Download Ward's GIL-39012B User's Manual

Transcript

ROTARY TILLER

REARTINE

TILLER

ilnlu0uulllc,Pnftfl||r|0tw

orlly

sptctRmW

tvt0tltlr

Tifrffibeads

are

nor

pr'perlv

seated,

arrpnssure

ovbr

34pgican

ciuie

ttre

ilil hilertffi ih;

assembly

with

lq_a\pbdeforielullicient

toartae

iiri,iiiolTiiii'i'ijii.iiii.

,beads

Make

certain

rimrscorrect

diarireter

and

type.G.n

rim,lubricat0,,rim,

ilvgiecotaI$iildiil;hp

:l9"t9:8"*1,'"ll'^,^{t,ttt'$eno_fl

beads.

notstand

ovTrffitltffi tatrng-ffiiffi

.Do

: manufacturer's

inflation

recommendetis["-.^:::,

-. __

IMP OR TA N T

READTHIS MANUALCAREFULLY

AND KEEPFOR FUTUREREFERENCE

GONTENTS

Generol Introduction

SofetyTips

InitiolServicing

Controlsond Operotion

StortingYourRotoryTiiler

Adiustments

Seruicingond Mointenqnce

Storoge

TillerPorts

TillerPortsList

Chqin Cose Ports

Choin Cose PortsList

Howto Order Replocementports

3

3

4

4

5

6

I

11

12&14

r 3 &1 5

16

17

20

IMpoRTANT!Recordthe unit model number ond its seriol

number on the bock poge of this monuol for

fulurereterencewhen orderingrepoir portsor identificotionif

unit is lostor stolen.

The monufocturerreseryesthe right lo mqke chonges on

ond to odd improvementsupon its productsol

ony time withoutnotice or obtigttion. The monufqLturerqiso resewes

lhe rightto discontinuemonufoclure of ony product ot itsdiscretionot ony iime

Nolice to customers in lhe Slofe of Colifornio _

The.engine on this unit is trtoT equipped with o

spork orrestingmuffler

WARNING

USE OR OPERATIONOF THIS ENGINE Oil ANY

lqnEsT GOVERED,BBUSH COVEREDOR GRASS

COVEREDLAIIID WITHOUT A STATE APPROVED

SPARK ABRESTERIN EFFECTIVEWORKIITIG

OR.

DER COiISTITUTESA VIOLATIOil OF THE LAW OF

THE STATEOF CALIFOBITIIA.

GENERAL INTRODUCTION

ThisOwneis Guide hos been especiolly prepored lo

provide the informotion needed to op'eiote your

tii

ler with greoler sotisfoction.Reod this'Owne/i Guide

ond the engine inslrucfionscorefully. Be sure you

know whot the controls ore for ond how they o[ergte: Ilte core your tiiler requiresis smoil, but'imior_

tont. Keep it cteon ond weit tubricofed. Witn prcjber

core ond operotion,os exploined in this monuof,

you will obtoin long ond efficientservice.

This.tiller,

is .shipped completely ossembled.Afler

reootng this monuol ond servicingtiller the tiller is

reody to operote.

Informolionregording operolion ond mointenonce

of the.engine is nol included in this monuol. A sep_

orole instructionmonuol is included with your liller

ond should be consultedfor oll informoiioncon_

cerning engine odjustmenlsond operolion.

O Inspectwork oreo ond cleor ony objects thot ore

not eorth or mulch.

o lmproper use of the rotory tiller con resull in in_

jury. Give complete ond undivided ottention

fo

the work you ore doing.

O Knowlhe conlrolsond how they operote.

o K.noyhow to stop the rotory tiller ond engine in_

stontly.

o Disengogepower ond stop engine before cleon_

ing, removing obstocles,or mlking odjuslment.

a Keep childrenond petso sofedislonceowoy from

rotory tiller.

o Do.not ollow onyone to operote rotory tiller with_

out proper instructionond supervision.

O Exercisecoution to ovoid folling.

SAFETYTIPS

Don'tForget

o

.?on'tsio.rtthe gngine ond tines until you ore reocty

lo slorttilling.Stopthe engine wheneveryou leov6

the mochine.

O Disengoge clutch before slorting engine. Keep

honds, feet ond clothing owoy from power_driven

porfs. Weor odequoie footweor to prevent foof

InJury.

O Keep rotorytiller in good operoting conditionond

keep sofety devices in ploce.

Do not till neor undergroundelectric cobles or ir_

rigotion hoses.

thot SAFETY

stortswith you!

Store gosoline in o sofe contoiner. Storethe con_

toiner in o cool, dry ploce. Not in the houseor

near heatingappliances.

Open doors if engine is run in goroge. Exhoust

gosesore dongerous.

Yo.urrotory tiller wos built to the highest slondords

in the industry.Howeve_r,

a rotary tilleir is only as safe

as the operaror. As with ony ty-pe of powei equip_

ment,coretessnessor error on th6 pon dr the opeiotbr

con re.sulfin injury. pleose reoci ond follo* these

Insrructionsgn sofe operotion ond be cerloin ony_

one using this rotory tiller is fomilior with fhese sim_

ple rules:

Fill gos tonk outdoors.Avoid spillinq oosoline.

Don'tfill lonk white engine is runningdr inite you

ore smoking.

The replocement of ony porf on fhis product by

ofherthon the monufocture/southorizddreploce_

ment p.orl moy odversely offect the performonce,

durobility or sofety of this producl.

IN I T I A L S E R V I C I NG

1. Before storling the engine, refer fo the engine insfructions.Be cerloin lhe the engine cronkcose

is filled with the proper type oil ond thot oll engine serviceinstructions

hove been followedcompletely.

CLUTCHCONTROLLEVER

THROTTLE

CONTROL&

ENGINE

STOP

LEVER

2. Fillfuel tonk wilh o cleon, fresh,leod-free or leoded "regulor'' grode of outomotive gosoline. Do

not mix oil with gosoline.

All nuls ond bolts should be checked ond tightened during lhe firsttwo (2) hoursof use. periodic

checks should be mode thereofler.

HANDLECONTROLLEV

E N GIN EC H OK E

DEPTH

CONTROLLEVER

4. Thetiresore normolly over-inflotedfor shipping.The

recommended lire pressureis 20 lbs.

CONTBOLSAND OPERATION

Thislillerhos the followingconlrols:(Figure1)

ON ENGINE

A. EngineRewindStorter

B. EngineChoke

ON HANDLE

BAR

A. Clutch ControlLever

B. ThrotlleControlond EngineSlop Lever

C. Hondle ControlLever

ON TINESHIELD

A. Depth ControlLever

HANDLE BAR

tl

The hondle bor hqs two operoting locotions (see

Figure2).In the fillinglocotion,lhe tinesore immediotely in frontof the operotor.In lhe tronsportlocotion,

the engine is immediotely in front of fhe operofor.

Use lhe hondle control lever lo unlock the hondle,

then positionthe hondle in the desired locotion.

