Download POLAR INSTRUMENTS Toneohm 950 Service

Transcript

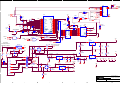

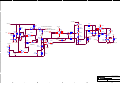

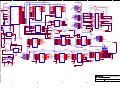

Polar Instruments Ltd. Garenne Park St. Sampson Guernsey Channel Islands GY2 4AF ENGLAND http://www.polar.co.uk Fax: +44 (0)1481 252476 Email: [email protected] MAN130–2011 TONEOHM 950 SERVICE MANUAL TONEOHM 950 SERVICE MANUAL POLAR INSTRUMENTS LTD. HARDWARE WARRANTY 1. Product Warranty. Product hardware is warranted to be free from defects in material and workmanship during the Warranty Period (as defined below). Product hardware is warranted to conform substantially to Polar’s then current (as of the date of Polar’s product shipment) published user documentation during the Warranty Period. The Warranty Period is twelve (12) months. Product support beyond these periods may be available at additional cost – consult Polar for details. 2. Warranty Claims. Polar shall incur no liability under this warranty if the end user fails to provide Polar with notice of the alleged defect during the applicable Warranty Period and within seven (7) days of delivery to end user or, if the defect would not have been reasonably apparent on inspection, within seven (7) days of its discovery by end user. After receiving such notice, Polar will notify the purchaser of its designation of one of the following problem resolution methods: Return to Factory: The allegedly defective goods must be returned to Polar within seven days of Polar’s notice and in accordance with Polar’s instructions advised at the time. Other: Polar will use commercially reasonable efforts to repair, correct or work around the problem by means of telephone support or other means reasonably determined by Polar. Polar shall incur no liability under this warranty if Polar’s tests disclose that the alleged defect is due to causes not within Polar’s reasonable control, including alteration or abuse of the goods. Under the Return to Factory alternative, if a Product is determined not to be defective or to have a defect due to causes not within Polar’s reasonable control, Polar reserves the right to apply a processing charge. 3. Damage in Transit. End user must notify Polar and the carrier of any claim for damage in transit within two (2) days of receipt of the damaged merchandise. Failure to do so may result in the carrier and/or Polar refusing to accept liability in which case end user must pay the purchase price as if the hardware had been delivered without damage. 4. Polar’s Liability Polar’s liability, and end user’s sole and exclusive remedy, shall be limited to the express remedies set forth in this Polar Hardware Warranty. 5. Disclaimer of Warranties. POLAR MAKES NO OTHER WARRANTIES, EXPRESS, IMPLIED OR STATUTORY, REGARDING PRODUCTS. ALL OTHER WARRANTIES AS TO THE QUALITY, CONDITION, MERCHANTABILLITY, FITNESS FOR A PARTICULAR PURPOSE, OR NON-INFRINGEMENT ARE EXPRESSLY DISCLAIMED. 6. Limitation of Liability. POLAR SHALL NOT BE RESPONSIBLE FOR DIRECT DAMAGES IN EXCESS OF THE PURCHASE PRICE PAID BY THE END USER OR FOR ANY SPECIAL, CONSEQUENTIAL, INCIDENTAL, OR PUNITIVE DAMAGE, INCLUDING, BUT NOT LIMITED TO, LOSS OF PROFITS OR DAMAGES TO BUSINESS OR BUSINESS RELATIONS, WHETHER OR NOT ADVISED IN ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES, THE FOREGOING LIMITATIONS SHALL APPLY, NOTWITHSTANDING THE FAILURE OF ANY EXCLUSIVE REMEDIES. DECLARATIONS DECLARATIONS European Community Directive Conformance Statement Refer to the Operator Manual to determine conformance with European Community Directives. v TONEOHM 950 SERVICE MANUAL SAFETY WARNING The service instructions contained in this manual are for use by qualified electronic service personnel only. WARNING The LIVE and NEUTRAL lines on this unit are BOTH fused. When the unit is connected to its supply, the opening of covers or removal of panels is likely to expose dangerous voltages. GROUNDING This unit must be earthed (grounded); do not operate the instrument with the safety earth disconnected. Ensure the instrument is connected to an outlet with an effective protective conductor terminal (earth). Do not negate this protective action by using an extension cord without a protective conductor. Note: This instrument is fitted with 3-wire grounding type plug designed to fit only into a grounding type power outlet. If a special local plug must be fitted to the power cord ensure this operation is performed by a skilled electronics technician and that the protective ground connection is maintained. The plug that is cut off from the power cord must be safely disposed of. Power cord color codes are as follows: Europe brown blue green/yellow live neutral earth (ground) United States black white green live neutral ground POWER SUPPLY Check that the indicated line voltage setting corresponds with the local mains power supply. See the rear panel for line voltage settings. Instruments with a serial number prefixed with a letter (e.g. A1234) are configured for 90 – 110 Volts only. Changing the line voltage settings on this instrument must only be performed by a skilled electronics technician. Instructions for changing the line voltage settings are contained in Section 5. vi SAFETY OPERATION This manual contains instructions and warnings which must be observed by the user to ensure safe operation. Operating this instrument in ways other than detailed in this manual may impair the protection provided by the instrument and may result in the instrument becoming unsafe. Retain these instructions for later use. The unit is designed for use indoors in an electrical workshop environment at a stable work station comprising a bench or similar work surface. Use only the accessories (e.g. test probes and clips) provided by Polar Instruments. The instrument must be maintained and repaired by a skilled electronics technician in accordance with the manufacturer’s instructions. If it is likely that the protection has been impaired the instrument must be made inoperative, secured against unintended operation and referred to qualified service personnel. Protection may be impaired if, for example, the instrument: • • • • • Shows signs of physical damage Fails to operate normally when the operating instructions are followed Has been stored for prolonged periods under unfavourable conditions Has been subjected to excessive transport stresses Has been exposed to rain or water or been subject to liquid spills CAUTION Electrical Isolation Always disconnect the board under test from the local mains supply (including ground) before using this instrument. Static Sensitive Devices This unit contains Static Sensitive Devices. Static discharge can damage some electronic components. Care must be taken when handling these components. Observe appropriate precautions to avoid damage. vii TONEOHM 950 SERVICE MANUAL SPECIFICATIONS Track Resistance RANGES ACCURACY [Ω] RANGE PROBE VOLTAGE INDICATION PROBE PROTECTION Track Current RANGES ACCURACY [Ω], 200mΩ, 2Ω, 200Ω, 20KΩ. Instruments with serial numbers below 005975 have a 2KΩ range instead of 200Ω. ±6% in 200mΩ, ±5% in 2Ω ±4% in 200Ω, ±5% in 20KΩ High sensitivity, uncalibrated. Approximately 40mΩ full scale. 60mV maximum. Tone and meter in all ranges. Momentary contact up to 250V. 200mA, 2A, TRACE. ±15% in 200mA, 2A for track resistance between 25mΩ and 500mΩ. Reading proportional to current when UNCALIBRATED LED is lit. UNCALIBRATED LED lit during ranging. TRACE SENSITIVITY PROBE VOLTAGE INJECTION CURRENT INDICATION PROBE PROTECTION Track Voltage RANGES ACCURACY INPUT RESISTANCE INDICATION PROBE PROTECTION Plane Shorts INDICATION SENSITIVITY Plane Stimulus OUTPUT VOLTAGE OUTPUT CURRENT PROTECTION viii Reading in TRACE is proportional to detected magnetic field strength. Capable of detecting current flow with 200Ω resistance across Drive Source. 600mV maximum in 200mA, 2A. Not applicable in TRACE. 250mA maximum. Not applicable in TRACE. Tone and meter in all ranges. Momentary contact up to 250V in 200mA, 2A. Not applicable in TRACE. 2mV, 20mV, 20V. ±4%, ±15µV. 120Ω in 2mV, 20mV. 1MΩ in 20V. Meter in all ranges. Tone in 2mV, 20mV. Momentary contact up to 250V in 20V. 30V in 20mV, 2mV. Tone, uncalibrated meter and fault direction arrows. Adjustable for differing plane resistance. Capable of detecting shorts up to 20Ω. 550mV maximum. Active only when PLANE SHORTS is ACTIVE and outputs are connected to a plane. 