a problem (although a problem is occurring), the problem can be determined by checking the

performance characteristics of each sensor using the Subaru Select Monitor. Indicator light signal is as

shown in the figure.

When the SPORT indicator light does not operates normally though the DTC is not stored, perform the

SPORT indicator light inspection. <Ref. to 5AT(diag)-24, INSPECTION, SPORT Indicator Light Display.>

(A)

(1)

(2)

(B)

(1)

(3)

(2)

(4)

(C)

(1)

(3)

(2)

(5)

AT-01750

(A)

Ignition switch (Engine OFF)

(B)

Normal (Engine ON)

(C)

Faulty (Engine ON)

(1)

(2)

ON

OFF

(3)

(4)

2 sec.

0.25 sec.

(5)

Blink

5AT(diag)-23

SPORT Indicator Light Display

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

B: INSPECTION

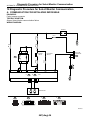

DIAGNOSIS:

SPORT indicator light circuit is open or shorted.

TROUBLE SYMPTOM:

When the ignition switch is turned to ON (engine OFF), SPORT indicator light does not illuminate.

WIRING DIAGRAM:

i10

IGNITION

SWITCH

SBF-1

6 7 8 9 10

1 2 3 4 5

11 12 13 14 15 16 17 18 19 20 21 22

SBF-7

BATTERY

No.12

i77

1 2 3 4 5 6 7 8 9 10 11 12

i84

4

3

A:

1 2

3 4

5 6

7 8

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

24 25 26 27 28 29 30 31 32 33 34 35

SPORT

E

COMBINATION

METER

B54

i84

22

7

1 2 3

4 5

6 7

8 9 10 11 12 13 14 15 16 17 18 19 20

21 22 23 24 25 26 27 28 29 30

JOINT

CONNECTOR

B54

i77

A27

1 2 3 4

10 11 12 13

19 20 21

5 6

14 15

7

16

22

8

17

23

9

18

24

BODY INTEGRATED UNIT

B30

A:

B: B280

3

4

B20

B: B280

2

21

A26

8

1

i10

TCM

AT-01452

5AT(diag)-24

SPORT Indicator Light Display

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

1

2

3

Step

CHECK SPORT INDICATOR LIGHT.

Turn the ignition switch to ON.

Check

Does the SPORT indicator

light illuminate?

Yes

Go to step 2.

CHECK SPORT INDICATOR LIGHT.

After the ignition switch is “ON”, wait for at least

2 seconds.

CHECK SPORT INDICATOR LIGHT.

Start the engine.

Does the SPORT indicator

light illuminate?

Go to step 3.

4

CHECK SUBARU SELECT MONITOR COMMUNICATION.

Connect the Subaru Select Monitor to data link

connector.

5

CHECK TCM.

Display the current data of TCM using Subaru

Select Monitor.

6

CHECK BODY INTEGRATED UNIT.

Display the current data of body integrated unit

using Subaru Select Monitor. <Ref. to

LAN(diag)-14, OPERATION, Subaru Select

Monitor.>

7

CHECK TCM.

1) Start the engine.

2) Display the current data of TCM using Subaru Select Monitor. <Ref. to 5AT(diag)-16,

OPERATION, Subaru Select Monitor.>

CHECK BODY INTEGRATED UNIT.

Display the current data of body integrated unit

using Subaru Select Monitor. <Ref. to

LAN(diag)-14, OPERATION, Subaru Select

Monitor.>

8

Does the SPORT indicator

light go off?

No

Perform the selfdiagnosis of combination meter.

Go to step 4.

Normal. Go back Go to step 7.

to “Basic Diagnosis Procedure”.

<Ref. to 5AT(diag)2, Basic Diagnostics Procedure.>

Is the communication between Go to step 5.

Check the TCM

Subaru Select Monitor and

power supply

TCM normal?

ground circuit and

Subaru Select

Monitor communication. <Ref. to

5AT(diag)-26,

Diagnostic Procedure for Select

Monitor Communication.>

Is “Diagnosis light” output sig- Go to step 6.

Replace the TCM.

nal set to “ON”?

<Ref. to 5AT-61,

Transmission Control Module

(TCM).>

Is “SPORT light” input signal

Replace the com- Check DTC of

set to “ON”?

bination meter

body integrated

assembly. <Ref. to unit. <Ref. to

IDI-16, Combina- LAN(diag)-14,

tion Meter Assem- OPERATION,

bly.>

Subaru Select

Monitor.>

Is “Diagnosis light” output sig- Replace the TCM. Go to step 8.

nal set to “ON”?

