Download "service manual"

Transcript

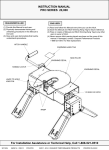

NATIONAL PARTS & SERVICE HOTLINE: 1-800-247-5767 WEB SITE: www.paceamerican.com Manufacturing Facility Dealer Location TRAILER USER’S GUIDE Pace American Inc. 11550 Harter Drive Middlebury, IN 46540 574-825-7223 Fax: 574-825-7393 Pace American of Georgia 223 Rip Wiley Road Fitzgerald, GA 31750 229-423-7966 Fax: 229-423-3859 Pace American of Utah 210 North Highway 91 Hurricane, UT 84737 435-628-7667 Fax: 435-628-7677 Pace American of Texas 2290 McGuffey Road McGregor, TX 76657 254-840-4323 Fax: 254-840-4002 2 1 Introduction to Pace American General Trailer Maintenance Loading Your Trailer 2 3 7 Tongue Jacks & Landing Gear Trailer Towing Safety Tips Hitching Up Your Trailer 18 19 21 Hitch Selection Chart Electrical and Wiring Systems Trailer Wheel Bearings Brake Adjustment/Maintenance Tire Load Limits Vendor Doors 8 9 11 15 16 17 Trailering Tactics Safety Checklist Pace Replacement Parts Trailer Information Form Maintenance Schedule/Record Warranty Information 22 24 25 26 27 29 CUSTOMER SERVICE HOTLINE 1-800-247-5767 USER’S GUIDE CONTENTS ™ LEGACY BY PACE AMERICAN You have chosen a quality trailer from America’s most popular trailer manufacturer—Pace American. Even though Pace American trailers are built for the long haul, proper and routine maintenance will assure even more years of hassle-free operation. Pace recommends you consider the inspection and service guidelines outlined in this easy-toR understand manual. Following these simple FAI • A instructions will help maintain proper operation STT ● F F● A FAS of electrical systems, wheels, bearings, hitches, and • STEST E ON N H other important function devices on your trailer. Should you have HO a problem, a Pace representative will review your warranty and take action to correct the problem immediately. Your complete satisfaction has and will always be our first objective at Pace. Please keep this manual in your trailer or tow vehicle and review the safety checklists before you set out on the road. For factory-installed options and accessories such as air conditioning units, awnings, heaters, winches, TVs and sound systems, refrigerators and other such items, consult the separate manufacturer’s owner’s manual you received with your trailer. And should there be a problem in workmanship or material, a service hotline is always open. Again, thank you for choosing a quality Pace American trailer! INTRODUCTION TO PACE AMERICAN THANK YOU FOR CHOOSING A PACE AMERICAN TRAILER USER’S GUIDE CONTENTS 4 3 GENERAL MAINTENANCE BREAKAWAY SYSTEM DOT regulations require that a trailer’s battery keep or hold the trailer from rolling forward for 15-minutes after stopping. Check the battery on a regular basis for adequate output and charge if necessary. The proper hookup for cable is to loop it around something permanent on the tow vehicle but not the ball hitch insert or hitch. If there is a failure of any of these THE BATTERY SUPPLIED WITH items, the plug pulls out of the switch THIS KIT IS RECHARGEABLE AND MUST BE MAINTAINED. and activates brakes. The plug must be pushed in completely so the brakes are not dragging. This will drain the battery if the pin remains pulled out. ROOF VENTS Roof vents on all Pace American trailers are designed to allow light into the trailer during the daytime along with fresh air. Also warm air will escape when the vent is open. However, your roof vent is not designed to be open when traveling. Make sure that all vents are closed prior to towing over the road. FRAME MAINTENANCE Cargo trailers take the worst kind of abuse on the underneath, frame side. Anything thrown up by the tow vehicle will chip away at the frame coating. It is suggested that inspections are made periodically and any bare spots be touched up with undercoating. • CHECK CONDITION OF BATTERY AND CHARGE PRIOR TO TRIP. • CHARGE BATTERY PER ENCLOSED INSTRUCTIONS. • DO NOT EXCEED 1.2 AMPS MAX. CHARGE. INLINE CHARGER IS AVAILABLE THROUGH PACE AMERICAN ROOF MAINTENANCE Inspect the roof coating once a year. Check for shrinking or cracked sealant that will lead to roof leak. Pace uses high quality self leveling caulk which is available through Pace or local RV dealers. Do not allow excessive snow build-up on the roof. Brush snow off of roof after a heavy snow. The excessive weight may damage trailer voiding warranty. Do not walk on trailer’s roof unless you ordered a trailer with extra support for that purpose. GENERAL MAINTENANCE EXTERIOR SKIN MAINTENANCE Clean exterior aluminum streaks with Black Streak Remover. Wash exterior often with a soft brush and a quality RV or Trailer Wash and Wax solution. • ALL FLOOR AND RAMP SURFACES ARE SLIPPERY WHEN COVERED WITH ICE, SNOW OR WET. FLOOR TREATMENT • TO PREVENT WARPING AND ROTTING OF FLOORING, REMOVE STANDING SNOW AND WATER AFTER EACH USE. To promote longevity and ease of • FOR BEST MAINTENANCE OF EXTERNAL FINISH, WASH ROAD SALT OFF TRAILER AFTER EACH USE. clean-up on your plywood floor we suggest painting it with a good quality oil-based porch and deck enamel. This will seal the floor and make oil clean-up and sweeping-out much easier. When parking trailer housing recently used snowmobiles, tilt the trailer and open doors to allow melted snow to run out. This will allow floor to dry. (continued) WHITE AND CHROME WHEEL MAINTENANCE Your new wheels do require care to maintain their factory appearance. We strongly suggest you take a few reasonable steps to protect your investment. Typical road soils trap moisture which can cause corrosion over a period of time. Brake dust is also corrosive and can cause pitting of the wheels finish. These soils must be removed regularly, possibly weekly, depending on your driving habits. After cleaning, always apply a coat of soft non-abrasive cream wax to help prevent surface corrosion. Surface corrosion or rust can be prevented with proper care and is not covered under warranty. ALUMINUM RIM MAINTENANCE Your wheels’ finish should be treated as you would treat the finish of your car. The aluminum rims are clearcoated to preserve the finish and ease the cleaning. Most household cleaning agents are too harsh for the finish on your wheels and must be avoided. Do not use any cleaning agent with a lye or acid base. The