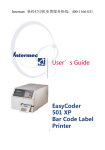

Download User's Guide EasyCoder PF4i Compact Indus- trial Printer

Transcript

Intermec 条码打印机免费服务热线:400-1199-021

User’s Guide

EasyCoder PF4i

Compact Industrial Printer

(Fingerprint Version)

IntermecTechnologiesCorporation

CorporateHeadquarters

600136thAve.W.

Everett,WA98203

U.S.A.

www.intermec.com

Theinformationcontainedhereinisproprietaryandisprovidedsolely

forthepurposeofallowingcustomerstooperateandserviceIntermecmanufacturedequipmentandisnottobereleased,reproduced,orused

foranyotherpurposewithoutwrittenpermissionofIntermec.

Informationandspecificationscontainedinthisdocumentaresubjectto

changewithoutpriornoticeanddonotrepresentacommitmentonthe

partofIntermecTechnologiesCorporation.

©2004byIntermecTechnologiesCorporation.Allrightsreserved.

ThewordIntermec,theIntermeclogo,Norand,ArciTech,CrossBar,

DataCollectionBrowser,dcBrowser,Duratherm,EasyCoder,EasyLAN,

EnterpriseWirelessLAN,EZBuilder,Fingerprint,i-gistics,INCA(under

license),InterDriver,IntermecPrinterNetworkManager,IRL,JANUS,

LabelShop,MobileFramework,MobileLAN,Nor*Ware,Pen*Key,

PrecisionPrint,PrintSet,RoutePower,TE2000,TrakkerAntares,UAP,

UniversalAccessPoint,andVirtualWedgeareeithertrademarksorregisteredtrademarksofIntermecTechnologiesCorporation.

Throughoutthismanual,trademarkednamesmaybeused.Ratherthan

putatrademark(™or®)symbolineveryoccurrenceofatrademarked

name,westatethatweareusingthenamesonlyinaneditorialfashion,

andtothebenefitofthetrademarkowner,withnointentionofinfringement.

ThereareU.S.andforeignpatentspending.

ThenameCentronicsiswhollyownedbyGENICOMCorporation.

KimduraisaregisteredtrademarkofKimberlyClark.

MicrosoftisaregisteredtrademarkofMicrosoftCorporation.

TorxisaregisteredtrademarkofCamcarDivisionofTextronInc.

TrueDocisaregisteredtrademarkofBitstream,Inc.

TrueTypeisatrademarkofAppleComputerInc.

UnicodeisatrademarkofUnicodeInc.

ValeronisaregisteredtrademarkofValéronStrengthFilms,anITW

Company.

WindowsisatrademarkofMicrosoftCorporation.

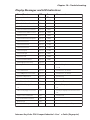

Document Change Record

Thispagerecordschangestothisdocument.Thedocumentwasoriginallyreleasedasversion-00.

Version

-00

-01

-02

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

FCC Notice (United States of America)

WARNING

Thisequipmentgenerates,uses,andcanradiateradiofrequencyenergy

andifnotinstalledandusedinaccordancewiththeinstructionsmanual,

maycauseinterferencetoradiocommunications.Ithasbeentestedand

foundtocomplywiththelimitsforaClassAcomputingdevicepursuanttoSubpartJofPart15ofFCCRules,whicharedesignedtoprovide

reasonableprotectionagainstsuchinterferencewhenoperatedinacommercialenvironment.Operationofthisequipmentinaresidentialarea

islikelytocauseinterferenceinwhichcasetheuserathisownexpense

willberequiredtotakewhatevermeasuresmayberequiredtocorrectthe

interference.

DOC Notice (Canada)

Canadian Dept. of Communication

REGULATIONS COMPLIANCE (DOC-A)

ThisdigitalapparatusdoesnotexceedtheclassAlimitsforradionoise

emissionsfromadigitalapparatusassetoutintheradiointerference

regulationsoftheCanadianDepartmentofCommunication.

Ministère des Communications du Canada

CONFORMITE DE REGLEMENTS (DOC-A)

Leprésentappareilnumériquen’émetpasdebruitsradio-électriques

dépassantleslimitesapplicablesauxappareilsnumériquesdeclasseA

prescritesdanslerèglementsurbrouillageradioélectriqueédictéparle

MinistèredesCommunicationsduCanada.

GS Notice (Germany)

ALLGEMEINE VORSCHRIFT

ReparaturenodersonstigeEingriffe,diesichnichtaufnormaleBedienungderMaschinebeziehen,dürfenausschließlichnurvoneinem

ausgebildeten,zuständigenFachmannvorgenommenwerden.

EU Standard EN 55022 (The European Union)

WARNING

ThisisaClassAITEproduct.Inadomesticenvironmentthisproduct

maycauseradiointerferenceinwhichcasetheusermayberequiredto

takeadequatemeasures.

iv

Industrial—User’s Guide (Fingerprint)

Declaration of Conformity (CE)

We,

Intermec Printer AB

Box 123

S-431 22 Mölndal

Sweden

declareunderoursoleresponsibility1thattheproduct

EasyCoder PF4i Compact Industrial

towhichthisdeclarationrelatesisinconformity

withthefollowingstandards

EMC:

EN 61000-6-4:2001

EN 61000-6-2:2001

Electrical Safety:

EN 60 950

followingtheprovisionsofDirectives

89/336/EEC and 73/23/EEC

Mölndal2003-03-12

....................................................

...............

Per-OveJacobsson

1

printerishandled,modified,orinstalledinothermannersthanthose

describedinIntermec’smanuals.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

vi

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Contents

Contents

BeforeYouBegin............................................

...............................xi

SafetySummary......................................

........................xi

SafetyIcons........................................

...........................xii

GlobalServicesandSupport..................................

.....................xiii

WarrantyInformation................................

...................xiii

WebSupport.........................................

.......................xiii

TelephoneSupport...................................

....................xiii

RelatedDocuments...................................

...................xiii

1

2

Introduction

DescriptionofEasyCoderPF4iCompactIndustrial.......................2

SafetySummary...................................................................

.........3

ProductIdenti

fi

cation....................................................................3

Installation

UnpackingthePrinter.............................................................

......6

FrontView.......................................................................

.............7

RearView........................................................................

.............8

MediaCompartment................................................................

....9

Description...............................................................

.......9

MediaSupplyRollPost.................................................10

MediaSupplyPositions..................................................11

PrintMechanism..................................................................

.......12

Connections.....................................................................

...........13

Power.....................................................................

.......13

Computer..................................................................

....13

ControlsandIndicators...........................................................

...14

IndicatorLamps............................................................

14

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Contents

4

5

6

viii

upply(Fanfold)............................................................38

Thermal Transfer Printing

RibbonLoad...................................................................

............40

Setting Up the Printer

Description..................................................................

...............46

DefaultSetup.................................................................

.............47

ReadingtheCurrentSetup.......................................................

...48

SetupParameters..............................................................

...........49

SerialCommunication...................................................

49

BaudRate.......................................................

49

CharacterLength............................................50

Parity..........................................................

.....50

StopBits........................................................

..50

FlowControl...................................................5

0

NewLine........................................................

51

ReceiveBuffer.................................................5

1

TransmitBuffer...............................................51

FeedAdjust.............................................................

.......52

StartAdjust.....................................................

52

StopAdjust.....................................................

52

RecommendedFeedAdjustments....................53

Media..................................................................

..........54

MediaSize.......................................................

54

MediaType.....................................................5

6

PaperType.......................................................

57

.................59

Testfeed........................................................

...59

PrintDe

fi

nes.................................................................59

HeadResistance..............................................59

Testprint.......................................................

...59

PrintSpeed......................................................

61

LSS(LabelStopSensor)..................................61

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Contents

LTS(LabelTakenSensor).......................

.........61

ReturningtoFactoryDefaultSetup............................

.................62

7

8

9

10

11

Options

Introduction....................................................................

...........86

SideDoorsandMegatop.............................................................

87

PaperCutter.....................................................................

...........87

IntegralLinerTakeupUnit.........................................................

.87

MediaSupplyHub..................................................................

....87

3-inchAdapter...................................................................

.........87

LabelTakenSensor................................................................

.....88

RealTimeClock...................................................................

......88

CompactFlashProtectionPlate....................................................8

8

SpecialPrintheads...............................................................

........88

InterfaceBoards.................................................................

.........89

Troubleshooting

IntermecReadinessIndicator......................................................

92

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Contents

12

A

B

C

D

.......................116

Media Specifications

MediaRollSize...................................................................

......120

Media...........................................................................

............122

Non-AdhesiveStrip.....................................................122

Self-AdhesiveStrip.......................................................

123

Self-AdhesiveLabels.....................................................1

24

TicketswithGap.........................................................12

6

TicketswithBlackMark..............................................128

Interfaces

RS-232Interface.................................................................

.......132

USBInterface....................................................................

.......133

BarCodeWandInterface...........................................................1

34

OptionalInterfaces..............................................................

.....135

Intermec Supplies

DirectThermalMedia..............................................................

x

Before You Begin

Before You Begin

Thissectionprovidesyouwithsafetyinformation,technicalsupport

information,andsourcesforadditionalproductinformation.

Safety Summary

Yoursafetyisextremelyimportant.Readandfollowallwarningsand

cautionsinthisdocumentbeforehandlingandoperatingIntermec

equipment.Youcanbeseriouslyinjured,andequipmentanddatacanbe

damagedifyoudonotfollowthesafetywarningsandcautions.

Do not repair or adjust alone

Donotrepairoradjustenergizedequipmentaloneunderanycircumstances.Someonecapableofprovidingfirstaidmustalwaysbepresent

foryoursafety.

First aid

Alwaysobtainfirstaidormedicalattentionimmediatelyafteraninjury.

Neverneglectaninjury,nomatterhowslightitseems.