<Ref. to 5AT-61,

Transmission Control Module

(TCM).>

Is “SPORT light” input signal

Check DTC of

Perform the selfset to “ON”?

body integrated

diagnosis for comunit. Perform the bination meter.

diagnosis accord- <Ref. to IDI-3,

ing to DTC. <Ref. INSPECTION,

to LAN(diag)-14, Combination

OPERATION,

Meter System.>

Subaru Select

Monitor.>

5AT(diag)-25

Diagnostic Procedure for Select Monitor Communication

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

12.Diagnostic Procedure for Select Monitor Communication

A: COMMUNICATION FOR INITIALIZING IMPOSSIBLE

DIAGNOSIS:

Faulty harness connector

TROUBLE SYMPTOM:

Subaru Select Monitor communication failure

WIRING DIAGRAM:

BATTERY

SBF-1

No.13

1

2

3

SBF-7

NO.32

E

10

ACCESSORY

SWITCH

IGNITION

SWITCH

12

B357

DATA LINK

CONNECTOR

B40

NO.31

NO.12

1

4

13

16

B21

B21

A5

E

E

B21

B40

1 2 3 4

5 6 7 8

9 10 11 12

13 14 15 16

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16

A20

B2

TCM

B55

E

A14

B:

B54

A19

A:

B1

B10

A10

A7

A8

A1

E2

TRANSMISSION

A:

B54

1 2 3 4

10 11 12 13

19 20 21

5 6

14 15

7

16

22

8 9

17 18

23 24

B:

B55

1 2 3 4

10 11 12 13

19 20 21

5 6

14 15

7

16

22

8

17

23

9

18

24

AT-01453

5AT(diag)-26

Diagnostic Procedure for Select Monitor Communication

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

1

Step

Check

Yes

CHECK SUBARU SELECT MONITOR POW- Is the voltage more than 10 V? Go to step 2.

ER SUPPLY CIRCUIT.

Measure the voltage between data link connector and chassis ground.

Connector & terminal

(B40) No. 1 (+) — Chassis ground (−):

2

CHECK SUBARU SELECT MONITOR

GROUND CIRCUIT.

Measure the resistance of harness between

data link connector and chassis ground.

Connector & terminal

(B40) No. 12 — Chassis ground:

(B40) No. 13 — Chassis ground:

Is the resistance less than 1

Ω?

3

CHECK COMMUNICATION OF SUBARU SELECT MONITOR.

1) Turn the ignition switch to ON.

2) Using the Subaru Select Monitor, check

whether communication to transmission systems can be executed normally.

CHECK COMMUNICATION OF SUBARU SELECT MONITOR.

1) Turn the ignition switch to OFF.

2) Disconnect the TCM connector.

3) Turn the ignition switch to ON.

4) Check whether communication to engine

systems can be executed normally.

CHECK COMMUNICATION OF SUBARU SELECT MONITOR.

1) Turn the ignition switch to OFF.

2) Connect the TCM connector.

3) Disconnect the ECM connector.

4) Turn the ignition switch to ON.

5) Check whether communication to transmission systems can be executed normally.

CHECK HARNESS CONNECTOR BETWEEN

EACH CONTROL UNIT AND DATA LINK

CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the TCM and ECM connector.

3) Measure the resistance between TCM connector and chassis ground.

Connector & terminal

(B40) No. 10 — Chassis ground:

CHECK OUTPUT SIGNAL OF TCM.

1) Turn the ignition switch to ON.

2) Measure the voltage between TCM and

chassis ground.

Connector & terminal

(B40) No. 10 (+) — Chassis ground (−):

CHECK HARNESS CONNECTOR BETWEEN

TCM AND DATA LINK CONNECTOR.

Measure the resistance between TCM connector and data link connector.

Connector & terminal

(B54) No. 20 — (B40) No. 10:

Are the name and year of sys- Go to step 8.

tem displayed on Subaru

Select Monitor?

4

5

6

7

8

Go to step 3.

No

Repair harness

connector and

connector

between battery

and data link connector, and poor

contact in coupling connector.

Repair the open

circuit in harness

between data link

connector and

ground terminal,

and poor contact

in coupling connector.

Go to step 4.

Are the name and year of sys- Go to step 6.

tem displayed on Subaru

Select Monitor?

Go to step 5.

Are the name and year of sys- Inspect the ECM.

tem displayed on Subaru

Select Monitor?

Go to step 6.

Is the resistance more than 1

MΩ?

Go to step 7.

Check harness

and connector

between each control unit and data

link connector.

Is the voltage more than 1 V?

Check harness

Go to step 8.

and connector

between each control unit and data

link connector.

Is the resistance less than 1

Ω?

Go to step 9.

5AT(diag)-27

Repair the harness and connector between TCM

and data link connector.

Diagnostic Procedure for Select Monitor Communication

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

9

10

11

Step

CHECK INSTALLATION OF TCM CONNECTOR.

Turn the ignition switch to OFF.