700mA RMS maximum. Each output separately fused (5A Fast). SPECIFICATIONS Drive Source OUTPUT VOLTAGE 0 to 550mV, adjustable. AC in TRACE, DC in all other ranges. Protected to ± 30V. PROTECTION ENVIRONMENTAL OPERATING CONDITIONS The instrument is designed for indoor use only under the following environmental conditions: Altitude Temperature Relative humidity Mains borne transients Pollution Degree Up to 2000m +5°C to +40°C ambient RH 80% maximum at 31°C — derate linearly to 50% at 40°C As defined by Installation Category II (Overvoltage Category II) in IEC664 2 (IEC664) Power Requirements 230V ± 10%, 115V ± 10% or 100V ± 10% at 50/60Hz, 25VA. Fuses Below Serial Nº. 11244 One fuse 230V 115V 160mAT 315mAT Serial Nº. 11265 – 12212 Two fuses as above Serial Nº. 12213 up 230V 115V 125mAT 250mAT Physical characteristics (excluding accessories) Dimensions 305mm (12 in.) wide. 150mm (5.9 in.) high. 275mm (10.8 in.) deep. Weight 3.5 kg. Flammability Enclosure to UL94 V-0. ix TONEOHM 950 SERVICE MANUAL SYMBOLS REFER TO MANUAL These sockets are for connecting only Polar Instruments probes and connectors for use as described in the Operator Manual. To prevent damage to this product and to ensure its safe use observe the specifications given in this manual when connecting to terminals marked with this symbol. ACCESSORIES Standard Accessories Needle Probes 950 Plane Probe/Clip assembly 950 Current Trace Probe assembly 950 Stimulus Lead (Set of 4) Lightweight Headphones ACC152 ACC113 ACC114 ACC134 EPM115 Optional Accessories Bare-board Stimulus Lead set (0.025") Bare-board Stimulus Lead set (0.031") Bare-board Stimulus Lead set (0.040") Bare-board Lead set (universal) Service Manual x ACC121/XG25 ACC121/XG31 ACC121/XG40 ACC154 MAN130 CONTENTS CONTENTS DECLARATIONS.......................................................................................................................................... v European Community Directive Conformance Statement .....................................................................v SAFETY ....................................................................................................................................................... vi WARNING.................................................................................................................................................vi GROUNDING ............................................................................................................................................vi POWER SUPPLY .....................................................................................................................................vi OPERATION ............................................................................................................................................ vii CAUTION ................................................................................................................................................. vii Electrical Isolation............................................................................................................................. vii Static Sensitive Devices ....................................................................................................................... vii SPECIFICATIONS ..................................................................................................................................... viii ENVIRONMENTAL OPERATING CONDITIONS .....................................................................................ix Power Requirements.............................................................................................................................ix Fuses.....................................................................................................................................................ix Physical characteristics (excluding accessories) ..................................................................................ix SYMBOLS ................................................................................................................................................. x ACCESSORIES ........................................................................................................................................ x Standard Accessories ........................................................................................................................... x Optional Accessories............................................................................................................................. x SECTION 1 PERFORMANCE CHECK ..................................................................................................... 1-1 MAINTENANCE AND CALIBRATION OF INSTRUMENTS .................................................................. 1-1 Performance Check ........................................................................................................................... 1-1 Adjustment Procedure........................................................................................................................ 1-1 Recommendations for Routine Maintenance ..................................................................................... 1-1 PERFORMANCE CHECK...................................................................................................................... 1-2 Equipment required ............................................................................................................................ 1-2 Procedure........................................................................................................................................... 1-2 SECTION 2 – ADJUSTMENT PROCEDURE ........................................................................................... 2-1 ADJUSTMENT PROCEDURE ............................................................................................................... 2-1 Equipment required ............................................................................................................................ 2-1 Display Calibration.............................................................................................................................. 2-1 A2D Calibration .................................................................................................................................. 2-1 Resistance Calibration ....................................................................................................................... 2-1 Current range adjustment .................................................................................................................. 2-2 Current offset calibration — Version 8 firmware and above............................................................... 2-2 Current Trace ..................................................................................................................................... 2-2 Plane Shorts ....................................................................................................................................... 2-3 SECTION 3 – CIRCUIT DESCRIPTION.................................................................................................... 3-1 TONEOHM 950 THEORY OF OPERATION. ........................................................................................ 3-1 Main Operating modes. ...................................................................................................................... 3-2 Track resistance ............................................................................................................................. 3-2 Track Current ................................................................................................................................. 3-2 Trace .............................................................................................................................................. 3-2 Track Voltage ................................................................................................................................. 3-2 xi TONEOHM 950 SERVICE MANUAL Plane Shorts ................................................................................................................................... 3-2 Detailed Theory of operation. ............................................................................................................. 3-3 Microvolt Amplifier .......................................................................................................................... 3-3 Trace Amplifier ............................................................................................................................... 3-3 Current Source ............................................................................................................................... 3-3 Plane Amplifier and Vector Discriminator....................................................................................... 3-3 Vectored Plane Stimulus ................................................................................................................ 3-4 Drive Source................................................................................................................................... 3-5 Tone Generator .............................................................................................................................. 3-5 A2D2A ............................................................................................................................................ 3-5 Power Supply. ................................................................................................................................ 3-5 Microprocessor............................................................................................................................... 3-6 Front Panel (Schematics 1 and 2).................................................................................................. 3-6 SECTION 4 – DISMANTLING INSTRUCTIONS ....................................................................................... 4-1 Removing the cover ........................................................................................................................... 4-1 SECTION 5 – LINE VOLTAGE AND FUSE CHANGING.......................................................................... 5-1 LINE VOLTAGE SELECTION AND FUSE CHANGING ........................................................................ 5-1 Changing the line voltage setting ....................................................................................................... 5-1 SECTION 6– FAULT DIAGNOSIS ............................................................................................................ 6-1 TROUBLESHOOTING HINTS ............................................................................................................... 6-1 SECTION 7 – MAINTENANCE AND CLEANING ..................................................................................... 7-1 Cleaning ............................................................................................................................................. 7-1 Technical Support .............................................................................................................................. 