Resuscitation

Beginresuscitationimmediatelyifsomeoneisinjuredandstopsbreathing.Anydelaycouldresultindeath.Toworkonornearhighvoltage,

youshouldbefamiliarwithapprovedindustrialfirstaidmethods.

Energized equipment

Neverworkonenergizedequipmentunlessauthorizedbyaresponsible

authority.Energizedelectricalequipmentisdangerous.Electricalsho

ck

fromenergizedequipmentcancausedeath.Ifyoumustperformauthorizedemergencyworkonenergizedequipment,besurethatyoucomply

strictlywithapprovedsafetyregulations.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Before You Begin

Safety Icons

Thissectionexplainshowtoidentifyandunderstanddangers,warnings,

cautions,andnotesthatareinthisdocument.Youmayalsoseeicons

thattellyouwhentofollowESDprocedures.

Awarningalertsyouofanoperatingprocedure,practice,

condition,orstatementthatmustbestrictlyobservedto

avoiddeathorseriousinjurytothepersonsworkingonthe

equipment.

Acautionalertsyoutoanoperatingprocedure,practice,

condition,orstatementthatmustbestrictlyobservedto

preventequipmentdamageordestruction,orcorruptionor

lossofdata.

Thisiconappearsatthebeginningofanyprocedureinthis

manualthatcouldcauseyoutotouchcomponents(suchas

printedcircuitboards)thataresusceptibletodamagefrom

electrostaticdischarge(ESD).Whenyouseethisicon,you

mustfollowstandardESDguidelinestoavoiddamaging

theequipmentyouareservicing.

Note:Noteseitherprovideextrainformationaboutatopicor

containspecialinstructionsforhandlingaparticularcondition

orsetofcircumstances.

xii

Industrial—User’s Guide (Fingerprint)

Before You Begin

Global Services and Support

Warranty Information

TounderstandthewarrantyforyourIntermecproduct,visitthe

Intermecwebsiteathttp://www.intermec.comandclickService&

Support.TheIntermecGlobalSales&Servicepageappears.Fromthe

Service&Supportmenu,moveyourpointeroverSupport,andthen

clickWarranty.

Web Support

VisittheIntermecwebsiteathttp://www.intermec.comtodownload

ourcurrentdocumentsinPDFformat.Toorderprintedversionsofthe

Intermecmanuals,contactyourlocalIntermecrepresentativeordistrib

utor.

VisittheIntermectechnicalknowledgebase(KnowledgeCentral)at

http://intermec.custhelp.comtoreviewtechnicalinformationorto

requesttechnicalsupportforyourIntermecproduct.

Telephone Support

ContactyourlocalIntermecrepresentative.Tosearchforyourlocalrepresentative,fromtheIntermecwebsite,clickContact.

Related Documents

TheIntermecwebsiteathttp://www.intermec.comcontainsourcurrent

documentsthatyoucandownloadinPDFformat.ToorderprintedversionsoftheIntermecmanuals,contactyourlocalIntermecrepresentativ

e

ordistributor.

xiii

Before You Begin

xiv

Industrial—User’s Guide (Fingerprint)

1

Introduction

ThischapterintroducestheEasyCoderPF4iCompact

Industrialprinter.Thechaptercoversthefollowing

topics:

·DescriptionofEasyCoderPF4iCompactIndustrial

·Safetysummary

·Productidentification

Intermec EasyCoder PF4i 1

Compact Industrial—User’

s Guide (Fingerprint)

Chapter 1—Introduction

Description of EasyCoder PF4i Compact

Industrial

TheEasyCoderPF4iCompactIndustrialisasturdyindustrialthermaltransferprinterwithaprintheadresolutionof8dots/mm=203.2

dot/inch(standard)or11.81dots/mm=300dpts/inch(option)anda

maximumprintwidthof104mm(4.095inches)or105.7mm(4.161

inches)respectively.Itoffersalargenumberofusefulfeatures,suchas:

·FlashmemorySIMMsforfirmware,fonts,barcodes,andapplication

programs

·Built-inCompactFlashmemorycardadapter

·Built-inRS-232andUSBinterfaces

·Provisionforextrainterfaceboardsincludingwiredandwireless

EasyLANconnections

·Keyboardanddisplaywithbacklightforimproveduserinterface.

Alargenumberoffactory-installedorfield-installableoptionsareavailable,sotheprintercanbeconfiguredforawiderangeofapplications.

SeeChapter9andAppendixAformoreinformation.

TheEasyCoderPF4iCompactIndustrialsupportstheuniqueandflexibleIntermecFingerprintv8.20programminglanguage,whichallowsthe

userorthird-partydevelopertocreatecustom-madeapplicationprogramsandlabelformatsinaBASIC-likeenvironment.

TheprinterisalsodesignedtoworkwiththeIntermecDirectProtocolprogramminglanguage,theIntermecInterDriverandIntermec

Labelshop.TheInterDriverallowsyoutoprintlabelsfromstandardMS

Windowsapplications,forexampleMicrosoftOffice.

TheEasyCoderPF4iCompactIndustrialsupports15scaleableUnicodeTrueTypeandTrueDocfontsasstandard.Additionalfontscanbe

downloadedintotheprinter’sFlashmemory,orbepluggedinusinga

CompactFlashcard.TheUnicodestandardallowstheuseofspecialcharactersforvariouslanguagesincludingnon-Latinfonts,suchasArabic,

Cyrillic,Chinese,Japanese,Korean,Hebrew,andsimilar.

AversionofEasyCoderPF4iCompactIndustrial,thatsupportsthe

IntermecProgrammingLanguage(IPL),isdescribedinaspecialUser’s

Guide.

2

Industrial—User’s Guide (Fingerprint)

Chapter 1—Introduction

Safety Summary

IntermecassumesnoresponsibilityregardingtheCEDirectiveifthe

printerishandled,modified,orinstalledinanywayotherthanthat

describedinIntermec’smanuals.

·Readthismanualcarefullybeforeconnectingtheprinter.

·Movingpartsareexposedwhenthedoorsareopen,soensurethatthe

doorsareclosedbeforeyouoperatetheprinter.

·Donotopenthefront/left-handcover.Dangerousvoltage!

·Donotremovethebottomplate.Dangerousvoltage!

·Donotputyourfingersinsidetheprintmechanismwhenthepoweris

on.

·Placetheprinteronanevensurfacewhichcansupportitsweightof

approximately7to8kg(15.5to17.7pounds)plussupplies.

·Donotspraytheprinterwithwater.Ifyouareusingahosetoclean

thepremisesinanindustrialenvironment,removetheprinterorprotectitcarefullyfromsprayandmoisture.

·Carefullyreadthewarningtextontheenvelopebeforeusingacleaningcard.

Product Identification

Themachinelabelisattachedtotheprinter’srearplateandcontains

informationontype,model,andserialnumberaswellasACvoltage.It

alsocontainsvarioussignsofapproval.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 1—Introduction

4

Industrial—User’s Guide (Fingerprint)

2

Installation

Thischapterexplainshowtounpackandinstallthe

EasyCoderPF4iCompactIndustrialprinterandalso

describestheprinter

svariouspartsindetail.Itcovers

thefollowingtopics:

·Unpackingtheprinter

·Partsontheprinter’sfront

·Partsontheprinter’srearplate

·Partsinthemediacompartment

·Partsintheprintmechanism

·Connectingtheprinter

·Usingthecontrolsandunderstandingtheindicators

s Guide (Fingerprint)

Intermec EasyCoder PF4i

Compact Industrial—User’

’

5

Chapter 2—Installation

Unpacking the Printer

Beforeyouinstalltheprinter,examinethepackageforpossibledamage

ormissingparts:

·Opentheboxandlifttheprinterout.

·Checkthattheprinterhasnotbeenvisiblydamagedduringtransportation.Keepthepackingmaterialsincaseyouneedtomoveorreship

theprinter.

·Checkthelabelontheprinter’srearplate,whichgivesthevoltage,the

partnumber,andtheserialnumber.

·Checkthatanyoptionsyouorderedareincluded.

·Checkthatalltheaccessoriesareincluded.Asstandard,theboxcontains:

-IntermecEasyCoderPF4iCompactIndustrialprinter

-TwosetsofQuick-LoadGuides(wideandnarrow)

-Powercord

-Qualitycheckcard

-Cleaningcard

-Shortstripoflabels

-Starterpackofthermaltransferribbon

-ThisUser’sGuide

-SupportingsoftwareandproductinformationonCD.

·Checkthatthetypeofpowercordisappropriateforthelocalstandard.Theprinterworkswithin90to265VAC,50to60Hz.

Iftheprinterhasbeendamagedinanywayduringtransportation,complaintothecarrierimmediately.

Ifthedeliveryisincorrectoranypartsaremissing,reportitimmediately

tothedistributor.

6

Industrial—User’s Guide (Fingerprint)

Chapter 2—Installation

Front View

Atthefrontoftheprinterarethedisplaywindow,theindicatorlamps,

andthekeyboard.Thesefeaturesallowtheoperatortocontrolandsetup

theprintermanually.

Theprintedlabels,tickets,ortagsarepresentedatthefrontoftheprint

mechanism.

Indicator lamps

Display window

Keyboard

Print button

Front door

Print mechanism

Side door

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 2—Installation

Rear View

TherearplatecontainstheOn/Offswitch,theACpowercordsocket,

andvariousinterfaceconnectorsandslots.

Provision for EasyLAN

Ethernet connection

(option)

Memory card slot

Provision for one optional

interface board

On/Off Switch

Bar code wand socket

AC Power cord socket

RS-232 serial interface

("uart1:")

USB Interface

("usb1:")

Machine label

8

Industrial—User’s Guide (Fingerprint)

Chapter 2—Installation

Media Compartment

Description

Themediacompartmentisasstandardcoveredbyalongsidedoorthat

completelyenclosestheprintmechanismandmediacompartment.

