Download OPERATING INSTRUCTIONS HYDRAULIC AIR PUMP

Transcript

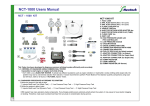

199 CHU LUN SING CO.,LTD No.199,Gangshan N. Rd., Gangshan Township, Kaohsiung County 820, Taiwan http://www.sunrun.com.tw E-mail:[email protected] TEL:886-7-6210505 FAX:886-7-6217575 R OPERATING INSTRUCTIONS HYDRAULIC AIR PUMP SPA-554TQ English E1~E5 Instructions for: Hydraulic Air Pump Models:SPA-554TQ 1. SAFETY PRECAUTIONS Fail to comply with the following cautions and warnings could cause equipment damage and personal injury. IMPORTANT :Minimum age of the operator must be 18 years The operator must have read and understood all instructions, safety issues, cautions and warnings before starting to operate the SUN RUN equipment. The operator is responsible for this activity towards other persons. CAUTION: Avoid sharp bends and kinks that will cause severe back-up pressure in hoses. Bends and kinks lead to premature hose failure. DO NOT drop heavy objects on hose. A sharp impact may cause internal damage to hose wire strands. Applying pressure to a damaged hose may cause it to rupture. IMPORTANT: Do not lift hydraulic equipment by the hoses or couplers. Use the carrying handle or other means of safe transport. WARNING : To avoid personal injury and possible equipment damage, make sure all hydraulic components withstand the maximum pressure of 700 bar(10,000psi). ! DANGER: Do not handle pressurized hoses. Escaping oil under pressure can penetrate the skin causing serious injury. If oil is injected under the skin, see a doctor immediately. WARNING: Always wear safety glasses. The operator must take precaution against injury due to failure the tool or workpiece. WARNING : The system operating pressure must not exceed the pressure rating of the lowest rated component in the system. Install pressure gauges in the system to monitor operating pressure. It is your window to what is happening in the system. WARNING: Never pressurize uncoupled couplers. Only use hydraulic equipment in a coupled system. WARNING: Immediately replace worn or damaged parts with genuine SUN RUN parts. SUN RUN parts are designed to fit properly and withstand rated loads. IMPORTANT: Hydraulic equipment must only be serviced by a qualified hydraulic technician. For repair service, contact the SUN RUN Service Center in your area. To protect your warranty, use only SUN RUN oil. R CHU LUN SING CO.,LTD ! WARNING: To avoid personal injuries and equipment damage, do not remove the shroud of the wrench. Do not modify any component of the wrench. Do not change the relief valve which is inside the swivel couplings. ! CAUTION: The incorrect system connection will cause failure and danger. Before connection, make sure the swivel couplings being clean. After application, the swivel couplings must be put on the dust caps. ! CAUTION: Do not use worn socket and square drive. ! CAUTION: Please use the socket of good performance. Page:E1 Instructions for: Hydraulic Air Pump Models:SPA-554TQ 2.SPECIFICATION 300mm Lubrication oil knob Air Press. Adjust 550mm Press. Gauge Zero button Oil/vent port Press. Adjust Model Number SPA-554TQ Air Supply Req'd 1.4M3/min @6 bar DBa at Idle and 700bar Flow rate Hp 75 320mm Oil tank 4 Weight (with oil) @115VAC(L/min) 0 (bar) 70 (bar) 350 (bar) 700 (bar) (L) (kg) 7.4 1.3 1.1 0.9 8 44 3.OPERATION 3.1 Hose and coupler install 3.11 Connect the one end of hose at pump coupler (HorA) and hose the other end connect to wrench (HorA). Pump H or A end can't be connected to wrench L or B end. 3.12 Check volt. 3.13 Check enough hydraulic oil (Aw32). 3.14 Check oil level in reservoir. Oil level should be 1" to 2" from the top of the reservoir plate. WARNING: CAN'T BE USE IN NO OIL OR FAIL OIL Pressure torque setting WARNING Make these adjustments BEFORE putting torque wrench on nut or bolt head. The pump pressure setting may be above the pressure needed to provide the required torque for your application. Exceeding required torque will cause equipment damage and may lead to serious personal injury. See torque wrench instructions for amount of pressure required to produce desired torque. Loosen lock unit and back out relief valve to prevent unintended pressure build-up. Turn pump on. Press and hold the "UP" button, and read pressure gauge. While holding the button, turn relief valve in (clockwise) to increase pressure or out (counterclockwise) to decrease maximum pressure. Repeat unit correct pressure is obtained. Run pump several times to test this setting. R CHU LUN SING CO.,LTD Page:E2 Instructions for: Hydraulic Air Pump Models:SPA-554TQ 3.OPERATION 3.2 When operating the pump for the first time: 3.21 Valve and hose connections must be tight, and the reservoir must be filled to the proper oil level. Start the motor. 3.22 Release Vent/ Fill cap to 1.5 circles. 3.23 To press remote button several times to build pressure. If the pump doesn't build pressure, it may not be primed. Disconnect a hose from the system and route it back to the pump reservoir. Run the pump until a steady flow of oil is observed free of suspended air bubbles. Reconnect the hose to the system. 3.24 Run hydraulic torque wrench out to its full travel several times to eliminate air from the system. For more complete instructions, refer to the section titled "Bleeding Air From The System." The pump is ready to be put into regular operation. Air press. Adjust oil/ vent port Lubrication oil knob Press. Adjust Press. Gauge Zero button 3.3 Adjusting The Pressure Regulating Valve NOTE: For easy adjustment of the pressure regulating valve, always adjust the pressure by increasing to the desired pressure Remote button setting. 3.31 One hand to press remote button continuity, on the other hand, slowly turn the pressure adjust in clockwise direction to increase pressure. If you want to reduce pressure just turn pressure adjust counterclockwise. 3.32 When the desired pressure is reached, please don't turn the knob anymore and the directed pressure will be set. 3.4 Pressure Zero 3.41 As release the remote button , the motor will stop and the pressure will go down, but maybe some ending pressure will be hold in the pump at this time. Pull the "Press. Gauge zero button" to release the ending pressure. 3.42 If you need to remove the coupler or something, we suggest to pull the"Press. Gauge zero button" at first to release all of the pressure. R CHU LUN SING CO.,LTD Page:E3 Instructions for: Hydraulic Air Pump Models:SPA-554TQ 4. Maintain oil level 4.1 Bleeding Air From The System Air can accumulate in the hydraulic system if the reservoir level is too low. This air cause the torque wrench to respond in an unstable or slow manner. Just put torque wrench on the smooth ground that is no load condition and operates it in full stroke for several times that will bleed air from torque wench system. 4.2 Hydraulic Fluid Level 4.21 Check the oil level in the reservoir after each 10 hours of use. Proper oil level is 1/2" (15mm) from the top of the fill hole when all wrench plungers are retraced. 4.2.2 Drain, flush, and refill the reservoir with an approved, high-grade hydraulic oil (Aw32) after approximately every 300 hours of use. The frequence of oil changes will depend upon the general working conditions, severity of use, and overall cleanliness and care given the pump. 4.3 Lubrication and Air pressure adjust 4.3.1If the pump is operated on a continuous duty cycle, 100 hours or a maximum speeds for extended periods, an automatic air line oiler should be installed in the air inlet line as close to the Lubricant Air pressure adjust pumping unit as possible. Set the unit to feed 1-3 drops of oil per minute. Turn clockwise is addition, counterclockwise is reduction. 4.3.2 Air pressure adjust operation is also clockwise to addition and counterclockwise is reduction. R CHU LUN SING CO.,LTD Page:E4 Instructions for: Hydraulic Air Pump Models:SPA-554TQ PROBLEM Pump is not delivering oil or delivers only enough oil to advance torque wrench(s) partially or erratically (continued) CAUSE 1.Oil level too low. 2.Loose-fitting coupler to cylinder. 3.Air in system. 4.Air leak in suction line. 5.Dirt in pump or filter plugged. SOLUTION 1.Fill reservoir to 1/2"(15mm) from top of filler hole with all wrench plungers retracted. 2.Check quick-disconnectcouplings to wrenches. Inspect couplers to ensure that they are completely coupled. Occasionally couplers have to be replaced because the ball check doesn't stay open due to wear. 3.Bleed the system. 4.Check and tighten suction line. 5.Pump filter should be cleaned and, if necessary, pump should be dismantled and all parts inspected and cleaned. 6.Change to lighter oil. 7.Adjust as needed. 6.Cold oil or oil too heavy. 7.Relief valve or low pressure unloading calve out of adjustment. 8.Reservoir capacity is too small. 8.Use smaller object or larger reservoir. 9.Inspect all parts carefully and 9.Defective directional valve. replace if necessary. 10.Motor rotating in wrong direction. 10.Air motor Air line connected into wrong port. 11.Check for plugged vent in filler 11.Vacuum in reservoir. plug. 12.Remove end cap from low 12.Low pressure pump wrong. pressure gear pump. Clean pump, and replace worn gears, shifting spool, body or end cap. Pump can't build full pressure. (Continued) Pump will not build full pressure R 1.Check to see if there are any external leaks. If no oil leakage is visible, the problem is internal. 2.To test for a leaking control valve, lift the pump from the reservoir but keep the filter in the oil. Remove the drain line to see if the oil is leaking from the valve. If the valve is not leaking, the internal check valve could be leaking. Refer to the note concerning checking for oil leaks at the beginning of this troubleshooting Guide. 3.Leaking pressure switch seal. 1.Faulty pressure gauge. 2.Check for external leakage. CHU LUN SING CO.,LTD 1.Seal leaking pipe fittings with pipe sealant. 2.Clean, reseat or replace flow control valve parts. If the intenal check valve(s) are leaking, the pump must be dismantled and the seat areas repaired, poppets replaced, etc. 3.repair or replace seal. 1.Calibrate gauge. 2.Seal faulty pipe fitting with pipe sealant. Page:E5