7-1 Instrument repair ................................................................................................................................ 7-1 SECTION 8 – REPLACEMENT PARTS.................................................................................................... 8-1 FRONT PANEL KIT ............................................................................................................................... 8-2 MAIN BOARD KIT .................................................................................................................................. 8-3 MECHANICAL KIT ................................................................................................................................. 8-7 SECTION 9 – SCHEMATIC DIAGRAMS .................................................................................................. 9-1 xii SECTION 1 PERFORMANCE CHECK MAINTENANCE AND CALIBRATION OF INSTRUMENTS For most of Polar Instruments’ products there are two maintenance procedures — the Performance Check and the Calibration. Some instruments may have a single (combined) procedure. Performance Check The Performance Check (or Checkout Procedure) is used to verify the basic functions of the instrument. This does not usually require the removal of instrument covers, but may require the use of external test equipment. This procedure is not intended to verify the calibration of the instrument. Adjustment Procedure The Adjustment Procedure (or Calibration Procedure) is used to check and, if necessary, adjust the instrument’s calibration settings. Before carrying out the Adjustment Procedure the instrument’s Performance Check (if applicable) should be carried out, and any detected defects should be rectified. The Adjustment Procedure and rectification of defects should only be carried out by qualified technician. Recommendations for Routine Maintenance Where a Performance Check is available for an instrument this may be used as required to confirm the basic operation of the product. To maintain the calibration of an instrument it is recommended that its Calibration/Adjustment Procedure is carried out at intervals not exceeding 12 months. 1-1 TONEOHM 950 SERVICE MANUAL PERFORMANCE CHECK Equipment required • DC voltage source, variable from 1V to 10V and accurate to 0.1%. • High tolerance resistors (0.5%) of the following values: 10KΩ, 1KΩ (serial numbers below 005975 only), 200Ω, 100Ω, 1Ω and 0.1Ω. Procedure • Switch on and allow the 950 to warm up for 15 minutes. 1. Plug in the Needle Probes and press 20V. 2. Apply 10V DC to the probes and check that the reading is 10V ± 4%. 3. Connect a 1KΩ 0.5% and a 1Ω 0.5% resistor in series. 4. Apply 10V to the series resistors. This produces 10mV across the 1Ω Resistor. 5. Press 20mV and check that the reading across the 1Ω resistor is 10mV ± 4%. 6. Adjust the voltage source from 0 to 20V and check that the tone varies in pitch. A steady warble should be generated with a negative voltage. 7. Apply 1V to the two resistors and press 2mV. 8. Check that the reading across the 1Ω resistor is 1mV ± 4%. 9. Check that varying the voltage generates varying tones. No tone should be produced below about 50uV. 10. Press 20KΩ and measure a 10KΩ 0.5% resistor. The reading should be within 4%. A warble may be generated in this range. (a) Serial numbers below 005975: Press 2KΩ and measure a 1KΩ 0.1% resistor. The reading should be within 4%. (b) Serial numbers 005975 up: Press 200Ω and measure a 100Ω 0.1% resistor. The reading should be within 4%. 11. Press 2Ω and measure a 1Ω 0.1% resistor. The reading should be within 4%. 12. Apply solder to the wire ends of a 100mΩ 0.5% resistor. 13. Press 200mΩ and measure the resistor by pressing the probe tips into the solder. The reading should be within 4%. Readings vary with the pressure applied to the probes. 14. Press TRACE and connect the Drive Source leads across a 200 Ω resistor. Turn the DRIVE SOURCE knob fully clockwise. 15. Hold the Current Trace Probe tip near to one of the Drive Source leads and align it for maximum response. 16. Check that the display shows 20 or more. 17. Connect the Blue and Yellow Stimulus lead together. Press PLANE twice — check for the warning bell and that the instrument returns to Standby. Leave leads connected. 18. Connect the Red and Green Stimulus lead together. Press PLANE once. Check for ACTIVE LED. 19. Connect the red and black Drive Source leads across a 0.1Ω resistor. Attach the Plane Clip to the black Drive Source lead. Probe the other end of the resistor with the probe. 1-2 PERFORMANCE CHECK 20. Slowly turn the DRIVE SOURCE from minimum to maximum (i.e. clockwise). As the control is rotated, check that initially all direction arrow LEDs are on, then the upper LED only, then all LEDs are off. At the same time the tone goes from high to low then off. 21. Reverse the connections to the Plane Probe and Clip. Rotate DRIVE SOURCE from maximum to minimum (i.e. anti-clockwise). As the control is rotated, check initially for no arrows or tone, then rising tone and bottom arrow on, finally all arrows on. 22. Disconnect the Red and Green Stimulus lead. PLANE should automatically ring warning bell and return to standby. Disconnect the Plane Probe and Clip from the 0.1Ω resistor. 23. Turn DRIVE SOURCE to maximum. Select 20mV, connect the Needle Probes and drive source leads across the 0.1Ω Resistor and note reading. 24. Select 200mA. Check that reading is: (10x Reading noted above) ±10% 25. Turn DRIVE SOURCE to minimum. Check for 0 ±1mA. 26. Disconnect all cables. 1-3 SECTION 2 – ADJUSTMENT PROCEDURE ADJUSTMENT PROCEDURE WARNING: Hazardous voltages are exposed on the PCB when the cover is removed. This procedure should only be performed by a technically qualified person aware of the hazards and taking all reasonable care. Equipment required • High tolerance(0.1%) voltage source — 10V and 10mv. • High tolerance(0.1%) 1Ω and 100mΩ resistors. • DVM • Power Supply. Before connecting to the supply:– 1. CHECK THE MAINS FUSES — see SPECIFICATIONS. 2. Connect the 950 to the appropriate line voltage and turn on. 3. CHECK the front panel lights sequence and that the 950 stops in the 20V range. PUSH 20mV. Display Calibration 1. Connect the Needle Probes to the 10mV source. 2. Adjust POT R196 (top RHS of Front Panel board) for a display of 10.00mV. A2D Calibration 1. Turn the power off then hold down 2mV and PLANE — re-apply power. 2. Connect needle probes to 10mV source. 3. Observe the Active and Standby (Pass and Fail) LEDs while adjusting R163 — the tone will decrease as the calibrated position is approached. When ACTIVE illuminates the A2D is calibrated. 4. PUSH 2mV. The 950 will beep and enter the 20V Range. Resistance Calibration 1. SELECT the 2Ω range. Place the probes across the 1Ω resistor. ADJUST R713 (R30 for instruments below S/N 012213) for 1.000Ω reading ± 3 Counts. 2-1 TONEOHM 950 SERVICE MANUAL Current range adjustment (Serial Nº. 012213 and above — below this Serial Nº. there is no adjustment.) 1. Select the 200mA range. Drive source control fully clockwise. 2. Connect the drive source and the DVM across the high tolerance 1Ω resistor. 3. Note the DVM reading. 4. Apply the needle probes across the resistor and adjust R 30 for the same reading as the DVM ± 5 counts. Current offset calibration — Version 8 firmware and above 1. Set the current limit to MINIMUM — switch the supply ON. 2. Select 2A on the 950. 3. Connect the power supply across the 100mΩ resistor. 4. Adjust the current limit to 1.6A. 5. Using the Needle Probes measure across the 100mΩ resistor CHECK for 1.44 to 1.76A on the 950 display. (Version 8 firmware and above, main board version 5 and above.) Select the most accurate 1.6A reading by optionally placing a jumper on one of the 4 locations adjacent to U46. No jumper is the mid setting, H fixes slight under-reading, HH corrects large underreading. L fixes slight over-reading, and LL corrects large over-reading. (Version 8 firmware, main board version 4 or below.) Connect a 20 way integrated circuit test clip to U46 Shorting Pin 17 to Gnd corresponds to HH 14 H 13 LL 8 L No connection is nominal setting. Once the best setting is established solder a link from the appropriate pin (if any ) to ground. 6. Version 7 firmware and below offer no fine adjustment. Current Trace 1. Connect Trace / Drive Source Probe. 2. Push TRACE. Adjust the volume as desired, short the drive source leads together and turn the drive source to MAXimum. 3. While holding the probe against the Drive Source lead ADJUST R94 for the highest displayed reading (> 500). Move the probe away from the Drive Source leads, 4. CHECK Tone turns off and displayed reading is less than 25. 2-2 ADJUSTMENT PROCEDURE Plane Shorts 1. CONNECT the 4 Plane Stimulus leads BLUE to YELLOW and RED to GREEN 2. Push PLANE twice to enter ACTIVE mode. 3. CONNECT the Plane Clip to the Plane Probe. Adjust R85 for a reading of 00.0 ± 3 counts. (Ser Nº 012213 up) Adjust R716 (located near U18, behind copper shield) for minimum (or most negative) reading. Re-adjust R85 for 00.0 ± 3 counts. 4. Reduce the Variac to: 190V (240V instruments) 95V (120V instruments) 85V (Japanese instruments) 5. Check that PLANE remains ACTIVE 6. Remove the Green clip from the demo board and check the 950 goes to standby. Reconnect the clip and select ACTIVE. 7. Repeat for the yellow clip. 8. Disconnect all probes. 2-3 SECTION 3 – CIRCUIT DESCRIPTION TONEOHM 950 THEORY OF OPERATION. The TONEOHM 950 consists of the following functional blocks. 1. Microvolt Amplifier Amplifies/attenuates PCB track voltages, and is used in conjunction with the internal current source for the calculation of track resistance and current. 2. Trace Amplifier Amplifies and rectifies the low level AC signal from the Trace probe to provide a DC voltage output proportional to magnetic field. 