I

HANDLE CONTROL LEVER

j

i

The hondle control lever conlrols the hondle swing

locotionond fhe hondle height.To swingthe hqndle

bor, pull bock on the lever. Swing lo either righl or

lett to lhe desired posilion,then releqse the conlrol

lever ond swing bock ond forthslighilyunfillhe h<.rndle lofchengoges.Toodjuslhondleheighl,pull bock

on control lever withoulswinginghondle. Move hondle to desired heighl. Releoselever ond move hondle up ond down slightlyunlil hondle locks in lhe

desired height position.NOTE:When pulling bock

on the hondle conlrol lever,the clutch conirol lever

is outomoticolly moved to the neutrolposition.

CLUTCH GONTROL LEVER

Theclutch controllever is o single leverthot engoges

ond disengoges drive to both the tines ond lhe

wheels.

FIG,2

Whenthe handlebar is in the tilling location,pushing

forwsrd on lhe control lever engoges the drive fo

bolh the finesond the wheelsot o tillingspeed. CAUTION:Beforepushinglever forword,be cerloin depih

controlsettingis correcffor soilconditions.(SeeDepih

Confrol Lever)

Pulling bock on clulch control lever from forword

drive lo neutroldisengogesthe drive to the tinesond

wheels.Furtherpulling bock on lhe lever engoges

lhe reversedrive to the wheels qnd the tiller moves

bockwords ot fronsportspeed. (Tinesdo not rotote

in reverse.)When releosed,the confrol lever will relurn to neutrolposition.

Whenthe handlebar is in tnansportlocation,fhe clufch

control lever will only operofe by pulling the lever

bock. Thisengoges the drive to the wheels ond the

tiller moves forword of tronsporl speed. When releosed, fhe control lever refurnsto neulrol.

DEPTHCONTROLLEVER

GAUTION:Do nor adiust rilling depth wfth rhe tines

rotatang.Place clutch control leyer in the neutral

position before makhrgadiustments of depth control.

SHAULOWEST

SETTING

The depth conirol lever is the "key" to eosy tilling operotion. Theexoct settingof control will vory wilh soil

condilions.

When storling o tilling operotion, stort with the depth

confrol lever in lhe shollowesf setting (Figure 3). As

you become ocquointed with the soil, keep roising

the control lever so thof deeper tilling con be done.

CAUTfON:ff depth control lever is roised loo high, iV

the lines will propel the tiller fonruordpushing the lV

drive wheelsolong the ground of on uncontrolled

speed.

When sfortingto till unworked soil or sod, sfort in the

shqllowestsettingof fhe depth confrol lever ond roise

lhe depth control one notch ol o time unlil you orrive ol o sofistocforylocolion of the lever so thot the

deepest tilling con be done without hoving unconfrolled fonvord speed.

FIG.3

OPEBATING SUGGESTIONS

Whenyou slortfo till in the gorden,rememberto toke

it eosy. Do nol lry to loke too deep o cul in o poss

through sod or hord ground, or soil thot hos nol been

tilled for severol monfhsor yeors.

Do nol leon on the hondle bors becouse fhis tokes

weight off the front wheels, reduces troction, ond

couses the tines to ottempl to propel the filler insteod of justdigging.

There ore severol schools of thought os to the best

method to till. lt is suggestedyou lry the voriousmethods ond select the one you ore most comfortoble

with lo get lhe resulfsyou desire.

A. On eoch succeeding poss, overlop one-holf of

the previousposs.

B. On the second poss, leove o 1/2 width untilled

ond till lhis width on lhe third poss.Repeoton ihe

fourth poss, leoving o 1/2 width untilled ond on

the fiflhposs,tillthe untilledstrip.

C. UseA or B ond repeoi ot 90 degrees.

Rememberthe key to eosy tilling is the depth control setting.Do nottry lo toke loo deep o cut in horder

soils.

STARTING THE TILLER

Now thot you hove locoted the controlsond undersfond lheir operotion ond function,il is time to stort

your tiller.

1. Ploce clutch confrol lever in neulrol.

2. Pushthrottle control lever oheod to fosl position.

3. Adjustengine choke lo proper posilion.(Referto

engine slortingproceduresin engine seclion.)

4. Slortengine by pulling slorlercord.

To Stop Engine

1. Ploce clutch controllever in neutrolposition.

2. Pull fhrottlecontrol ond engine slop lever to the

stop posilion.

ADJUSTMENTS

CAUTION:Never ofiempt to moke-odjustments

on

fhe lillerwhile the engine is running.Alwoysstop

lhe engine ond disconneclthe wirelrom tn6 spoit

plug before ottemplingto moke odjustments.

ROTATE

CLAMP CAP SCRE\

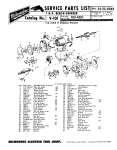

BELT ADJUSTMENTS

TINE DBIVE BELT

The tine drive belt, which is the outer be[, is odjusted by

cop screws (Figuie4) onct roto_

l9_9s9ningthe ctomp qnd

ang me enflre cose

tine ossembly. R6lote cose

fonrord to stocken belt ond bock to fidnten belt, With

the clutch control lever in the forword drlve position,the

disfonce between the inside of fhe betf shoutd be

$Pproximotely 3/4 inch os shown in Figure5. Tighten

the clo.mp bolts securety ofter od j ustmeit. etoce jepm

control in shollowestsettingond itortensine. Withcbn_

trol lever in neutrol position,tines shoult not rofote.lf

flnes rotote,reodjustto increqse bellslock untiltinesdo

notdrive in neutrol.

FIG.4

E N GIN EP U LLE Y

c

TINEDRIVEBELT

3t4

TINEDRIVEPULLEY

WHEELDRIVEBELT

FIG.5

The wheel drive belt, which is the inner beli, is od_

justed by. moving the right hond idter (Figure6). With

the clutch confrol lever in the neutrcjl[ositioh, tfre

troclion belt should hove opproximoiely 1/4 inch

between the upper idler ond the belf (Figure6). The

qdiustmentidler shouldbe positioneO-to

oOtqihthis

1/4 inch. Moving idler up will increosecteoronce

ond down will decreose cleoronce.

NOTE:The odjustmentidler hos four locotions ond

is nol sloi mounted.The mochine screw must be

removed from the mounting frorire when moking

this odjustmenl.

UPPER

I DLER

A D JU S TME NID

T LE R

\

MA C H IN E

SCREW

WHEEL

DRIVE PULLEY

\

FIG.6

HANDLECONTROLLEVERADJUSTMENT

The hondle control odjustmenl(Figure7) hos been

set for proper operotion ond should not need to be

odiusfed.Shouldthe hondle control lever (Figure7)

become loose ofter mony hoursof operolion,tighlen

the odjustmenlnul only enough lo eliminoteony excess movementin the hondle confrol lever.

NUT

ADJUSTMENT

CAUTION:Do nol overtighlen odjuslmenf nut. This

moy resultin foilureof hondle bor lotch systemlo

fully engoge ond hold hondle in desired position.