only factory-approved wheel cleaner is: Aluminum Wash and Brightener, Wheel Care Symbol F, by Eagle One. Always follow the manufacturer’s recommendations on the bottle for safe and effective cleaning. TIRES, RIMS AND LUGNUTS This trailer is equipped with quality • ON THE FIRST TRIP, TIGHTEN WHEEL LUGS AT START AND AT 10 MILES, 25 MILES AND AGAIN AT 50 MILES. tubeless tires. The recommended • THEREAFTER, CHECK WHEEL LUGS BEFORE EACH TRIP. air pressure is found on the tire • FOLLOWING WINTER STORAGE, CHECK BEFORE BEGINNING A TRIP. sidewall. Always replace tires with • FOLLOWING EXCESSIVE BRAKING, INSPECT WHEEL LUGS. the same designated type and size. It is extremely important to apply and maintain proper wheel mounting torque on your trailer axle. Torque is a measure of the amount of tightening applied to a fastener (nut or bolt) and is expressed as length x force. For example, a force of 90 pounds applied at the end of wrench one foot long will yield 90 GENERAL MAINTENANCE GENERAL MAINTENANCE 6 5 GENERAL MAINTENANCE (continued) lbs.-ft. of torque. Torque wrenches are the best method to assure the proper amount of torque is being applied to a fastener. NOTE: Wheel nut or bolts must be applied and maintained at the proper torque levels to prevent loose wheels, broken studs, and possible dangerous separation of wheels from your axle. Be sure to always use only the fasteners matched to the cone angle of your wheel (usually 60° or 90°). The proper procedure for attaching your wheels is: 1. Start all bolts or nuts by hand to prevent cross threading. 2. Tighten bolts or nuts in the following sequence. 1 1 1 4 3 6 6 3 3 8 5 2 5 BOLT 4 7 4 5 2 6 BOLT 8 BOLT GENERAL MAINTENANCE 1st Stage 20/25 ft. lbs. WHEEL TORQUE REQUIREMENTS AXLE WHEEL STUD SIZE SIZE SIZE 2000# 13" 1/2” 3500# 15" 1/2” 5200# 15" 1/2” 6000# 16" 9/16” 7200# 16" 9/16” 8000# 12"-16.5" 5/8” 8000# 17.5" 5/8” 2nd Stage 55/80 ft. lbs. STEEL WHEEL TORQUE 50#-75# 90#-120# 90#-120# 90#-120# 90#-120# 90#-120# 275#-325# Warranties on axles and trailer will not apply to damage or injuries caused by loose or improperly tightened lug nuts or broken studs. Inspect wheel stud holes for roundness. If oblong, this is a sure sign that the unit has been run with improperly tightened lugnuts. In these instances, the rim must be replaced. DOORS, BARLOCKS AND RAMP HINGES Door holdbacks are designed to hold doors open when on uneven ground. They are not designed to hold doors open under windy conditions. Lubricate all door and ramp hinges every 3 months with a SAE 30 weight engine oil. WD-40 and similar lubricants will free hinges, however, they will also lose all lubricating qualities within a short period of time. Use a conventional grease gun tip to apply grease at ramp hinges. 5 2 RIGHT 3. The tightening of the fasteners should be done in stages. Following the recommended sequence, tighten fasteners per wheel torque chart below. 4. Wheel nuts/bolts should be torqued before first road use and after each wheel removal. Check and re-torque after the first 10 miles, 25 miles, and again at 50 miles. Check periodically thereafter. TORQUE STAGES (continued) 3rd Stage Full Torque ALUMINUM WHEEL TORQUE N/A 90#-120# 90#-120# 90#-120# 90#-120# N/A N/A Parallel with ground and tow vehicle WRONG Trailer not level, adjust hitch HITCH HEIGHT You must adjust the hitch ball height to position tag trailers in a level condition. This loads the axles equally and gives a desirable tongue weight. Under these conditions your trailer should ride properly and not sway back and forth. COUPLER OPERATION Check the coupler or Kingpin for fatigue, damage, CHECK COUPLER SIZE cracks or missing parts before towing. Test the lock PRIOR TO HOOKUP mechanism for complete and correct latching so the trailer will not come unhooked. For ball type couplers, make sure the coupler and ball size match. If you are using a bumper hitch type coupler, it is recommended to put a bolt or similar device through the latch mechanism when hooking to the tow vehicle for safety. It is advised that mini fifth wheel hitches should have a wheel diameter that is close to the width of Pace American’s Pinbox. A smaller wheel diameter does not get adequate vertical support from the Pinbox and pushes the bottom plate upward. GENERAL MAINTENANCE GENERAL MAINTENANCE 8 7 Always refer to your car or truck manufacturer’s owner’s manual for additional trailer towing information and limitations. Class IV Weight-Distributing Hitch Class II Frame Hitch Class I Sportframe Class I Sportframe Minivans Full-Size Cars, Pick-ups Vans, Utility Vehicles Class II Frame Hitch Class I Sportframe Sportframe Deluxe Class II Frame Hitch Class IV 5,000–10,000 lbs. (GTW) 500–1,000 lbs. (TW) Class I 2,000 lbs. (GTW) 200 lbs. (TW) Class II 3,500 lbs. (GTW) 300 lbs. (TW) Mid–Size Cars/ Small Pick-ups YOU MUST HOOK TRAILER TO SECURE THE LOAD TOW VEHICLE WHEN LOADING, Motorcycles, cars and cargo should be ESPECIALLY WHEN LOADING secured in your trailer. Pace American offers TRAILER FROM THE REAR. various solutions and items such as wheel chocks, E-track and a variety of tie-down rings installed wherever you wish inside the trailer. Your trailer must be hooked to the tow vehicle when loading or unloading a car or heavy item from the rear. Inspect E-track and tie-downs regularly for cracks or damage that may weaken them or cause them to fail. TOW VEHICLES 70% OF WEIGHT TRAILERS 30% OF WEIGHT JUDGING TONGUE WEIGHT The desired hitch weight is 10% of the total loaded trailer weight. If scales are not readily available, you may estimate your total loaded hitch weight by comparing a known weight to the hitch weight. The proper way, however, to accurately measure tongue weight is by taking your loaded trailer to a local scale, such as those found at gravel companies or highway weigh station scales. Weigh the trailer and then the tongue separately and the tongue should be 10% of total loaded trailer weight. 