3. Current source Provides a range of currents for resistance and noninvasive current measurement. 4. Plane Amplifier and Vector discriminator Amplifies low level plane signals, separates vector and magnitude components. 5. Vectored Plane Stimulus Provides the four vectored signals for Plane Shorts mode. 6. Drive Source User adjustable constant current DC supply for noninvasive current measurement/ µV measurement. Also operates in a.c. for non-contact current tracing. 7. Tone Generator Voltage controlled oscillator which provides varying tone proportional to meter reading. 8. A2D2A Analog to digital convertor used for providing microprocessor with data for non-invasive current measurement, also used for internal calibration and QC. Digital to analog converter provides output for tone generator in 2A and 200mA modes and output to front panel meter. 9. Power Supply 10. Microprocessor ± 5V analog and digital supplies. 12/5V floating supply for drive source. 4V a.c. supply for vectored plane stimulus. Controls hardware and performs current calculation. 11. Front Panel Keyboard and display D2A. 3-1 TONEOHM 950 SERVICE MANUAL Main Operating modes. Track resistance Current is injected into the track with the needle probes using the CURRENT SOURCE module, the µV AMPLIFIER conditions the resulting track voltage and displays the result directly on the LCD. Track Current 200mA, 2A. These ranges compute the current by measuring the voltage drop across a length of track carrying the fault current and then injecting a known current in addition to the fault current. The voltage drop is then remeasured and the resistance calculated hence the fault current can be derived. e.g. Track Resistance = V due to fault I – (V due to fault I + V due to injected I) Injected I V due to fault I Hence Fault Current = Track Resistance The 950 first reads the track voltage with the µV AMPLIFIER and uses the A2D2A to digitise the value. The amplifier auto-ranges if necessary, then a small current is injected from the CURRENT source, the track voltage is read again, if the second voltage is not significantly different (<10% higher) the 950 injects more current. This process reiterates up to a maximum of 240mA injection at which point the microprocessor will force a calculation and send the resultant value to the D2A. This is sent both to the front panel meter and via the conditioning network on U59 (Schematic 1) to the TONE GENERATOR. During the initial ranging and for on track resistances below approximately 25mΩ the un-calibrated indicator will illuminate. Once ranging has taken place the initial injection/ attenuation settings are held and the current is calculated continuously. The 950 will only measure positive conventional current. If the probes are reversed the condition will be indicated on the front panel and the display will blank. Trace In TRACE mode the 950 uses an inductive pick up to detect an ac current in a faulty track. The ac current is supplied from the DRIVE SOURCE leads, the detected signal is conditioned by the TRACE amplifier and then switched to the LCD and TONE GENERATOR by U25 (sheet 6) and U59 (sheet 1) respectively. Track Voltage The µV AMPLIFIER conditions the track voltage and sends it to the LCD via U25 (sheet 6) and to the TONE GENERATOR. The tone is disabled on the 20V range. Plane Shorts In Plane Shorts mode the 950 uses VECTORED PLANE Stimulus to set up a field pattern on the plane under test, the Plane Clip references the short to ground and the voltage measured on the Plane Probe is an a.c. signal providing both magnitude and position information. The PLANE AMPLIFIER and VECTOR DISCRIMINATOR resolve this into a magnitude signal (sent to the LCD and TONE GENERATOR and a vector signal for the 4 direction arrows on the front panel). 3-2 CIRCUIT DESCRIPTION Detailed Theory of operation. Microvolt Amplifier JP11 is the input connection from the probe sockets. Relays K1, 2 and 3 provide ÷ 1, ÷ 10 and ÷ 1000 attenuation setting for the main Amplifier U1. K4 provides a switchable 120Ω input resistance used in 2mV and 20mV. U1 is a low offset voltage chopper stabilised amplifier with gains of x10 or x100 (selected by the analog switch U24 on the Tone Generator schematic). The network on the output of U1 provides an idealised response for the tone generator. "HI" and "LO" are the calibrated outputs to the front panel meter (via analog switch U25 on sheet 6). U59 and associated components provide a second nonlinear amplifier for use in TRACE, PLANE, 200mA and 2A modes. Trace Amplifier Refer to Microvolt Amplifier schematic. The DRIVE Source provides PCB tracks with an 80kHz (approximately) current; this is detected by the Trace Probe. The low level signal is first amplified and filtered by U2B, further amplification and conditioning is provided by nonlinear amplifier U2A, the a.c. signal is then rectified and smoothed by active rectifier U2D; after buffering and attenuation U25 (A–D Converter schematic) directs the output to the front panel meter. Current Source Refer to A–D Converter schematic The current source provides a range of known dc currents for resistance and non-invasive current measurement. The loop formed by U5A, U62A, Q2, D13 and associated components provide a low impedance 56mV or 0.56V (approximately) source. The microprocessor is both able to select the voltage via U24 on the Tone Generator schematic, or gate the supply via Q2 and U62B. Q2 and D13 also afford protection against inadvertently connecting high voltages to the probes. The voltage is applied via relays R1 to R7 across a series resistance and via the Kelvin connected Needle Probes, to provide a known current through the track resistance under test. In order to correct for offsets caused in the needle probes when measuring low resistances, U4 and associated components apply offset to the µV Amplifier in order to achieve a zero reading in 2Ω and 200mΩ; in the [Ω] range offset is applied to give a stable reading but a zero is not achieved when the probes are shorted. Plane Amplifier and Vector Discriminator Refer to Plane Input Amplifier Schematic The Vectored Plane Stimulus sets up a field on the plane under test such that when the plane is probed the following waveforms are detected: above the short two positive going half sine waves below the short two negative going half sine waves left of the short a positive followed by a negative half sine wave right of the short a negative followed by a positive half sine wave The magnitude of the half waves detected increases with increasing distance from the short. 3-3 TONEOHM 950 SERVICE MANUAL The 950 extracts this information as follows: U12 Amplifies the low level signal from the Plane Probe; this chopper-stabilised amplifier is clocked by a signal synchronous with the Vectored Stimulus to minimise clock noise on the a.c. output signal. JP12 connects to the Drive Source/Sensitivity control to allow user adjustment of sensitivity. U6 forms an active rectifier for the incoming signal which is taken to sample-and-hold gate U8, along with the unrectified component. U8 is clocked and gated so that the peak amplitudes of each halfwave in both rectified and unrectified form are sampled and held on C11, C12, C13 and C16. Magnitude signals on C11 and C12 are added then switched via U25 (A–D Converter schematic) and U59 (Microvolt Amplifier schematic) to the LCD and TONE GENERATOR respectively. C13 and C16 hold the unrectified component of the plane signal; here only their polarities are of interest, these are detected and converted to TTL levels by comparators U10 and U14 the two resultant signals (QUADRANT0 and QUADRANT1) are taken to the front panel and decoded to illuminate the appropriate direction arrow. Finally U17A and B monitor the level of PLANEV+ and through the control signals ARROW OFF and CENTRE... 1. Turn the arrows off when the probes are open circuit. 2. Allow the QUADRANT signals to control the arrow when the plane is being probed. 3. Turn all the arrows on when the probe is a few centimetres from the short. Vectored Plane Stimulus Refer to Drive Source schematic The stimulus runs at power line frequency and provides a nominal 2A (peak) current from top left to bottom right of the plane during the first 180 degrees of the line signal followed by the same signal from top right to bottom left during the second 180 degrees. The two halves of the stimulus circuit are identical except for the phase of the inputs which allow the steering diodes (D31, D32, D73, D35) to pass current on alternate half cycles. Relay K14 allows the microprocessor to turn the stimulus off and on. Taking the top circuit as the example, +2A and -2A are the outputs of the 4V RMS transformer winding. As +2A goes positive D31 conducts and attempts to pass current through L1, F1 through its stimulus lead and return through the lead at the opposite diagonal of the board, during this half cycle the other stimulus circuit is inactive. As current flows through inductor L1 Hall sensor Q12 detects its presence and the monostable U61A is repeatedly clocked, the output of the monostable is OR'd with its equivalent in the other stimulus circuit and if either inductor L1 or L2 is NOT conducting NO_PLANE_DS will be low. NO_PLANE_DS is monitored by the microprocessor in PLANE SHORTS mode. When the user presses PLANE to activate the mode the 950 will turn on relay K14 on; if no current is detected in L1 or L2, K14 will be turned off. 3-4 CIRCUIT DESCRIPTION In order to protect semiconductor devices, D30 and D34 are Schottky diodes which conduct if the stimulus voltage attempts to rise above approximately 0.4 volts. This will occur if the stimulus is not connected correctly. As D30 or D34 conduct, current no longer flows through L1 or L2, the microprocessor registers NO_PLANE_DS and turns off K14. This feature will turn off the stimulus at any time it is disconnected