CHECK INSTALLATION OF TRANSMISSION

HARNESS CONNECTOR.

Check

Is TCM connector connected

to TCM?

Yes

Go to step 10.

No

Connect the TCM

connector to TCM.

Is the transmission harness

connector connected to bulkhead harness connector?

Go to step 11.

Connect the bulkhead harness connector to

transmission harness connector.

Go to step 12.

CHECK POOR CONTACT IN CONNECTORS. Is there poor contact in control

unit power supply and data link

connector?

Is the voltage 10 — 13 V?

CHECK POWER SUPPLY OF TCM.

1) Disconnect the connector from TCM.

2) Turn the ignition switch to ON.

3) Measure the voltage between TCM connector and chassis ground.

Connector & terminal

(B54) No. 1 (+) — Chassis ground (−):

CHECK FUSE (No. 32).

Is the fuse (No. 32) blown out?

1) Turn the ignition switch to OFF.

2) Remove the fuse (No. 32).

Repair the poor

contact.

14

CHECK HARNESS.

Is the resistance less than 10

Measure the resistance between TCM connec- Ω?

tor and chassis ground.

Connector & terminal

(B54) No. 1 — Chassis ground:

15

CHECK IGNITION POWER SUPPLY CIRCUIT.

1) Turn the ignition switch to ON (engine

OFF).

2) Measure the ignition power supply voltage

between TCM connector and chassis ground.

Connector & terminal

(B55) No. 1 (+) — Chassis ground (−):

(B55) No. 10 (+) — Chassis ground (−):

CHECK FUSE (No. 12).

Remove the fuse (No. 12).

Replace the fuse

(No. 32). If the

replaced fuse (No.

32) has blown out

easily, repair the

short circuit in harness between fuse

(No. 32) and TCM.

Go to step 17.

Go to step 16.

12

13

16

Is the voltage 10 — 13 V?

Go to step 15.

Go to step 13.

Go to step 14.

Repair the open

circuit in harness

between fuse (No.

32) and TCM, or

fuse (No. 32) and

battery, and poor

contact in coupling connector.

Replace the fuse

(No. 32).

Is the fuse (No. 12) blown out? Replace the fuse

(No. 12). If the

replaced fuse (No.

12) has blown out

easily, repair the

short circuit in harness between fuse

(No. 12) and TCM.

5AT(diag)-28

Repair the open

circuit in harness

between fuse (No.

12) and TCM, or

fuse (No. 12) and

battery, and poor

contact in coupling connector.

Diagnostic Procedure for Select Monitor Communication

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

17

18

Step

Check

Yes

CHECK HARNESS CONNECTOR BETWEEN Is the resistance more than 1 Go to step 18.

TCM AND TRANSMISSION.

MΩ?

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM and

transmission.

3) Measure the resistance of harness

between TCM and transmission connector.

Connector & terminal

(B54) No. 19 — Chassis ground:

(B55) No. 21 — Chassis ground:

(B54) No. 5 — Chassis ground:

(B54) No. 14 — Chassis ground:

CHECK POOR CONTACT IN CONNECTORS. Is there poor contact in TCM

Repair the conpower supply, ground and data nector.

link connector?

5AT(diag)-29

No

Repair the short

circuit in harness

between TCM and

transmission harness connector,

and poor contact

in coupling connector.

Replace the TCM.

<Ref. to 5AT-61,

Transmission Control Module

(TCM).>

List of Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

13.List of Diagnostic Trouble Code (DTC)

A: LIST

DTC

Item

Content of diagnosis

P0705

Transmission Range

Sensor Circuit (PRNDL

Input)

Inhibitor switch 1 malfunction,

open or short circuit

P0712

Transmission Fluid Temperature Sensor Circuit

Low Input

ATF temperature sensor 1 malfunction, open input signal circuit

P0713

Transmission Fluid Temperature Sensor Circuit

High Input

ATF temperature sensor 1 malfunction, short input signal circuit

P0715

Input/Turbine Speed

Sensor Circuit

Turbine speed sensor 1 malfunction, short input signal circuit

P0719

Torque Converter/Brake

Switch “B” Circuit Low

P0720

Output Speed Sensor

Circuit

P0724

Torque Converter/Brake

Switch “B” Circuit High

P0725

Engine Speed Input Circuit

P0731

Gear 1 Incorrect Ratio

P0732

Gear 2 Incorrect Ratio

P0733

Gear 3 Incorrect Ratio

Vehicle sensor, turbine speed

sensor, or shift clutch malfunction

P0734

Gear 4 Incorrect Ratio

Vehicle sensor, turbine speed

sensor, or shift clutch malfunction

P0735

Gear 5 Incorrect Ratio

Vehicle sensor, turbine speed

sensor, or shift clutch malfunction

P0736

Reverse Incorrect Ratio

Vehicle sensor, turbine speed

sensor, or shift clutch malfunction

P0741

Torque Converter Clutch

Circuit Performance or

Stuck Off

Lock-up clutch is faulty or valve is

stuck.