10% tongue weight is necessary for safe towing and handling of trailer. To obtain the correct tongue weight, the trailer must be setting level to the ground. HITCH SELECTION CHART For a gooseneck type trailer you should load 70% of your cargo’s weight in the front of the trailer as depicted below This will put approximately 10% of the loaded trailer weight on the hitch. If there is insufficient or too much hitch weight, the trailer will not tow properly. Class IV Weight-Distributing Hitch Class V 10,000–14,000 lbs. (GTW) 1,400 lbs. (TW) (continued) LOADING TRAILER You should load 60% of your cargo’s weight in the front of the trailer. This will put approximately 10% of the loaded trailer weight on the hitch. If there is insufficient hitch weight the trailer will not tow properly. It could be unstable, difficult to control, and make towing unsafe. Proper weight distribution is imperative and diagramed below. 40% OF 60% OF Always secure trailer to tow vehicle WEIGHT WEIGHT when loading or unloading, especially from the rear of trailer. GENERAL MAINTENANCE HITCH SELECTION CHART GENERAL MAINTENANCE 10 9 ELECTRICAL AND WIRING GREEN Use 8ga for triple axle units 2 TRAILER CONNECTOR 2 3 3 BREAK-AWAY SWITCH TOW VEHICLE WIRING 110 VOLT POWER INLET 15 Amp Motorbase Extension Cord 30 Amp Motorbase NEMA L 530 30 Amp Lifeline NEMA 3830 Rcpt. 50 Amp Lifeline NEMA 3894 Rcpt. 4 ROADSIDE BRAKE ASSEMBLY 4 4 4 4 GROUND LEFT TURN RUNNING LIGHTS WHITE 1 YELLOW Use 10ga for single & tandem axle units YELLOW 1 BRAKE CONTROLLER BROWN RIGHT TURN Tow vehicles must have the correct plug at the hitch and be connected to the correct tow vehicle circuits using acceptable practices in wire routing and connections. Pace uses two different types of plugs. Trailers that are not equipped with brakes will have the 4-way 4-WAY PLUG flat plug like the wiring code pictured at right. TRAILER END All other trailers will have the larger 7-way plug which accommodates electric brakes and a separate line for inside lights. The inside lights are wired to the #4 post. THIS TRAILER IS EQUIPPED WITH 120 VOLT/60 HZ/AC (HOUSE CURRENT) ELECTRICAL POWER. UL APPROVED NON-METALLIC SHEATHED CABLE (IE. ROMEX) HAS The auxiliary center post is used for backup BEEN INSTALLED IN THE WALL/ROOF CAVITY OF THE TRAILER. PROCEED WITH CAUTION WHEN ATTACHING EQUIPMENT TO THE TRAILER OR CUTTING INTO THE lights or other special order/use wiring. ROOF OR WALLS OF THE TRAILER. IF YOU ARE IN DOUBT, CALL It is important to ground the wiring propPACE CUSTOMER SERVICE AT 1-800-247-5767 erly. The ground wire should run from the plug and attach to tow vehicle’s frame. Hitches, coupler/ball, safety chains and load leveling equalizer bars will NOT provide an adequate continuous ground and may result in electrical system failure. In addition, any hot line or auxiliary 4 3 line should be run with an in-line fuse. If an auxiliary battery is added to the trailer, 6 5 7 there must be a fuse installed between the battery and the load. 2 1 Pace recommends that a separate fused line be run from the tow vehicle’s battery, through a 20 Amp inline fuse, to an aftermarket toggle switch mounted on the TOW VEHICLE dash. This switch should have a 20 Amp capacity. Wiring RECEPT. WHITE 1 GROUND should be run from the switch to the #3 post for running BLUE 2 BRAKES lights. Newer vehicles’ wiring and headlight switches are GREEN 3 RNG LTS many times marginal and do not have the capacity to BLACK 4 HOT LINE carry the current required for larger trailers with lots of RED 5 L/H TURN BROWN 6 R/H TURN running lights. If your tow vehicle has amber turn signals, YELLOW 7 AUXIL. see your hitch & wiring specialist for installation of a relay or "splitter" to operate your trailer turn signals and brake lights. The hot line should have a 15 Amp in-line fuse installed between battery & tow vehicle plug. ELECTRICAL AND WIRING TOW VEHICLE WIRING 12 11 Trouble-free trailering depends upon proper bearing lubrication, maintenance and inspections. Bearings fail when lubrication fails or when improperly adjusted. In both cases, heat build up occurs. Normal bearing operating temperate is up to 140° and can be touched by hand without burning. Above this temperature, the grease will start INACTIVITY CAN to fail and destroy the bearings, drum and/or the BE MORE DAMAGING spindle. Brakes are designed to operate at up to TO BEARINGS THAN EVERYDAY USE 600°F. A good practice for both experienced and new trailer owners is to touch each hub within ten miles of starting out when bearings have been repacked and at each stop along the way. (Do not try testing the hub after several miles of continuous hard braking). This will give an advanced warning of pending trouble so corrections can be made prior to failure and breakdown. Remember, inactivity can be more damaging to bearings than every day use. When a trailer is parked, many times the spindle, bearings BEARING, RACE & SEAL NUMBERS Axle Size 2000# Brake Size N/A 14 1 2 3 11 4 5 10 5200# 6000# 7200# 8000# 10 x 2 12 x 2 12 x 2 12 x 2 121/4 x 33/8 1/4 1/2 Typical Bolt Pat. 5 on 4 ” Bolt Circle 5 on 4 ” Bolt Circle 6 on 5 “ Bolt Circle 8 on 6 ” Bolt Circle 8 on 6 ” Bolt Circle 8 on 61/2” Bolt Circle Inner Bearing L44649 L68149 25580 25580 25580 25580 Inner Race L44610 L68111 25520 25520 25520 25520 Outer Bearing L44649 L44649 LM67048 14125A 02475 02475 Outer Race L44610 L44610 LM67010 14276 02420 02420 1/2 1/2 1/2 1/2 1/2 GREASE SEALS 2000# 2500#/3500# 5200# 6000# 7200# 8000# — — — 442109 — — National NOK 13 2500#/3500# AD2548-EO — — — — Chicago Rawhide 533409 AD2267-EO — — — — — Dexter Replacements 010-019 010-036 010-036 010-063 010-063 Magnet Kit N/A K71-104 K71-105 K71-105 K71-441 K71-375 Shoe & Lining N/A K71-047 K71-048 23-105/23106 K71-048 23-105/23106 K71-410 23-105/23106 K71-049 LH 23-105/23106 Electric Brakes 23-26/23-27 All Parts are available through Pace American Corporate Pars Dept., Middlebury, IN at 800-247-5767 Exp3500 12 EXP3500.eps 9-28-94 4/4/96 1. Grease Seal for E-Z Lube TM 2. Inner Bearing Cone WHEEL BEARINGS Inner Bearing Cup 3,5003.lbs. 4. Outer Bearing Cup 5. Outer Bearing Cone 6. Special Jam Nut 7. Spindle Nut Retainer 6 7 8 8. Grease Cap for E-Z LubeTM 9. Rubber Plug for E-Z LubeTM 10. Spindle Washer 11. 