while "Active". Drive Source The Drive Source provides both an 80kHz ac low impedance output for non-contact current tracing and an adjustable DC output for non-invasive current measurement and microvolt measurement. U13 and U19 form a gated oscillator, enabled only in TRACE mode. Q3 and Q4 provide a low impedance output, U13A monitors the output current turning on the front panel DRIVE SOURCE indicator when a current of > approximately 5mA is flowing. U13D and Q4 comprise a protection circuit which cuts off drive to Q3 should the leads be connected to a negative voltage. D39 provides protection from positive voltages. Tone Generator U20D and Q7 form a VCO whose frequency is proportional to the voltage at TONE_GEN or its inverse if INVERT is selected. The output of the VCO is made symmetrical by U21B, which is also gated by the microprocessor to allow the tone to be turned off in the 20V range and during current auto-ranging. U64 is a voltage controlled amplifier providing volume adjustment from the front panel, U22 provides the audio power output. The following controls are applied to the tone generator: • 20V range — gated off by NO_TONE • 200mA 2A — gated off below 10mA (approximately) and during auto-ranging. • 2mV and 20mV Invert selected — U20A and B detect a band of ± 40µV and turn off the tone in this region, more negative than 40uV oscillator U17D runs causing a unique pulsing tone. Reversed signal also taken to front panel led. • All resistance ranges — Invert is off and at low readings U20A goes high allowing U17D to oscillate and cause a pulsing tone at low readings. • TRACE — as 2mV. A2D2A Refer to A–D Converter Schematic U26 and associated logic interface the µV AMPLIFIER with the microprocessor allowing it to read the 12bit conversion in a high and low order byte. The data is used for current calculation and system calibration. U28 8-bit D2A convertor allows the computed current to be sent to the TONE GENERATOR and the LCD. U25 is controlled by the processor to route analog signals from the main modules to the display. Power Supply. U32 and U33 provide analog ± 5 Volt supplies. LK7 or 8 allow the Phase of the line signal to be selected in case of transformer phase change. (This will affect left and right arrows in PLANE SHORTS.) U31 provides a separately regulated 5V supply for the digital systems and relay drive. U30 Provides a floating +5Volts for the drive source. +2A and -2A is a floating 4V RMS supply for the Vectored Stimulus. 3-5 TONEOHM 950 SERVICE MANUAL Note that from Serial Nº. 011265 a line filter was fitted and the line voltage selector switch was replaced by links. The power transformer has undergone several changes — check the REPLACEMENT PARTS list before ordering spares. Microprocessor The system is based on a Z80 U35 which is reset and shut down by controller U38. 4MHz Resonator X1 is divided by 2 to produce a 2MHz system clock. Firmware is held in ROM U36, and U34 provides 2K of utility RAM. The remainder of the bus related circuits provide I/O for controlling or monitoring the instrument. U43 and U37 provide appropriate address decoding. Front Panel (Schematics 1 and 2) The digital part of the front panel is an extension of the processor system providing a keyboard row and column decoder U49 and U52 and other ports for LED drive. U57 and associated components form the drive for the Plane Direction arrows and come under the control of the Vector discriminator circuit. D76 is a backlight array for the LCD whilst U53 provides display A2D conversion and LCD Drive, U56 provides logic level conversion for decimal points and U54 is the LCD. 3-6 SECTION 4 – DISMANTLING INSTRUCTIONS WARNING Service of this instrument should only be performed by skilled electronics service personnel. There are hazardous voltages inside the instrument when connected to its power supply. REMOVE THE POWER CORD before touching any part of the line input circuit. Note that high voltages may continue to be present for 2 minutes after power is removed until internal capacitors discharge. Removing the cover Undo the two screws in the rear of the cover, then lift the cover rear edge first and remove. The main printed circuit board must be removed before the front moulding or feet can be removed 4-1 SECTION 5 – LINE VOLTAGE AND FUSE CHANGING WARNING Service of this instrument should only be performed by skilled electronics service personnel. There are hazardous voltages inside the instrument when connected to its power supply. REMOVE THE POWER CORD before touching any part of the line input circuit. Note that high voltages may continue to be present for 2 minutes after power is removed until internal capacitors discharge. LINE VOLTAGE SELECTION AND FUSE CHANGING Note: When replacing fuses always use the type and rating stated in SPECIFICATIONS. Changing the line voltage setting When changing the line voltage it will be necessary to dismantle the instrument as described in Section 4 — changes may be made as follows: 1. Remove the two screws in the rear of the cover and lift off (lift the rear first). 2. In early instruments locate the line selector switch and change to the local line voltage. 3. In later instruments remove the gold plated links (extract the links with small pliers) and replace them in the locations corresponding to the local line voltage. 4. Locate the supply fuse (2 fuses in later instruments) and replace with the value and rating stated in SPECIFICATIONS. 5. Replace the cover. 6. Erase the marking on the label on the rear of the instrument and mark in the new voltage setting. NOTE: 100V instruments cannot be changed. 5-1 SECTION 6– FAULT DIAGNOSIS WARNING Service of this instrument should only be performed by skilled electronics service personnel. Hazardous voltages are exposed on the PCB when the cover is removed. These procedures should only be performed by a technically qualified person aware of the hazards and taking all reasonable care. TROUBLESHOOTING HINTS 1. If the instrument is completely dead check the fuses and line voltage selection. Inspect carefully for signs of damage, loose wires, etc. Rectify any faults before applying power. 2. If there is no "beep" or flashing LED sequence at switch on, the microprocessor is not operating. Check the internal power supplies, ROM, crystal and microprocessor reset circuits. 3. If there is an OHMS fault check the input amplifier in VOLTS mode first, then check the operation of the current generator. 4. If ACTIVE cannot be engaged in PLANE SHORTS check the 5A fuses in the stimulus circuit. The connections to the plane drive sockets should also be checked, and the sense coils which should be close around the sensor IC. 5. In TRACE mode, for optimum sensitivity tune the circuit to the Trace Probe (Probes may differ). 6-1 SECTION 7 – MAINTENANCE AND CLEANING Cleaning Clean the unit with a cloth lightly moistened with water with a small amount of mild detergent. Alternatively, a cloth lightly moistened with alcohol (ethanol or methylated spirit) or isopropyl alcohol (IPA) may be used. Do not spray cleaners directly onto the instrument. Technical Support For technical support contact your local Polar Instruments distributor or Polar Instruments Ltd. at the address at the front of this manual. Instrument repair If it becomes necessary to repair the instrument, in the first instance contact the Polar Instruments distributor in your country. In case of difficulty contact Polar Instruments Ltd. at the address at the front of this manual. Do not send the instrument until shipping instructions have been received from the repairer. 7-1 SECTION 8 – REPLACEMENT PARTS To ensure correct parts are supplied, orders for replacements should include the following details: Instrument type Instrument serial number Firmware version (if applicable) Circuit reference (if applicable) and description Note: Parts marked with an asterisk (*) have been subject to modification in later instruments. Safety critical parts (listed in bold type) must be replaced with parts obtained from Polar Instruments Ltd or your Polar Instruments distributor to ensure continued safe operation. 8-1 TONEOHM 950 SERVICE MANUAL FRONT PANEL KIT 8-2 Part Nº CEA103 CVD101 CVD102 CVD105 CVD116 CVD136 CVD154 * ICA129 ICA130 ICA192 ICA208 ICA221 ICA243 LDD116 LDD117 LED115 LED116 Qty 3 1 1 2 1 4 2 1 1 3 1 1 1 1 1 12 10 Description 10µF Electrolytic 0.1µF Polyester 0.01µF Polyester 0.22µF Polyester 100pF Ceramic 0.1µF Mini Ceramic 2n2 Polyester 7106 4070 74HC374 74HCT373 74HC139 4051 LCD Backlight LED Red LED Yellow LED117 MKB154 MPP200 MPP201 MQX138 MQX238 QNN304 RCC127 RCF100K RCF1M0 RCF200R RCF22K RCF270R 1 12 16 7 1 2 1 1 1 4 1 1 20 LED Green Button Cap 3.8mm Spacer 4.3mm Spacer 28 Pin IC Socket LCD Connector 2N3904 Transistor 8 x 22K Rpak 100K 1/4W 1M0 1/4W 200R 1/4W 22K 1/4W 270R 1/4W 5% 5% 5% 5% 5% RCF330R * RCF390R 4 7 330R 390R 1/4W 1/4W 5% 5% RCF39R 7 39R 1/4W 5% RVB320 RVP114 RVP115 SWB141 1 1 1 12 1K Preset 100K Panel Pot 100K Panel Pot (Dual) Push-Button WMA196 WMA198 WMA199 WMA206 1 1 1 1 Cable Assembly Headphone Cable I/P Board Cable Drive Source Cable CircuitReference C57, C66, C68 C61 C62 C58, C59 C60 C67, C69 C700, C701 U53 U55 U50, U51, U52 U49 U57 U56 U54 D76 D46-D48, D50-D52, D54, D65-D69 D53, D55, D56, D57, D58, D59, D60, D61, D62, D63 D64 Q10 RP5 R195 R194, R198, R199, R200 R185 R197 R174, R175, R176, R177, R178, R179 R180, R181, R182, R183, R184, R216 R217, R218, R219, R220, R221, R222 R223, R224 R700, R701, R702, R703 R186, R187, R188, R189, R190, R214 R215 R227, R228, R229, R230, R231, R232 R233 R196 R192 R191 S2, S3, S4, S5, S6, S7, S8, S9, S10, S12, S13, S14 JP4 REPLACEMENT PARTS MAIN BOARD KIT Part Nº CEA103 Qty 12 Description 10µF Electrolytic CEA105 CEA117 CEA122 CVD101 1 4 2 24 220µF 2,200µF 1µF 63V 0.1µF Electrolytic Electrolytic Electrolytic Polyester CVD102 13 0.01µF Polyester CVD105 CVD106 CVD109 