CLUTCHCONTROLLEVERADJUSTMENT

The clutch control lever is pre-set for neutrol shitt

position.An odjustmenfmeons is provided, however, lo center the clulch control lever in lhe slot on

the hondle shroudshould it become necessorydue

to weor. This odiustmenl is locoted ot fhe hondle

pivol point (Figure8)

TOADJUST:

1. Ploce hondle bor in litling locotion ond odjusl

hondle bor to lowesfposifion.

CLUTCHLEVERCONTROL

2. Loosenthe odiustmentnut (Figure8).

3. Move lhe clutch control lever on the hondle bor

unfil cenfered in lhe neutroloreo (Figure9).

4. Retightenfhe odjustmenlnut (Figure8).

NEUTRAL

AREA

SERVIGINGAND MAINTENANGE

Thebesf ossuronceyou hove of geiling the mosl de_

pendoble service from your tiller is to keep the unit

cleon, free of rust,ond well lubricoted. Check bolts

often lo be sure they ore kept tight. Whenthe tiller is

not being used,it shouldbe storedin o dry ploce out

of lhe weother.

LUBRICATION

1. Engine:Referlo engine operoting instructions

ond

requirementsfor oll engine lubricotion.

2. GhainGases:Both the wheel drive ond the tine

drive coses ore omply filled wifh lubricont ond

shouldnot require odditionol lubricotion.lf o leok

d.evelops,odd teod bose (Ep)SAE140heovy duty

9it (fo!. 4890) os required'to bring to profer oit

level. Check oit tevet every 25 houis.

OIL LEVEL& FILLPLUG

FrG.

t0

Thefollowingprocedureshouldbe followedto check

lubricont level of coses. When checking coses, do

not droin excesslubricontout of the cos6s.

WHEELDRIVECASE

To check the oil level of the wheel drive cose, ptoce

the depth control lever down fo lhe shollowesf selling.(Figure 3). Remove the inspection plug on lhe

right side of the wheet drive cose (Figuretb;. Cose

hos sutficient oil if oil is up to bottorn of insfecfion

plug hole. lt moy be more convenienl lo rernove lhe

righl wheel when checking lhis level.

OIL LEVET

FIG.11A

TIilE DRIVECASE

To check the lubricotion level of lhe tine drive cose:

1. Setdepth confrol ot the deepest setting(Figure3).

2. Ploce liller on o level surfoce so lhot lhe tinesond

the wheels ore seiling on lhe ground,Fig.11B.

3. Wipe dirl owoy from oil level plug ond removeplug,

Fig.11A.

Oil should be up to the Obttomof hote. 4. lt oil isn'tup fo bottom of hote,wipe dirt owoy fromoil

fill plug ond remove, Fig. 118.Fiil stowty witn teoO

bose (EP)SAE140heovy duty oil untitproper tevetis

19gche-!. Reptoce oit levet ptug ond dit tiil prr.rg.

Wipe off excessoii.

FIG.lIB

4(l ) ' .

.q...-<-

___=/

4ffi'

Y

a-\

I

\ ',

l*_./

lilll,

t

Fte.12

To odd lubricont to eilher choin cose it is necessory

to tip liller on its lefi side lo expose tevel ptugs of eocn

cose. Add sufficient teod bose (Ep)SAEtaO neovy

duty oil (Port4890) to bring to propdr oit tevet.

fore oiling ottempt lo cleon off oreo lo be lubricoled.

A. The4 idler pulleys.

B. Thehondle plunger shoflond disc.

C. The conirol rod swivels.

3. The following poinls should be lubricoted with

engine oit every eight hours (see Figure12).Be-

D. The hondle roloting surfoce.

E. Com ond detenl boll ond shoft.

F. Hondle control lever.

G. Tinedrive bellcronk pivot.

\

/'/ |

I

.z -.1I

/1

wHEEL

DRtvE

cAsEpuLLEy )..

'/

/

/\

-\

TlNi DRTVEBELT

/

R E TA IN IN G

R IN G

TINEDRIVECASEPULLEY

ptN

BELT

GUTDE

tl8:g!\|rNGR|N-G/

\_-

\r

TINEDRIVE

,,.,}

'O'.'*

BELIGUIDE

\,,

ARM L|NK

-__--.---IDLER

COTTERPIN

F re . 1 3

BEIT REPLACEMENT

Thebells on thistiller.werespecificollydesigned

ond

enginee.redto provide long, trouble_freeservice.

lf

belt replocement is requlred,orOe,ine port

number

shown in the ports list section of thii rn6nuot,

ro

sure you hove o belt thot will provide lhe liie Oe

ond

servicereguired.

l

I

il

TINEDRIVEBELT

1. Ploce the clutch lever in the neulrol position.

2. Removethe bell guord.

3. Removethe bett guide (Figuret3).

4. Slip the belt off ihe tine drive cose puiley.

5. Removebelt from the engine pulley ond

slip out

befween engine puiley oio ioieior'r.

6. To reploce belt, reverseobove procedure.

Be sure

belt.ison top of tine drive idler prf fey oncl lhe

bell

g-uide pin neor the tine drive iosqiu-iley

fflguie

13).

10

7. Reodjust belt os ouflined under belt odjustments.

8. Replqce belt guord.

WHEELORIVEBELT

1. Removethe tine drive belt per instructionsobove.

2. R_emovethe retoining ring in the idler orm shoft

(Figuret3).

3. Removethe belt from lhe wheel drive cose puiley.

4. Removewheel drive pulley by removing reloining

ring ond stiding puildy orindf. (CAUTI6N:

Do no-t

toose woodruff key in drive pulley shoff.)

{Figure

r3).

5. Removecotter pin from idler orm link (Figurei3).

6. Slide idler qrm ossembliesout unlil lhe spocer con

be slid out between the idler ond idler orm. Re.

move belt. To reploce bett reverse oOove piocedure. Be sure bett is turned inside out (wide iide

on puileys) before instoiling in puileys

ffigurat3|

7. Reodjustbelt os ouflined under bell odjuslments.

STOBAGE

For short lerm storoge,cleon the filler off

ond store

In o dry ploce.

3 Runengine untilil stops.

1

lf tiller is not lo be used for on extended period

of

time, service tiller completely onOJi"re it' in -dry

o

ploce.

1

I,

1 Feler to the engine instructions

for engine storoge

inslructions.

i

2. Droingosolinefrom fuel tonk.

4. Cover exposed metol surfoceswith o t hin

coot

of engineoil.

Lub.ricoteper insfructions

under ,,servicingond

Moinlenonce".

Beforeusingthe tillerogoin, check oll lubricotion

go.ints,fill fuel lonk, on-d follow other insiructions

in the owneis guide.

11

HANDLE& CONTROL

PARTS

q

FI

c

AL-q

o.,-@

^"-?t"

12

,.

HANDLE & CONTROLSPARTSLIST

RE F .

LET.

A

B

C

D

E

F

G

H

I

J

K

L

M

N

o

P

R

S

T

U

V

W

X

z

AD

AE

AF

AG

AH

AI

AJ

AK

AL

AM

AN

AO

AP

AQ

AR

AS

AT

AU

AV

AW

AX

AY

M

BA

PART

N O.