(Optionally,theprintercanbefittedwithatwopart“Megatop”that

allowsalargermediarolltobeused.)Thedoorisheldbyamagnetic

lock.Itcanbeopened180°toprovidefullaccesstothemediacompartment.

Themediasupplycanbefromasupplypost,orfromanexternalsupply

offanfoldsbehindtheprinter.Thereisalsoanoptionalrotatingmedia

supplyhub.AlsoseeChapter9,“Options.”

Thermal transfer

mechanism

Optional integral

liner takeup with

guide shaft

Front door

Print

mechanism

Long side door

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 2—Installation

TheEasyCoderPF4iCompactIndustrialusesamediasupplyrollpost

thatcanbefittedinthreedifferentpositionsinsidethemediacompartment.Thepositiondependsonthetypeofsidedoorandwhetherthe

printerisfittedwithanintegrallinertakeupornot.Alternatively,an

externalmediasupply(forexampleaboxoffan-foldedtickets)behind

theprintercanbeused.Arotatingmediasupplyhubisalsoavailableas

anoption,seeChapter9,“Options.”

Media Supply Roll Post

Themediasupplyrollpostfitsboth38-40mm(1.5inches)and76mm

(3.0inches)coressinceitcanbemovedverticallyintheslotinthecenter

section.Thebottompositionisintendedforsmallcoresandthetop

positionisforlargecores.Thepostislockedbyastraight-slotscrewand

hasamoveableedgeguidetofitvariousmediawidths.

Edge guide

Screw

Tomovetheposttoadifferentslot;removethescrew,twisttheposta

quarterofaturn,andpullitout.

Tofitthepost;rotateitaquarterofaturn,insertitintotheappropriateslotinthecentersection(seenextpage),andtwistbacksothelips

engagethecutoutsinthesidesoftheslot.Moveitup(largecore)or

down(smallcore)asfarasitgoesandsecureitwiththescrew.

10

Industrial—User’s Guide (Fingerprint)

Chapter 2—Installation

Media Supply Positions

Therearefoursetsofslotsandthreadedholesintheprinter’scentersectionforthemediasupplyrollpostorrotatinghub(optional).Theseslots

allowthelargestpossiblerollsizeto

fi

t,giventhelimitationsofanyliner

takeupunitand/orthefullenclosureprovidedbythelongsidedooror

Megatop.Thepositionsareindicatedbynumbersengravedinthecenter

section.

·Position1isusedwhenthemediacompartmentisfullyenclosedbya

longsidedoor,regardlessoftheexistenceofanyintegrallinertakeup

unit.Maximumrollsizeis152mm(6inches).

·Position2isnotused.

·Position3isusedwhentheprinterhasanintegrallinertakeupunit

andalongsidedoor.Thispositionisalsousedwiththe8-inch

Megatop.Maximumrollsizeis213mm(8.38inches).

·Position4isnotused.

Theprintercanalsouseanexternalmediasupplylocatedbehindthe

printer,exceptwhenithasan8-inchMegatop.

Position 3

Position 2

(not used)

Position 1

Position 4

(not used)

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 2—Installation

Print Mechanism

Theprintmechanismfeaturesahigh-performancethermalprinthead

withquick-mountfittingstofacilitatereplacement.

Thermal

printhead

Tear bar

(tear upwards)

Pressure arm

Tear bar

(tear downwards

and peel-off))

Platen roller

12

Chapter 2—Installation

Connections

Power

1Placetheprinteronalevelsurface,nearanACoutlet.Youshouldbe

abletoaccesstheprintertoloadsuppliesandtoremovetheprintout.

2Checkthattheprinterisswitchedoff.

3Connectthepowercordfromthesocketontherearplatetoanelectricaloutlet(90to265VAC).

Computer

TheEasycoderPF4iCompactIndustrialisfittedwithone9-pinD-style

subminiature(DB9)socketfortheRS-232serialinterfaceportandone

classBconnectorfortheUSBinterfaceport(seeAppendixC).

RS-232 Serial Interface ("uart1:")

UsetheserialinterfacewithIntermecLabelShoportheIntermecInterDriver.AlsouseitwiththeIntermecDirectProtocolortheIntermec

Fingerprintprogramminglanguagebecauseyoucanreceiveerrormessagesfromyourprinter.Beforeyoucanusetheserialinterface,youmay

needtosetupthecommunicationparameters,suchasbaudrate,parity,

etc.asdescribedinChapter6,“SettingUpthePrinter.”

USB Interface ("usb1:")

UsetheUSBinterfacewithanUSB-compatibleversionoftheIntermec

InterDriverforprinting.TheUSBinterfaceisnotsuitableforprogrammingbecausethehostcannotreceiveerrormessagesfromyourprinter.

Optional Interface and Network Boards

("uart2:", "uart3:", "centronics:", or "net1:")

Severaltypesareavailable(seeChapter9,“Options”).RefertoChapter

6,Chapter7,andAppendixCforconnectionandsetupinstructions.

Theprintercanbesettoscanallcommunicationports.Whenitdetects

incomingdataonaport,theprinterautomaticallyswitchestousethat

portforbothinputandoutput.Thisfacility("auto")canbeselectedin

IntermecShell(seeChapter8)orusingtheIntermecFingerprintinstructionSETSTDIO,seeIntermecFingerprintv8.xx,Programmer’sReference

Manual.Usethe<F5/i>keytogetinformationontheactivecommunicationchannels.

SwitchoffbothPCandprinterbeforeconnectingthemtogether.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 2—Installation

Controls and Indicators

TheEasyCoderPF4iCompactIndustrialhasseveralwaysofcommunicatingdirectlywithitsoperator:threecoloredindicatorlamps,adisplay

window,amembrane-switchkeyboardwith22programmablekeys,abig

programmable“Print”buttonontheprinter’sfront,andabeeper.

Indicator Lamps

TheindicatorsarecoloredLEDs(LightEmittingDiodes)andareused

forthefollowingpurposes:

Power(solidgreen)indicatesthatthepowerison.

Status(solidgreen)indicatesthattheprinterisreadyforuse.

Status(flashinggreen)indicatesthattheprinteriscommunicating.

Status(solidred)indicatesanerrorcondition(seeChapter10).

IntermecReadinessIndicator(blue;on,blink,oroff).

RepresentedbyabluelightonIntermechandheldcomputers,access

points,andprinters,theIntermecReadinessIndicatorispartofan

exclusivemonitoringsystemfromIntermec.TheIntermecReadiness

IndicatorhelpsusersquicklydeterminethereadinessoftheIntermec

deviceindividuallyandaspartofasolution.TheIntermecReadiness

Indicatorhasthreedifferentstates:On,Blinking,andOff.Whenthe

Indicatorisoff,thedeviceisnotreadytooperateindividuallyoras

partofasolution.WhentheIndicatorisblinking,thedevicemaybe

initializing,waitingforexternalresources,orinneedofuserattention.AndwhentheIndicatorisOn,thedeviceisreadyforuseas

partofasolution.AlsoseeChapter10.

14

Industrial—User’s Guide (Fingerprint)

Chapter 2—Installation

Display

ThedisplaywindowcontainsanLCD(LiquidCrystalDisplay)with

backgroundilluminationandtwolinesoftext,eachwith16characters.

Itguidestheoperatorthroughthesetupandindicatespossibleerrors

duringprinting.

TheIntermecFingerprintprogramminglanguageandtheIntermec

DirectProtocolallowcustom-mademessagestobecomposedanddisplayedaccordingtotherequirementsoftheapplication.

Keyboard

Thekeyboardisofthemembrane-switchtypeandhas22keys.Thekeyboardissupplementedbyalarge“Print”buttonontheprinter’sfront.

Somekeyshavehard-codedfunctionsinthestartupandsetupmodes.

Print button

+

+

Displayerrormessages,IRIstatus,andcommunicationchannel

information.

Scrollbetweenvarioustypesofinformationafterpressingthe

<F5/i>key.Possibleerrormessagesandinformationonactive

communicationchannelsareshowninaloop.

KeyboardColorCode

YellowOperationoftheprinter(operatorlevel)

GreenSetuporservice(siteorservicetechnicianlevel)

WhiteDatainputtoprinter(operatorortechnicianlevel)

InapplicationprogramscreatedusingtheIntermecFingerprintprogramminglanguage,thekeyscanbeassignedtovariousfunctionsor

bedisabledindividually.Sinceonekeyisassignedasshiftkey,upto44

differentkeycombinationsarepossible.Anaudiblesignal,whichcanbe

turnedoffifsodesired,acknowledgesthatakeyhasbeenpressed.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 2—Installation

Beeper

Thebeepernotifiestheoperatorwhenanerrorhasoccurredand

acknowledgesthatakeyhasbeenpressed.TheIntermecFingerprintprogramminglanguageallowsthekeyacknowledgesignaltobeturnedoff.

Thefrequencyanddurationofsignalscanbespecified.Thus,itispossibletocreatedifferentsignalsfordifferentconditionsoreventomake

theprinterplaysimplemelodies!

16

Industrial—User’s Guide (Fingerprint)

3

Starting Up

Thischapterexplainshowtostartuptheprinterafter

installationorafterhavingbeenswitchedoff.Itcover

s

thefollowingtopics:

·Startupfiles

·Memorycards

·Switchingontheprinter

·Displaymessagesatstartup

s Guide (Fingerprint)

Intermec EasyCoder PF4i

Compact Industrial—User’

17

Chapter 3—Starting Up

Startup Files

Whentheprinterisswitchedon,itsbehaviordependsontheexistenceof

astartupfile(autoexec.bat)initsmemory.Therearetwocases:

ATheprinterisonlyfittedwiththeIntermecShellfile-managing

program,whichallowstheoperatortochoosebetweenavarietyof

applicationsandfunctions.