3 2 30 0.22µF 82pF 0.1µF Polyester Ceramic Radial Ceramic CVD113 CVD115 CVD116 CVD130 CVD143 CVD144 CVD146 CVD147 CVD148 DBA102 DSP101 3 3 1 1 2 5 2 2 2 2 40 1µF Polyester 33pF Ceramic 100pF Ceramic 0.022µF Polyester 0.1µF Polyester 0.47µF Polyester 1nF Polyester 4n7 Polyester 1nF Polyester Rectifier Bridge 1.2A Diode Signal 150mA DSP102 DSP105 DSP107 DZA303 DZA320 EPM112 FCA124 * FCA130 FSW122 ICA106 ICA116 ICA122 ICA125 ICA126 ICA128 ICA158 ICA161 ICA162 ICA164 ICA165 2 2 6 2 1 1 4 1 1 4 1 1 2 1 3 1 1 1 1 2 Diode Power 1A 1kV Diode Schottky 7.5A Diode 1N5401 Zener Diode 3.3V Zener Diode 5V1 Buzzer 5A Fuse Wire ended 0.5A T Wire ended Firmware ROM LM339N MC14016BCP MC14013BCP ICL7650CPD CA3140E MC7805CT MC74HC00N MC7905CT LF353N 74HC132 LM311N CircuitReference C4, C5, C29, C41, C49, C50, C52, C53, C71, C75*, C78*, C82 C32 C40, C43, C45, C46 C75*, C79* C1, C6, C7, C8, C9, C14, C15, C17, C18, C26, C31, C33, C56, C64, C65 C70, C72, C74, C75*, C76, C78, C79*, C85, C90* C3, C20, C24, C27, C28, C30, C35, C39, C73, C77, C89, C705, C706 C36, C80, C81 C19, C38 C44, C48, C83, C86, C702, C707, C714 C23, C34, C88 C21, C54, C55 C708 C2 C51, C91 C11, C12, C13, C16, C37 C92, C93* C703, C704 C90*, C93* D43, D44 D2, D3, D4, D5, D6, D7, D8, D9, D10, D11, D12, D14, D16, D18, D19 D21, D25, D37, D38, D40, D41, D42 D72, D79, D80, D81, D82, D84, D85 D86, D87, D88, D89, D90, D91, D92 D93, D94, D96, D97 D13, D39 D30, D34 D31, D32, D35, D73, D77, D78 D1, D83 D29 SP2 F1, F2, F3, F4 F7 U36 U13, U17, U20, U61 U23 U21 U1, U12 U16 U30, U31, U32 U15, U18* U33 U60 U18* U10, U14 8-3 TONEOHM 950 SERVICE MANUAL 8-4 ICA166 ICA173 ICA186 ICA187 ICA188 ICA189 ICA190 ICA191 ICA192 ICA195 ICA198 ICA208 ICA212 ICA234 ICA239 ICA241 ICA245 ICA263 ICA265 ICA266 ICA267 ICA268 ICA269 ICA299 ICA305 IND107 IND105 LDD115 MAA123 MQX138 MQX139 MQX140 MQX158 MQX259P3 MQX259P10 MQX237 MQX284 MQX299 * MQX300 * QNN304 QPP102 QPP103 RCC103 RCC108 RCC120 RCC127 RCC143 RCC161 RCF100K 1 1 2 1 1 1 2 1 6 1 1 1 1 1 1 3 1 2 2 1 1 1 3 1 1 1 2 1 2 1 2 1 2 2 1 4 1 2 5 2 3 1 1 1 1 5 2 2 20 CD74HC74E MC74HC04N TL084CN (or LF347N) LM386N-1 Z80 TL 7705 74HC138 74HC08 74HC374 74HC32 74HC245 74HCT373 L272 Quad Opto-Isolator 6116 RAM 4052B DAC0800 74HC4053 Ratiometric Hall Sensor CA3080E ICL7109 REF25Z TLC279 TL082 74C04 10uH Inductor 10TURN 4MHz Ceramic Resonator Fuseholder 28 PIN IC SKT 40 PIN IC SKT PIN HEADER 2-Way Header 3 X 1 Pin Header 10 X 1 Pin Header 6.35mm Spade Connector Latched Header Link 1mm Socket 2N3904 2N3906 MJE350 120R 5% 68R 2W 5% 3K3 x 8 SILPAK 8 x 22K SILPAK 2R2 11W V33ZA5 100K 5% RCF100R 2 100R 5% U44 U3 U2, U9 U22 U35 U38 U37, U43 U41 U28, U39, U40, U46, U47, U63 U29 U45 U48 U62 U19 U34 U8, U25, U59 U27 U4, U24 Q11, Q12 U64 U26 U65 U6, U7, U58 U5 U42 L700 L1, L2 X1 F5, F6 JP3 JP9,JP13 JP10, JP12 JP11 Vertical 40 Pin Line Select Q3, Q8 Q4, Q7, Q9 Q2 R7 R102 RP1 RP2, RP3, RP4, RP6, RP7 R125, R126 R710, R711 R6, R7,R17, R33, R72,.R78, R83, R93, R128, R130, R138, R152, R154, R158, R164,R247, R259, R264, R289, R297 R79, R298 REPLACEMENT PARTS RCF10K 25 10K 5% RCF10M RCF10R RCF150K RCF15K RCF1K0 1 1 2 1 25 10M 10R 150K 15K 1K0 5% 5% 5% 5% 5% RCF1K2 RCF1K5 RCF1K8 RCF1M0 RCF1R0 RCF200R RCF20K RCF22K 2 1 2 3 3 4 6 6 1K2 1K5 1K8 1M0 1R0 200R 20K 22K 5% 5% 5% 5% 5% 5% 5% 5% RCF22R RCF270R RCF2K2 RCF2M2 RCF2R2 RCF330R RCF360K RCF390R RCF3K9 RCF470K 1 1 2 1 2 1 2 3 3 7 22R 270R 2K2 2M2 2R2 330R 360K 390R 3K9 470K 5% 5% 5% 5% 5% 5% 5% 5% 5% 5% RCF47K 11 47K 5% RCF4K7 10 4K7 5% RCF4M7 RCF560K RCF56K RCF56R RCF5K6 RCF68K RCF8K2 RCF820K RCF91K RCT100K RCT10K 2 1 1 3 4 1 2 1 2 5 8 4M7 560K 56K 56R 5K6 68K 8K2 820K 91K 100K 10K 5% 5% 5% 5% 5% 5% 5% 5% 5% 1/4W 1% 1/4W 1% RCT10R RCT113K RCT11R0 RCT180K 1 1 2 1 10R 113K 11R0 180K 1/4W 1/4W 1/4W 1/4W % 1% 1% 1% R12, R29, R31*, R63, R64, R74, R75, R86, R88, R89, R112, R124, R127, R147, R155, R171, R207, R208, R209, R256, R260, R265, R279, R281, R282, R717 R251 R174, R714 R2, R244 R28* R15, R16, R18, R21, R23, R92, R100, R109, R129, R201, R206, R213, R234, R235*, R236, R237, R253, R258, R263, R266, R269, R272, R276, R286, R290 R140, R142 R288 R144, R274 R145, R161, R172, R715 R4, R273, R277 R8, R239, R245, R287 R22, R28*, R162, R240, R241, R246 R133, R134, R136, R137, R157, R165 R268 R148 R242, R271 R151 R5, R103 R235* R243, R280 R108, R122, R173 R104, R105, R275 R26*, R80, R153, R156, R249, R262 R270 R32, R90, R91, R131, R132, R139, R141, R149, R150, R261, R267 R19, R82, R110, R111, R250, R254, R255, R278, R294, R296 R106, R107 R1 R27* R20, R24, R257 R101, R135, R143, R248 R27* R31*, R712 R26* R123, R291 R45, R58, R59, R60, R68, R99 R51, R52, R53, R55, R57, R292, R293, R295 R38 R95 R37, R42 R87 8-5 TONEOHM 950 SERVICE MANUAL 8-6 RCT1K RCT1M0 RCT1R0 RCT200R RCT20K RCT220K RCT24K RCT2K0 RCT430K RCT470K RCT560K RCT56K RCT56R RCT75K REL111 1 3 3 1 2 1 1 3 1 1 1 1 1 1 9 1K 1/4W 1MO 1/4W 1RO 1/4W 200R 1/4W 20K 1/4W 220K 1/4W 24K 1/4W 2K0 1/4W 430K 1/4W 470K 1/4W 560K 1/4W 56K 1/4W 56R 1/4W 75K 1/4W Reed Relay REL112 REL113 RVB315 RVB316 RVB319 RVB320 RVB323 SWB133 SWB143 TXM125 TXM146 WMA108 2 1 1 2 1 1 1 1 1 1 1 2 2-POLE Reed Relay SPNO 5A Relay 100K Preset 10K Preset 10K Preset 1K Preset 100K Preset Power Switch Line Selector Switch Power Transformer Power Transformer 0.5"Link 1% 1% 1% 1% 1% 1% 1% 1% 1% 1% 1% 1% 1% 1% R3 R46, R54, R56 R36, R43, R284 R203 R11, R96 R97 R14 R10, R159, 5160 R204 R13 R41 R40 R39 R205 K2, K3, K6, K7, K8, K9, K10, K11, K12 K1, K4, K14 R94 R30*, R713, R716 R30* R163 R85 S1 S15* T2* T2* LK8, R252 REPLACEMENT PARTS MECHANICAL KIT 0Part Nº CVD155 * Qty 5 Description 470pF Polypropylene EPM111 FCA112 FCA119 FCA121 FCA122 IND107 * IND109 MCA138 MCA139 MCA143 MKB127 MKB128 MKB153 MMP107 MNS107 MNS117 MNS163 MNS164 MNS175 MNS176 MPP142 MPP155 MPP191 MPP193 MPP198 MPP210 MPP230 MPP231 MQX154 MQX155 MQX158 MQX179 MQX210 MQX222 MQX223 MQX224 MQX225 MQX254 * MQX314 * MWP233 MWP234 MWP235* MWPD1057* MWPD1079 RCC129 RCC133 WMA104 WMA108 1 2 2 2 2 1 1 1 1 1 2 2 1 5 17 2 2 4 2 2 2 1 2 4 2 1 3 2 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 4 0.25m 1 Loudspeaker Fuse 250mA T Fuse 125mA T Fuse 160mA T Fuse 315mA T 10uH Ferrite Clamp Enclosure Top Enclosure Bottom Front Moulding Knob – Cap grey with line Knob – Grey push on Button (Round Black) Nylon Cable Tie 75mm O/A K30 x 6 self tap M3 x 10 Pan Hd M3 x 12 Csk K30 x 10 self tap M3 Flange nut K30 x 8 self tap PCB support Cable Clip Tilt Assembly Leg Bumper Foot Tilt Assembly Base IEC Inlet Boot Cable tie Insert Cover Din Socket 5 x 45' Din Socket 5 x 60' 2-Way Header 4mm Red Socket 4mm Blue Socket 3.5mm Stereo PCB Jack 5 Pin Din "Domino", Polarised 4mm Yellow Socket 4mm Green Socket IEC Inlet Connector IEC Filtered Inlet Front Panel Label LCD Window Label Rear panel Label Rear Label Flexishield 82ZA2 Varistor 22ZA1 Varistor Green/Yellow wire 0.5" Link CircuitReference C709, C710, C711, C712, C713 F5*, F6* 115V F5*, F6* 230V F5*,F6* 230V F5*,F6* 115V L701 R705, R710 R706, R707, R708, R709 8-7 TONEOHM 950 SERVICE MANUAL WMA197 WMA202* WMA305* 8-8 2 4 1 Speaker Lead Plane Cable Blue Plane Drive Cable REPLACEMENT PARTS SECTION 9 – SCHEMATIC DIAGRAMS 9-1 TONEOHM 950 SERVICE MANUAL This page is intentionally blank. 9-2 A B C D +5A 2 D15 D16 U62A 6 3 5 TL082 4 L272 R272 1K 4 D20 R273 1R -5A D18 Not used on 970 1 4 R46 1M 1% U5A + 2 3 O_I 4 R45 100K 1% +5UREG 8 USES 4053 ON TONE GENERATOR +5ADIAGRAM E C80 .22u -5A C10 270pF D19 Q2 MJE350 R713 10K R30 10K 05 Boards and later 56mV D21 Ohms Adjust .56V D13 1N4007 C91 .1u 400V R33 100K 3 D14 R31 8K2 R712 8K2 3 R32 +5A 47K 7 U62B R275 3K9 R287 1 8 200R L272 R276 1K R277 1R R274 I_ON C81 .22u 1K8 Kelvin Connected RELAY D88 - 94 may be omitted when /D relays are used. 2 D89 D88 R_2 R_1 D91 D90 R_3 R_4 D93 D92 R_5 R_6 K6 RELAY-SPST K7 RELAY-SPST R38 10R 1% R37 11R 1% R36 1R 1% Next to High HIGH A K8 RELAY-SPST R39 56R 1% MEDIUM K9 RELAY-SPST R40 5K6 1% B RELAY-SPST R41 560R 1% Next to LOW LOW K10 U4 12 13 D94 R_7 U3D 9 OHMS 1 2 +5A K11 RELAY-SPST R42 11R 1% 74HC04 K12 RELAY-SPST 8 14 2 1 15 Y0 Y1 Y Z 4 5 3 Z0 Z1 6 11 10 9 INH A B C OHMS_NULL R27 68K R26 470K To TONE_GEN R29 10K 7 8 200mOHM_THRESHOLD 1. All Diodes 1N4148 unless specified 1 Polar Intruments Ltd Garenne Park, St. Sampsons Guernsey, Channel Islands I_SOURCE Inst. C X 4053 R_1 R_2 R_3 R43 1R0 1% R284 1R0 1% X0 X1 TO uV_AMP R28 20K 970 D Title Current Source E A B C D C706 47n U25 PLANEV+ Trace+ 4 R158 TRACE100K R289 REF- +5D C34 1uF C35 .01u REF+ +5A C36 .22u R165 22k A2D Calibrate R162 20K -5A RUN REF- R163 REF+ C37 .47u R164 C38 82p R288 1K0 1K +5D 100k 40 39 38 37 36 35 34 33 32 31 30 29 28 27 26 25 24 23 22 21 GND +5V STATUS REF INPOL REF CAPOR REF CAP+ B12 REF IN+ B11 IN HI B10 IN LO B9 COMMON B8 INT B7 AZ B6 BUF B5 REF OUT B4 VB3 SEND B2 RUN/HOLD B1 BUF OSC OUT TEST OSC SEL LBEN OSC OUT OSC IN HBEN MODE CE/LOAD 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 R290 BUSY D5 D4 D3 D2 D1 D0 D7 D6 D5 D4 D3 D2 D1 D0 A2D2A /RD 5 U29D 6 74HC32 /WR U28 +5D N R710 R168 N C88 E 1uF D45 3 4 7 8 13 14 17 18 D0 D1 D2 D3 D4 D5 D6 D7 1 11 OC CLK Q0 Q1 Q2 Q3 Q4 Q5 Q6 Q7 2 5 6 9 12 15 16 19 2K0 1% 15 VR- 14 VR+ 5 6 7 8 9 10 11 12 B1 B2 B3 B4 B5 B6 B7 B8 +5UREG C87 Not Fitted T2 LK? Transformer IOUT 4 3 VO C40 2200uF VI RELAY C86 .1uF + VI + C49 10uF C48 .1uF + C50 10uF 2 VO R170 C41 10uF C42 .1uF + U30 LM7805 D43 W02 R167 C47 .1uF -5A C46 2200uF +5D +12V DS F7 0.5A T 230V 3 +5A VO -2A 115V 2 2200uF 10R C82 10uF + C83 .1uF U33 LM7905 +5D VCC VDD V+ VEE -5A V- VSS +5V DS GND POWER IOUT + C45 +2A 230V -5A .01u VI U31 LM7805 VI + S1 16 LK8 LINK R169 1M0 C51 .1uF 400V C39 COMP D[0..7] GND F6 VLC 1 -5A + F5 7 8 R203 200R 1% 13 DAC0800 W02 33ZA5 2 DMM_LO -5A +5D U27 LK7 LINK Only Fit Lk7 or Lk8 2APHASE L DMM_HI 4 MODE_0 MODE_1 7 74HC374 D[0..7] L D7 D6 D5 D4 D3 D2 D1 D0 12 74HC32 IEC filter 3 U32 LM7805 Line Fuses 90-120V, 250mA T 220-240V, 125mA T Y0 Y1 Y2 Y3 INH A B 13 Y 4052 U9B R159 2K0 1% R160 11 13 1 5 2 