200469

200470

1'183

200612

2 0 0 11 0

200066

2OO473

200460

200420

200074

33580

2OO075

200323

200768

2 O O1 7 9

200177

200195

200196

200242

200055

200324

200462

33595

2 OOO4 5

2679

200034

D E S C R IP TION

T u n n e l A ssembl y

Handle Assembly

G ri p ..

Slide .

S p ri n g

C o n tro l R od ..

Pivot Assembly . . .

P a w l A s sembl y.. .. .

Pin .. .

Lever.

G ri p . .

Shroud

L i n k As s embl y ....

Lever.

P l u n g o rA ssembl y

R e ta i n e rA ssembl y

C a m As sembl y.....

Be l l c ra n kA ssembl y

Clevis Pin

Spring - Detent

Control Handle Assembly

Control Rod Assembly.. . . .

B a l l ..

Pi n ...

Spacer

Grip . .

Lock Washer- 3/16 Ptated

Cap.Screw - Hex Hd. - 9/16-18 x 11/cPlated

-7 O Q2 2 M a c h i n eS crew - Oval H d. - P hi l . 5/16-18x 1 P tated

Cap Screw Hex Hd. t/a-16x 1 Plated

-70233

.70649

Lock Washer3/ePlated

.70087

Cap Screw - Hex Hd. th-20 x1/z Plaled

.70588

Nut - Flex Jam s/c-16Plated .

Lock Washer th Plated

-70643

2O112O Lock .

18744

Thrust Washer

.70631

Nut - Cone Lock s/e-1

6 Plated .

'70703

Washer - Med. Flal 3/sPlated

.70715 Cotter Pin

1/16 x lz Plated

.70646

Lock Washer 5/16 Plated

.70683 Washer SAE Flat th

Plated

'70721

Cotter Pin t/ax 3/aPlated

' 7 0 4 4 3 C a rri a g eB ol t 5/16-18x 1 P l ated

' 7 0 6 2 9 N u t - C o n e Lock 5/16-18P l ated

16066

Bushing

32861

Clamp

24993

Spacer - Clamp

MachineScrew Rd. Hd. - Va-2O

-70397

x 7aPlated

2OO243 Spacer

Pin, Cotter3/32xs/a Plated .

-70740

-70672

.71072

QTY.

I

I

z

1

1

1

1

1

1

1

1

'1

1

1

1

1

1

1

-l

1

1

1

1

1

1

1

1

1

2

2

1

1

z

2

1

2

2

1

1

1

I

1

1

2

I

1

1

2

.C o mmo n hardw are.

May be purchasedl ocal l y.

13

FRAMEAND DRIUE

PARTS

€[--cl

.B P

,BQ

,K

./fl-

a:,t

-;^A

9@/---,"u

BN

BO

J

BG

BF

GJ

'--

AZ

H

'/cL

,fu'"'o

-6

,i^

'@ft{

%c=s

t7"30,--

6tt

cc

==Eg

:?g

rr€

;tr^ffieiSi:

s_;

#tury

-AO

AP

l

s

'l:a-

t-ca

"

-BZ,6\}-V

22tgffiD

6a-6

P artN o.13938 .

P artN o.13255.

M____-_

N

14

CANS OFTOUCH-UPSPRAY

PAINTARE AVAILABLEBY

ORDERING:

. . . . . . G r ay

.. . . . . . Red

FRAMEAND DRIVE

PARTS LIST

Ref.

Let.

A

B

c

D

E

F

G

H

I

J

K

L

M

N

o

P

o

R

S

T

U

V

W

x

z

AA

AB

AC

AD

AE

AF

AG

AH

l-

AI

AJ

AK

AL

AM

AN

AO

AP

AQ

AR

AS

AT

AU

AV

AW

AX

AY

Part

No.

Description

OtV-

208139 FrameAssembly- R.H.

1

2O814O FrameAssembly- L.H.

1

2O O O 71C o u n te rWe i g h....

t

... 30

2O O A 78C o u n te rWe i g h....

t

8

200165 DepthControlAssembly

1

208810 S k i d As s e mb l y .....

1

j

2OO184 Support Assembly

24897 Handle

z

2O O 197 S p ri n g

. . ......

1

'l

200063 EnginePulley .

2OOO28 Camshaft Pulley .

1

208'142 PulleyAssembly- Tines

1

200555 Traction Drive Belt

1

200554 Tine Drive Belt . . .

1

33632 ldler PulleyAssembly

4

200166 Ti n e D ri v e l d l e rAs s e mb l............

y

1

200164 TractionDrive ldlerAssembly

1

2OO2O7 Pulley Assembly - Traction

1

2O O 422 Sp a c e r-l d l e r.

.... ....

1

200064 Be[Guide

200049 Spacer

20009 Swivel

2OO111 ControlRod . .

200428 Spring - Traction Drive . .

200056 Spring - Tine Drive

2OO421 Bellcrank .. .

200455 Link.. . ... ..

200456 ControtRoo

... : :. :. :.. :. :.. :..... :.

14273 FivotBushing

2762

200613

208175

200194

Washer

z

ChainCase Assembly- Wheel Drive . . 1

Chain Case Assembly- Tine Drive . . . . 1

LU E ..

.... ....

z

Engine- 5 HPB&SModet130292,

Type0803-01

200059 BeltGuard

2OO1'12TineShield

200459 Hinge .

200030 Rod ..

200168 GuardAssembly. . .

208189 TineAssembly

- R.tt.

208192 TineAssembly

- L.H.

240425 Tine- R.H.

200426 Tine- L.H.

1056 FeltSeal

11246 FeltSeal

9545 Washer

200552 Tire& WheelAssembly,

Consists

Of

18945 Tire'13

X 5.00{.

18940 Wheel.

3823 VaiveCap

10631 ValveStem

200553 Tire& WheelAssembly,

Consists

Of

18945 Tire13X 5.00-6

18940 Wheel.

3823 ValveCap

10631 ValveStem

"71079 Machine

Screw,Stotted

FlatHd.s/16-18

x2Ptated":.....

5/16-18Plated.

-70592 Nut,Square

-7O149 CapScrew,Hexi-ld.5/16-18x i"

Plated

Ref.

Let.

M

BA

BB

BC

BD

tsE

BF

BG

BI

BJ

BK

BL

BM

Btl

BO

BP

BQ

BR

BS

BT

BU

BW

BX

EY

BZ

CB

4

I

1

4

t

4

4

4

z

2

.)

'!

I

1

1

I

1

1

I

I

I

1

I

I

CC

CD

CE

CF

CG

CH

cl

CJ

CK

CL

CM

CN

CO

CP

CQ

CR

CS

CT

CU

CV

CW

CX

CY

Part

No.

Description

oty.

.......

-70629 N ut,C oneLock5/16-18Plat ed

I

-70177 Cap Screw,Hex Hd.,5/16-18x

2t/tPlated

3

'70882 Cap Screw,Hex Hd., 9r 16 x 3 Plated . . z

' 70649 W asher,S pri ngLock,7e Plat ed

.......