1/2-20 Pressed Wheel Stud 12. Lug Nut 13. LH/RH Electric Brake 14. Hub/Drum 9 or hub is warm. As these cool down, a spot of condensation forms which is the start of a rust spot. The longer the trailer sits idle, the deeper this rust spot becomes. When in doubt of the coverage of grease on bearings—inspect and replace those that have rust spots, metal flaking, wear, cage damage or other visual damage. If you ever have questions regarding maintenance requirements or how to perform a maintenance task, please do not hesitate to contact us at our customer service hotline listed below or on the back of this manual. A Pace representative will be glad to answer your questions. Ask for a Customer Service Representative at: 1-800-247-5767 WHEEL BEARINGS WHEEL BEARINGS 14 1 2 7 8 REMOVE HUB ASSEMBLY Pry dust cap off with screwdriver. Straighten out tang washer. Remove spindle nut, tang washer and spindle washer. Pull hub toward you to loosen outer bearing. Do not let bearing fall. Pull the hub assembly off spindle. The inner bearing and seal will come with it. Pry out the inner seal and discard. The inner bearing will now come out. Caution- do not remove seal by hitting the inner bearing. INSPECT BEARING RACES (CUPS) AND HUB Inspect races for pitting, rusting, frosting, scoring, metal flaking and other obvious damage. If damaged, remove with brass bar or mild steel bar. Inspect race seat and remove any burrs or nicks that prevent the race from seating correctly. Replace races and bearings in sets. INSTALL HUB ASSEMBLY Slide the hub over the spindle with care not to damage the seal or spindle threads. Seat the hub against the seal journal. Insert the outer bearing, D-Shaped spindle washer, tang washer, and spindle nut. 3 4 9 CLEAN AND INSPECT THE SPINDLE Clean spindle with solvent to remove old grease. Inspect the spindle for nicks, scratches, scoring, damaged threads, or bending. File off nicks or burrs and smooth out with emory cloth. Apply thin film of bearing grease to spindle. CLEAN AND INSPECT BEARINGS (CONES) Clean bearings with solvent and long bristled brush. Do NOT use air pressure to clean out old grease or to dry. Allow to air dry. Inspect bearings for pitting, rusting, frosting, scoring, metal flaking, cage damage or other obvious damage. Replace all damaged bearings and mating races in sets. ADJUST BEARING Using a 12” wrench on the spindle nut apply 50ft-lb of torque at the same time the hub is rotated counterclockwise. Leave the hub stationary while backing off the spindle nut to relieve the preload torque. Then hand tighten 5 6 INSTALL RACE (CUP) Using a brass bar or a mild steel bar to drive in new race into hub until solidly seated against hub shoulder. Use caution to not damage race surfaces. Never use a bearing to drive a race. INSTALL GREASE SEAL Install new seals when they leak or when bearings are being visually inspected. Install inner bearing in hub, then the seal. Make sure the seal is installed correct side in. Use soft wood to seat seal in flush with hub. 11 FILL WITH GREASE Apply nozzle of grease gun to the grease zerk at the end of the spindle. Pump grease into the assembly until it comes out around the spindle washer. 10 the spindle nut to the first slot that lines up with a tang on the washer. Flatten the tang into the slot as far as it will go. Use caution that the tang is not fractured in this step. The correct adjustment for all bearings is .001 to .012 end play. 12 INSTALL DUST CAP Install dust cap with rubber plug. Care must be taken so that cap goes on evenly and is not crimped on inner lip. Cap is fully seated when rib on the cap is up against the hub all the way around. This prevents grease from being thrown out of hub onto the rim. WHEEL BEARINGS WHEEL BEARINGS 13 16 Actual unit or axle load ratings will be determined by the lowest rated component (Tire, Wheel, or Axle) 3695 Note: Load capacity limited to 4500 lbs. @ 125 PSI with Dexter 17-241 single wheel 215/75R17.5 The information shown above is valid only for trailer (ST) or light truck (LT) design tires. Passenger car tires (P designation) used in trailer service must be de-rated 10% from the maximum load capacity branded on the tire sidewall (branded load capacity divided by 1.10 equals the load capacity for trailer service.) 4340 4495 4650 4805(H) 4180 3860 4020 3415 3550 2485 2623(D) 2765 2905 3042(E) 3170 3300 2335 1700 1870 2030 LT235/85R16 2600 2090(B) 2270 2430 ST235/80R16 2205 2730 3000(D) 2380 2540(D) 2270 2150 1760 1880 2020 1480 1610 1720 1820(C) Note: capacity limited to 2150 lbs. @ 50 PSI when mounted on 5 bolt wheel 1600 1360 1260 ST225/75R15 1430 1070 ST205/75R15 1120 1430 1530 1640 1760(C) 1300 1030 ST205/75R14 1170 1480 1610 1720 1820(C) 1360 1070 F78-15 bias (ST205/75D15) 1120 1430 1530 1640 1760(C) 1300 1030 F78-14bias (ST205/75D14) 1170 1100 1190 1270 1360(C) 1000 905 795 B78-13 bias (ST175/80D13) 25 Note: Load range G tire requires compatible wheel, cannot be used with standard 16" wheels 1045(C) 840(B) 5.30-12 bias EZ-LUBE HUBS See EZ-Lube Hub instructions in Dexter service manual. Lube hubs every 12 months or 12,000 miles. Check the Dexter Service Manual for recommended wheel bearing lubrication specifications. PSI 20 Spring Loaded Double Lip Seal TIRE SIZE TRAILER BRAKES Grease Zerk Metal End Cap 3675 3750(G) 125 115 110 105 100 95 90 85 80 75 70 65 60 55 50 45 40 30 Grease Flow 35 Rubber Plug (Letters in parenthesis denote load range for which BOLD FACE loads are maximum) Outer Bearing & ADJUSTMENT SEE ENCLOSED DEXTER SERVICE MANUAL. Inner Bearing TIRE LOAD LIMITS (LBS) AT VARIOUS INFLATION PRESSURES (PSI) COLD See your hitch specialist for your brake controller. They will provide a brake controller manual which gives information on proper controller adjustments. Load and road conditions will require different sensitivity settings of the controller. Heavy loads will need maximum sensitivity as opposed to an empty trailer which will require a very light braking action. *FOR ADDITIONAL SERVICE MATCH AIR PRESSURE & TIRE CAPACITY TO WEIGHT ON AXLES 1.) Jack up trailer and secure on adequate capacity jack stands. Lifting and supporting must be on the main I-beams or the perimeter tube frame that the axle is attached to. Check that the wheel and drum rotates freely. 2.) Remove the adjusting hole cover from the adjusting slot on the bottom of the brake backing plate. 3.) With a screwdriver or standard adjusting tool, rotate the starwheel of the adjuster assembly to expand the brake shoes. Adjust the brake shoes out until the pressure of the linings against the drum makes the wheel very difficult to turn. 4.) Now rotate the starwheel in the opposite direction until the wheel turns freely with a slight lining drag. Usually 8 clicks. 