Download COP. ING.fm

Transcript

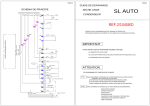

Language: English MMA UNITS 125-130A Date Creation: Jan. 2005 Rev.: 00 Service Manual 1105 INVERTERS MMA 130A 1.0 REPAIR INSTRUCTIONS 2. Check on all the harnesses the insulation of the cables and the state at the connection points. 1.1 GENERAL CLEANING Remove the machine shell and clean carefully with compressed air. 1.2 MACHINE: VISUAL INSPECTION 1. Check the general conditions of the electronic circuit ref. 1, particularly: • the varistor (RV1) (fig. 1) if it presents bursting marks 1.3 CHECK OF THE MAIN COMPONENTS WITH TESTER (OHMMETER) ON THE CIRCUIT REF. 1 1. Check for the presence of short circuits on the rectifier bridge (VD1) and the correct value of the power resistance (R14) (fig. 3). R14 • the state of the levelling condensers C32 and C33 (fig. 2) check if there are swellings or breaks on the container RV1 VB1 FIG.3 RIF. 1 FIG. 1 REF. 1 1. IGBT of the primary circuit and diodes of recycle: test points G-C, G-E, C-E of components 1 and 2; points A-K of components 3 and 4 (fig. 4). 1 3 C32 2 4 C33 FIG. 2 REF. 1 • check for the presence of cracks or breaks on the welds of the following components: • transformer T1 • impedance L2 • the presence of burn tracks or electric discharge marks on the printed circuit In case of faults, replace the electronic circuit ref. 1 1105 FIG. 4 RIF. 1 2. Diodes of the secondary circuit: check points 1-K of diodes VD1 and VD2 (fig. 5). If there are short circuits or faults during these tests, replace the electronic circuit. Pag. 3 INVERTERS MMA 130A VD1 VD2 FIG. 5 REF. 1 1.4 CHECK OF GENERATOR OPERATION WITH OSCILLOSCOPE AND VOLTMETER FIG. 8 REF. 1 2. Disconnect the feeder; set the oscilloscope with a range of 1V/Div and connect the probe X100 between points M and P (fig. 9); connect the machine to the power supply, switch it on: 1. Connect a feeder on the zener V13 with GND on the anode and supply with approx. 15Vdc; set the oscilloscope on a time base of 5 uS and a range of 0.5 V/Div with probe x10 and verify: • the presence between points: E (GND) - A (probe) and F (GND) - B (probe) (fig. 6) of the waveform shown in fig. 7: if the waveform differs from the one in the figure or it is not present, the electronic circuit is broken. Solution: board replacement ref. 1. A P M E FIG.8 RIF. 1 B • the motor fan starts up, and after approx. 2 seconds a wave will appear as in fig. 9. F FIG. 7 REF. 1 FIG. 9 REF.1 1105 Pag. 5 INVERTERS MMA 130A • check with a voltmeter that the output voltage is approx. 47Vdc (see test specification point 2). • If the wave form does not appear or the output voltage is not correct, replace the electronic circuit ref. 1 Carry out the final test after the repair. U T 2.0 FINAL TEST 1. Carry out the safety test according to our operative instruction N. SLL12, before proceeding, act as follows: FIG. 10 RIF. 1 • on the electronic board (ref. 1) short-circuit points U, T and a rheophore of the primary circuit of the transformer (fig. 10) PRIMARY CIRCUIT OF THE TRASF. • switch on • short-circuit the feeder plug • short-circuit the output dinse.. After the test remove all the short circuits and switch off. 2. Connect the generator to the power supply (230 Vac), switch it on and check if the voltage of the outputs is 47 Vdc (+/- 5%): switch off the generator. 3. Connect the generator to the resistive load: the load must be regulated so that the voltage on the load, with maximum current, is between 20V and 23V. Apply oscilloscope probe as in fig. 8 4. Set the regulation knob to the centre of the dial, switch on the generator, turn the knob to the maximum welding current and read with the amperometer the maximum current indicated on the technical table with +/- 5% tolerance. You will see on the oscilloscope a waveform as in fig. 11. 5. If the current readings differ, use the trimmer T (fig. 13) to obtain the correct current value. FIG. 11 REF. 1 T 6. Short-circuit the load and verify that after 1,5 sec. the current descends to approx. 25A. 7. Regulate the resistive load to measure the minimum current (5A - 20V), set the minimum current on the frontal panel and check with the amperometer that there is a value near than the one indicated on the technical table. FIG. 12 REF. 1 8. Disconnect the probe, switch off the generator and with the load to the maximum current, let the machine work at the greatest capacity. 9. Carry out MMA welding tests at maximum current (one electrode) 1105 Pag. 7 LISTA PEZZI DI RICAMBIO - SPARE PARTS LIST - PIÈCES DÉTACHÉES - ERSATZTEILLISTE - LISTA DE LAS PIEZAS DE RECAMBIO 06 05 11 09 56 12 08 72 14 01 SAXO 1300 R. COD. 01 05 06 DESCRIZIONE DESCRIPTION DESCRIPTION BESCHREIBUNG DESCRIPCIÓN W000050018 CIRCUITO ELETTRONICO CE 22599 CIRCUIT BOARD CE 22599 CIRCUIT ÉLECTRONIQUE CE 22599 STEUERPLATINE CE 22599 CIRCUITO ELECTRÓNICO CE 22599 W000050019 POTENZIOMETRO POTENTIOMETER POTENTIOMÉTRE POTENTIOMETER W000050028 AGGANCIO CINGHIA STRAP ATTACHMENT ANNEAU ACC. DE LA SANGLE CÂBLE D'ALIMENTATION RIEMENKUPPLUNG NETZKABEL POTENCIÓMETRO ENGANCE DE LA CORREA CABLE DE ALIMENTACIÓN 08 W000050020 CAVO ALIMENTAZIONE POWER CABLE 09 W000050021 PRESSACAVO CABLE CLAMP SERRE-CABLE KABELSCHELLE PRENSACABLE 11 W000050022 INTERRUTTORE SWITCH INTERRUPTEUR SCHALTER INTERRUPTOR RACOR DE SALIDA 12 W000050023 RACCORDO USCITA OUTLET CONNECTOR RACCORD SORTIE AUSGANGSANSCHLUSS 14 W000050026 MOTOVENTILATORE ELECTRIC FAN MOTOVENTILATEUR MOTORLÜFTER VEN. ELÉCTRICO -- W000050029 CINGHIA NYLON NYLON STRAP COURROIE NYLON NYLONRIEMEN CORREA DE NYLON 56 W000050025 MANOPOLA KNOB BOUTON DREHKNOPF PERILLA 56 W000050024 CAPPUCCIO HOOD CAPUCHON KAPPE CAPUCHÓN 72 W000050027 SUPPORTO SCHEDA SUPPORT SUPPORT AUFHANGUNG SUPORTE 1105 SAXO 1300 SCHEMA ELETTRICO - WIRING DIAGRAM - SCHÉMA ÉLECTRIQUE - STROMLAUFPLAN - ESQUEMA ELÉCTRICO 1105 TAV. 2 R37 V26 2 3 RB1 R35 E3 RB2 V17 1 V29 1 R34 R41 3 V27 R36 V21 R29 R28 1 VM3 C25 3 2 3 R38 V24 VM4 3 R32 V18 2 VM2 R27 R39 V25 V19 TA1 XTA2 RTH1 ISOLANTE PRESSPAN 2 1 V20 2 VM1 E2 2 E6 V23 R31 1 C19 XTA1 E1+E5 VB1 A T1 K VD1 A 6 E8 E7 R16 V16 C7 C17 C16 3 M1 AIR FLOW C12 XP2 L1 C11 C9 R23 R25 R24 E4 A XP4 XP3 2 1 V3 3 V2 R3 R4 V6 XPE1 R2 C6 K VD2 R33 C2 A 3 RP2 2 1 L4 TI1 V1 A C10 K VD3 C22 A 1 XP7 C15 R8 XP8 V4 R10 V9 V10 X1 R12 1 2 3 XPE2 + XP10 - XP9 C5 C3 R18 R19 XP1 1 R26 R1 V13 V7 V11 C13 R20 K1 U1 V14 V15 V5 1 2 3 C14 R17 V12 R21 R22 C18 R13 R14 R15 L2 8 L3 7 5 V8 4 RTH2 3 R30 2 C20 R5 C4 R6 R7 1 1 C24 2 1105 3 C1 VH1 21min 23max RP1 CIRCUITO ELETTRONICO - ELECTRONIC CIRCUIT - CIRCUIT ÉLECTRONIQUE - ELEKTRONIKSCHALTUNG - CIRCUITO ELECTRÓNICO RIF.01 - CE 22599 - COD. 800022599 2 1 TAV. 3 A CIRCUITO ELETTRONICO - ELECTRONIC CIRCUIT - CIRCUIT ÉLECTRONIQUE - ELEKTRONIKSCHALTUNG - CIRCUITO ELECTRÓNICO RIF. 01 - CE 22599 - COD. 800022599 1105 TAV. 3 B R17 R16 R15 R14 R13 R12 R11 C9 C4 C3 R10 C8 R18 R9 C2 R8 R7 R6 R5 C1 V5 V6 V10 V11 R32 R31 R30 R29 R27 R28 N1 R19 C19 C10 C18 R26 R25 C17 R24 C15 C16 C14 R23 R22 C13 R21 C12 V9 R20 C11 U1 C6 V8 V12 X1 1 1105 C5 V4 V7 C20 C7 V3 V2 R4 R3 R2 V1 R1 CIRCUITO ELETTRONICO - ELECTRONIC CIRCUIT - CIRCUIT ÉLECTRONIQUE - ELEKTRONIKSCHALTUNG - CIRCUITO ELECTRÓNICO RIF. 1 - CE 22597 - COD. 800022597 23 25 TAV. 3 C CIRCUITO ELETTRONICO - ELECTRONIC CIRCUIT - CIRCUIT ÉLECTRONIQUE - ELEKTRONIKSCHALTUNG - CIRCUITO ELECTRÓNICO COLT 1300 - RIF. 1 - CE 22597 - COD. 800022597 1105