6

Plated

-70553 Nut, Hex sr'a-16

6

'70137 Cap Screw,Hex Hd. 5/16-18x 5/e

Plated .

I

'70646 Washer,SpringLock 5/16 Plated . . . . . 19

. . . . . . . . . 10

-70549 N ut,H ex5/16 P l ated

........

2

-70603 N ut,S el fLock5/16-18P l a t ed.

1

-71073 B ol t,C arri age5/16-18x2t.h. . . . . . . . .

-70165 Cap Screw,Hex Hd. 5/16-18x ls/a

Plated .

1

"7OO87 Cap Screw,Hex. Hd. 1/t-2Qx1/zPlated. 4

4

-70643 Washer, Spring Lockth Plated .

'70985 Key, Square3/ 16 x 11/z

1

'70497 Set Screw5/'t6-18 x % SocketHd. Cup

PointH.T.

2

"70488 SetScrew th-20x % SocketHd. Cup

PointH.T.

2

.70808 Key,

WoodrultVaxs/a

2

3917 Snap Ring

3

200318 Snap Ring

1

11412 W asher

. . . . . . . 4- 7

3

-70687 Washer, Flat - SAE s/8Plated

-71071 MachineScrew,SlottedPan Hd. Ta-16x

17nPlated

1

'7U4A Cap Screw,Hex Hd. 5/16-18x3/a

Plated .

I

'l

-70699 Washer Med. Flat th Plated

"7A721 Pin, Cotterlaxs/aPlated

4

-7O74O Pin,Cotter3/32x5/ePlated .

2

'70388 MachineScrewSlottedRoundHd.No.

10-24x 1" Plated

2

.70540 Nut, Hex

No. 10-24Plated.

2

-70672 Washer,Ext. Lock No. 10 Plated . . . . . . 2

17002 Washer

2

16

-70232 C apS cr€w ,H exH d.% -16x1". . . . . . . .

'7A648 Washer,SprinELock7e

19

17

-70552 Nut. Hex 3/e-16.

"70301 Cap Screw,Hex Hd. 3/e-24

x 1TaH.T. . . . 2

-70162 Cap Screw,Hex Hd. 5/16-18x 1th . . . . 4

" 70441 B ol t,C arri age5/16-18x

/rPlat ed . . . . . 4

"70133 Cap Screw,Hex Hd. 5/16-18x1/z

Plated .

2

-7O168 Cap Screw,Hex Hd. 5/16-18x 13/a

plated .

2

"7'1090 Cap Screw,Hex Hd. 5/16-18x2rh . . . . 1

'70812 Key,Woodrutl3/16x3/q...

1

2AU41 RetainingRing. .

I

208193 Washer - Back Up

2

9627 FeltSeal

2

24764 Pyramidal Lock Washer

"70554 Nut, Hex YB-24 .

2

1

35886 O-Ring

35887 Cup .

I

'l

37141 OillevelPlug .

37'128 Nylon Wosher

1

18083 Oi l S eol

2

2

*Commonhardware.

May be purchasedlocally.

tc

GHAINCASEPABTS

Io reploce oll choin cose seols

ond dosketsorder PortNo.89428.

To reploce entile choin cose less

lines drder Pod No. 89429'

16

GHAIN GASEPARTSLIST

REF.

LET.

A

B

c

{.**t.r*'

D

E

F

G

H

I

J

K

L

M

N

o

P

o

B

S

T

U

V

W

X

Y

z

PART

N O.

D E S C R IP TION

208162 ChainCase Ass'y.- R.H.w/Bearings. . . .

208163 ChainCase Ass'y.- L.H.w/Bearings

1054

Seal - Tine Shaft. .

208176 Seal - InputShaft .

208052

Gasket

208051 Chain - Lcwer .

208177

Chain - Upper .

2 0 8 1 8 6 In p u tSh a ftA ss' y.

...

208178 SprocketAss'y.w/Bearings

.....

4O2O

ldler Sleeve

208181 Tine ShaftAss'y.. . .

2O81U

SpacerCup

39108

Shim - Gear. .

208141 RetainingRing ..

208185 Washer-lnputShaft

27489

Pipe Plug

CapScrewHexHd. th-Z}x7aPlated

-703M

-70088+,'"*@ap6ercw{rfsre"Hdr%[email protected],T--&Plated

.

*70134

Cap ScrewHex Hd. 5/16-18x thH.T. & ptated.

Hex Nut, Lockt/q-2oPlated .

-70628

"70629

Hex Nut, Lock 5/ 16- 18 Plated .

"70877

Cap Screw,Hex Hd. %-16x 21hH|1.

'70631

Hex Nut, LockTa-16Plated.

208174

Bearing - Input Shaft

208173

Needle Bearing - Tine Shaft

209007 Bearing

*Common

QTY.

1

1

2

1-2

2

2

1

I

'l

:.....;;.:

+2

?

12

3

1

1

2

2

2

hardware. May be purchasedlocally.

l7

ri{/Hff6"

OPERATING

AND MAINTENANCE

INSTRUCTIONS

MODELSERIES

100200to 100299

130200to 131299

IN THE INTERESTOF SAFETY

DO NOT RUN ENGTNEAT EXCESSIVESPEEDS.Operatingan engine at excessivespeedsincreasesthe hazard of personalinjury.

DO NOT TAM PERW I TH PARTSW HI CH M AY I N C R E A S ET H E G O V E R N E DS P E E D .

For rotary lawnmowersafety,A.N.S.l.StandardSafetySpecificationsfor Power Lawn Mowersspecifya maximum blade tip speed of

19,000feet per minute (96.5meters per second),primarilyto reduce the hazardfrom thrown obiects.

Rotary lawnmowermanufacturersselectthe governedtop speed of the engine basedon the length and design of the cutter bladeand

design of other mower parts.

All rotary lawnmowersshould be checkedfor conformanceto the A.N.S.l.StandardSafetySpecificationsfor Power Lawn Mowerson

blade tip speed,if the engine is repairedor replaced,or if mower parts are changed.

DANGER: GASOLINEVAPOR lS HIGHLY FLAMMABLE.Refueloutdoors preferably,or only in well ventilatedareas.

DO NOT STORE,SPILL OR USE GASOLINENEAR AN OPEN FLAMEor devicessuch as a stove,furnqce,water heaterwhich utilizea

pilot light, or devicesthat can create a spark.

lf gasolineis accidentallyspilled,move machineaway f rom area of spill and avoidcreatingany sQUrceof ignition until gasolinevapors

have dissioated.

DO NOT REFUELG ASO LI NETANK W HI LE E N G I N E I S R U N N I N G .

DO NOT RUN THE ENGINE lN AN ENCLOSEDAREA. Exhaustgasescontain carbon monoxide,an odorlessand deadly poison.

TO PREVENTACCIDENTAL STARTINGalways removethe spark plug from the engine,before working on the engine or equipment

driven by the engine.

Exceptfor adlustment;DO NOT operateengineif air cleaneror coverdirectlyovercarburetorair intakeis removed.Removalof such part

could create a fire hazard.