Brake switch malfunction, open

input signal circuit, body integrated unit malfunction, CAN

communication malfunction

Front wheel speed sensor is

faulty or input signal circuit,

ground, power supply is open or

shorted.

Brake switch malfunction, short

circuit of input signal, body integrated unit malfunction, CAN

communication malfunction

Open or short engine speed output signal circuit, ECM malfunction, CAN communication

malfunction

Vehicle sensor, turbine speed

sensor, control valve malfunction

or shift clutch malfunction

Vehicle sensor, turbine speed

sensor, control valve malfunction

or shift clutch malfunction

5AT(diag)-30

Reference target

<Ref. to 5AT(diag)-34, DTC P0705 TRANSMISSION RANGE SENSOR CIRCUIT (PRNDL

INPUT), Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

<Ref. to 5AT(diag)-39, DTC P0712 TRANSMISSION FLUID TEMPERATURE SENSOR

CIRCUIT LOW INPUT, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-42, DTC P0713 TRANSMISSION FLUID TEMPERATURE SENSOR

CIRCUIT HIGH INPUT, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-45, DTC P0715 INPUT/

TURBINE SPEED SENSOR CIRCUIT, Diagnostic Procedure with Diagnostic Trouble Code

(DTC).>

<Ref. to 5AT(diag)-49, DTC P0719 TORQUE

CONVERTER/BRAKE SWITCH “B” CIRCUIT

LOW, Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

<Ref. to 5AT(diag)-51, DTC P0720 OUTPUT

SPEED SENSOR CIRCUIT, Diagnostic Procedure with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-56, DTC P0724 TORQUE

CONVERTER/BRAKE SWITCH “B” CIRCUIT

HIGH, Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

<Ref. to 5AT(diag)-58, DTC P0725 ENGINE

SPEED INPUT CIRCUIT, Diagnostic Procedure with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-58, DTC P0731 GEAR 1

INCORRECT RATIO, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-58, DTC P0732 GEAR 2

INCORRECT RATIO, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-58, DTC P0733 GEAR 3

INCORRECT RATIO, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-58, DTC P0734 GEAR 4

INCORRECT RATIO, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-58, DTC P0735 GEAR 5

INCORRECT RATIO, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-59, DTC P0736 REVERSE

INCORRECT RATIO, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-60, DTC P0741 TORQUE

CONVERTER CLUTCH CIRCUIT PERFORMANCE OR STUCK OFF, Diagnostic Procedure with Diagnostic Trouble Code (DTC).>

List of Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

DTC

Item

P0743

Torque Converter Clutch

Circuit Electrical

P0748

Pressure Control Solenoid “A” Electrical

P0751

Shift Solenoid “A” Performance or Stuck Off

P0753

Shift Solenoid “A” Electrical

P0756

Shift Solenoid “B” Performance or Stuck Off

P0758

Shift Solenoid “B” Electrical

P0761

Shift Solenoid “C” Performance or Stuck Off

P0763

Shift Solenoid “C” Electrical

P0766

Shift Solenoid “D” Performance or Stuck Off

P0768

Shift Solenoid “D” Electrical

P0771

Shift Solenoid “E” Performance or Stuck Off

P0773

Shift Solenoid “E” Electrical

P0801

Reverse Inhibit Control

Circuit

P0817

Starter Disable Circuit

P0882

PVIGN Power Supply

Circuit (Low)

Content of diagnosis

Reference target

<Ref. to 5AT(diag)-61, DTC P0743 TORQUE

L/U solenoid circuit malfunction

CONVERTER CLUTCH CIRCUIT ELECTRIor L/U solenoid body malfunction CAL, Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

<Ref. to 5AT(diag)-63, DTC P0748 PRESLine pressure solenoid circuit

SURE CONTROL SOLENOID “A” ELECTRImalfunction or line pressure soleCAL, Diagnostic Procedure with Diagnostic

noid body malfunction

Trouble Code (DTC).>

<Ref. to 5AT(diag)-65, DTC P0751 SHIFT

Shift Solenoid “A” performance

SOLENOID “A” PERFORMANCE OR STUCK

malfunction

OFF, Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

<Ref. to 5AT(diag)-69, DTC P0753 SHIFT

Fr/B solenoid circuit malfunction

SOLENOID “A” ELECTRICAL, Diagnostic Proor Fr/B solenoid body malfunction

cedure with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-72, DTC P0756 SHIFT

Shift Solenoid “B” Performance

SOLENOID “B” PERFORMANCE OR STUCK

malfunction

OFF, Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

<Ref. to 5AT(diag)-75, DTC P0758 SHIFT

I/C solenoid circuit malfunction or

SOLENOID “B” ELECTRICAL, Diagnostic ProI/C solenoid body malfunction

cedure with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-78, DTC P0761 SHIFT