BInadditiontoIntermecShell,theprinterisalsofittedwithacustommadeapplicationprogramthatisdesigntoperformaspecifictask,for

exampletoprinttickets,baggagetags,orproductlabelsforacertain

company.Suchaprogrammaybeinitiatedbyastartupfile(autoexec.

bat)storedintheprinter’spermanentmemoryorinamemorycard.

Therecanbeonestartupfilestoredineachofthreedifferentpartsofthe

printer’smemory.Iftherearestartupfilesstoredinmorethanonepart,

onlyonewillbeusedwiththefollowingpriority:

1.Anautoexec.batfilestoredinamemorycard,providedthecardwas

insertedintheprinterbeforethepowerwasswitchedon.

2.Anautoexec.batfilestoredintheread/writepartoftheprinter’spermanentmemory(device"/c").

3.Thepup.batfile(IntermecShell)intheread-onlypartoftheprinter’s

permanentmemory(device"/rom").

Note:IfyouinsertaCompactFlashmemorycardthatcontains

astartupfilebeforeyouswitchontheprinter,thisstartupfile

willbeusedinsteadofIntermecShell.

18

Industrial—User’s Guide (Fingerprint)

Chapter 3—Starting Up

Memory Card

Ifyouwanttouseamemorycard,youmustinsertitintotheslotinthe

printer’srearplatebeforeyouswitchonthepower.Thememorycard

mustbeaCompactFlashcard(8MB-1GB).CompactFlashcardsmarked

“CF+”willnotwork.YoucanusetheCompactFlashcardtoexpandthe

printer’sstoragememory("card1:").TherearealsothreetypesofpreprogrammedCompactFlashcards:

·FontCardsprovideadditionalfontsthatcanbeusedaslongasthe

cardremainsinsertedintheprinter.

·FontInstallCardspermanentlyinstalladditionalfontsintheprinter,

whichcanbeusedevenafterthecardhasbeenremoved.

·FirmwareCardsautomaticallyreplacetheprinter’sfirmware,usually

withanupdatedversion.

CompactFlashcardsarewidelyusedforconsumer’scomputerproducts

likedigitalcameras.YoucangetacertainprotectionfromtheftbyinstallinganoptionalplatethatcoversaninsertedCompactFlashcard.

CompactFlash

memory card

Protection plate

with screw

(option)

Note:Alwaysswitchoffthepowerbeforeinsertingorremoving

amemorycard!Thecardwillonlyfitinoneway.Amemory

cardisonlydetectedifitisinsertedbeforetheprinteris

started.

Intermec EasyCoder PF4i Compact Industrial—User ’s Guide (Fingerprint)

Chapter 3—Starting Up

Switching On the Printer

Beforeswitchingontheprinter,makethenecessaryconnections,insert

anymemorycardyouwanttouse,andcheckthattheprintheadis

engaged.

SwitchonthepowerusingtheOn/Offswitchontherearplate.The

“Power”controllamponthefrontpanellightsupwhenthepowerison.

Waitforafewmoments,whiletheprinterloadstheprogramandruns

someself-diagnostictests:

Starting

Afterashorttime,theprinterisinitialized.Theprogressoftheinitializationisindicatedbyanincreasingnumberofcolonsonthelowerlinein

thedisplay:

Initializing

:::

Thetypeofstartupfilerunningintheprinterisindicatedbythemessage

showninthedisplaywindowimmediatelyafterinitialization.

A. Intermec Shell Startup Program

ENTER=SHELL

5 sec. v.8.1

4 sec. v.8.1

3 sec. v.8.1

2 sec. v.8.1

1 sec. v.8.1

RefertoChapter8formoreinformationonIntermecShell.Thedigits

inthelowerrightcornerofthedisplayindicatetheversionofIntermec

Shell.

B. Custom-Made Application Program

Anyotherdisplaymessagesthanthoseillustratedaboveindicatesthatthe

printerisrunningsomecustom-made,non-standardapplicationprogram,orthatsomeerrorhasoccurred.

20

Industrial—User’s Guide (Fingerprint)

4

Media Load

Thischapterexplainshowtoloadtheprinterwith

media,thatislabels,tickets,tag,orstrips,forthefo

llowingmodesofoperation:

·Tear-Off(straight-through)

·Tear-OffwithQuick-Load(straight-through)

·Cut-Off

·Peel-Off(self-strip)

·Externalsupply(fan-folds)

s Guide (Fingerprint)

Intermec EasyCoder PF4i

Compact Industrial—User’

21

Chapter 4—Media Load

Tear-Off (Straight-through)

TheEasyCoderPF4iCompactIndustrialcanprintonlabels,tickets,

tags,andcontinuousstockinvariousforms.Thissectiondescribesthe

casewhenthemediaistornoffmanuallyagainsttheprinter’stearbar.

Thismethodisalsoknownas“straight-throughprinting.”

Usethe<Feed>key(seefigure#10)whenloadingthesametypeof

media.Whenswitchingtoanewtypeofmedia,oriftheprinterdoesnot

feedoutthemediaproperly,simultaneouslypressthe<Shift>and<Feed>

keystoperforma“testfeed.”

Tear-offcanbeusedfor:

·Non-adhesivecontinuousstock

·Self-adhesivecontinuousstockwithliner

·Self-adhesivelabelswithliner

·Ticketswithgaps,withorwithoutperforations

·Ticketswithblackmarks,withorwithoutperforations

Anoptionallabeltakensensorcanholdtheprintingofthenextcopy

inthebatchuntilthepresentcopyhasbeenremoved,seeChapter9,

“Options.”

22

Industrial—User’s Guide (Fingerprint)

Chapter 4—Media Load

Tear-Off , cont.

1

Open the front and side doors.

3

If necessary, fold down the edge guide.

Remove any empty core from the media

supply roll post.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 4—Media Load

Tear-Off , cont.

5

Route the media through the print

mechanism. Then push it inwards as far

as it will go. Close the edge guide on the

media supply post.

7

Turn the printhead lift lever counterclockwise to engage the printhead.

24

Chapter 4—Media Load

Tear-Off , cont.

9

Close the front and side door, making

sure that the media runs through the

slot in the front door.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 4—Media Load

Tear-O

ff

(Straight-through)

with

Quick-Load

Inadditiontothemedialoadprocedurefortear-off(straight-through)

operationdescribedearlierinthischapter,theEasyCoderPF4iCompact

IndustrialcanoptionallybefittedwithasetofQuick-Loadguidesthat

makesmedialoadmucheasierandquicker.

TheprinterisnormallydeliveredwithtwodifferentsetsofQuick-Load

guides:wideandnarrow.Thewidetypegenerallyguidesthemedia

better,butthemediamustbeatleast80mm(3.15inches)wide.The

narrowtypeallowsamediawidthasnarrowas40mm(1.57inches),but

itmaybelesssuitedforwideandthinmedia.

Quick-Loadcannotbecombinedwithpeel-off(self-strip)operation.

Anoptionallabeltakensensorcanholdtheprintingofthenextcopy

inthebatchuntilthepresentcopyhasbeenremoved,seeChapter9,

“Options.”

Usethe<Feed>key(seefigure#5)whenloadingthesametypeofmedia.

Whenswitchingtoanewtypeofmedia,oriftheprinterdoesnotfeed

outthemediaproperly,simultaneouslypressthe<Shift>and<Feed>

keystoperforma“testfeed.”Fullyautomaticloading,withouttheoperatorhavingtopressanykey,requiresaspecialsetofIntermecFingerprint

instructionsintheapplicationprogram.

26

EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 4—Media Load

Tear-Off with Quick-Load, cont.

1

2

Narrow

Guides

Rail

Lift up the upper media guide and

Notch

Wide Guides

Press the wide or narrow Quick-Load

guides onto

illustrated,

3

the

shaft

as

media between

the

4

Insert

the

If necessary, adjust the outer Quick-

Load guide to fi t the width of the

media.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 4—Media Load

Tear-Off with Quick-Load, cont.

5

Keep pushing the media forward while

pressing the Feed key.

28

Chapter 4—Media Load

Cut-Off

TheEasyCoderPF4iCompactIndustrialcanprintonlabels,tickets,

tags,andcontinuousstockinvariousforms.Thissectiondescribes

thecasewhenthemediaistobecutoffbyanautomaticpapercutter

(option).

Usethe<Feed>key(seefigure#12)whenloadingthesametypeof

media.Whenswitchingtoanewtypeofmediaoriftheprinterdoesnot

feedoutthemediaproperly,simultaneouslypressthe<Shift>and<Feed>

keystoperforma“testfeed.”

Cut-offcanbeusedfor:

·Non-adhesivecontinuousstock

·Self-adhesivelabelswithliner(cutonlylinerbetweenlabels)

Thecutterisdesignedtocutthroughpaper-basedmediawithathickness

between60and175µm,whickroughlycorrespondstoapaperweight

of60to175grams/m2(basisweight40to120lb).Thecuttershould

notbeusedtocutthroughlabels,becausetheadhesivewillsticktothe

shears,whichcandamagethecutter.

Thecutterisheldbyasnap-lockandcanbetiltedforwardtofacilitate

mediaload.Aswitchpreventsthecutterfromoperatingwheninopen

position.

Theoptionallabeltakensensorcannotbeusedwiththecutter.

Thepapercuttercanbeusedwithbothastandardedgeguideand

Quick-Loadguidesandwithanytypeofsidedoor.Inthischapter,a

printerwithastandardedgeguideandalongsidedoorisillustrated.

Thereisnofrontdoorwhenacutterisinstalled.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 4—Media Load

Cut-Off , cont.

1

Open the cutter and the side door.

