Download Installation Manual WIRED TRAWL SONAR TS-331A

Transcript

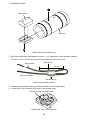

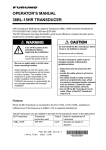

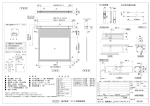

Back Installation Manual WIRED TRAWL SONAR TS-331A SAFETY INSTRUCTIONS...................................................................................... i SYSTEM CONFIGURATION................................................................................. ii EQUIPMENT LISTS ............................................................................................. iii 1. UNDERWATER UNIT ....................................................................................... 1 1.1 Wiring ........................................................................................................................... 1 1.2 Connecting the Cable to the Underwater Unit ............................................................... 7 2. SURFACE PROCESSOR UNIT ..................................................................... 10 2.1 Mounting..................................................................................................................... 10 2.2 Wiring ..........................................................................................................................11 3. CATCH SENSOR (OPTION) .......................................................................... 12 PACKING LISTS ............................................................................................... A-1 OUTLINE DRAWING......................................................................................... D-1 SCHEMATIC DIAGRAM ....................................................................................S-1 SAFETY INSTRUCTIONS CAUTION WARNING ELECTRICAL SHOCK HAZARD Attach protection earth securely to the ship's body. Do not open the equipment. Only qualified personnel should work inside the equipment. The protection earth is required for the surface processor unit to prevent electrical shock. When using a two prong outlet, use the adaptor with the earth wire (pin). Turn off the power at the switchboard before beginning the installation. Fire or electrical shock can result if the power is left on. Observe the following compass safe distances to prevent deviation of a magnetic compass: Do not install the surface processor unit where it may get wet from rain or water splash. Surface processor unit Water in the equipment can result in fire, electrical shock or damage to equipment. Be sure that the power supply is compatible with the voltage rating of the equipment. Connection of an incorrect power supply can cause fire or damage the equipment. i Standard Steering 0.3 m 0.3 m SYSTEM CONFIGURATION PC Monitor (User supply) Power source 110/220 VAC 1f, 50/60Hz Surface Processor Unit Mouse Keyboard Winch Cable Block SHIPBOARD SECTION UNDERWATER SECTION Underwater Unit : Standard supply : Optional supply : Local, user supply Catch Sensor (option) (4 max.) ii EQUIPMENT LISTS Standard Supply Name Surface Processor Unit Underwater Unit Installation Materials Accessories Spare Parts Type MODEL854-000-002 MODEL854-000-360 CP01-01400 Code No. - Qty 1 1 1 FP03-01100 - 1 FP01-01200 SP01-01300 - 1 1 Remarks Power cable Test cable, mouse (w/USB adapter + MS-14S connector) U/W connector Fuse Optional Supply Name Catch Sensor Type CS-400 Code No. 000-060-120 iii Qty 1 Remarks Maximum four available. This page is intentionally left blank. 