SOLENOID “C” PERFORMANCE OR STUCK

H&LR/C solenoid malfunction

OFF, Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

H&LR/C solenoid circuit malfunc- <Ref. to 5AT(diag)-82, DTC P0763 SHIFT

SOLENOID “C” ELECTRICAL, Diagnostic Protion or H&LR/C solenoid body

cedure with Diagnostic Trouble Code (DTC).>

malfunction

<Ref. to 5AT(diag)-85, DTC P0766 SHIFT

SOLENOID “D” PERFORMANCE OR STUCK

D/C solenoid malfunction

OFF, Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

<Ref. to 5AT(diag)-88, DTC P0768 SHIFT

D/C solenoid circuit malfunction

SOLENOID “D” ELECTRICAL, Diagnostic Proor D/C solenoid body malfunction

cedure with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-91, DTC P0771 SHIFT

SOLENOID “E” PERFORMANCE OR STUCK

LC/B solenoid malfunction

OFF, Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

• LC/B solenoid circuit malfunction or LC/B solenoid body mal<Ref. to 5AT(diag)-94, DTC P0773 SHIFT

function

SOLENOID “E” ELECTRICAL, Diagnostic Pro• OFF malfunction of PVIGN

cedure with Diagnostic Trouble Code (DTC).>

relay circuit or relay body

• Shift lock solenoid is faulty or

<Ref. to 5AT(diag)-97, DTC P0801 REVERSE

output signal circuit is open or

INHIBIT CONTROL CIRCUIT, Diagnostic Proshorted.

cedure with Diagnostic Trouble Code (DTC).>

• Brown out of TCM+B fuse

• PN signal output circuit is open

or shorted.

<Ref. to 5AT(diag)-100, DTC P0817 STARTER

• ECM Source Voltage Is Abnor- DISABLE CIRCUIT, Diagnostic Procedure with

mal

Diagnostic Trouble Code (DTC).>

• Brown out of TCM+B fuse

PVIGN relay output circuit is

<Ref. to 5AT(diag)-102, DTC P0882 TCM

open, shorted or relay malfuncPOWER INPUT SIGNAL LOW, Diagnostic Protion

cedure with Diagnostic Trouble Code (DTC).>

5AT(diag)-31

List of Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

DTC

Item

Content of diagnosis

Back-up relay output circuit is

open, shorted or relay OFF malfunction

Back-up relay output circuit is

open, shorted or relay ON malfunction

P0957

Backup Light Relay Circuit Low

P0958

Backup Light Relay Circuit High

P1601

TCM Communication

Malfunction

Communication Failure between

TCM and Memory Box

P1706

AT Vehicle Speed Sensor Circuit Malfunction

(Rear Wheel)

Rear wheel speed sensor is faulty

or input circuit, ground, power

supply is open or shorted.

P1707

AT AWD Solenoid Valve

Circuit Malfunction

AWD solenoid circuit malfunction

or AWD solenoid body malfunction

P1710

Torque Converter Turbine 2 Speed Signal Circuit 2 Malfunction

Torque converter sensor 2 malfunction, input circuit, ground,

power open, short circuit

P1716

ATF Temp. Sensor 2 Circuit Low

ATF temperature sensor 2 malfunction, open input signal circuit

P1717

ATF Temp. Sensor 2 Circuit High

ATF temperature sensor 2 malfunction, short input signal circuit

P1718

AT CAN Communication

Circuit

CAN communication line bus off

is open, EUM short circuit, ABS/

VDCCM, integrated CU malfunction

P1760

Lateral Acceleration

Sensor Performance

Problem

Lateral G sensor malfunction

P1761

Lateral Acceleration

Sensor Circuit Low

Lateral G sensor is faulty or input

signal circuit is open.

P1762

Lateral Acceleration

Sensor Circuit High

Lateral G sensor is faulty or input

signal circuit is shorted.

P1798

Gear 1 Engine Brake

P1799

Interlock

P1817

SPORTS Mode Switch

Circuit (Manual Switch)

Malfunction of clutch oil pressure

related to 1st engine brake, solenoid current malfunction

Malfunction of clutch oil pressure

which emit interlock, solenoid

current malfunction

Manual mode switch is open or

shorted, or switch malfunction

5AT(diag)-32

Reference target

<Ref. to 5AT(diag)-104, DTC P0957 BACKUP

LIGHT RELAY CIRCUIT LOW, Diagnostic Procedure with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-106, DTC P0958 BACKUP

LIGHT RELAY CIRCUIT HIGH, Diagnostic Procedure with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-108, DTC P1601 TCM