3

If necessary, fold down the edge guide.

Remove any empty core from the media

supply roll post.

30

Chapter 4—Media Load

Cut-Off , cont.

5

Route the media through the print

mechanism and cutter. Then push it

towards the center section as far as it

will go.

7

Turn the printhead lift lever counterclockwise to engage the printhead.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 4—Media Load

Cut-Off , cont.

9

Close the side door.

11

An optional tray can be attached to the

cutter to collect the cut off labels, tickets,

or tags.

32

Chapter 4—Media Load

Peel-Off (Self-strip)

TheEasyCoderPF4iCompactIndustrialcanprintonlabels,tickets,

tags,andcontinuousstockinvariousforms.Thissectiondescribesthe

casewhenself-adhesivelabelsareseparatedfromthelinerimmediately

afterprinting.Thelineristhenwounduponanintegrallinertakeup

hub.Thisisalsoknownas“Self-strip”operation.

Peel-offoperationcannotbeperformedwhenQuick-Loadguidesare

fitted.

Usethe<Feed>key(seefigure#13)whenloadingthesametypeof

media.Whenswitchingtoanewtypeofmedia,oriftheprinterdoesnot

feedoutthemediaproperly,simultaneouslypressthe<Shift>and<Feed>

keystoperforma“testfeeed.”

Peel-offcanonlybeusedfor:

·Self-adhesivelabelswithliner

Anoptionallabel-takensensorcanholdtheprintingofthenextlabel

inabatchuntilthepresentlabelhasbeenremoved,seeChapter9,

“Options.”

Note:Peel-offoperationsetshighdemandsonthemediain

regardoflabelstiffness,releasecharacteristicsoftheadhes

ive

andliner,resistanceagainstelectrostaticchargingetc.,sot

he

labelswillbedispensedproperly.Consultyourmediasupplier

ortestthemediatoascertainthatitissuitableforyourapplica

tion.

33

Chapter 4—Media Load

Peel-Off , cont.

1

Open the front and side doors.

3

Pull out the handle to collapse the

takeup hub, then remove any liner.

34

Chapter 4—Media Load

Peel-Off , cont.

5

Fit a new roll of labels on the supply

post.

7

Close the edge guide on the supply post.

Route the liner around the tear bar and

the liner drive roller and back under the

print mechanism and guide shaft.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 4—Media Load

Peel-Off , cont.

9

This diagram shows the media and liner

paths.

11

Adjust the position of the green edge

guide so the media is guided with a

minimum of play.

36

Chapter 4—Media Load

Peel-Off , cont.

13

Press the Feed key to advance the media

and adjust the media feed.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 4—Media Load

External Supply (Fan-fold)

TheEasyCoderPF4iCompactIndustrialcanprintonlabels,tickets,

tags,andcontinuousstockinvariousforms.Thissectiondescribesthe

casewhenthemediasupplyisplacedbehindtheprinter,usuallyinthe

formoffan-foldedticketsortags.Externalsupplycanbeusedwithtearoff(straight-through)printing—preferablywithQuick-Load.

Externalsupplycanonlybeusedwithalongsidedoor,notthemegatop.

Thereisnoneedtoremovethemediasupplyrollpost.

Whenusinganexternalmediasupply,takecaretoprotectthemedia

fromdust,dirtorotherforeignparticles,thatcanimpairtheprintout

qualityorcauseunnecessaryweartotheprinthead.

Dependingonbrandandquality,alldirectthermalmediaaremoreor

lesssensitivetoheat,directsunlight,moisture,oil,plasticizers,fat,and

othersubstances.Youshouldprotectthemaccordingly.

This diagram shows the media path from an external supply. In case of the standard

edge guide (as opposed to Quick-Load guides), turn it to vertical position.

38

Industrial—User’s Guide (Fingerprint)

5

Thermal Transfer

Printing

Thischapterexplainshowtoloadtheprinterwith

ribbonforthermaltransferprinting.

Intermec EasyCoder PF4i 39

Compact Industrial—User’

s Guide (Fingerprint)

Chapter 5—Thermal Transfer Printing

Ribbon Load

TheEasyCoderPF4iCompactIndustrialcanprintonlabels,tickets,

tags,andcontinuousstockusingeitherdirectthermalprintingonspecial

heat-sensitivemediaorthermaltransferprintingusingaspecialinkcoatedribbon.

Thermaltransferprintingmakesitpossibletouseawiderangeofreceivingfacematerialsandgivesadurableprintoutlessvulnerabletofat,

chemicals,heat,sunlightetc.thandirectthermalprinting.Makesureto

selectatypeofribbonthatmatchesthetypeofreceivingfacematerial

andtosetuptheprinteraccordingly.

TheEasyCoderPF4iCompactIndustrialcanusetransferribbonrolls

woundwiththeink-coatedsidefacingeitheroutwardorinward.Illustrationsinthismanualshowtheink-coatedsidefacinginward.

Evenifribbonusuallyisloadedinconnectionwithmediareplenishment,

noloadedmediaareshownintheillustrationsinthischapterinorderto

giveaclearerviewoftheribbonpath.RefertoChapter4formediaload

instructions.

Mosttransferribbonsdonotsmearatroomtemperature.

40

Industrial—User’s Guide (Fingerprint)

Chapter 5—Thermal Transfer Printing

Ribbon Load, cont.

1

Open the front and side doors.

3

In case of ribbon reload, remove any

used ribbon and empty ribbon core.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 5—Thermal Transfer Printing

Ribbon Load, cont.

5

Slide the ribbon roll onto the supply hub

so the ink-coated side faces down when

the ribbon is routed through the print

mechanism.

7

Without releasing the ribbon, turn the

printhead lift lever counterclockwise

to engage the printhead and lock the

ribbon.

42

Chapter 5—Thermal Transfer Printing

Ribbon Load, cont.

9

Turn the printhead lift lever clockwise

to raise the printhead and release the

ribbon.

11

Turn the printhead lift knob counterclockwise to engage the printhead.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 5—Thermal Transfer Printing

44

Industrial—User’s Guide (Fingerprint)

6

Setting Up the Printer

Thischapterdescribesthevariousparametersthatare

usedintheSetupMode(seeChapter7)orinthevariousapplicationprogramstoconfiguretheprinterfor

theuser

’

sspeci

fi

crequirements.Itcoversthefollowing

topics:

·Description

·Defaultsetup

·SetupParametersinregardofcommunication,feed

adjust,media,andprintdefines.

Whenmeasuresarespecifiedas“dots”,theactual

lengthinmillimetersorinchesdependsonthe

printheaddensity.Convertasfollows:

8dots/mm(203.2dots/inch)printhead:

1dots=0.125mm=0.0049inches(4.9mils)

11.81dots/mm(300dots/inch)printhead:

1dot=0.085mm=0.0033inches(3.3mils)

s Guide (Fingerprint)

Intermec EasyCoder PF4i

Compact Industrial—User’

45

Chapter 6—Setting Up the Printer

Description

Thesetupcontrolstheprinterinregardofserialcommunication,media

feed,andprintspeed,andspecifieswhichtypeofmediaand(optionally)

ribbonisloadedintheprinter.

Checkthelistoftheprinter’sdefaultsetupparametersonthenextpage

toseeiftheymatchyourrequirements.Ifnot,youwillhavetochange

thesetupusingoneofthemethodsdescribedbelow.Thesetupmayalso

bechangedbyIntermecPrintSet,InterDriver,andLabelShop,orthirdpartyapplicationprograms.

Setup Mode

·Pressthe<Setup>keyontheprinter’sbuilt-inkeyboardtoenterthe

SetupMode,or

·selecttheSetupoptioninIntermecShelltoentertheSetupMode,or

·executetheIntermecFingerprint SETUPinstructiontoenterthe

SetupMode,or

·accesstheSetupModeviatheprinter’shome(requiresanoptional

EasyLANinterfaceboard).

SeeChapter7,“SetupMode”inthismanualandtheEasyLANdocumentation.

Intermec Fingerprint

·Usesetupstringstochangeindividualsetupparametersremotely

fromthehost,or

·usesetupfilestocreatesetsofsetupparametersremotelyfromthe

host.

SeetheIntermecFingerprintv8.xxmanuals.

Intermec Direct Protocol

·Usesetupstringstochangeindividualsetupparametersremotely

fromthehost.

SeetheIntermecDirectProtocolv8.xxmanuals.

46

Industrial—User’s Guide (Fingerprint)

Chapter 6—Setting Up the Printer

Default Setup

Theprinter

’

sdefaultsetupislistedbelow(assumingnooptionsinstalled):

Ser-Com "uart1:"

Baudrate

9600bps

Characterlength

8bits

Parity

None

Stopbits

1bit

RTS/CTS

Disable

ENQ/ACK

Disable

XON/XOFF,datatohost

Disable

XON/XOFF,datafromhost

Disable

Newline

CR/LF

Receivebuffer

1024bytes

Transmitbuffer

1024bytes

Feedadjust:

Startadjust

0

Stopadjust

0

Media:

X-start(8dots/mm=203.2dpi)

24

X-start(11.81dots/mm=300dpi)

36(option)

Width(8dots/mm=203.2dpi)

832

Width(11.81dots/mm=300dpi)

1248(option

Length(8dots/mm=203.2dpi)

1200

Length(11.81dots/mm=300dpi)

1800(option

Mediatype

Label(wGaps

Papertype

Thermaltran

Ribbonconstant

90

Ribbonfactor

25

Labeloffset

0

Lowdiameter

0

Contrast

±0%

Print Defines:

Printspeed

100mm/sec.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 6—Setting Up the Printer

Reading the Current Setup

Theprinter’scurrentsetupvaluescanbereadfromtheprinter’sdisplay

windowbybrowsingthroughtheSetupMode.