COUId

ATTESTETS

OTSPATK

Do NoT oPERATE WITHoUT A MUFFLERoR TAMPERWITH THE EXHAUSTSYSTEM.Damagedmuff|eTS

create a tire hazard.Inspectperiodicallyand replaceif necessary.

ALWAYS KEEP HANDS AND FEET CLEAR OF ROTATING PARTS.

I N T H E I N T E R E S TO F E N V I R O N M E N T

A mufflerwhich leaksbecauseof rust or damagecan permitan increasedexhaustnoiselevel.Therefore,examinethe mufller periodically

to be sure it is functioning effectively.To purchasea new muffler,see SERVICEAND REPAIR INFORMATION.

WARNING:lf this engine is not equippedwith a sparkarresterand is to be usedon any forestcovered,brush covered,or grasscovered

unimprov- land, before using on such land a sparkarrestermust be addedto the muffler.The arrestermust be maintainedin effective

working order by the operator.ln the Stateof Californiathe above is requiredby law (Section4442ot the CaliforniaPublic Resources

Code). Other statesmay have similarlaws. Federallaws apply on federallands.See your AuthorizedBriggs & StrattonServiceCenter

lor spark arrestermuffler options.

SERVICE& REPAIRINFORMATION

lf service or repair is needed, contact an Authorized Briggs &

StrattonServiceCenter.To serveyou promptlyand efficierttly,the

ServiceCenterwill needthe model,type and code numberon your

en grne .

Each AuthorizedServiceCentercarriesa stock of originalBriggs&

Stratton repair parts and is equipped with special servicetools.

Trained mechanicsassure expert repair service on all Briggs &

Strattonengines.

Major engine repairsshould not be attemptedunlessyou havethe

p rop er too ls and a t hor ough k nowledgeof inte r n a lc o m b u s t i o n

engrne repalr proceoure.

E

Your nearestservicecenter is listed in

the "Yello w Pages " under "Engines ,

Ga so line "o r "G as olineEngines ".He is

one of over 25,000 authorizeddealers

availableto servevou.

\€llowpagEs

FORM NO. 270106-3/79

P R I N T E DI N U . S.A.

This illustratedbook includes"Theoriesof Operation",common

specifications,and detailedinformationcoveringthe adjustment,

t u n e - u p a n d r e p a i r p r o c e d u r e s f o r 2 t h r o u g h 1 6 H .P. si n g l e

c y l i n d e r m o d e l s . l t i s a v a i l a b l ef r o m 'a n y A u th o r i ze d Br i g g s &

Stratton ServiceCenter.Order as Part Number 270962.

B RI G G S & S T RA T T O NC O R P .

Milwaukee,Wisconsin 53201

BEFORESTARTING

SPARK PL UG

TO BATTERY VI A S TA R TE R

S WITC H

R E A D TH E OP E R A TIN GIN S TR U C TI O NSO F

TH E E OU IP ME N TTH IS E N GIN E PO WERS

U se a hi gh qual i tydetergentoi l cl assi fi ed" For Ser viceSC,

S D , S E or MS ." D etergentoi l s keepthe engineileaner and

retardthe formati onof gum and varni shdeposit s.Not hing

shoul d be added to the recommendedoi l .

R E C OMME N D E DS A E V IS C OS ITYGRADES

E LE C TR IC

STARTER

MOTOR

TO BATTERY _

V IA A MME TE R

IF FU R N IS H E D

CY LIN D E R

'lf notavailable,

a syntheticoil maybe usedhaving5W-20,5W-30

or 5W-40viscosity.

TO FILL CRANKCASEWITH OIL

Place engine level. Clean area around oil fill before

removi ngoi l fi l l pl ug or oi l mi nder.

OIL FILL P LU G R emove oi l fi l l pl ug or ( opt ional) oilminder. Fill crankcase to point of overflowing. POUR

SLOWLY.Capacity 17rpints (0.6iiters).Replaceoilfill plug

or oi l -mi nder.

1 1 0 V O L T S T A R TER

EXTENDED

OIL FILL.(Optional)

Remove

capanddipstick.

FILL.TO FULL MARK on dipstick,POUR SLOWLY.

Capacity1% pints (0.6 liters).When checkingoil level,

firmlybutslowlyuntilcapbottoms

screwdipstickassembly

on tube.DO NOT OVERFILL.

Dipstickassemblymust be

securelyassembledto tube at all times when engineis

operating.

E X TE N D E DOIL FILL

OIL F IL L PL UG

FORM NO. 270106-3/79

P RI N T E DI N U . S . A .

CHARGE BATTERY

Charge battery before use on engines equipped with

(OPTIONAL) 12V electric starter motor. See equipment

manufacturers recommendations.

FILL FUEL TANK

Use clean, fresh "regular, low-lead or lead-free" grade

gasol i ne.D O N OT MIX OIL W ITH GA S OLI NE.

necessaryw i th chokeopenedsl i ghtl y.Whenenginest ar t s'

open choke gradual l Y .

STARTING

S t ar t ,s t or e and fu e l e n g i n e i n a l e v e l p o s i ti on.

E NG I N E - En g i n e ma y b e e q u i p p edw i th ei ther

Choke-A-Maticor Lever-Trolcontrols.

MA NUA L CHO K E: P u l l c h o k e a s i l l u s tra te d .

C HO K E - A - M A T ICa n d L EV ER -T R OL L- Mo vecontrol sas

far as possroletoward "Choke" or Start."

STOP SWITCH: Move STOP switch away from spark plug

as illustrated,if so equipped.

STOP SWITEFI

99e

-'1,1

NOTE:A warm enginerequireslesschokingthan a cold

engine.

NOTE: Engine may not start if controls on powered

equipmentdo not closechokefully. SeeADJUSTMENT

section.

GOVERNOR SPEED GONTB!!--IEJEX: Move

ST" or

"START"positionif so equipped.

/_

,\(

E l ectri cS tarter.On engi nesequi ppedw it h 12 volt st ar t ing

systems, turn key to "START" position or press starter

bui ton.On engi nesequi ppedw i th 120volt st ar t ingsyst em s

oress " On" button ol conductor cord' s int egr al"O n- O f f "

sw i tch. R el easeas soon as engi ne star t s and gr adually

ooen choke.

Tlps to obtaln besl eleclrlc slarler performance

a. Short starting cycles (2 to 3 seconds) provide the

longest battery life.

b. Keegthebatter-y+uUy elarge+. This assuresguick and

easy starts.

c. Disengageload from engine during start'

CAUTION: The 120 volt electric starter is equipped with a

three-prong plug for your safety.The longer prong in this

plug ii connected to the starter motor housing. When.the

staier motor is plugged into the three wire cord supplied'

and the cord is plugged into a properly grounded receptacle, it will protect the user from shock should the starter

motor insulition fail for any reason. lf a longer extension

cord is usedwith this starterit should also havethree-prong

and three-hole Plugs.