COMMUNICATION MALFUNCTION, Diagnostic Procedure with Diagnostic Trouble Code

(DTC).>

<Ref. to 5AT(diag)-110, DTC P1706 AT VEHICLE SPEED SENSOR CIRCUIT MALFUNCTION (REAR WHEEL), Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-114, DTC P1707 AT AWD

SOLENOID VALVE CIRCUIT MALFUNCTION, Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

<Ref. to 5AT(diag)-116, DTC P1710 TORQUE

CONVERTER TURBINE 2 SPEED SIGNAL

CIRCUIT 2 MALFUNCTION, Diagnostic Procedure with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-120, DTC P1716 ATF

TEMP. SENSOR 2 CIRCUIT LOW, Diagnostic

Procedure with Diagnostic Trouble Code

(DTC).>

<Ref. to 5AT(diag)-123, DTC P1717 ATF

TEMP. SENSOR 2 CIRCUIT HIGH, Diagnostic

Procedure with Diagnostic Trouble Code

(DTC).>

<Ref. to 5AT(diag)-125, DTC P1718 AT CAN

COMMUNICATION CIRCUIT, Diagnostic Procedure with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-126, DTC P1760 LATERAL

ACCELERATION SENSOR PERFORMANCE

PROBLEM, Diagnostic Procedure with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-129, DTC P1761 LATERAL

ACCELERATION SENSOR CIRCUIT LOW,

Diagnostic Procedure with Diagnostic Trouble

Code (DTC).>

<Ref. to 5AT(diag)-131, DTC P1762 LATERAL

ACCELERATION SENSOR CIRCUIT HIGH,

Diagnostic Procedure with Diagnostic Trouble

Code (DTC).>

<Ref. to 5AT(diag)-133, DTC P1798 GEAR 1

ENGINE BRAKE, Diagnostic Procedure with

Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-134, DTC P1799 INTERLOCK, Diagnostic Procedure with Diagnostic

Trouble Code (DTC).>

<Ref. to 5AT(diag)-135, DTC P1817 SPORTS

MODE SWITCH CIRCUIT (MANUAL

SWITCH), Diagnostic Procedure with Diagnostic Trouble Code (DTC).>

List of Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

DTC

Item

Content of diagnosis

P1840

Transmission Fluid Pressure Sensor/Switch A

Circuit

H&LR/C oil pressure switch is

open or shorted, or switch malfunction

P1841

Transmission Fluid Pressure Sensor/Switch B

Circuit

D/C oil pressure switch is open or

shorted, or switch malfunction

P1842

Transmission Fluid Pressure Sensor/Switch C

Circuit

Fr/B oil pressure switch is open or

shorted, or switch malfunction

P1843

Transmission Fluid Pressure Sensor/Switch D

Circuit

I/C oil pressure switch is open or

shorted, or switch malfunction

P1844

Transmission Fluid Pressure Sensor/Switch E

Circuit

LC/B oil pressure switch is open

or shorted, or switch malfunction

5AT(diag)-33

Reference target

<Ref. to 5AT(diag)-137, DTC P1840 TRANSMISSION FLUID PRESSURE SENSOR/

SWITCH A CIRCUIT, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-137, DTC P1841 TRANSMISSION FLUID PRESSURE SENSOR/

SWITCH B CIRCUIT, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-137, DTC P1842 TRANSMISSION FLUID PRESSURE SENSOR/

SWITCH C CIRCUIT, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-137, DTC P1843 TRANSMISSION FLUID PRESSURE SENSOR/

SWITCH D CIRCUIT, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

<Ref. to 5AT(diag)-137, DTC P1844 TRANSMISSION FLUID PRESSURE SENSOR/

SWITCH E CIRCUIT, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

14.Diagnostic Procedure with Diagnostic Trouble Code (DTC)

A: DTC P0705 TRANSMISSION RANGE SENSOR CIRCUIT (PRNDL INPUT)

DTC DETECTING CONDITION:

The inhibitor switch is open or short.

TROUBLE SYMPTOM:

• Shift characteristics are erroneous.

• Shift indicator light does not match with select lever.

• Shift indicator light does not illuminate.

• N-D, N-R shock occur.