4 6 10 9 X DACV+ 74HC04 12 A2D2A X0 X1 X2 X3 TL084 U65 REF25Z U42F 13 HIGH 5 12 14 15 11 D[0..7] 7109 U29B 4 100K 1K0 6 GND R161 1M0 GND LO +5A - U26 + HI 3 1 E VO C43 2200uF C44 .1uF 0V DS 115V Line Select 1 R711 33ZA5 Polar Intruments Ltd Garenne Park, St. Sampsons Guernsey, Channel Islands Inst. A B C D 950 Title A to D Converter E A B C D E +5A +5A +5A 3 O_I D15 R46 1M 1% R45 100K 1% 56mV 1 - D20 TL082 L272 R30 10K To U5A Pin 3 R272 1K C80 .22u -5A C10 270pF D19 R713 10K Current Q2 MJE350 05 Boards and later 56mV D13 1N4007 D21 Ohms Adjust .56V 4 R273 1R -5A D18 Ohms Adjust 3 5 0_I R30 10K U62A 6 4 .56V D16 U5A + 4 4 2 2 R46 1M 1% +5UREG 8 R45 100K 1% USES 4053 ON TONE GENERATOR DIAGRAM C91 .1u 400V R33 100K R31 10K D14 R31 8K2 R712 8K2 R32 +5A 47K 7 U62B 1 8 3 R275 3K9 Adjustment up to S/No 012212 L272 R287 200R R276 1K 3 R277 1R R274 I_ON C81 .22u 1K8 Kelvin Connected RELAY D88 - 94 may be omitted when /D relays are used. +5A D89 D88 R_2 R_1 D91 D90 R_3 R_4 D93 D92 R_5 R_6 D94 R_7 U3D 9 OHMS 2 K6 RELAY-SPST R36 1R 1% K7 RELAY-SPST K8 RELAY-SPST K9 RELAY-SPST R39 56R 1% R40 5K6 1% R38 10R 1% R37 11R 1% K10 RELAY-SPST R41 560K 1% K11 RELAY-SPST 200m 2R 100mA 10mA 200 OHMS X0 X1 X 14 2 1 Y 15 Y0 Y1 Z 4 5 3 Z0 Z1 6 11 10 9 INH A B C 4053 R_1 R_2 R_3 R43 1R0 1% R42 11R 1% R284 1R0 1% SUPA 74HC04 K12 RELAY-SPST 8 U4 12 13 TO uV_AMP R28 20K OHMS_NULL R27 68K R26 470K To TONE_GEN R29 10K 7 2 8 200mOHM_THRESHOLD 1. All Diodes 1N4148 unless specified I_SOURCE 20K 50mA 200mA 1 1 Polar Intruments Ltd Garenne Park, St. Sampsons Guernsey, Channel Islands Inst. A B C D 950 Title Current Source E D +12V DS Q4 2N3906 8 R88 10K - 100K 1% RELAY 1R5 S/n13884up R126 2R 1N4148 R201 1K Not Fitted C174 .1uF K14 R125 1N5401 2R L2 12 3 5 R267 47K R266 U61A 4 2 C75 LM339 1uF 6 7 3 LM339 RED R708 R269 1K 22R 22ZA2 NO_PLANE_DS Optional Q11 Hall C77 1K R259 100K 6 5 C76 .1u F3 R261 47K .01u R260 D31 D35 1N5401 22ZA2 5A Fast +5D R258 10K C78 R703 7 LF353 U60B R262 470K 8 9 U61C 10 14 11 LM339 100R U61D YELLOW R707 22ZA2 13 F4 LM339 .1u 5A Fast D78 1N5401 BLUE R706 5A Fast C79 1uF 22ZA2 +5A R128 GREEN R709 F2 1 10Turn D34 MBR745 9 D77 1N5401 R271 2K2 U61B R268 +5A 1R5 S/n13884up 10 8 12 .1u 1 U60A LF353 R270 470K +5A +2A -2A R109 R704 100R 1K D73 1N5401 Q8 NPN 3 C72 .1u +5A D30 MBR745 D32 1N5401 2 .01u 5A Fast +5D C74 R124 NO_TRACK_DS +5D Optional 4 R264 100K R99 C20 .01uF LM339 D72 R263 1K 14 0V DS STANDBY C73 U13C + 10K R265 +5D 10K F1 Q12 Hall +5V DS 9 R108 390R U19D ILQ74 10Turn +5A R98 180K 1% R89 10K 4M7 R107 4M7 +5V DS 4 0V DS 0V DS L1 Frequency C22 .1uF 7 7 13 3 11 R286 1K0 R103 2R2 1N4148 - 15 4 10 LM339 U13D 8 R94 100K 100K 5K6 0V DS + 16 0V DS +5V DS 0V DS 2 D38 1N4148 DS+ 0V DS R101 D40 220K 1% R93 D39 1N4007 - 1 0V DS R97 0V DS C21 33pF + 2 LM339 C19 82pF U13A R106 - - 1K CA3140 0V DS +5V DS 5 LM339 3K9 D37 1N4148 Q3 2N3904 + 1 - 4 R105 + U19A ILQ74 + 2 R100 - 6 1 8 6 5 + + 7 - R122 390R 3 PIN 3 OF POT TO 0V DS U13B R91 47K + R112 10K U16 DS_POT2 R96 20K 1% R102 68R 2W - 113K 1% 3K9 +5V DS DS_POT1 91K DC To front panel connector R95 + R123 R90 47K R104 - R92 1K E - 2 C +5V DS 4 3 B + A 2 2APHASE 1K 100K C26 .1u C23 1uF R130 U58B 5 6 R127 10K R132 +5A + 7 - R129 TL084 1K 8 +5D U20C + - R110 14 3 2 4K7 .01u Optional U18A 1 U15D 4K7 C24 LM339 -5A -5A D29 5V6 9 +5D R111 100K 12 C27 11 13 9 10 74HC00 C28 .01u U15B 47K .01u 4 U15C 6 5 8 74HC00 SAMPLE 74HC00 R131 47K PHASE 74HC00 later units 74HC132 1 1 Polar Intruments Ltd Garenne Park, St. Sampsons Guernsey, Channel Islands Inst. A B C D 950 Title Drive Source E A B C D E 4 4 +12V DS 100K R94 100K 11 Frequency C22 .1uF 1N4148 13 12 D39 1N4007 R106 D38 1N4148 DS+0V DS R286 1K0 5K6 R103 2R2 4M7 R107 4M7 R108 390R U19D ILQ74 +5V DS 3 0V DS 9 0V DS 3K9 D37 1N4148 Q3 2N3904 10 U13D 2 LM339 3 D40 10 1K C21 33pF R101 0V DS 0V DS R93 +5V DS 7 LM339 220K 1% R97 0V DS R100 CA3140 0V DS +5V DS C19 82pF 0V DS - U13A 7 - 1 1 8 6 5 + 5 8 + - 15 2 + 16 3 DS_POT2 4 R105 U16 4 7 6 1 PIN 3 OF POT TO 0V DS U13B R122 390R 2 113K 1% R96 20K 1% R91 47K U19A ILQ74 R102 68R 2W DS_POT1 R112 10K 3K9 +5V DS R95 91K DC To front panel connector R123 R104 - R90 47K 3 2 Q4 2N3906 R92 1K + +5V DS 0V DS +5D R124 10K NO_TRACK_DS LM339 R98 180K 1% R89 10K +5V DS U13C 9 8 R88 10K 0V DS + 14 LM339 2 R99 100K 1% C20 .01uF 1 1 Polar Intruments Ltd Garenne Park, St. Sampsons Guernsey, Channel Islands Inst. A B C D 950 Title Drive Source E A B J2 PLANE C JP8 D J1 3 2 1 HEADER3 4 VPLANE+ E Headphones L701 10uH 4 R710 82ZA2 VSHORT C709 470pF C710 470pF Track DS / Current Probe JP7 J3 1 2 3 4 5 6 7 8 9 10 Trace DS- DS+ 3 NEEDLE PROBES 1 3 HEADER10 J4 3 4 Kelvin+ 5 Probe+ 2 ProbeKelvin - C712 470pF C713 470pF C711 470pF 2 2 R705 82ZA2 1 1 Polar Intruments Ltd Garenne Park, St. Sampsons Guernsey, Channel Islands Inst. A B C D 950 Title Input Sockets E B C /WR /MREQ /WR /RD /RD +5D M1 19 20 22 21 MREQ IORQ WR RD 28 REFSH 18 HALT 24 WAIT 16 17 INT NMI 26 RESET 25 23 A0 A1 A2 A3 A4 A5 A6 A7 A8 A9 A10 A11 A12 A13 A14 A15 30 31 32 33 34 35 36 37 38 39 40 1 2 3 4 5 D0 D1 D2 D3 D4 D5 D6 D7 14 15 12 8 7 9 10 13 BUSRQ BUSAK 6 CLK R171 10K A0 A1 A2 A3 A4 A5 A6 A7 A8 A9 A10 A11 A12 A13 A14 A15 D0 D1 D2 D3 D4 D5 D6 D7 A0 A1 A2 A3 A4 A5 A6 A7 A8 A9 A10 A11 A12 A13 A14 10 9 8 7 6 5 4 3 25 24 21 23 2 26 27 A0 A1 A2 A3 A4 A5 A6 A7 A8 A9 A10 A11 A12 A13 A14 A15 /RD 20 22 1 CE OE VPP + C52 10uF 7 SEN 2 R-IN 3 CT A0 A1 A2 A3 A4 A5 A6 A7 A8 A9 A10 /RD /WR 74HC138 Y0 Y1 Y2 Y3 Y4 Y5 Y6 Y7 1 2 3 A B C A15 6 4 5 G1 G2A G2B 15 14 13 12 11 10 9 7 1 VR 2 RST 6 6 4 5 G1 G2A G2B BDB0 BDB1 BDB2 BDB3 BDB4 BDB5 BDB6 BDB7 +5D 10 CS2 4 D 11 CLK PR 12 13 1M +5D U44B Q 9 Q 8 D0 D1 D2 D3 D4 D5 D6 D7 1 11 OC CLK Q0 Q1 Q2 Q3 Q4 Q5 Q6 Q7 VOLTS X10 /1 /10 /1000 OHMS CONTACT_I HIGH CS31 CS33 CS32 CS34 CS2 15 14 13 12 11 10 9 7 +5D 1 RP3 8-22K 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 CS5 CS7 QUADRANT_0 REVERSED +5D -5A BD[0..7] DMM_HI 6 5 RP7 1 8-22K 9BDB0 8BDB1 7BDB2 6BDB3 5BDB4 4BDB5 3BDB6 2BDB7 BDB[0..7] CS31 BDB0 BDB1 BDB2 BDB3 BDB4 BDB5 BDB6 BDB7 3 4 7 8 13 14 17 18 1 11 D0 D1 D2 D3 D4 D5 D6 D7 Q0 Q1 Q2 Q3 Q4 Q5 Q6 Q7 OC CLK 2 5 6 9 12 15 16 19 U63 BDB3 BDB4 BDB2 BDB5 BDB1 BDB6 BDB0 BDB7 11 12 13 14 15 16 17 18 B8 B7 B6 B5 B4 B3 B2 B1 BD[0..7] U45 DIR G 1 19 A8 A7 A6 A5 A4 A3 A2 A1 9 8 7 6 5 4 3 2 D3 D4 D2 D5 D1 D6 D0 D7 D0 D1 D2 D3 D4 D5 D6 D7 1 19 DIR G 9 8 7 6 5 4 3 2 A8 A7 A6 A5 A4 A3 A2 A1 D[0..7] CS32 0V DS VOLUME_POT2 +5D +5A -5A B8 B7 B6 B5 B4 B3 B2 B1 11 12 13 14 15 16 17 18 1 BD0 BD1 BD2 BD3 BD4 BD5 BD6 BD7 RP4 8-22K 3 +5D D[0..7] 1 11 U40 D0 D1 D2 D3 D4 D5 D6 D7 Q0 Q1 Q2 Q3 Q4 Q5 Q6 Q7 OC CLK 2 5 6 9 12 15 16 19 R_1 R_2 R_3 R_4 R_5 R_6 R_7 R_8 BDB0 BDB1 BDB2 BDB3 BDB4 BDB5 BDB6 BDB7 CS33 74HC374 U46 3 4 7 8 13 14 17 18 1 11 D0 D1 D2 D3 D4 D5 D6 D7 Q0 Q1 Q2 Q3 Q4 Q5 Q6 Q7 2 5 6 9 12 15 16 19 120R RUN /REV I_ON R298 100R OC CLK RP6 8-22K FROM A2D2A BDB[0..7] BDB[0..7] BD[0..7] NO_PLANE_DS BD[0..7] D[0..7] BDB[0..7] BDB0 3 BDB1 4 BDB2 7 BDB3 8 BDB4 13 BDB5 14 BDB6 17 BDB7 18 2BD0 3BD1 4BD2 5BD3 6BD4 7BD5 8BD6 9BD7 +5D 74HC245 BDB[0..7] TRACE DC PLANE STANDBY NO_TONE INVERT MODE_0 MODE_1 CS6 CS8 /RD 8 U47 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 74HC00 BDB[0..7] 74HC74 BD0 BD2 BD4 BD6 CENTRE NO_TRACK_DS DMM_LO D[0..7] BDB[0..7] BDB[0..7] 4 JP3 BD1 BD3 BD5 BD7 U18B 4 BDB[0..7] +5D BD[0..7] 2A8 3A9 4A10 5A11 6A12 7A13 8A14 9A15 74HC08 74HC32 QUADRANT_1 ARROW_OFF DS_POT2 74HC245 74HC374 X1 Y0 Y1 Y2 Y3 Y4 Y5 Y6 Y7 3 9 2 5 6 9 12 15 16 19 DS_POT1 2A0 3A1 4A2 5A3 6A4 7A5 8A6 9A7 1 74C04 U41A 74HC374 6 U42C 74C04 3 4 7 8 13 14 17 18 RP1 8-3K3 RP2 8-22K U29C C56 .1uF 1 +5D 8 10 R172 C55 33pF A B C 9 1 U42B 74C04 5 1 2 3 2D0 3D1 4D2 5D3 6D4 7D5 8D6 9D7 +5D A[0..15] U42D CS5 CS6 CS7 CS8 5 10uF 2 CE OE WE D[0..7] 74HC138 RST L700 10uH 3 18 20 21 D0 D1 D2 D3 D4 D5 D6 D7 9 10 11 13 14 15 16 17 D0 D1 D2 D3 D4 D5 D6 D7 A2D2A U39 + C53 A0 A1 A2 A3 A4 A5 A6 A7 A8 A9 A10 U43 A9 A10 A11 +5D 7705 C702 0.1uF 8 7 6 5 4 3 2 1 23 22 19 6116 U37 A12 A13 A14 /MREQ U38 3 D0 D1 D2 D3 D4 D5 D6 D7 A[0..15] A14 A15 +5D 11 12 13 15 16 17 18 19 O0 O1 O2 O3 O4 O5 O6 O7 27256 +5D A[0..15] R173 390R D[0..7] U34 U36 CL 4 27 Z80A E D[0..7] D[0..7] U35 D A[0..15] 1 A[0..15] BUSY BDB0 BDB1 BDB2 BDB3 BDB4 BDB5 BDB6 BDB7 2 5 6 9 12 15 16 19 Q0 Q1 Q2 Q3 Q4 Q5 Q6 Q7 SP2 2 3 4 5 6 7 8 9 A D0 D1 D2 D3 D4 D5 D6 D7 3 4 7 8 13 14 17 18 OC G 1 CS34 11 +5D 2 AC BEEP L LL H HH JP14 U48 74HC373 74HC374 C54 33pF INHIBITREV 4MHz Ceramic res 1 1 Polar Intruments Ltd Garenne Park, St. Sampsons Guernsey, Channel Islands Inst. A B C D 950 Title Microprocessor E A B R24 D E D10 1N4148 -5A + 56R DS+ C4 D11 1N4148 D12 10uF JP13 6 1K C2 .022uF 1N4148 U2B C3 7 - 5 0V DS + R15 .01uF TL084 R18 R19 4K7 4 1K 4 2 1 4 2 R17 JP11 3 100K R16 1K C5 + R20 +5A U2A + 11 10 9 8 7 6 5 4 3 2 1 C90 U2D 1 12 13 .1uF TL084 + - R297 100K 10uF D2 14 10 VSHORT PLANE+ 9 1N4148 TL084 C6 .1uF 56R U2C + - R22 8 TL084 Trace+ 20K C7 .1uF R23 1K0 R21 1K Trace- RELAY K1 connected this way for thermal match I_SOURCE K1 R6 U1 R13 100K D7 470K 1% 3 /1 R204 430K 1% R14 D84 1N4148 1N4148 R8 R10 2K 1% K3 1N4148 (USES 4053 ON TONE DIAGRAM) 75K 1% 120R 1W 3 4 GUARD V- 5 6 V+ GUARD 9 CLAMP C9 8 2 1 7 .1u -5A RET CA CB V- OUT +5A 100K R11 20K 1% C8 .1u D3 1N4148 10 V+ INT/EXT CLK CLK OUT C63 .1u 11 14 13 12 R12 1N4148 D4 1N4148 R1 560K 3 D6 D5 1N4148 1N4148 D1 3V3 7650 10 /1000 D86 R9 200R /10 D85 R3 1K0 1% D8 1N4148 2R2 24K R205 R7 R5 K2 C1 .1uF C708 100pF R2 150K 10RET HI LO 10K 4 R4 1R0 120R K4 3 OHMS_NULL D87 2 1N4148 U58A + 1 2 11 2 C D9 1N4148 TLC279 U59 NC R245 200R R25 Not fitted 10 DACV+ 9 R239 200R R240 20K U58C + 8 - TLC279 PLANEV+ TRACE+ MODE_0 MODE_1 12 14 15 11 X0 X1 X2 X3 1 5 2 4 6 10 9 Y0 Y1 Y2 Y3 INH A B X 13 Y 3 D79 1N4148 D80 1N4148 D82 1N4148 TONE_GEN C70 .1u R246 20K R243 360K D81 1N4148 R242 7 8 2K2 -5A R241 20K 4052 D83 3V3 R244 150K 1 1 Polar Intruments Ltd Garenne Park, St. Sampsons Guernsey, Channel Islands Inst. A B C D 950 