5.) Replace the adjusting hole cover and lower the wheel to the ground. 6.) Repeat the above procedure on all brakes. 120 Brakes must be adjusted after the first 200 miles of operation when the brake shoes and drums have seated. After the initial adjustment the brakes should be readjusted at 3000 mile intervals or as use and performance requires. The brakes should be adjusted in the following manner: TIRE LOAD LIMITS TRAILER BRAKES –BRAKE ADJUSTMENT* USE ONLY APPROVED TIRE AND WHEEL COMBINATIONS. FAILURE TO DO SO OR FAILURE TO COMPLY WITH LOAD AND INFLATION LIMITS MAY RESULT IN SERIOUS INJURY OR DEATH. 15 18 17 TONGUE JACKS FOR BUMPER- PULL MODELS If your trailer was ordered with a vendor door(s), it may have the ratchet style door prop to open the door. The operation of this type of prop is to swing the door open until the ratchet system engages and holds the door open. There will be a safety pin provided for each door prop that must be installed. This ensures the door will not come down. To release the prop system, first remove the safety pin, then lift the door slightly to release the ratchet assembly system. If the door is SAFETY PINS ARE PROVIDED FOR USE ON pulled downward without first lifting, the THE VENDOR DOOR PROPS. WHEN IN THE OPEN POSITION, SAFETY PIN SHOULD BE ratchet system will be damaged. INSERTED THROUGH THE INNER AND Pace American also offers the OUTER SLIDES TO PREVENT INADVERTENT UNLATCHING OF THE PROP. option of gas shocks to assist in the opening of the vendor door, especially helpful with heavier, large doors. After unlatching the door, install one end of each of the pipe-style props provided into the “camel back” bracket mounted on the lower side of the vendor door. One prop goes on each end of the door. After installing both props onto the vendor door, lift the door and allow the gas shocks to push up to the full open Pace American uses two types of manual tongue jacks. Lubrication and proper maintenance of jacks will enhance jack life and make operation smoother. The two types that Pace American uses are: 1) the side-wind model and 2) the top-wind model. The internal gearing and bearings of the jack must be kept lubricated. Using a needle nose applicator, pump a small amount of automotive grease through the lubrication opening. The lubrication opening can be found on the side of the jack tube, directly below the handle. Rotate the jack handle to distribute the grease evenly. Lightly grease the inner tube of the jack using the same type of grease. A lightweight oil must also be applied to the handle unit at both ends of the outer tube. The top-wind jack has an access hole on the front side that will allow oil to be sprayed into the threaded rod. By using a product similar to ANTI-SEIZE TECHNOLOGY’s product no. 17061, you will be able to free up rusty and corroded parts, and it leaves a protective anti-rust film. Some sprayon lubricants will only provide short term lubrication and will need to be reapplied more frequently than once a year. VENDOR DOORS AND TONGUE JACKS FIFTH WHEEL AND GOOSENECK LANDING GEAR The vendor door on the left is held open by a ratchet style prop that requires a safety pin. The swing-out arm is shown on the right. position. Next, install the bottom end of the pipe props into the “camel back” brackets mounted on each side of the opening. Use of these pipe props ensures the doors will not close due to high wind when people may be standing underneath the vendor door. To close doors, unfasten the lower end of the pipe props and pull the door down by using the pipe props. These kinds of trailers are equipped with a two-speed, twin landing gear. Low speed eases the raising of the unit. High speed will rapidly retract the legs into the travel position. The shaft that the crank handle attaches to is what accomplishes this gear change. Pushed IN sets the high speed operation while pulling OUT is low speed. If you have questions, please contact us at the Customer Service Hotline toll-free number: 1-800-247-5767. TONGUE JACKS AND LANDING GEAR VENDOR DOORS 20 19 TRAILER TOWING SAFETY TIPS INSTABILITY Swaying (or whipping) of a tow vehicle/trailer combination at low speeds may get worse as speed increases. If this happens, take your foot off the gas pedal. Steer straight ahead while manually applying the trailer brakes. Then brake gently after the combination has begun to stabilize itself. Stabilizer or weight NEVER INCREASE SPEED WHEN TRAILER equalizing bars will help reduce trailer sway and may IS SWAYING also be required by law in some states. OR WHIPPING Check cargo first to be sure that the trailer is loaded heavier in the front. If not, reposition the load so you get 10% of the total trailer weight on the tongue. Next, make certain the rear of the tow vehicle is not overloaded. Then check for wheel wobble on both vehicles caused by bearing failure, loose lug nuts or loose spindle nuts. Now check the tow vehicle’s suspension alignment. Finally, make sure that you are not exceeding the recommended maximum speed limit for safety and IT’S THE LAW. If the above instructions have been followed, instability should now be corrected. If not, something may be wrong with your tow vehicle. TIPS FOR THE BEGINNER (ALSO SEE HITCHING UP ON P. 21) Place your hand at the bottom of the steering wheel. While watching in your outside mirrors, if you want the rear of the trailer to go to the right, move your hand to the right. If you want the rear of the trailer to go to the left, move your hand to the left. If the trailer starts to jackknife—STOP—pull ahead to straighten out then start procedure over again. When making turns, be aware the trailer will turn quicker than a tow vehicle. Allow extra turning space so that the trailer wheels don’t jump over a curb, hit a soft shoulder, road sign or tree. TRAILER TURNS QUICKER THAN TOW VEHICLE. Your axle and/or tire and rim can be severely damALLOW EXTRA TURNING aged as a result or from hitting the curb at a bad SPACE FOR TRAILER. angle and too hard. CHECK YOUR POLICY Most automobile and some homeowners insurance policies will provide some coverage for cargo trailers. They should also provide for you a “grace period” of a set number of days from the date of purchase. Call your agent. HITCH AND BRAKE SAFETY For safe towing it is the trailer owner’s responsibility to CORRECTLY MATCH the combination of tow vehicle and trailer. 