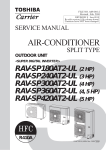

Download Installation Manual

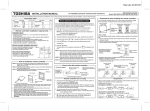

Transcript