5AT(diag)-34

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

WIRING DIAGRAM:

SBF-1

SBF-7

No.12

BATTERY

4

3

i10

6 7 8 9 10

1 2 3 4 5

11 12 13 14 15 16 17 18 19 20 21 22

COMBINATION

METER

P

R

N

D

i10

i77

E

21

22

1

7

1 2 3 4 5 6 7 8 9 10 11 12

A:

JOINT

CONNECTOR

2

8

A27

A26

i77

BODY INTEGRATED UNIT

A:

B54

B30

i84

B: B280

A3

A4

B20

A:

B:

i84

1 2

3 4

5 6

7 8

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

24 25 26 27 28 29 30 31 32 33 34 35

B:

B280

1 2 3

4 5

6 7

8 9 10 11 12 13 14 15 16 17 18 19 20

21 22 23 24 25 26 27 28 29 30

A:

B54

1 2 3 4

10 11 12 13

19 20 21

5 6

14 15

B:

B55

1 2 3 4

10 11 12 13

19 20 21

5 6

14 15

7

16

22

8

17

23

9

18

24

7

16

22

8

17

23

9

18

24

TCM

B55

B13

B20

8

1

B3

B14

2

3

B12

4

B4

B12

1 2 3 4

5 6 7 8

T3

TRANSMISSION

E

AT-02073

5AT(diag)-35

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

1

Step

CHECK DTC OF TCM.

2

PREPARE SUBARU SELECT MONITOR.

3

CHECK INHIBITOR SWITCH.

1) Shift the select lever to “P” range.

2) Check input signal of inhibitor SW 1 — 4

and inhibitor SW 3 monitor using Subaru

Select Monitor.

CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM and

transmission.

3) Measure the resistance between TCM connector and chassis ground about the item

which indicated Low on step 3.

Connector & terminal

(B55) No. 4 — Chassis ground:

(B55) No. 3 — Chassis ground:

(B55) No. 14 — Chassis ground:

(B55) No. 13 — Chassis ground:

(B55) No. 20 — Chassis ground:

CHECK INHIBITOR SWITCH.

1) Shift the select lever to “D” range.

2) Check input signal of inhibitor SW 1 — 4

and inhibitor SW 3 monitor using Subaru

Select Monitor.

CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM and

transmission.

3) Measure the resistance of harness

between TCM and transmission connector

about the item which indicated High on step 5.

Connector & terminal

(B55) No. 4 — (B12) No. 4:

(B55) No. 3 — (B12) No. 3:

(B55) No. 14 — (B12) No. 2:

(B55) No. 13 — (B12) No. 1:

(B55) No. 20 — (B12) No. 8:

CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM and

transmission.

3) Measure the resistance of harness

between TCM and transmission connector.

Connector & terminal

(B55) No. 4 — (B12) No. 4:

(B55) No. 3 — (B12) No. 3:

(B55) No. 14 — (B12) No. 2:

(B55) No. 13 — (B12) No. 1:

(B55) No. 20 — (B12) No. 8:

4

5

6

7

Check

Yes

No

Is DTC of AT CAN communica- Perform the diag- Go to step 2.

tion circuit displayed?

nosis according to

DTC.

Do you have a Subaru Select Go to step 3.

Go to step 7.

Monitor?

Are all indications High?

Go to step 5.

Go to step 4.

Is the resistance more than 1

MΩ?

Go to step 9.

Repair the short

circuit in harness

between TCM connector and chassis

ground.

Are all indications High?

Go to step 9.

Go to step 6.

Is the resistance less than 1

Ω?

Go to step 9.

Repair the open

circuit in harness

between TCM connector and transmission connector.

Is the resistance less than 1

Ω?

Go to step 8.

Repair the open

circuit in harness

between TCM connector and transmission connector.

5AT(diag)-36

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

8

9

10

11

Step

CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

Measure the resistance between TCM connector and chassis ground.

Connector & terminal

(B55) No. 4 — Chassis ground:

(B55) No. 3 — Chassis ground:

(B55) No. 14 — Chassis ground:

(B55) No. 13 — Chassis ground:

(B55) No. 20 — Chassis ground:

CHECK INPUT SIGNAL FOR TCM USING

CIRCUIT TESTER.

1) Turn the ignition switch to OFF.

2) Disconnect the transmission connector

(B12).

3) Connect the TCM connector.

4) Turn the ignition switch to ON.

5) Measure the voltage between TCM terminals.

Connector & terminal

(B55) No. 4 — (B54) No. 19:

(B55) No. 3 — (B54) No. 19:

(B55) No. 14 — (B54) No. 19:

(B55) No. 13 — (B54) No. 19:

(B55) No. 20 — (B54) No. 19:

CHECK TCM I/O SIGNAL.

Check I/O signal of power supply, ground and

PVIGN power supply relay.

<Ref. to 5AT(diag)-12, ELECTRICAL SPECIFICATION, Transmission Control Module (TCM)

I/O Signal.>

Check

Is the resistance more than 1

MΩ?

Yes

Go to step 9.

No

Repair the short

circuit in harness

between TCM connector and chassis

ground.

Is the voltage 4 — 6 V for the

inhibitor SW 1 — 4?

Is the voltage 3.5 — 5.5 V for

the inhibitor SW 3 monitor?

Go to step 11.

Go to step 10.

Is TCM I/O signal OK?

Replace the TCM.

<Ref. to 5AT-61,

Transmission Control Module

(TCM).>

Repair the open or

short circuit for

power supply and

ground. Perform

the diagnosis

according to DTC

for PVIGN power

supply relay.

Repair the open

circuit in harness

between control

valve body connector and transmission connector.

CHECK HARNESS CONNECTOR BETWEEN Is the resistance less than 1

Ω?

TRANSMISSION AND CONTROL VALVE

BODY.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from transmission.

3) Remove the transmission connector from

bracket.

4) Lift-up the vehicle and place it on rigid

racks.

NOTE:

Raise all wheels off floor.

5) Drain the ATF.

CAUTION:

Do not drain the ATF until it cools down.

6) Remove the oil pan, and disconnect the

connector from control valve body connector.

7) Measure the resistance between transmission connector and control valve body connector.

Connector & terminal

(T3) No. 4 — (T5) No. 6:

(T3) No. 3 — (T5) No. 5:

(T3) No. 2 — (T5) No. 4:

(T3) No. 1 — (T5) No. 3:

(T3) No. 8 — (T5) No. 2:

5AT(diag)-37

Go to step 12.

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

12

13

Step

Check

Yes

CHECK HARNESS CONNECTOR BETWEEN Is the resistance more than 1 Go to step 13.

TRANSMISSION AND CONTROL VALVE

MΩ?

BODY.

Measure the resistance between transmission

ground and control valve body connector.

Connector & terminal

(T5) No. 6 — Transmission ground:

(T5) No. 5 — Transmission ground:

(T5) No. 4 — Transmission ground:

(T5) No. 3 — Transmission ground:

(T5) No. 2 — Transmission ground:

CHECK POOR CONTACT.

Is there any poor contact in

Repair the poor

inhibitor SW 1 — 4 or inhibitor contact.

SW 3 monitor circuit?

5AT(diag)-38

No

Repair the short

circuit in harness

between control

valve body connector and transmission connector.

Replace the control valve body.

<Ref. to 5AT-58,

Control Valve

Body.>

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

B: DTC P0712 TRANSMISSION FLUID TEMPERATURE SENSOR CIRCUIT LOW

INPUT

DTC DETECTING CONDITION:

Input signal circuit of TCM to ATF temperature sensor 1 is opened.

TROUBLE SYMPTOM:

Excessive shift shock.

WIRING DIAGRAM:

B54

TCM

1 2 3 4

10 11 12 13

19 20 21

5 6

14 15

7

16

22

8

17

23

9

18

24

2

13

B54

B11

1 2

3 4

6 7

8

9 10

11 12

13

14 15

16

17 18

19 20

B11

5

12

5

T4

T5

16

1

1 2 3

4 5 6

7 8 9 10 11 12 13 14 15 16

T5

TRANSMISSION

AT-02037

5AT(diag)-39

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

1

2

3

4

5

Step

CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM and

transmission.

3) Measure the resistance of harness

between TCM and transmission connector.

Connector & terminal

(B54) No. 13 — (B11) No. 12:

(B54) No. 2 — (B11) No. 5:

CHECK ATF TEMPERATURE SENSOR.

1) Turn the ignition switch to OFF.

2) Connect the connectors to transmission

and TCM.

3) Turn the ignition switch to ON and start

engine.

4) Warm-up the transmission until the ATF

temperature reaches to 80°C (176°F).

NOTE:

If the ambient temperature is below 0°C (32°F),

drive the vehicle until the ATF reaches its operating temperature.

5) Disconnect the connector from transmission.

6) Measure the resistance between transmission connector terminals.

Connector & terminal

(T4) No. 5 — (T4) No. 12:

CHECK ATF TEMPERATURE SENSOR.

Measure the resistance between transmission

connector terminals.

Connector & terminal

(T4) No. 5 — (T4) No. 12:

PREPARE SUBARU SELECT MONITOR.

CHECK INPUT SIGNAL FROM TCM.

1) Connect the connector to transmission.

2) Warm-up the transmission until the ATF

temperature is approx. 80°C (176°F).

Check

Is the resistance less than 1

Ω?

Yes

Go to step 2.

No

Repair the open

circuit in harness

between TCM and

transmission connector.

Is the resistance 500 — 1,200 Go to step 3.

Ω?

Go to step 7.

Does the resistance value

Go to step 4.

increase while the ATF temperature decreases?

Go to step 7.

Do you have a Subaru Select

Monitor?

Is the voltage 0.5 — 1.2 V?

Go to step 5.

NOTE:

If the ambient temperature is below 0°C (32°F),

drive the vehicle until the ATF reaches its operating temperature.

3) Measure the voltage between TCM connector terminals.

Connector & terminal

(B54) No. 2 (+) — (B54) No. 13 (−):

5AT(diag)-40

Go to step 6.

Even if the SPORT Go to step 8.

indicator lights

blinks, the system