Youcanlisttheprinter’scurrentsetupvaluesbyprintingtestlabel“Setup

Info”intheSetupModeorbyusingIntermecShell.

Thecurrentsetupvaluescanbesenttothehostviathestandardserial

communicationchannelusinga SETUP WRITE "uart1:"statement(seeIntermecFingerprintv8.xx,Programmer’sReferenceManual).

48

Industrial—User’s Guide (Fingerprint)

Chapter 6—Setting Up the Printer

Setup Parameters

Serial Communication

Theserialcommunicationparameterscontrolthecommunication

betweentheprinterandtheconnectedcomputerorotherdevicesonthe

standardserialport"uart1:"andtheoptionalserialports"uart2:"and

"uart3:".Theoptionalportsrequireanoptionalinterfaceboard.The

printer

’

s

fi

rmwaredetectsifaninterfaceboardisinstalledintheprinter

andpresentsadditionalsetsofcommunicationsetupmenusdepending

ontypeofcommunication(refertodiagrams3-5inChapter7,“Setup

Mode”).

Note:Theserialcommunicationparametershavenoeffecton

parallelorEasyLANcommunications,orontheINandOUT

portsontheoptionalIndustrialInterfaceBoard.

Fortheserialcommunicationchannel"uart1:",thefollowingparameters

canbeset.Makesuretheymatchthesetupoftheconnecteddeviceor

viceversa.Ifthesetupoftheprinterandthesetupofthehostdonot

match,theresponsefromtheprintertohostwillbegarbled.

Baud Rate

Thebaudrateisthetransmissionspeedinbitspersecond.Thereare10

options:

·

·

·

·

·

·

·

·

·

·

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 6—Setting Up the Printer

Character Length

Thecharacterlengthspecifiesthenumberofbitsthatwilldefinea

character.Eightbitsarerecommended,becausethatoptionallowsmore

specialcharactersandcharactersspecificforforeignlanguagestobeused.

RefertotheIntermecFingerprintv8.xx,Programmer’sReferenceManual

formoreinformation.

·7

·8

Parity

Theparitydecideshowthefirmwarewillcheckfortransmissionerrors.

Therearefiveoptions:

·

·

·

·

·

Stop Bits

Thenumberofstopbitsspecifieshowmanybitswilldefinetheendofa

character.Therearetwooptions:

·1

·2

Flow Control

RTS/CTSisaprotocolwherethecommunicationiscontrolledbycurrentsthroughseparatelinesinthecablebeingseteithertohighorlow.

Bydefault,thisoptionisdisabled.

RTShighindicatesthatthetransmittingunitisabletoreceivecharacters.

RTSlowindicatesthatthereceivebufferisfilledto75%(seeXON/

XOFF).

CTShighindicatesthattheunittransmittingtheCTSsignalisreadyto

receivedata.CTSlowindicatesthatthereceivebufferisfull(seeXON/

XOFF).Insomecomputerprograms,forexampleMSWindowsTerminal,RTS/CTSisdesignated“Hardware.”

ENQ/ACKisaprotocolwherethecommunicationiscontrolledby

thecontrolcharactersENQ(ASCII05dec.)andACK(ASCII06dec.)

beingtransmittedonthesamelineasthedata.ThesendingunittransmitsENQatregularintervals.IftheresponseACKisnotreceived,the

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 6—Setting Up the Printer

transmissionisheldupawaitinganACKcharacterfromthereceiving

unit.Bydefault,ENQ/ACKisdisabled.

XON/XOFFisaprotocolwherethecommunicationiscontrolledby

thecontrolcharactersXON(ASCII17dec.)andXOFF(ASCII19dec.)

beingtransmittedonthesamelineasthedata.XON/XOFFcanbe

enabled/disabledseparatelyfordatareceivedfromthehostbytheprinte

r

(printersendsXON/XOFF)andfordatatransmittedtothehostfrom

theprinter(hostsendsXON/XOFF).

XOFFissentfromtheprinterwhenitsreceivebufferisfilledto75%,

andthetransmissionfromthehostisheld,waitingforanXONcharacter.Whenenoughdatahavebeenprocessedsothereceivebufferisfilled

onlyto50%,theprintersendsanXONcharacterandthehostresumes

transmittingdata.ThesameprinciplesapplytoXON/XOFFsentbythe

host,evenifthepercentagefiguremaydiffer.Bydefault,XON/XOFFis

disabledfordatainbothdirections.

New Line

Selectsthecharacter(s)transmittedfromtheprintertospecifytheswit

chingtoanewline.Therearethreeoptions:

·CR/LF

·LF

·CR

Receive Buff er

Thereceivebufferstorestheinputdatabeforeprocessing.Defaultsizei

s

1024bytes.

Transmit Buff er

Thetransmitbufferstorestheoutputdatatobetransmittedbeforetransmission.Defaultsizeis1024bytes.

51

Chapter 6—Setting Up the Printer

Feedadjust

TheFeedadjustpartoftheSetupModecontrolshowmuchofthemedia

isfedoutorpulledbackbeforeand/oraftertheactualprinting.These

settingsareglobalandwillbeeffectedregardlessofwhichprogramis

run.

Note:Thefirmwareusesthefrontedgesoflabelsw.gaps,the

endsofdetectionslots,andtheforwardedgesofblackmarks

fordetection,allseeninrelationtothefeeddirection.

Start Adjust

TheStartAdjustvalueisgivenasapositiveornegativenumberofdots.

Defaultvalueis0,whichplacestheoriginacertaindistancebackfrom

theforwardedgeofthecopy.

·Apositivestartadjustmentmeansthatthespecifiedlengthofmedia

willbefedoutbeforetheprintingstarts.Thus,theoriginismoved

furtherbackfromtheforwardedgeofthecopy.

·Anegativestartadjustmentmeansthatthespecifiedlengthofmedia

willbepulledbackbeforetheprintingstarts.Thus,theoriginis

movedtowardstheforwardedgeofthecopy.

Stop Adjust

TheStopAdjustvalueisgivenasapositiveornegativenumberofdots.

Defaultvalueis0,whichstopsthemediafeedinapositionsuitablefor

tearoffoperation.

·Apositivestopadjustmentmeansthatthenormalmediafeedafter

theprintingiscompletedwillbeincreasedbythespecifiedvalue.

·Anegativestopadjustmentmeansthatthenormalmediafeedafter

theprintingiscompletedwillbedecreasedbythespecifiedvalue.

52

Industrial—User’s Guide (Fingerprint)

Chapter 6—Setting Up the Printer

Recommended Feed Adjustments

Thefollowingsettingsallowprintingfromthetopofthelabel.Minor

deviationsfromtherecommendedvaluesmayberequiredduetovarious

combinationsofmediatypes,rollsize,typeofmediasupplydevice,and

individualdifferencesbetweenprinters.

Adjustment

type

Tear-Off (Straight-through)

Startadjust:-100dots

Stopadjust:0dots

Peel-Off (Self-strip)

Startadjust:-56dots

Stopadjust:-44dots

Cut between labels

Startadjust:0dots

Stopadjust:+160dots

Cut between labels and print from leading edge of next label

Startadjust:-250dots-369dots31.25

Stopadjust:+160dots+236dots20.0

Cut variable length strip (No liner allowed!)

Startadjust:-250dots-369dots

Stopadjust:+275dots+406dots

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 6—Setting Up the Printer

Media

Themediaparameterstellthefirmwarethecharacteristicsofthemedia

thatwillbeused,sotheprintoutwillbepositionedcorrectlyandgetthe

bestqualitypossible.

Media Size

Thesizeoftheprintableareaisdefinedbythreeparameters;X-Start,

Width,andLength.

X-Start

Specifiesthepositionoftheoriginalongthedotsontheprinthead.

ThedefaultX-startvaluepreventsprintingoutsidelabelswhentheliner

isslightlywiderthanthelabels.Ifyouwanttomaximizetheprintwidth,

resettheX-startvalueto0.

ByincreasingthevaluefortheX-startparameter,theoriginwillbe

movedoutwards,awayfromtheinneredgeofthemediapath.Inother

words,thelargerX-startvalue,thewiderinnermarginandthelessavailableprintwidth.

Width

Specifiesthewidthoftheprintableareainnumberofdotsfromthe

origin.Thus,thesumoftheX-startandwidthvaluesgivestheouter

marginoftheprintablearea.Thewidthshouldbesettopreventprinting

outsidethemedia,whichmayharmtheprinthead.

Length

Specifiesthelengthoftheprintableareainnumberofdotsfromthe

originalongtheY-coordinateandallocatesmemoryspacefortwoidenticalimagebuffersintheprinter’stemporarymemory.

Thesizeofeachbuffercanbecalculatedusingthisformula:

Buffer size (bits) = [Print length in dots] x [Printhead width in dots]

Note:Thetemporarymemoryhasotherfunctionsthatalso

requiresomememoryspace.Toobtainalongerprintarea,the

memorycanbeincreasedbyfittingalargerSDRAMSIMMon

theprinter’sCPUboardasdescribedintheServiceManual.

·Thelengthsetupalsodecidestheamountofmediafeedwhenusing

“fixlengthstrip.”

54

Industrial—User’s Guide (Fingerprint)

Chapter 6—Setting Up the Printer

·Thelengthsetupcreatesanemergencystop,whichworkswhenthe

printerissetupfor“Label(wgaps)”,“Ticket(wmark)”,or“Ticket

(wgaps).”Ifthelabelstopsensor(LSS)hasnotdetectedagapor

markwithin150%ofthesetlength,themediafeedisautomatically

stoppedtoavoidfeedingoutawholerollofmedia,becauseofanLSS

malfunction.