1. MATCH the maximum trailer weight allowed for the tow vehicle to the GVWR of the trailer. 2. MATCH the hitch weight carrying capacity of the tow vehicle with the loaded tongue weight of the trailer. This is generally 10% of GVWR on tag models and 20% of GVWR on 5th wheels and Goosenecks. Tag models may require a weight distributing hitch with sway controls. Contact your hitch specialist to properly set up your tow vehicle/trailer combination. 3. MATCH the size of the brake controller to the number of braking wheels on your trailer. These are sold usually as 2 to 4 wheel brake or 2 to 6 wheel brake units. For proper controller adjustment, see your brake controller manual. 4. MATCH the wiring of the tow vehicle to the wiring code on the trailer. Ensure your tow vehicle does have a ground wire running from the receptacle to the frame. 5. MATCH the ball size to the coupler size. 6. MATCH your Fifth Wheel or Gooseneck trailer to a correct and compatible hitch provided by your hitch specialist. Then consult your hitch specialist for proper maintenance of the hitch assembly. 7. Match your rear vehicle suspension to the loaded hitch weight of the rear axle of the tow vehicle. All marginal situations should be corrected for safe trailering. Remember, you are the one that will be trying to control a large combination of weight and size at high speeds. It is your responsibility to set up tow vehicle/trailer properly. Contact or confirm your set up with a local hitch company professional. GROSS TRAILER WEIGHT (GTW) & TONGUE WEIGHT (TW) Class I Class II Class III 2,000 lbs. (GTW) 200 lbs. (TW) Compact Cars 3,500 lbs. (GTW) 300 lbs. (TW) Mid Size Cars & Small Pick Ups 3,500–5,000 lbs. (GTW) 300–500 lbs. (TW) Minivans Class III Class IV Class V 4,000 lbs. (GTW) 350 lbs. (TW) Mid Size Cars Small Pick Ups Minivans 5,000–10,000 lbs. (GTW) 500–1,000 lbs. (TW) Pick Ups SUV's 14,000 lbs. (GTW) 1,700 lbs. (TW) 20,000 lbs. (GTW) 2,000 lbs. (TW) Also see Hitch Selection chart on page 8 TRAILER TOWING SAFETY TIPS TRAILER TOWING SAFETY TIPS 22 21 TRAILERING TACTICS* Hitching up a trailer to your tow vehicle is usually a one-person job, but it is easier if someone helps you. Here are a few of the basic steps: With a trailer in tow, you’re operating a vehicle combination that is longer, heavier and sometimes wider and taller, than you’re used to. So you’ll have to make some compensating adjustments in your normal driving practices. The following is advice in trailering tactics: 1. Back your tow vehicle as close as possible to the trailer. It is easier and safer to do this than it is to pick up and pull the trailer to your car or truck. 2. Release the coupler locking device. 3. Raise the front end of the trailer. Place coupler directly over the hitch ball then lower it until it is seated on the hitch ball, covering it completely. 4. Check under the coupling to ensure the ball clamp is below the ball and not riding on top of it. 5. Latch the coupler to the hitch ball. Make sure it is locked in place by lifting up the trailer tongue. If the coupler comes loose form the ball, unlatch it and go back to Step 3. 6. Make sure your jack is fully raised. HITCHING UP YOUR TRAILER 7. If you have a weight distributing hitch with spring bars, follow the above procedures. Then attach the spring bar chain to the trailer and tighten it until your trailer and car are in a normal, level position. 8. If your trailer has a surge brake breakaway cable or chain, attach the cable or chain to your tow vehicle, allowing enough slack for you to make tight turns. Take a “Shakedown Cruise”. At least one short trial run before your first trip will help familiarize you with your trailer’s operating characteristics. It will also allow you to check the trailer’s lights, brakes, hitch, etc., and let you know they are all working properly. Slow down. Moderate to slower driving speeds put less strain on your tow vehicle and trailer and make for safer traveling. Allow extra time and space between your rig and traffic. You will need both when passing and stopping, especially if your trailer is not equipped with brakes. Check rear view mirrors. Doing this frequently will let you know that your trailer is riding properly. We recommend outside rear view mirrors on both sides of your tow vehicle. Swing wider. You need to make wider swings (turns) at curves and corners because your trailer’s wheels are generally closer to the inside of a turn than the wheels on your tow vehicle. Pass with extra care and caution. It takes more time and distance to get around a slower vehicle and return to the correct lane when you’ve got a trailer in tow. 9. Attach the safety chains as described on page 22. 10. Connect the trailer wiring harness to the lighting system of your tow vehicle and check its operation (also see page 9 in this manual for details). * Hitching Up courtesy of REESE PRODUCTS, INC. Watch the wind direction and speed. To avoid swaying, be prepared for sudden changes in air pressure and wind buffeting when larger vehicles pass from either direction. Slow down a bit and keep a firm hold on your steering wheel. Aim straight down your lane. Conserve fuel. You’ll go farther on a tank of gas at moderate speeds. Higher speeds increase wind resistance against the trailer and reduce fuel mileage. TRAILERING TACTICS HITCHING UP YOUR TRAILER* 24 23 Avoid sudden stops and starts. This can cause skidding, sliding, or jackknifing, even if your trailer has brakes. Avoid quick stops while turning. Smooth, gradual starts and stops will improve your gas mileage. Signal your intentions. Let surrounding vehicles know what you intend to do well in advance before you stop, turn, change lanes, or pass. Shift to a lower gear. A lower gear will help ease the load on the transmission and engine when going over steep hills, sand, gravel, or dirt roads. If your tow vehicle has an “overdrive” gear, shifting out of overdrive to a lower gear may improve your gas mileage. Always be courteous. Make it as easy as possible for faster moving vehicles to pass you. Keep to the right of the road and prepare to slow down if passing vehicles need extra time to return to their proper lane. TRAILERING TACTICS Don’t tailgate. Allow at least one car and trailer length between you and the vehicle ahead for each 10 mph on your speedometer. Three seconds should be the minimum distance. If a problem occurs don’t panic. Stay calm and cool. Say you experience a sudden bumping or fishtailing. It may indicate a flat tire. Don’t jam on the brakes or mash the accelerator in an attempt to drive out of it. Instead, come to a stop slowly as you keep driving in as straight a line as possible. If conditions permit, coast to a very slow speed and try to avoid braking, except when your wheels are straight ahead and your trailer and tow vehicle are in line with each other. If your trailer begins to fishtail as you accelerate to highway speed, back off the accelerator a bit. This should stop the fishtailing. If it begins again as you increase speed, stop and check you load. It probably isn’t distributed evenly from side to side, or it is too far back to put a sufficient load on the hitch ball. It is recommended that 10% of the trailer load be on the hitch. (See page 19 for more details). Redistribute the load as necessity dictates before continuing on the highway. * Trailering Tactics courtesy of REESE PRODUCTS, INC. SAFETY CHECKLIST ❏ Maintenance Checklist (Up to Date) ❏ Hitch Ball Tight ❏ Hitch Ball Lubricated ❏ Hitch Secured in Receiver ❏ Safety Chains Crossed and Attached* ❏ Coupler Latched onto Ball ❏ Load Distributed Correctly and Securely ❏ Trailer Level when Hooked Up ❏ Trailer Lights Working Correctly ❏ Lug Nuts Checked and Tightened ❏ Inspect Tires for Cuts ❏ Tire Pressure Checks ❏ Breakaway Battery Charged ❏ Breakaway Cable Hooked Up ❏ Pin or Bolt through Coupler Latch ❏ Block Tires when Loading and Unloading * If safety chains are too long, twist to shorten. THE MAIN CAUSES OF TRAILERING ACCIDENTS 1. Driver error. 2. Failure to MATCH speed with weather and road conditions. 3. Trailer sway due to improper loading — more or less than 10% cargo hitch weight. 4. Failure to perform routine maintenance. Remember, never carry passengers in trailer while moving. Check hub temperature at each stop. Adjust sensitivity of brake controller to match load. 102" axles are legal on all Federally-funded highways (and some state highways). SAFETY CHECKLIST TRAILERING TACTICS* ( continued) 26 25 FACTORY SERVICE Call the Customer Service Hotline for your nearest Pace American factory location to schedule quality factory service, retrofitting, reskining, accident repairs or any other service your dealer can’t do. And let Pace handle the jobs your dealer may not want to do. Whatever it takes, Pace is dedicated to your complete satisfaction. Replacement parts are available through Pace. Call your authorized dealer or the nearest Pace American manufacturing plant. Be prepared to give the following information including everything listed on the Trailer Information Form located opposite this page: VIN and Model Number: TRAILER INFORMATION FORM / Description of Part, Size, Color, Location on trailer, etc.: Most small parts are shipped via ground UPS. All larger parts orders will be crated and shipped by truck freight lines. CUSTOMER SERVICE HOTLINE 1-800-247-5767 Fill in the information form below for future use. This critical information should be used for quick reference when ordering genuine Pace American replacement parts, factory service or refer to it if you should have a warranty claim. Keep it handy so Pace American can serve you promptly and efficiently. Owner: Address: City: State: Zip: City: State: Zip: Model No: Tire Size: Date Purchased: Dealership: Dealership phone number: PACE REPLACEMENT PARTS Address: Serial (VIN) No: Color Name: (from copy of order) Hitch Size: TRAILER INFORMATION FORM GENUINE PACE AMERICAN REPLACEMENT PARTS AND ACCESSORIES 28 27 ITEM COUPLER EVERY 3000 MI REQUIRED TRIP 3 MONTHS CHECK FOR FATIGUE & • 6 • 23 • 3 • 4-5 • 7 • 10 LATCHING OPERATION SAFETY CHECK FOR DRAGGING & CHAINS POSSIBLE STRENGTH LOSS BREAKAWAY SYSTEM LUGNUTS PIGTAIL LIGHTS & SWITCH OPERATION CHECK FOR CORRECT TORQUE CHECK FOR DRAGGING & STRESS CHECK THAT ALL ARE OPERATING CHECK FOR CORRECT TORQUE & ELONGATION OF BOLTS THE SHACKLE LINK HOLES CHECK PRESSURE & UNUSUAL WEAR BEARINGS REPACK HINGES LUBRICATE STABILIZER LUBRICATE JACK-SCREW THREADED ROD HYDRAULIC CHECK FLUID FLUID LEVEL ROOF INSPECT FOR CRACKS SEALANT OR DRYING OUT JACKS BRAKES 12000 MI PG CABLE FOR DAMAGE AXLE & WHEELS 6000 MI 6 MONTHS 12 MONTHS # CHECK BATTERY CHARGE SPRING TIRES MAINTENANCE SCHEDULE FUNCTION INSPECT FOR CRACKS INDENTATIONS • • 4 • • 6 • OPERATION BRAKE ADJUST FOR OPTIMUM ADJUSTMENT PERFORMANCE INSPECT FRAME WELDS CHECK FOR CRACKING 22 • • • 3 4-6 • LUBRICATE CHECK FOR 11-14 • 22 15 • 15 • DATE MILES SERVICE PERFORMED MAINTENANCE RECORD MAINTENANCE RECORD MAINTENANCE SCHEDULE 30 29 NOTES THREE YEAR LIMITED WARRANTY The Pace American, Inc. subsidiary whose name appears on your “Certificate of Origin” (PACE AMERICAN) warrants to the original owner that your PACE AMERICAN trailer will be free from defects in materials and workmanship for the period of three (3) years except as herein limited, from the date of the first retail purchase provided all stated conditions and exclusions are met and satisfied. The obligation of this warranty shall be limited to repairing or replacing any part or parts which, in the opinion of the factory are defective in materials or workmanship under normal use and service during the three(3) year period commencing with the date of the first retail purchase. Electrical components, lights, mechanical jacks, fiberglass, doors, sealants, seals, locks, couplers, and paint are warranted for a one (1) year period from the date of the first retail purchase, subject to the limitations contained in this limited warranty. WARRANTY VALIDATION A warranty registration certificate is included with the dealer paperwork. The dealer must fill out and mail this certificate to the factory within ten (10) days after making delivery of the trailer. This purchaser record is required by federal law. Failure to fill out and return this warranty registration certificate within the above period will automatically void the warranty. HOW TO OBTAIN WARRANTY SERVICE 1. All warranty requests must be presented to PACE AMERICAN and proper arrangements must be made and approved by the factory prior to any work being done. 2. All warranty repairs must be made at the PACE AMERICAN factory, unless prior written approval is obtained from the factory before said repairs begin. In certain cases, the PACE AMERICAN factory may, at its option, elect to have warranty work performed in the field by a qualified repair shop. 3. PACE AMERICAN will not be obligated in any way to pay for repairs made without specific written approval in advance, repairs made in any manner other than that approved by PACE AMERICAN, labor charges in excess of those deemed reasonable by PACE AMERICAN or any parts, bills in excess of the cost if PACE AMERICAN had supplied those parts. Labor and parts charges for any covered warranty work are limited to the amount charged by PACE AMERICAN for such labor and/or parts. 