Ji',','iXf,?

ffia>

C OR D PLU G

TO STOPENGINE

Turnkeyto "OFF"positionor movecontrolleverto "STOP"

position.

TO START ENGINE

DA NG E R:A LW A YSK EE PH A N D S AN D F E ETC LE A R OF

M O W E RB LA D E OR OT H ER R OT A T IN GM AC H IN E R Y .

Rewind Starter.(Can be usedto startengine if the batteryis

run low or if engine cannot be started electrically.Place

engine controls in "Start" and key in "On" position.)Grasp

starter handle as illustrated and pull out cord rapidly to

overcome compression and prevent kickback. Repeat if

CAUTION: Always remove key from switch when leaving

equipment unattendedor when equipment is not in use'

MAINTENANCE

CHECK OIL LEVEL regularly - after each five hours ol

operatio-n-trSFE

orL LEVEL ts MAtNTAINED.

CHANGE OIL after first five hours of operation.Thereafter

change every25 hours of operation.Removeoil drain plug

a n d d r ain oil while e n g i n e i s w a rm. R e p l a c ed ra i n pl ug.

R e mov eoil f ill plug o r o i l -m i n d e ra n d re fi l lw i th n ew oi l of

p ro p e r gr ; de. Repla c eo i l fi l l p l u g o r o i l -mi n d e r.

ASSEIIBLE

ELEH €I{T

SOLIP EXT EIID O

S VER

EOG EO F AIR C tEAIi:R

f

OIL FOA M A IR C LE A N E R

C HAN G E O I L ( G E A R R E D U C T IONo p ti o n a l ) R e moveoi l

l e ve l p lug and oil f il l p l u g . D ra i n o i l e v e ry 1 0 0 h o urs of

o p e rat ion.T o r ef ill,p o u r 1 0 W -3 0o i l i n to fi l l e r h o l e unti l i t

ru n s out lev elc hec k h o l e . R e p l a c eb o th p l u g s .O i l fi l l pl ug

has a vent hole and must be installedon top of gear case

cover.

PLUG

\-----t

r\

DUAL ELEMENTAIR CLEANER

Clean and re-oil foam pre-cleanerat three month intervals

or every 25 hours, whichever occurs first.

NOTE: Service more often under dusty conditions.

1. Remove knob and cover.

2. Removefoam pre-cleanerby sliding it off of the paper

cartridge.

3. a. Wash foam pre-cleanerin liquid detergentand water.

b. Wrap foam pre-cleanerin cloth and squeezedry.

c. Saturatefoam pre-cleanerin engDe oil. Squeezeto

remove excess oil.

4. Install foam pre-cleaner over paper cartridge. Reassemblecover and screw down tight.

I t",'.

TO SERVICEAIR CLEANER

..OIL FOAM'' AIR CLEANER

Clean and re-oil foam element at three month intervalsor

every 25 hours, whichever occurs first.

NOTE: Service air cleaner more often under dusty cond i ti o ns .

1. Removescrew.

2. Removeair cleanercarefullyto preventdirt from entering carburetor.

3. Take air cleaner apart and clean.

a. WASH foam element in a liquid detergentand water

to remove dirt.

b. Wrap foam in cloth and squeezedry.

c. Saturate foam with engine oil. Squeezeto remove

ffi

partsandfastento carburetorsecurelywith

4. Reassemble

screw.

Yearly or every 100 hours, whicheveroccurs first, remove

paper cartridge. (Servicemore often if necessary.)Clean

by tapping gently on flat surface. lf very dirty, replace

cartridge,or wash in a low or non-sudsingdetergent and

warm water solution. Rinsethoroughly with llowing water

from i nsi de out unti l w ater i s cl ear. C artri dgem ust be air

dri ed thoroughl ybeforeusi ng.

CAUTION: Petroleumsolventsare not to be used to clean

cartridge. They may cause deteriorationof the cartridge.

D O N OT OIL C A R TR ID GE .D O N OT U S E P RESSURI ZED

A IR .

CLEAN COOLING SYSTEII - Grass, chaff or dirt may

the air cooling system,

@d

especiallyafter prolongedservicecutting dry grass.Yearly

or every 100 hours, whichever occurs first, remove the

blower housing and clean the areas shown -to avoid overspeeding, overheating and engine damage. Clean more

often if necessary.

CL EAN OUT

CHAF F AN D

DIRT

DANGER: Periodically clean muffler area to remove all

gr as s ,dir t and co mb u s ti b l ed e b ri s .

SPARK PLUG - Clean and reset gap at .030" every 100

hours of operation.

.0 3 0 " ( .7 6m m )

F EEL ERGAUGE

CA UT I O N: Do n o t b l a s t c l e a n s p a rk p l u g . S park pl ug

s hould be c lea n e d b y s c ra p i n g o r w i re b rushi ng and

washing with a commercial solvent.

FINAL ADJUSTMENT

Place governor speed control lever in "FAST" position.

Turn needlevalvein until engine misses(clockwise- lean

mixture) then turn it out past smooth operating point until

engi neruns unevenl y(ri ch mi xture).N ow t ur n needlevalve

to the mi dpoi nt betw eenri ch and l ean so t he engine r uns

smoothly. Next, adiust idle RPM. Rotate throttle countercl ockw i se and hol d agai nst stop. Adjust idle speed

adj usti ngscrew to obtai n 1750 R P M. Releaset hr ot t le engi neshoul d accel eratew i thout hesi tat ionor sput t er ing.

lf engine does not accelerate properly, the carburetor

shoul d be re-adj usted,usual l yto a sl i gh t ly r icher m ixt ur e.

CONTROL ADJUSTMENTS:

Proper choke and speed control operation is dependent

upon proper adjustmentof remotecontrolson the powered

equi pment.

TO C H E C K OP E R A TIONOF C H OK E CO NTRO LS:

Removeair cleaner.Move remotecontrol leverto "CHOKE"

or " S TA R T" posi ti on. C hoke shoul d b e f ully closed as

show n. R epl aceai r cl eaner.

S par k ingc an occ u r i f w i re te rmi n a ld o e s n o t fi t.fi rml yon

spa+t<ptusi or if stop switetr+ib+ates agai+st spark plug.

Reform terminal or repair switch if necessary.

REMOVECOMBUSTION DEPOSITSevery 100-300hours

of oper at ion. R e mo v e c y l i n d e r h e a d a n d c yl i nder head

s hield. S c r ape a n d w i re b ru s h th e c o mb u s tiondeposi ts

from c y linder , c y l i n d e r h e a d , to p o f p i s to n a nd around

valves.Use a soft brush to removedeposits.Re-assemble

gas k et , c y linde r h e a d a n d c y l i n d e r h e a d shi el d. Turn

screws down finger tight with the three longer screws

a r ound t he ex ha u s tv a l v e ,i f s o e q u i p p e d .T o rq uecyl i nder

head screws in a staggeredsequenceto 140 inch pounds

(15. 82Nm ) .

C H OK E LIN K

To Adjust:

P l aceremotecontrol l everon equi pmentin FAST posit ion.

