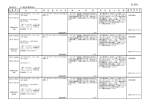

Download MAINTENANCE INTERVALS - Safety

Transcript