Title Microvolt Amplifier E A R715 B 1M0 +5A R54 R251 10M CLAMP 8 2 1 7 VSHORT R57 U6B 5 C64 .1u +5A 11 14 13 12 JP12 C17 .1u .1u U6A 3 + 2 1 2 3 PHASE C18 + 6 7650 -5A C704 4n7 7 U8 8 -5A 10K V+ INT/EXT CLK CLK OUT RET CA CB V- 10 - TLC279 R292 1 10K 1% D97 R294 4K7 R291 91K C705 0.01 1 R51 10K 1% 10K 1% VX 10K 10 R85 100K +5A 2 6 - R78 100K 7 + -5A U17B LM339 1 R80 4 5 U17A 2 LM339 - 10K TLC279 U18D 12 11 13 U3B 3 2 R74 10K 3 C14 .1u 5 6 7 1 + - LM311 4 74HC04 6 R250 4K7 R255 11 13 R235 1K QUADRANT_0 QUADRANT_1 1K 2 +5D +5A CENTRE C16 .47u U6D + R63 14 - 2 3 10K TLC279 C15 .1u + - U10 5 6 7 1 R75 10K LM311 74HC08 3 4K7 12 13 8 10 R234 74HC08 U41C 9 ARROW_OFF U41D 12 74HC08 +5D -5A -5A 74HC00 later units 74HC132 U41B 4 5 4K7 12 0.1 R248 5K6 R82 4K7 R254 R64 8 C13 .47u PLANEV+ VY - R247 100K 8 PLANE 470K + +5A R79 100R C65 9 U6C + +5A +5D R253 1K 330R in later units - R86 10 R213 1K U7C TLC279 + 9 +5D +5A U14 11 - TLC279 R53 -5A R83 100K R60 100K 1% 8 2 C12 .47u 4052 3 +5A U7A + A B 10K 1% TLC279 8 3 +5A - 4 C11 .47u 11 15 14 12 R296 4K7 R52 14 X X3 X2 X1 X0 VX VY R295 U7D + Y 4 4 13 R237 1K TLC279 3 13 9 10 6 4 2 5 1 4 12 R68 100K 1% R236 1K 7 B A INH Y3 Y2 Y1 Y0 1N4148 10K 1% A B 6 5 R293 Sensitivity Pot 100K 1% U7B R58 100K 1% D96 1N4148 10K 1% TLC279 -5A R59 7 - 4 D24 DIODE OUT R714 10R R209 11 V+ GUARD 9 GUARD V- - 5 6 C89 0.01 3 12 74HC04 + 100K R56 1M 1% U3F 13 R716 10K C714 0.1uF R72 10K 1% +5A SAMPLE 10K U12 3 4 PLANE+ D25 DIODE E PHASE C703 4n7 10K 1% D R717 1M 1% R252 10M R55 4 C Fitted from S/No 012213 -5A R249 470K 1 1 Polar Intruments Ltd Garenne Park, St. Sampsons Guernsey, Channel Islands Inst. A B C D 950 Title Plane Input Amplifier E C D E +5D R206 Q9 PNP +5A 3 1K 5 D 3 CLK R 7 Invert ON for uV U24 12 13 X0 X1 2 1 Y0 Y1 5 3 Z0 Z1 6 11 10 9 INH A B C 10 .56V 56mV R137 22K Tone_Gen -5A 15 Z 4 R150 47K 7 8 R133 22K -5A Hi>-60mV 1 - 10 11 +5D 200mOHM_THRESHOLD - 470K 4 Pin7 to -5A VOLUME_POT2 2 C92 1nF R208 10K U17D R280 C707 0.1uF - 3 6 3 + R281 10K 13 CA3080 +5A +5A 13 R154 To Loudspeaker JP9 100K 1 2 C85 .1u 2 A U23A 4016 C R282 10K U18C B 2 4013 -5A 1N4148 10 Hi<+60mV 3 C93 1nF LM386 U22 To Headphone Jack C32 5 JP10 3 2 1 220uF +5D 8 9 2 3 + 10K 2 R257 56R 74HC00 12 4 R142 1K2 R278 4K7 47K 1 +5A 5 2M2 LM339 D41 U20A LM339 R279 R152 100K C31 .1uF 470K 12 CLK +5D R153 R155 10K R141 56K Q R151 360K +5A C33 .1uF 13 U64 - + R156 11 Q O_I LM339 R140 1K2 13 D R149 + 6 9 1M -5A 7 U20D LM339 U20B R139 47K 11 R145 C30 .01uF 10RET 4053 INVERT X10 OHMS R138 100K Y R157 22K 4 5 22K 14 2 -5A U21B 4 R136 X 10 Q 7 - 1N4148 + + 270R 4 6 R135 5K6 D42 1 6 Pin7 to -5A Q7 PNP R148 8 4 5 10uF Q 4013 R207 10K S A + C29 U5B LF353 R144 1K8 R143 5K6 R C R147 10K 10 B R134 22K - 5 +5D S NO_TONE +5A U23C 4016 U21A 6 +5A 3 2 B + 4 A R256 10K U42E 11 + C71 U29A 10 Turns tone off <+60mV in uV 10uF 1 3 2 74HC04 /REV U23,U21 Pin7 to -5A REVERSED 74HC32 INHIBITREV 1 1 Polar Intruments Ltd Garenne Park, St. Sampsons Guernsey, Channel Islands Inst. A B C D 950 Title Tone Generator E A B C BD[0..7] CS5 CS7 4 QUADRANT_0 DS_POT2 VOLUME_POT1 REVERSED +5D -5A BD0 BD2 BD4 BD6 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 R191A 100K Ganged DS_POT2 Volume CS6 CS8 R192 100K Panel ARROW_OFF QUADRANT_1 DS_POT1 DS_POT3 VOLUME_POT2 NO_TRACK_DS +5D HEADER20X2 R700 330R CS5 BD[0..7] +5A CENTRE +5A -5A DMM_LO BD0 BD1 BD2 BD3 BD4 BD5 BD6 BD7 VOLUME_POT1 -5A +5D C69 .1uF C68 C66 10uF DMM_HI + C67 .1uF D[0..7] BD0 BD1 BD2 BD3 BD4 BD5 BD6 BD7 BD[0..7] + C57 10uF 10uF + 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 CS6 BD[0..7] R701 330R BD[0..7] BD0 BD1 BD2 BD3 BD4 BD5 BD6 BD7 BD[0..7] +5D 1 3 BD[0..7] RP5 8-22K VSS GND VDD VCC +5D CS7 R702 330R Q0 Q1 Q2 Q3 Q4 Q5 Q6 Q7 D0 D1 D2 D3 D4 D5 D6 D7 3 4 7 8 13 14 17 18 CS8 1 11 OC CLK +5D Q0 Q1 Q2 Q3 Q4 Q5 Q6 Q7 2 5 6 9 12 15 16 19 Q0 Q1 Q2 Q3 Q4 Q5 Q6 Q7 2 5 6 9 12 15 16 19 R174 270R D53 R176 270R D55 R178 270R D57 R184 OC G 1 11 R175 270R R177 270R +5D D0 D1 D2 D3 D4 D5 D6 D7 1 11 OC CLK 3 4 7 8 13 14 17 18 D0 D1 D2 D3 D4 D5 D6 D7 1 11 OC CLK R186 390R D65 R188 390R D67 R185 270R D64 R187 390R LED R189 390R D68 D? PLANE STANDBY PROBE_1 PROBE_2 PROBE_3 74HC374 Q0 Q1 Q2 Q3 Q4 Q5 Q6 Q7 2 5 6 9 12 15 16 19 3 DEC_1 DEC_2 +5D D50 D52 D46 D47 RIGHT LEFT DOWN D48 R216 270R 390R +5D R217 270R R218 270R R219 270R U57A QUADRANT_0 QUADRANT_1 2 3 A B ARROW_OFF 1 G 4 5 6 7 Y0 Y1 Y2 Y3 2 74HC139 S4 2 Ohms S6 Super Shorts R224 CENTRE 270R S5 200mOHM S7 TRACE R221 270R R222 270R R223 270R Q10 NPN S9 PLANE 1 Polar Intruments Ltd Garenne Park, St. Sampsons Guernsey, Channel Islands Inst. 970 A 4 U51 3 4 7 8 13 14 17 18 R220 270R S3 20R TRACE 270R R215 330R 1 D56 NO_TRACK_DS R703 S2 200R OHMS 20mOHMS 2OHMS 2KOHMS 20KOHMS D54 D58 UP 74HC373 2 D0 D1 D2 D3 D4 D5 D6 D7 2 3 4 5 6 7 8 9 2 5 6 9 12 15 16 19 3 4 7 8 13 14 17 18 U52 74HC374 U49 BD0 BD1 BD2 BD3 BD4 BD5 BD6 BD7 E U50 74HC374 Sensitivity JP4 BD1 BD3 BD5 BD7 D B C D Title FRONT PANEL PAGE1 E A B CS5 CS7 QUADRANT_0 DS_POT2 VOLUME_POT1 REVERSED +5D -5A BD0 BD2 BD4 BD6 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 R191A 100K Ganged DS_POT2 Volume CS6 CS8 R192 100K Panel ARROW_OFF QUADRANT_1 DS_POT1 DS_POT3 VOLUME_POT2 NO_TRACK_DS +5D HEADER20X2 R700 330R CS5 BD[0..7] +5A CENTRE +5A -5A DMM_LO BD0 BD1 BD2 BD3 BD4 BD5 BD6 BD7 VOLUME_POT1 C66 10uF DMM_HI + -5A +5D C67 .1uF D[0..7] BD0 BD1 BD2 BD3 BD4 BD5 BD6 BD7 BD[0..7] C68 + C57 10uF 10uF C69 .1uF + 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 CS6 R701 330R BD[0..7] BD0 BD1 BD2 BD3 BD4 BD5 BD6 BD7 BD[0..7] +5D 1 BD[0..7] BD[0..7] RP5 8-22K 3 VSS GND VDD VCC CS7 +5D R702 330R Q0 Q1 Q2 Q3 Q4 Q5 Q6 Q7 D0 D1 D2 D3 D4 D5 D6 D7 3 4 7 8 13 14 17 18 OC G 1 11 D0 D1 D2 D3 D4 D5 D6 D7 1 11 OC CLK Q0 Q1 Q2 Q3 Q4 Q5 Q6 Q7 +5D 2 5 6 9 12 15 16 19 R174 270R D53 R176 270R D55 R178 270R D57 R181 270R D59 R175 R177 270R D56 270R D58 R180 270R D60 4 U51 3 4 7 8 13 14 17 18 D0 D1 D2 D3 D4 D5 D6 D7 1 11 OC CLK Q0 Q1 Q2 Q3 Q4 Q5 Q6 Q7 2 5 6 9 12 15 16 19 R182 270R D61 R184 270R D63 R186 390R D65 R188 390R D67 D0 D1 D2 D3 D4 D5 D6 D7 1 11 OC CLK Q0 Q1 Q2 Q3 Q4 Q5 Q6 Q7 R183 270R D62 D64 LED R185 270R R187 390R R189 390R 2mV 20mV 20V PLANE STANDBY PROBE_1 PROBE_2 PROBE_3 D68 D? +5D 74HC374 3 4 7 8 13 14 17 18 OHMS 20mOHMS 2OHMS 2KOHMS 20KOHMS 200mA 2A TRACE D54 +5D 2 5 6 9 12 15 16 19 REVERSED R283 D69 390R UNCAL DEC_1 DEC_2 +5D 3 D51 R214 390R NO_TRACK_DS +5D D50 D52 D46 D47 D48 RIGHT LEFT DOWN R215 390R R216 270R R217 270R R218 270R R219 270R U57A R703 330R QUADRANT_0 QUADRANT_1 2 3 A B ARROW_OFF 1 G Y0 Y1 Y2 Y3 4 5 6 7 74HC139 R220 270R S2 20K 270R R179 UP 74HC373 CS8 E 2 3 4 5 6 7 8 9 2 5 6 9 12 15 16 19 3 4 7 8 13 14 17 18 U52 74HC374 U49 BD0 BD1 BD2 BD3 BD4 BD5 BD6 BD7 D U50 74HC374 Sensitivity JP4 BD1 BD3 BD5 BD7 4 2 C BD[0..7] S4 2 Ohms S6 Super Shorts S8 2A S10 20mV S12 20mV S13 20V R221 270R R222 270R R223 270R 2 S14 Plane CENTRE R224 270R Q10 NPN S3 200 Ohm Late S5 200mOHM 2K Early S7 200mA S9 Trace 1 1 Polar Intruments Ltd Garenne Park, St. Sampsons Guernsey, Channel Islands Inst. A B C D 950 Title Front Panel page 1 E 4 A B R227 39R R228 39R R229 39R R230 39R R231 39R C R232 39R D E R233 39R U54 BP D76 BACKLIGHT ARRAY U53 C58 R226 21 22 23 24 25 .22uF 47K BP G3 A3 C3 G2 -5A -5A 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 C59 .22uF DMM_LO R194 C700 2n2 C61 .1uF DMM_HI C701 2n2 1M0 R197 C62 R196 1K .01uF Volts Cal +5A 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 DP3 DP2 DP1 BP X Z NC NC NC NC NC G3 F3 A3 B3 L G2 F2 A2 B2 G1 F1 A1 BP Y K NC NC NC NC DP3 E3 D3 C3 DP2 E2 D2 C2 DP1 E1 D1 C1 B1 C60 100pF R195 100K LCD +5A 3 R200 U55A 1M0 1 3 2 VEE 4070 -5A DP1 U55D 12 11 13 +5D U56 X 2 4 -5A *1 3 40 39 38 37 36 35 34 33 32 31 30 29 28 27 26 25 24 23 22 21 7106 22K 3 VINT BUFF A/Z IN LO IN HI COMMON C- REF C+ REF REF LO REF HI TEST OSC3 OSC2 OSC1 POL AB4 E3 F3 B3 D3 E2 F2 A2 B2 C2 D2 E1 G1 F1 A1 B1 C1 D1 V+ 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 X0 X1 X2 X3 X4 X5 X6 X7 13 14 15 12 1 5 2 4 INH A B C 6 11 10 9 R199 1M0 4070 U55B 5 4 6 DP2 4070 -5A R198 1M0 4051 2 U55C *2 8 10 9 DEC_1 DEC_2 4070 DP3 *2 *1 NOTE:Pin 7 to Test PIN 8 TO GND -VE SUPPLY FOR 4070/4051 BP 1 1 Polar Intruments Ltd Garenne Park, St. Sampsons Guernsey, Channel Islands Inst. A B C D 950 Title Front Panel page 2 E A R715 B 1M0 +5A R54 R251 10M CLAMP 8 2 1 7 VSHORT R57 U6B 5 C64 .1u +5A 11 14 13 12 JP12 C17 .1u .1u U6A 3 + 2 1 2 3 PHASE C18 + 6 7650 -5A C704 4n7 7 U8 8 -5A 10K V+ INT/EXT CLK CLK OUT RET CA CB V- 10 - TLC279 R292 1 10K 1% D97 R294 4K7 R291 91K C705 0.01 1 R51 10K 1% 10K 1% VX 10K 10 R85 100K +5A 2 6 - R78 100K 7 + -5A U17B LM339 1 R80 4 5 U17A 2 LM339 - 10K TLC279 U18D 12 11 13 U3B 3 2 R74 10K 3 C14 .1u 5 6 7 1 + - LM311 4 74HC04 6 R250 4K7 R255 11 13 R235 1K QUADRANT_0 QUADRANT_1 1K 2 +5D +5A CENTRE C16 .47u U6D + R63 14 - 2 3 10K TLC279 C15 .1u + - U10 5 6 7 1 R75 10K LM311 74HC08 3 4K7 12 13 8 10 R234 74HC08 U41C 9 ARROW_OFF U41D 12 74HC08 +5D -5A -5A 74HC00 later units 74HC132 U41B 4 5 4K7 12 0.1 R248 5K6 R82 4K7 R254 R64 8 C13 .47u PLANEV+ VY - R247 100K 8 PLANE 470K + +5A R79 100R C65 9 U6C + +5A +5D R253 1K 330R in later units - R86 10 R213 1K U7C TLC279 + 9 +5D +5A U14 11 - TLC279 R53 -5A R83 100K R60 100K 1% 8 2 C12 .47u 4052 3 +5A U7A + A B 10K 1% TLC279 8 3 +5A - 4 C11 .47u 11 15 14 12 R296 4K7 R52 14 X X3 X2 X1 X0 VX VY R295 U7D + Y 4 4 13 R237 1K TLC279 3 13 9 10 6 4 2 5 1 4 12 R68 100K 1% R236 1K 7 B A INH Y3 Y2 Y1 Y0 1N4148 10K 1% A B 6 5 R293 Sensitivity Pot 100K 1% U7B R58 100K 1% D96 1N4148 10K 1% TLC279 -5A R59 7 - 4 D24 DIODE OUT R714 10R R209 11 V+ GUARD 9 GUARD V- - 5 6 C89 0.01 3 12 74HC04 + 100K R56 1M 1% U3F 13 R716 10K C714 0.1uF R72 10K 1% +5A SAMPLE 10K U12 3 4 PLANE+ D25 DIODE E PHASE C703 4n7 10K 1% D R717 1M 1% R252 10M R55 4 C Fitted from S/No 012213 -5A R249 470K 1 1 Polar Intruments Ltd Garenne Park, St. Sampsons Guernsey, Channel Islands Inst. A B C D 950 Title Plane Input Amplifier E