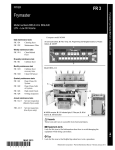

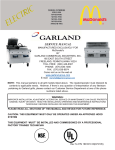

Download MWE3W / MWG3W Service Manual

Transcript