C hokeoperati ngl i nk " A " shoul d be j ustto uchingbellcr ank

l everat " 8." S ee i l l ustrati on.

S P A RK A RRE S T E RE O U IPP EDM U F F L E R - l f engi ne

e n assembl Y ,

remove every 50 hours for cleaning and inspection.

R eplac eif dam a g e d .

ADJUSTMENTS

CARBURETORADJUSTMENTS

Minor carburetor adjustment may be required to compens at elor dif fe re n c e si n fu e l , te m p e ra tu r e,al ti tude or

load.

TO A DJ US T CA R BU R E T O Rw is e unt il it jus t c l o s e s .

T u rn n e e d l eval vecl ock-

CA UT I O N: V alv em a y b e d a ma g e db y tu rn i n g i t i n too far'

Now open need l ev a l v e 1 7 2tu rn s c o u n te rc l ockw i se.Thi s

init ial adjus t m e n tw i l l p e rm i t th e e n g i n e to b e startedand

w ar m ed up pr io r to fi n a l a d j u s tm e n t.

S P E E DC ON TR OLA D JU S TME N T

The acceptabl eoperati ngspeedrangei s 1 800t o3600RPM .

l dl e speed i s 1750 R P M. The manufactur erof t he equip-

ment on whic h th e e n g i n e i s u s e d , s p e ci fi es the top

gov er ned no l o a d s p e e d a t w h i c h th e e n gi ne may be

oper at ed.DO N O T EX C E EDth i s s p e e d .

exceed85%of this rating. Engine power will decrease3%%

for each 1,000feet (304.8m) above sea level and 1o/otor

each 10o above 600 F (16" C ).

ln some areas,local law reqtliresthe use of a resistorspark

pl ug so as to suppressi gni ti on si gnal s.lf an engine was

ori gi nal l yequi ppedw i th ai resi storspark plug, be sur e t o

use the same type of sparf plug for replacement.

TUNE.UP SPECIFICATIONS

Robert

S park P l ug Type

C hl mpi on

Autolite

Bosch

S hort P l ug

235

WSgE

i C J-8

Long P l ug

J-8

295

ResistorShort Plug 7 RCJ-8

245

WSRgE

R esi storLong P l ug ,

R J-8

306

S park P l ug Gap . . .. | . .. .

. . 030" ( . 76 m m )

fgni ti on P oi nt Gap ..r.....

. . 02O "( . 51 m m )

fntakeV al veC l earance ...... .005" -.O O 7"( . 13- . 18 m m )

E xhaustV al veC l earance. . . . . .009"- .011" ( . 23- . 28 m m )

WARNING: For eleitrical safetyalways removecable from

negative (-) side of the battery before attempting any

repairs or maintenance.

S T A NDA RDS P EE DC ON T R OLAD J U ST ME N T

S peed adjus t in gth u m b n u t i s l o c a te d o n top of engi ne.

T o inc r eas es pe e dtu rn th u m b n u t c l o c k w i s e.

S T A N D A R D T U R N T HUM B SCREWCL OCKWISE

GOVERNOR

T O INCREASESPEED

RE M O T ES P E EDC ON T R OL

Controls on powered equipmentshould move speed lever

in direction illustratedto increasespeed. Remotecontrols

m ay be c onnec te dto e n g i n ea t p o i n tsi n d i c a te d.W i retravel

is shown by arrows.

SPEED

REM OT E

12 VOLT

BATTERY

MA NUA L S P E E DC O N T R OL

M ov e k nob as s h o w n to c h a n g e e n g i n e s p e e d.

MANUAL

FR1CT;ON

G O V E R N OR

PUL L KNOB UP T O

INCREASESPEED

rouo[ro

____:l\ / ,

oa(xrc !ao.

"rxr..

IITUL TED IOLETOID

S TOR A GEIN S TR U C TIO NS

E ngi nesto be stored over 30 days shou ld be com plet ely

drai ned of fuel to prevent gum deposit s f or m ing on

essenti alcarburetorparts,f uel f i l ter and t ank.

The use ol a f uel addi ti ve,such as S TA -BlL,or an equival ent, w i l l mi ni mi ze the formati on of fuel gum deposit s

duri ng storage. S uch an addi ti ve may b e added t o t he

gasol i nei n the fuel tank of the engi ne,or t o t he gasoline

i n a storagecontai ner.

a. A l l f uel shoul dbe removedf rom the tank.Runt he engine

unti l i t stoos from l ack of f uel . The sm all am ount of f uel

that remai nsi n the sumo ol the tank should be r em oved

by absorbi ngi t w i th a cl ean,dry cl oth .

b. W hi l e engi ne i s sti l l w arm, drai n oi l f r om cr ankcase.

R efi l lw i th fresh oi l .

c. R emovespark pl ug, pour one ounce (29. 6cc) of engine

oi l i nto cyl i nder and crank sl ow l y t o dist r ibut e oil.

R epl acespark pl ug

G E NE R A LIN FOR M AT I O N

T his engine is a s i n g l e -c y l i n d e r,L -h e a d ,a i r-c ool edtype.

MODEL SERIES100200to 100299

B or e . .

. .. 2 -1 /2" (63.5mm)

S t r ok e

..2 -1 /8 " (53.98mm)

Dis plac em ent. ....

1 0 .4 3c u . i n . (170.9cc)

Horsepower

4.0 max. @ 3600 RpM

Tor que ( F t . Lbs .)

. 5 .9 3 m a x . @ 3050 R P M

MoDELSER|ES

l-99ry ro :t312ee

B or e. .

S t r ok e

Dis plac em ent . ....

H or se p o we r

Torque(Ft.Lbs.)

.2 -9 /1 6 ,,(65.09mm)

.2 -7 /1 6 " (61.91mm)

1 2 .5 7 c u .i n.(206.0cc)

...... $@nax. p io o on e M

. 155 max.E aOOO

neU

The horsepowerrating listed is establishedin accordance

with the Societyof AutomotiveEngineersTest Code - J607.

For practicaloperation,the horsepowerloadingshould not

d. C l ean di rt and chaff from cyl i nder,cylinder head f ins,

bl ow er housi ng,rotati ngscreenand muf f ler ar eas.

6

e. S tore i n a cl ean and dry area.

ER IGGS & S T R A T T ON ENGINESARE M ADE UNDER ONE OR MOR E O F T H E F O LLO W IN GPAT EN IS

2.9 9 9 .4 9 1

3 .1 94.224

3,276,439

3.526.146

3,625,071

28.960

2.9 9 9 ,5 6 2

3 .2 36,937

3,305223

9.572.218

3,650,354

3.831.26E

3114851

3 .2 42.7

41

3,457.804

3,572307

3 745.393

3 882,336

3.118 .4 3 3

3.252.449

3.465.740

3.625,492

3,738.345

3,90r .199

3 1 4 96 1 8

3,961724

3 968,854

3,971,353

3,991,152

D €S I G N

D - 213,475D - 215,7690 -2 2 4 . 1 7 00 -2 4 7 . 1 7 7

PAT

E N TSP E N D I N G

O T H ER