BysettinguptheX-start,theWidth,andtheLength,youwillcreatea

printwindowinsidewhichtheprintingcanbeperformed.Anyobjector

fieldextendingoutsidetheprintwindowinanydirectionwilleitherbe

clippedorcauseanerrorcondition(Error1003“Fieldoutoflabel”),see

IntermecFingerprintv8.xx,Programmer’sReferenceManual.

Print Window (8 dots/mm standard printhead)

10.3 mm (0.41 in)

max. 104.0 mm (4.095 in)

Length

Dot-line

on printhead

X-start

FEED

Dot #0

25-114.3 mm (1-4.5 in)

Intermecoffersanumberofnon-standardthermalprintheads,seeChapter8.

Intermec EasyCoder PF4i Compact Industrial—User ’s Guide (Fingerprint)

Chapter 6—Setting Up the Printer

Media Type

TheMediaTypeparameterscontrolhowthelabelstopsensor(LSS)and

themediafeedwork.Therearefivemediatypeoptions:

·Label(wgaps)isusedforadhesivelabelsmountedonliner.

·Ticket(wmark)isusedforlabels,tickets,orcontinuousstockprovidedwithblackmarksattheback.

·Ticket(wgaps)isusedforticketsandtagswithdetectionslits.

·Fixlengthstripisusedforcontinuousstockwherethelengthoftheprint

windowdecidesthelengthofmediatobefedout.

·Varlengthstripisusedforcontinuousstock.Thesizeoftheprint

imagedecidesthelengthofeachcopy.

Itisimportanttoselectthecorrectmediatype,sotheprintercanindicatethefollowingerrors.

·Error1005“Outofpaper”indicatesthatthelastorderedcopycould

notbeprintedbecauseofanemptymediastock.

·Error1031“Nextlabelnotfound”indicatesthatthelastorderedlabel

orticketwassuccessfullyprinted,butnomorelabels/ticketscanbe

printedbecauseofanemptymediastock.

56

Industrial—User’s Guide (Fingerprint)

Chapter 6—Setting Up the Printer

Paper Type

ThePaperTypeparameterscontroltheheatemittedfromtheprinthead

tothedirectthermalmediaor,optionally,thetransferribboninorderto

producethedotsthatmakeuptheprintoutimage.

Labels,tickets,tags,strip,andribbonsforvarioustypesofapplicatio

n

areavailablefromIntermec.Forthebestprintoutqualityandmaximum

lifeoftheprinthead,useIntermecsupplies.Setuprecommendations

forIntermecsuppliesofferedinEuropeandNorthAmericaarelistedin

AppendixD.

Asageneralrule,highenergyand/orhighprintspeedwillshortenthe

lifeoftheprinthead.Neverusehigherpapertypeandprintspeedsettingsthannecessaryforobtaininganacceptableprintoutqualityand

throughputspeed.

Iftheambienttemperatureislowerthan+15°C(+59°F),decreasethe

printspeedby50mm/sec.

Startbychoosingbetweentwoalternatives:

·DirectThermalprinting

·ThermalTransferprinting

Yourchoicewilldecidewhichparameterstoenternext:

Direct Thermal Printing

·LabelConstant

·LabelFactor

Whenadjustingtheimagedarknessfornon-Intermecdirectthermal

media,settheLabelFactortotherecommendedvalueforthetypeof

directthermalmedia.SettheLabelConstanttothevaluelistedbelow

anddecreaseorincreaseitforlighterordarkerimagesrespectivelyunti

l

youaresatisfiedwiththeprintoutquality.

General Paper Type Settings Guide (Direct Thermal)

Sensitivity1

Low

Standard

High

Ultrahigh6040200150

1

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 6—Setting Up the Printer

Thermal Transfer Printing

·

·

·

·

·

Whenadjustingtheimagedarknessfornon-Intermecmediaandtransfer

ribbons,settheRibbonFactortotherecommendedvalueforthetype

ofthermaltransferribbon.SettheRibbonConstantatthevaluelisted

belowanddecreaseorincreaseitforlighterordarkerimagesrespectively

untilyouaresatisfiedwiththeprintoutquality.TheLabelOffsetparameterispresentlynotused,sokeepitatthedefaultvalue0.

General Paper Type Settings Guide (Thermal Transfer)

Type

Wax(Europe)

Wax(U.S.A.)

Wax/Resin(Europe)

Wax/Resin(U.S.A.)

Resin(Europe)

Resin(U.S.A.)

TheRibbonSensorparameterisread-only.WhenperformingaTestfeed

orwhenpressingthe<Enter>keywhentheRibbonSensormenuisdisplayed,theprinterwillfeedoutsomemediaandautoadjustthesensor.

Theresultingsettingisdisplayedinthemenu.

TheLowDiameterparameterspecifiesthediameteroftheribbonsupply

roll,whereSYSVAR(26)switchesfrom0to1.SYSVAR(26)=0means

thatthereisstillasufficientsupplyofribbon,whereasSYSVAR(26)

=1meansthatitistimetoconsiderreplacingtheribbonsupply.The

diameterisexpressedinmillimetres(1mm=0.04in.)andanaccuracy

of±3mmcanbeexpected.Notethatthissettinghaslittleeffectunless

SYSVAR(26)isreadbyaFingerprintprogram.However,Error1083

“RibbonLow”isreportedateverytenthprintingoperation.Bydefault,

thelowdiameteris0,thatis,theribbonlowfunctionisdisabled.

58

Chapter 6—Setting Up the Printer

Contrast

Usethecontrastparametertomakeminoradjustmentsoftheblackness

intheprintout,forexampletoadapttheprintertovariationsinquality

betweendifferentbatchesofthesamemedia.11optionsaredisplayedin

anendlessloopfrom-10%to+10%.Defaultvalueis0%.Thecontrast

isresettothedefault(±0)wheneveranewpapertypeisspecified,regardlesswhichmethodhasbeenused.

Testfeed

Thesensitivityofthelabelstopsensor(LSS)mayneedtobeadjusted

whenswitchingfromonetypeofmediatoanother.Thisisespecially

thecasewhenusingadhesivelabelssincethetransparencyoftheliner

(backingpaper)mayvary.WhentheTestfeedmenuisdisplayed,press

the<Enter>key.Anumberofblankcopieswillbefedoutuntilthe

firmwarehasdecidedthepropersettingfortheLSS.Atthesametime,

thefrontedgesofthelabels,tickets,etc.aredetectedsothefeedcontro

l

canpositionthemediaaccordingtotheFeedadjustparameter(sameas

theIntermecFingerprintstatementTESTFEED).Fourvaluesusedfor

troubleshootingtheLSSaredisplayed(read-onlyinformation).

Print Defines

Head Resistance

Theprintheadresistanceismeasuredautomaticallyatstartup(read-onl

y

information).

Testprint

Thetestlabels”Diamonds”,“Chess”,“BarCodes#1”,and“BarCodes

#2”areusedtochecktheprintoutqualityandfacilitateadjustmentof

theprintheadpressure,seeChapter12.Thetestlabels“SetupInfo”and

“HardwareInfo”listtheprinter’scurrentsetupandtheinstalledelectronicdevices.Testlabel“NetworkInfo”isonlyprintediftheprinter

hasanoptionalEasyLANinterfaceboard.Iftheinformationdoesnotfit

ononelabel,twoormorelabelswillbeprinted.Iftheprinterrefusesto

printatestlabel,pressthe<i>keytofindoutwhatiswrong,forexample

“printheadlifted”or“out-ofpaper”.Seenextpageforexamplesoftest

labels.

59

60

DISABLE

DISABLE

(versio n number)

9600-8- N-1

U ART1

RTS/CTS

DISABLE

300

300

Setup Info

0

0

+0%

100

192.168 .234.1

PF4i

0 (m)

3702056 bytes free

Odomete r

4023296 bytes free

c:

0 (k)

0+4096 (k)

8192 (k)

4.0 (CLIC version 1)

tmp:

Compact Flash

Flash

Ram

Hardwar e version

Model

EasyLAN / 00104017B 872

1-97164 1-50 / IEEE128 4-1 / 1.1 / 0146-00001 0

1-97163 0-50 / CPU / 1.1 / 0030-00 0016

1-95903 2-01 / TPH / 0.0 / 0001Z-0 0085

1-97163 3-25 / Console / 1.1 / 0033-00 0000

1-97163 1-50 / PSU / 1.0 / 0031-00 0000

H ardwa re

MCS (number, date, time, and processo r family)

Fingerp rint

FIRMWAR E

192.169 .234.2 0

255.255 .254.0

NETMASK

NAMESER VER

192.168 .235.1 04

IP ADDRESS

DEFAULT ROUTER

DHCP+BO OTP

IP SELECTI ON

8

702

PRINT SPEED

LTS VALUE

HEAD RESIST

170 202 2 5

36

TESTFEE D

0

14

CONTRAS T

25

LOW DIAMETER

90

RIBBON SENSOR

40

LABEL OFFSET

LABEL FACTOR

RIBBON FACTOR

85

TRANSFE R

LABEL (w GAPS)

RIBBON CONSTAN T

LABEL CONSTAN T

PAPER TYPE

MEDIA TYPE

808

24

1200

XSTART

WIDTH

STOPADJ

LENGTH

STARTAD J

P RINT C ONFIG

REC BUF

TRANS BUF

CR/LF

DISABLE

DATA FROM HOST

NEW LINE

DATA TO HOST

XON/XOF F

ENQ/ACK

Chapter 6—Setting Up the Printer

Test Labels

702 ohms/8 dots

Diamonds

Bar Codes #1

Chapter 6—Setting Up the Printer

Print Speed

Theprintspeedisvariablebetween100and200mm/sec.forprinters

fittedwithan8dots/mm(203.2dpi)printheadandbetween100and

150mm/sec.forprinterswithanoptional11.81dots/mm(300dpi)

printhead.Generally,thelowerthespeed,thebettertheprintoutquality.Thisisespeciallytruewhenprintingbarcodeswiththebarsrunning

acrossthemediapath(“ladderstyle”),whenprintingondemandingface

materials,andwhenprintingatlowambienttemperatures.Thedefault

settingis100mm/sec.(approximately4inches/sec.).