1. UNDERWATER UNIT 1.1 Wiring The underwater unit is connected to the surface processor unit with an armored coaxial cable (user supply, maximum length: 3000 m). If necessary, a winch (local supply) is placed between the underwater unit and the surface processor unit. Recommended cable is shown below. Outer conductor Armored wire (inner) Conductor Armored wire (outer) Insulator Recommended armored coaxial cable, sectional view Construction Conductor: Insulator: Screen: Jacket: Armor wire: 1.9 mm² plain copper strand (1 ea) Polyethylene Served plain copper Polyethylene Two contrahelical layers of high tensile galvanized steel wires Mechanical Diameter: Weight in air: Weight in seawater: Rec. bending radius: Breaking strength: Working load: 11.2 mm 452 kg/km 366 kg/km 230 mm 72 kN 18 kN Electrical Maximum working voltage: Conductor resistance: Impedance: Attenuation: 1.9 kVDC 9.8 Ω/km for conductor, 6.9Ω/km for screen 40 Ω 10.5 dB/km at 1 MHz, 23.3 dB/km at 5 MHz 1 1. UNDERWATER UNIT 1 .1.1 Tension relief system The first thing to do is to construct the tension relief system, an example of which is shown below. The connection of the underwater unit is described in the next section. Rubber plates (2 pcs.) Buoy (Styrofoam) Twist the cable grip termination around the wire. (Recommended cable grip is: P/N: 2202148, LOT: S1313 PMI Dia.: 437"-456" LAY LHL PMI Industries, Inc.) Wire clamps Leave slack in cable. Attach a spring-loaded hook (shackle) at the fold of the cable grip termination. Run the bridle through the hook on the shackle. Bridle (crowfoot, steel wire) Head rope Underwater unit Typical tension relief system 2 1. UNDERWATER UNIT 1.1.2 Connecting the armored coaxial cable and U/W connector The end of the armored coaxial cable should be fabricated for connection to the underwater unit. Follow the steps shown below. Necessary parts for fabrication • Vinyl tape • Self-binding tape • Shrink tubes Fabricating 1. Wrap vinyl tape around the armored coaxial cable at the position of 280 mm from the end. Vinyl tape 280 mm Underwater side Armored coaxial cable Winding vinyl tape 2. Cut off the outer armor wire as shown below at the position of 280 mm from the end. Cut off the outer armor wire. Outer armor wire Inner armor wire Cutting outer armor wire Note: Do not make scratches on inner armor wires. 3 1. UNDERWATER UNIT 3. Wrap vinyl tape around the wire at the position of 240 mm from the end, and then untwist inner armors at the position of taping. 4. Cut each wire off. Cut off inner armor wires. Outer armor Vinyl tape Inner armor 240 mm 40 mm Trimming inner armors 5. Wind self-binding tape (local supply) around the end of the inner armor, and then slip the shrink tube (length: approx. 100 mm, type: e.g. TMX 12.7/4.1 manufactured by Novatio, local supply) onto the cable. Slip a shrink tube. Self-binding tape Self-binding tape and shrink tubing 4 1. UNDERWATER UNIT 6. Shift the shrink tube to the position as below, and heat it. Note: Heat the shrink tubing from its center to allow air to pass out. Shrink tube Heating the shrink tubing 7. Wrap vinyl tape with uniform thickness around the shrink tube. Inner: Shrink tube Outer: Vinyl tape Vinyl tape and shrink tubing 8. Fabricate the end of the cable as below. mm 20 20 mm Twist the outer conductor. 20 mm Fabricating the cable end 5 1. UNDERWATER UNIT 9. Pass the shrink tubing (type: e.g. TMX 12.7/4.1, local supply) through the U/W connector. 10. Pass the shrink tubing (type: e.g. TMX 4.8/1.5, local supply) into both of the cables of the U/W connector. 11. Solder cables as shown below. Soldering Twisted uctor d outer con Armored coaxial cable Core Soldering White Shrink tube U/W connector Black Shrink tube Soldering the armored coaxial cable and underwater unit cable 12. Shift the shrink tube to the position covering the connection position. 13. Heat the shrink tube. 14. Wind self-binding tape around the connection of the armored coaxial cable and U/W connector, and then wrap vinyl tape with uniform thickness over self-binding tape. 15. Slide the shrink tube onto the connection point. 16. Heat the shrink tube from its center. Note: Heat the shrink tubing from its center to allow air pass out. 17. Wind vinyl tape around the shrink tube. 18. Finally, wind vinyl tape as below, overlapping by 1/2 the width of the tape. 370 mm End of shrink tubing (127/41) U/W connector Taping 6 1. UNDERWATER UNIT 1.2 Connecting the Cable to the Underwater Unit To connect the cable assy. fabricated in section “1.1.2 Connecting the armored coaxial cable and U/W connector” to the underwater unit, dismount the cable retainer from the underwater unit. 1. Unfasten six hex. bolts to open the underwater unit cover. Hex. bolt (6 pcs.) Clamp assy Underwater unit, cover removed 2. Loosen two bolts to dismount the cable retainer from the inside of the clamp assy. 3. Loosen two bolts to separate the cable retainer. 7 1. UNDERWATER UNIT Cable retainer Clamp assy Cable retainer and clamp assy 4. Bend the cable assy. (connected in section 1.1.2), and fasten it with the cable retainer. The armor of the coaxial cable should be placed into the narrower groove. U/W connector Wider groove 370 mm Armor coaxial cable Narrower groove Cable assy w/cable retainer 5. Reassemble the cable retainer, and then reattach it to the clamp assy. 6. Connect the U/W connector to the top of the vertical sonar. Connect the U/W connector to here. Underwater unit, cover removed 8 1. UNDERWATER UNIT Notch Underwater unit, cover removed 7. Run the armored coaxial cable through the notch on the housing. 8. Reattach the underwater unit cover with six bolts. 9 2. SURFACE PROCESSOR UNIT 2.1 Mounting The surface processor unit is designed to be mounted on a desktop. To fix the surface processor unit, use the following fastener or equivalent. Note: Install the surface processor unit in the wheelhouse to prevent effects associated with vibration and water spray. Supplier 3M Name Dual lock fastener Type SJ-3551J SJ-3552J 1. Cut each fastener so its length is 440 mm. Three sets are required. 2. Attach fasteners (loop-type) at the bottom of the unit and mounting location (hook type). 3. Place the unit so that the fasteners unite. 2 86 433 433 88 27 9 454 20 86 : Positions where to attach fasteners. (at bottom) 483 Surface processor unit, mounting dimensions 10 2. SURFACE PROCESSOR UNIT 2.2 Wiring To underwater unit (via MS-14S connector) To Mouse (via USB-P/S2 converter) (Supplied) Power cord 54-080100 (Supplied) Power supply* To Monitor, D-sub 15P (User supply) To Keyboard (Local supply) Ground cable IV-2.0SQ (Local supply) *: Separate the power cable at least 300 mm from high tension cables. To ship's ground Surface processor unit, rear view Fabricating the MS-14S connector Use cable DPYCY-1.5 (Japan industrial standard cable) or equivalent between the MS-14S connector and armored coaxial cable. The length is determined according to the distance between the bridge and winch. Connect the DPYCY-1.5 and armored coaxial cable as below. After connection, wrap the cable with vinyl tape. Solder lead wire to armor and connect the twisted armor to A pin of connector. B + (from B) C A - (from C) Armor DPYCY-1.5 cable MS-14S connector Soldering Taping DPYCY-1.5, sectional view Armor Conductor 2 S = 1.5 mm φ = 1.56 mm Core Sheath φ = 11 mm 11 Armored coaxial cable 3. CATCH SENSOR (OPTION) Max. four optional catch sensors can be mounted depending on the trawl. 1. Fasten the four ropes (local supply) to fix the catch sensor to the trawl. 2. Use rubber ropes and shackles (local supply) to attach the sensor wire to the trawl. 3. Use rubber rope, a shackle and ropes (local supply) to fix the catch sensor on the opposite side of the sensor wire. Sensor wire (Step 2) Catch sensor Shackle (Step 2) Rubber rope (Step 3) Shackle (Step 3) Rubber rope (Step 2) Rope (Step 1) 12 Ropes (Step 3) NAME ACCESSORIES 38-076 WINDOWS XP CD-ROM INSTALLATION MATERIALS 999-999-083 54-080100* 999-999-075 (略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.) (*1)は、ダミーコードに付き、注文できません。 (*1)THIS CODE CANNOT BE ORDERED. POWER CORD 電源コード 工事材料 MOUSE マウス(USBアダプター付き) 999-999-037 999-999-077 CD-ROM(FOR COMMUNICATION BOARD) WINDOWS XP SOFT PACK CD-ROM PCI16C550 999-999-078 TS-331A_EXE 999-999-079 D845GLVA 999-999-080 1A 250V 999-999-081 2A 250V 000-060-122 MODEL854-000-002 (*1) 1 (*1) 1 (*1) 1 (*1) 1 (*1) 1 (*1) 1 (*1) 2 (*1) 2 1 Q'TY NAME OPERATOR'S MANUAL 取扱説明書 INSTALLATION MANUAL 装備要領書 図書 U/W CONNECTOR U/Wコネクター MS CONNECTOR MSコネクター BOLT SET ボルトセット TS-331A SARFACE PROCESSOR UNIT DESCRIPTION/CODE № 通信ボード用ドライバーCD-ROM FD(TS-331A APPLECATION) TS-331AアプリケーションFD CD-ROM(FOR MOTHER BOARD) OUTLINE SPARE PARTS UNIT マザーボード用ドライバーCD-ROM 付属品 FESE 管入りヒューズ FESE 管入りヒューズ 予備品 SURFACE PROCESSOR UNIT 操作部 ユニット PACKING LIST DOCUMENT OUTLINE 1/1 01AO-X-9852 000-151-384 OME-13210-* 000-151-385 IME-13210-* 999-999-073 854-460-304 999-999-074 854-460-335 999-999-076 W3/8X40 DESCRIPTION/CODE № 01AO-X-9852 -0 1 1 (*1) 1 (*1) 1 (*1) 1 Q'TY A-1 A-2 PACKING LIST 01AO-X-9851 -0 1/1 TS-331A UNDERWATER UNIT N A M E ユニット O U T L I N E DESCRIPTION/CODE № Q'TY UNIT MODEL854-000-360 発信器 1 UNDERWATER UNIT 000-060-118 (略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.) 01AO-X-9851 Y. Hatai 署名は検 証されて いません 。 電子署名者 : Yoshitoshi Hatai DN: cn=Yoshitoshi Hatai, o=Furuno, c=JP 日付 : 2004.10.13 16:56:52 + 09'00' Yoshitoshi Hatai D-1 C B A 110/220VAC 1φ,50/60Hz NOTE *1. *2. *3. *4. *5. SHIPYARD SUPPLY. OPTION. FACTORY FITTED. GROUND THRU CONNECTOR CLAMP. USER SUPPLY. 注記 *1)造船所手配。 *2)オプション。 *3)工場にて取付済み。 *4)コネクタクランプでアースに落とす。 *5)ユーザー手配。 1 H. MAKI kg C1321-C01- A NAME 名称 TITLE 半田付 SOLDERED CS-400(MAX.4) CATCH SENSOR キャッチセンサー 1 2 TS-331A ワイアードトロールソナー クロ BLK シロ WHT U/W CONNECTOR 発信器 UNDERWATER UNIT Model854-000-360 INTERCONNECTION DIAGRAM WIRED TRAWL SONAR DWG No. MASS DPYCY-1.5 *1 VGAモニター *5 VGA MONITOR 鎧装同軸ケーブル *5 ARMORED COAXIAL CABLE (MAX.3000m) Sync:H31.5kHz,V60Hz,TTL RGB:Analog 0.7Vpp(75Ω) *5 MONITOR CABLE SCALE *5 4 相互結線図 MS-14S *4 D-sub15P 3 APPROVED B C A 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 GND *1 IV-2.0SQ + GND SONAR HEAD SIG-R SIG-G SIG-B NC NC GND GND GND NC GND GND NC H_SYNC V_SINC NC TAKAHASHI.T DRAWN Feb. 7, '05 CHECKED 110/220VAC L AC N AC G GND DATA IN/OUT NC GND +5V KCLK NC DATA IN/OUT NC GND +5V KCLK NC P/N54-080100,1.2m DIN6 1 2 3 4 5 6 Model854-000-002 1 2 3 4 5 6 *5 1.5m USB-P/S2 SURFACE PROCESSOR UNIT 操作部 KEYBOARD マウス MOUSE 2 S-1 The paper used in this manual is elemental chlorine free. FURUNO Authorized Distributor/Dealer 9-52 Ashihara-cho, Nishinomiya 662-8580, JAPAN Telephone : 0798-65-2111 Fax 0798-65-4200 : All rights reserved. Printed in Japan Pub. No. IME-13210-A ( HIMA ) TS-331A FIRST EDITION : FEB. 2005 *00015138510* *00015138510* *00015138510* *IME13210A00* *IME13210A00* *IME13210A00*