4. Except as described in this limited warranty, PACE AMERICAN will not pay any other charge or expenses including, without implied limitation, any charges for overtime labor, service calls, towing charges or transportation costs. Such charges or expenses are the responsibility of the customer and will not be paid for by PACE AMERICAN. WHAT IS NOT COVERED BY THIS LIMITED WARRANTY 1. Items covered by another warranty: Any claims on items that are covered by their manufacturer’s warranty must be presented to those manufacturers for adjustment. The following items would be subject to the manufacturer’s warranty, including, but not limited to: a. Axles and axle components including, without implied g. Winches. o. Stove/Cook Tip limitation, tow in/tow out and camber on axles. h. Electric Jacks. p. Microwave b. Tires: present a claim for tire adjustments to a tire dealer who handles i. Hydraulic Jacks. q. Furniture the brand in question and is authorized to make the adjustments. j. Food Service Equipment. r. Water Pump c. Rims. k. Beverage Equipment. s. TV, VCR, Stereo Equipment d. Air Conditioners. l. Water Heaters. t. furnaces e. Generators. m. Refrigerators. f. Awnings. n. Landing Gear. Subject to the other terms of this limited warranty, PACE AMERICAN warrants the proper installation of the above listed items. 2. Tow vehicle wiring. 3. Damage or wear caused by unreasonable use or failure to provide reasonable and necessary repairs or maintenance. 4. PACE AMERICAN will not be responsible for work performed or options installed by others. Customer will be charged for any labor, material, or parts resulting from work performed or options installed by others, including without implied limitation: a. Graphics. b. Special Awnings. c. Hydraulic Lift Systems. 5. Damage or defects resulting from or repairs required because of misuse including, but not limited to, overloading (as determined by the gross vehicle weight rating and not payload capacity as shown on the vehicle identification label), improper loading, negligence, alteration, accident, or lack of reasonable and proper maintenance. 6. Replacement of maintenance items that are worn out from normal use, including but not limited to bearings, magnets and brake shoes. 7. Deterioration of paint and appearance due to use and exposure. 8. Damages caused by loose or improperly torqued lug nuts. 9. Damages caused by the use of an incorrect or altered hitch ball or improper latching. 10. Damages caused by loose nuts, bolts or screws. Maintaining necessary tightness of these items is the owner’s responsibility. 11. Loss of time, inconvenience, loss of use of trailer, rental of substitute equipment, loss of revenues, or other commercial loss. 12. Trailers covered by this warranty are designed to be towed by a vehicle with up to one (1) ton capacity. 13. At no time should a towing vehicle be used with a trailer that exceeds the tow vehicle manufacturer’s specific limitations. 14. Tow vehicle wear. ANY EXPRESSED OR IMPLIED WARRANTY NOT PROVIDED HEREIN, INCLUDING WITHOUT IMPLIED LIMITATION, ANY WARRANTIES OF MERCHANT-ABILITY OR FITNESS FOR A PARTICULAR PURPOSE, AND ANY REMEDY FOR BREACH OF CONTRACT, WHICH BUT FOR THIS PROVISION MIGHT ARISE BY IMPLICATION OF OPERATION OF LAW, ARE HEREBY EXCLUDED AND DISCLAIMED. IF THEY CANNOT BE DISCLAIMED, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND OF FITNESS FOR ANY PARTICULAR PURPOSE ARE EXPRESSLY LIMITED TO A TERM OF ONE YEAR. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. UNDER NO CIRCUMSTANCES SHALL PACE AMERICAN BE LIABLE TO PURCHASER OR ANY OTHER PERSON FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, WHETHER ARISING OUT OF BREACH OF WARRANTY, BREACH OF CONTRACT, TORT OR OTHERWISE. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE. WARRANTY NOT WITHSTANDING ANYTHING TO THE CONTRARY HEREIN, THIS LIMITED WARRANTY IS LIMITED TO REPAIR OR REPLACEMENT AND IF SUCH WARRANTY FAILS BECAUSE ATTEMPTS AT REPAIR ARE NOT COMPLETED WITHIN A REASONABLE TIME, OR IT FAILS FOR ANY OTHER REASON, ANY DAMAGES ARE LIMITED TO THE LESSER OF EITHER THE COST OF NEEDED REPAIRS OR REDUCTION IN THE MARKET VALUE OF THE TRAILER CAUSED BY THE LACK OF REPAIRS, IN ANY CASE. The factory neither assumes nor authorizes any other person to give any other warranty or to assume on its behalf any other obligation or liability. This warranty is non-transferable from original owner. MODEL NO.: DATE PURCHASED: VIN NO.: DEALER: ADDRESS: Reporting Safety Defects Pace American, Inc. 11550 Harter Drive, Middlebury, IN 46540 If you believe that your vehicle has a defect which could cause a crash or could cause injury or death, you should immediately inform the National Highway Traffic Safety Administration (NHTSA) in addition to notifying Pace American, Inc. If NHTSA receives similar complaints, it may open an investigation, and if it finds that a safety defect exists in a group of vehicles, it may order a recall and remedy campaign. However, NHTSA cannot become involved in individual problems between you, your dealer, or Pace American, Inc. To contact NHTSA, you may either call the Auto Safety Hotline toll-free at 1-800-4249393 (or 366-0123 in Washington, DC area) or write to: NHTSA U.S. Department of Transportation 400 7th Street SW, (NSA-11) Washington, DC 20590 You can also obtain other information about motor vehicle safety from the Hotline.