Thecombinationofalargemediaroll(>152mm/6inches

diameter)and/ornarrowmediawidthincombinationwith

highprintspeed(>150mm/6inchespersec.)couldcause

jerksinthemediafeed.Suchjerkswillcompresstextand

spoilthereadabilityofladder-stylebarcodesplacedclose

tothefrontedgeofthelabel.Incaseofbatchprinting,

onlythefirstlabelinthebatchwillbeaffected.Negative

startadjustvaluestendtoincreasethejerks.

·Ifthemediarollislargerthan152mm(6inches),do

notuseaprintspeed>150mm/sec.

·Ifanegativestartadjustisused,donotuseaprintspeed

>125mm/sec.

·Narrowmediawidthmayrequirefurtherrestrictionson

printspeed.

·Avoidplacingtextandladder-stylebarcodesclosetothe

frontedgeoflabels.

LSS Test

Thefunctiononthelabelstopsensor(LSS)canbetestedautomatically

ormanuallyasdecribedinChapter12“Adjustments.”

LTS (Label Taken Sensor)

ThesensitivityoftheLTScanbetestedandadjustedasdescribedin

Chapter12“Adjustments.”

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 6—Setting Up the Printer

Returning to Factory Default Setup

Therearetwowaystoreturntothefactorydefaultsetupoftheprinter:

AInsertaspecialCompactFlashmemorycardandrestarttheprinter.

BUsingtheprinter’sbuilt-inkeyboard.

Toresettheprinterusingthekeyboard,dolikethis:

1Lifttheprinthead.

2Switchonthepowertotheprinterandpressthe<i/F5>keyandwait

untiltheprinterbeeps.

3Swiftlypressthefollowingkeys:

</F4>

4Thefollowingmessagewillbedisplayed:

Factory Default?

Enter=Yes ESC=No

5Within10seconds,press<Enter>toresettheprintertofactory

default.Theparameterswillberesetandtheprinterwillcontinuethe

normalstartup.

Ifyoupress<Esc/F2>orwaituntilthe10secondstimeouthaspassed,

thenormalstartupwillcontinuewithoutanyresetbeingperformed.

Note:Ifanyofthefiles"card:NOSHELL.CFG",

rom:NOSHELL.CFG",or"c:NOSHELL.CFG"existsinthe

printer’smemory,noresettofactorydefaultwillbeperformed.

Thefactorydefaultwillremoveallfilesusedtostoresettings.

Itwillnotresetsettingsthatalreadyhasbeenreadwhenthe

filesareremoved.ThismeansthatEasyLANWirelesssettings

(SSID,keys,etc.)willretaintheirvaluesfromtheprevious

start.However,thenextrebootwillresetthemtofactory

default.

62

Guide (Fingerprint)

7

Setup Mode

Thischapterdescribeshowtoenterthesetupmode

atinstallation,explainshowtonavigateinthesetup

mode,andprovidesoverviewsoverwhichparameters

andmessagesareavailableforthestandardprinterand

withvariousinterfaceboards.

Intermec EasyCoder PF4i 63

Compact Industrial—User’

s Guide (Fingerprint)

Chapter 7—Setup Mode

Entering Setup Mode at Installation

ThemethodofenteringtheSetupModedependsonwhichstartupfiles

arestoredintheprinter’smemory,asubjectthatwasmorethoroughly

discussedinChapter3,“StartingUp.”

EasyCoder PF4i Compact Industrial with Intermec Shell

·Switchonthepower.

·Whenthedisplayshowsthemessage“Enter=Shell;xsec...”,press

<Enter>.

·Press<Setup>(thisfacilitycanbeusedanywherewithinIntermec

Shell).

·Setuptheprinterasdescribedinthischapter.

·ReturntoIntermecShellbypressing<Setup>.

EasyCoder

PF4i

Compact

custom-made

application program

Industrial

with

·Normally,thereisnoneedtoentertheSetupModeforcustom-made

applicationprograms.Necessaryprovisionsforchangingthesetup,

manuallyorautomatically,shouldbeprovidedbytheprogram.

64

a

PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 7—Setup Mode

Navigating in Setup Mode

Whilegoingthroughthesetupprocedure,youareguidedbytextsinthe

printer’sdisplay.Youcannavigatebetweensetupmenus,acknowledge

displayedvalues,selectortypenewvalues,etc.byusingthekeysonthe

printer’skeyboard.

Note:AnexternalkeyboardcannotbeusedinsidetheSetup

Mode.

Moveonemenutoth

eleftonthesamel

1

Moveuponelevel.

Moveonemenutotherightonthesamelevelorscrollforw

ard

1

Movedownonelevel.

Displayerrormessagesattestlabelprintingfailure.

-

Enternumericvalues.

Specifynegativevalues(leadingposition).

Cleardisplayedvalues.

Acknowledgeandmovetonextmenuorperformtestfeedsi

n

1

ExittheSetupMode.CanbeusedanywhereinSetupMode.

/.“Left”,“right”,“up”

,and“down”refertotheoverviewslaterinthischapter.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 7—Setup Mode

TheSetupModeisorganizedasanendlessloop,fromwhichyoucan

selectanumberofsub-categories.Atstartup,thefirmwaredetermines

ifoptionssuchasalabeltakensensor,acutter,oraninterfaceboardis

installedintheprinter.OnlyinstalledoptionsareshownintheSetup

Mode.

Thediagrambelowshowstheoptionsinthemainloop.Detailedoverviewsareshownonthepagesthatfollow.

Starting point

SETUP:

SETUP:

SER-COM, UART1

SETUP:

PRINT DEFS

SETUP:

MEDIA

SETUP:

FEEDADJ

66

Chapter 7—Setup Mode

Setup Mode; Serial Communication "uart1:"

(Intermec Fingerprint v8.20)

SETUP:

SER -C OM , UAR T1

SER-C OM, UART 1:

BAUDRATE

BAUDRATE;

960 BAUDRATE;

1920 BAUDRATE;

3840 BAUDRATE;

5750 BAUDRATE;

1 520 BAUDRATE;

30 BAUDRATE;

600BAUDRATE;

120 BAUDRATE;

240 BAUDRATE;

4800

NONE

EVEN

OD

MARK

DISABL E

DISABL E

Scroll forward

Scroll back

SER -CO M, UART 1:

NEW LINE

FLOW CONTROL:

XON/XOFF

NEW

LFNEW LINE:

CR

XON/XOFF:

DATA TO HOST

DA TA TO HO ST:

DIS ABL EDTATOA HOS T:

ENABLE

DATA

Scroll forward

Scroll back

Legend:

Dottedboxesandlinesindicateoptions.

Thickboxesindicatesdefaultoptions.

Valuesinsidebracketsindicatedefaultsettings.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 7—Setup Mode

Setup Mode; Feed Adjust

(Intermec Fingerprint v8.20)

Continued from the

previous page

68

Industrial—User’s Guide (Fingerprint)

Chapter 7—Setup Mode

Setup Mode; Media

(Intermec Fingerprint v8.20)

Continued from

the previous page

MEDIA SIZE:

XSTART

(w GAPS)M EDIA

TICKET

MEDIA (w TYPE:MARK)

MEDIA (w

FIX TYPE:

XSTART:

[24]:

Scroll forward

Scroll back

MEDIA:

PAPER TYPE

Not displayed if a transfer

ribbon mechanism is

not installed in the

printer.

MEDIA:

CONTRAST

PAPER TYPE:

DIRECT THERMAL

+0%

+2%

DIR ECT THER MAL :

LA BE L CON ST ANT

LA BE L CON ST ANT

[85]:

+4%

+6%

+8%

+10%CONTRAST:

-10%

-8%

-6%

-4%

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 7—Setup Mode

Setup Mode; Print Defs

(Intermec Fingerprint v8.20)

Continued from

the previous page

PRINT DEFS:

HEAD RESIST

HEAD RESIST:

[nnn]:

Read-only

CODES #1

CODES #2

SETUP INFO

TESTPRINT:

NET WO RK INF O

Scroll forward

Scroll back

<Enter> to print

<?> for error info

PRINT DEFS:

LTS

LTS:

LTS ADJUST

REMO VE LABE L AND

PRESS ENTER

SE NS IT IVI TY 10

OUT OF 9-10

70

Industrial—User’s Guide (Fingerprint)

TESTPR INT:

TESTPR INT:

BARTESTPRINT:

BARTESTPRINT:

TESTPR INT:

HARDWA RE INFO

Chapter 7—Setup Mode

Setup Mode;

(option)

Serial

Communication

"uart2:"

(Intermec Fingerprint v8.20)

SETUP:SETUP:

SER-COM, UART2

SE R-COM, UA RT2:

DATA

BAUDRATE

96 00

19 200

38 400

BAUDRATE; 57 500

BAUDRATE; 1 520 0

BAUDRATE; 30 0

BAUDRATE;

BAUDRATE; 12 00

BAUD RAT E; 24 00

BA U D R A T E;

600BAUDRATE;

BAUDRATE;

BAUDRATE;

4800

NONE

EVEN

OD

MARK

DISABL E

Menus inside this dotted box are not displayed in case of RS485 on "uart2:".

SER -C OM , UAR T2 :

NEW NELINE

W

FL OW CO NTROL :

ENQ/ACK

DISABL E

ENQ-ACK:

ENQ/ACK:

ENABLE

LFNEW LINE:

CR

DATA

DATA

SER -C OM , UAR T2 :

TRANS BUF

TRANS BUF:

[1024]: