Download Jenn-Air CCG2523 User's Manual

Transcript

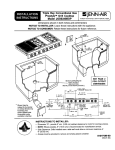

INSTALLATION MANUAL JGC7430 ANDcoorops JGC7536 SEALED GAS I F_"JENN-AIR JENN-AIR CCG2423AND CCG2523 [ 403WEST IMPORTANT: Dimensions Shownin BothInchesandCentimeters. IMPORTANT: Besuretheappliancebeinginstalled isequipped forthegastobesupplied. Refertoserialplateonunderside of burner boxforthis information. Donotattempt toconvert thisappliance forusewitha gasotherthanthetypespecified. 30" MODEL 76.2 ¢m __, _=_ = = '-_"-=--_ ,Is._,o_ _L'__._._ , 1%" _ _ '-f \\ _\ 27._=n t. ! i"/// Z /f"_YI/ \\ I _( 4.21 ¢rn 36" MODEL 329/_s"± V_e".-/S6' _ 82.71 cm Er_ . Clearance I s'_, I_ D 4._m _ _._A9"_ _ // _50.96 I I / _ii_ _ cm , I ,_'-_',,.,,;,=----,i._ll. ,,L_.I "=" \\IY _/ P0rAI IMPORTAN1 CUTOUT DIMENSIONS ARE CRITICAL canresultinserious injury orproperty damage. NOTICETO INSTALLER:LEAVETHESEINSTRUCTIONS WITHTHEAPPUANCE. NOTICETO CONSUMER:RETAINTHESEINSTRUCTIONS FORFUTUREREFERENCE. SPECIALWARNING:Improper installation, adjust ment, alteration, service, maintenance oruseofappliance 8101 P401-60 (o8-ol-oo) LOCATION OFYOURJENN-AIR APPUANCE PREPARATION OFCOUNTERTOP Locatethisappliance awayfromcombustible materials suchas window curtains andcombustible walldecorations, Minimumhorizontal clearance betweentheedgeoftheappliance and combustible construction extending fromthecooking surface to18_(45.72 cm)abovethecooking surface is Thecountertop cutoutmustbe prepared according to theillustration on page1 oftheseinstructions. 1" (2.54cm)atrear 4" (10.16cm)atsides (Dimensions applyto both30"and36"widemodels) * Jenn-AJr Over-the-Range microwave m,ens(model #M418andM438) havebeenlistedbyUL for use overGasandElectric Ranges.When properly installedata minimum heightof 66 inches(167.64cm)fromthe floortothetopofthemicrowave, theclearance tothecooking surfaceat i .............. , 1. ,,jr (2_4 ore) -.-_; -_ ___r/_ 2" I 11._' Min. (_.81crn] _`%',,. I -_ __. thecenter willbe 13-3/4itches(34.93cm). 1 " ---[ '18' IMPORTANT PREPARATION SUGGESTIONS ',45.72,)_ . 4...__ _ (tO.t6cm) FIGURE1 INSTALLING CABINETRY OVERYOUR JENN-AIR COOKTOP A= 30" (76.2 cm) minimum vertical clearance between cooking surfaceand construction abovethe appliance, This clearancemaybe reducedto notless than24inches(60.96cm)by protecting theunderside ofthecombustible material surfacewithnotlessthan1/4inch(.635 or metal cabinetab°vethe co°king! cm) insulatingmillboardcoveredwith ! sheetmetalnot lessthan0.0122inch ,I, CAUTION: Cutout dimensions arecritical. Dimensions mustbemeasured andcutaccurately towithin..+. 1/16"(.159cm)toensureproper fit. ___ B __ thick* J--[ B= 13" (33.02 crn) maximumdepth of cabinets installed abovecooking top. FIGURE2 Avoiduseof cabinetsabovecooktopfor storagespaceto eliminate associated potentialhazards suchasreaching overopenflames. I. damagefrom Chamfer chipping. all exposededges ofdscorativelaminateto prevent 2. Radiuscornersof cutoutandfileto insuresmoothedgesandprevent cemarcracking, 3. Roughedges,insidecornerswhich havenotbeenrounded andforced fitscancontribute tocracking of thecountertop laminate. 4. Countertop mustbesupported within3" (7.62cm)of cutoat. INSTALLATION OFAPPLIANCE CONNECTING APPLIANCE TOGASSUPPLY Theinstallation of thisappliance mustconform withlocalcodesor,inthe absenceof local codas,with the NationalFuel Gas Code,ANSI Z223.1-LatestEdition, or,inCanada,CAN/CGA-B149 Installation Code, latestEdition. A TRAINEDSERVICEMAN ORGASAPPLIANCE INSTALLER MUST MAKETHEGASSUPPLYCONNECTION.Leaktastingoltheappliance shall be conducted by the installeraccordingto the instructions given. This appliance,when installed,must be electrically groundedin accordance withlocalcodesor,intheabsence of localcodes, withthe National Electrical CodeANSI/NFPA No.70-latestEdition, or,inCanada, current CSAStandard C22.1Canadian Electrical Code,Part1. Allsupplypiping,exceptas noted,shouldusecommon National Pipe Thread(N.P.T.).Forall pipeconnections usean approved pipejoint compound rasistant totheactionofLP gas. 1. IF NOOTHERAPPLIANCE IS TO BEINSTALLEDBELOWTHIS COOKTOP Jointheappliance pressure regulator supplied withthisappliance tothe entrance threads oftheGasManifold. Theappliance regulator ismarked witha directional arrowindicating correct direction of gasflow.Ensure the appliance regulator is installedwiththearrowpointing towardthegas manifold entrance. Tightentheappliance regulator to20 to30 ft-lbsof torque. CAUTION: Warranty isvoidonJenn-Air equipment installed otherthanas I recommended bymanufacturer. Thisappliance is designed for usewiththe appliance gaspressure I pipe Never tighten tomore than35ft-lbs oftorque. Alwaysuseanapproved joint compound rasistant totheaction ofLPgas. regulator supplied withthisappliance. Itmustbeinstalled inthegasway aheadofthegasmanifold entrance. Itispreset forusewithnatural gasand mustbe converted, as described onpage6, forusewithLPgas.(See figures 10and11.) Installtheappliance initscounter cutout. Thisappliance isdesigned tooperateat a pressure of 5 inches ofwater column on natural gasor,if converted forusewithLPgas(propane or butane), 10inches watercolumn. Makesurethisappliance issupplied with andadjusted forthetypeofgasforwhichit isdesigned. Installa manualshut-off valvein anaccessible location in thegasline aheadoftheappliance pressure regulator andexternaltothis appliaoce for thepurpose ofturning onorshutting offgastotheappliance. IMPORTANT Makethegasconnection totheinletof theappliance pressure regulator with1/2"malepipethreads. Thisappliance wasadjusted atthefactory forusewithnatural gas.If,atany time,thisappliance istobe usedwitha different typeof gas,all ofthe conversion adjustments described onpages5 and7 mustbe madebya qualified service technician beforeattempting tooperate thecooktop on thatgas.Natural gasshould besupplied totheappliance pressure regulator ata linepressure between 6 and14inches ofwatercolumn or,ifconverted forIF'gas,between 11and14 inches, WARNING:If the line pressuresupplyingthe appliancepressure Makeadditional pipeconnections asnecessary aheadoftheshut-off valve tothegassupply source. Assureallpipejointconnections aregastight. IMPORTANT Applya non-corrosive leakdetection fluidtoalljointsandfittings inthe gasconnection between thesupplylineshut-off valveandtherange. Include gasfittings andjointsintherangeifconnections weredisturbed during installation. Checkforleaks!Bubbles appearing around fittings andconnections willindicate a leak.If a leakappears, turnoffsupply line gasshut-off valve,tighten connections, turnonthesupply linegasshut offvalve,andretestforleaks.Nevertestforgas leakswithan open flame. regulator exceeds 14"W.C.(anygas),an external regulator mustbeI installed inthegaslineaheadoftheappliance regulator toreduce theI pressure to nomorethan14"W.C. Failure to do thiscanresultin malfunction anddamage totheapplance. ILLUSTRATIVE GAS SUPPLY PIPING (NO OTHER APPLIANCE BELOW COOKTOP) Insurethisappliance isadjusted forthetypeofgassupplied toitandthat thegassupplypressure totheappliance regulator iswithintheproper pressure range. _ I • If thisisa 36"widemodel,orif it isa 30"widemodelandnoother applianceis to be installed in the cabinetry belowit, proceed as instructed underparagraph I. I (REAROFAPPLIANCE) BURNER BOX I I I_ MANIFOLD I_, _ ENTRANCE _ APPLIANCE WallOvenis to beanda installed in cabinetry proceed as • Electric If thisisa 30"widemodel Jenn-Alr Modelb Welow, 30XXX orW131 instructed underparagraph II. __ / I REGULATOR PRESSURE • Donotremove protective capfrompipestubatmanifold entrance until _ ALLPIPEJOINTS MANUAL SHUTOFF NOTE:In Canada, gasutilization codasprohibit useofstreetelbows. Use standardpipeelbowsandmakemodifications to theseinstructions as necessary. readytojoingassupply pipingtoappliance. VALVE .j.. _i 1/2 N.P.T. |-ELBOW 3 FIGURE3 TOGAS INLET 2. IF THISISA 30" WIDECOOKTOP ANDAJENN-NR,MODEL W30XXXORW131,ELECTRIC WALLOVENISTOBEINSTALLED BELOWTHISCOOKTOR NOTE1:Thisappliance anditsgasandelectrical supply sources mustbe installed before thewallovenisinstalled, Seeillustration (Electrical Wiring tnformahon - page4;figure6)forrecommended electrical supply source (ovations. NOTE2: Itmaybenecessary toextend gassupply piping forthisappliance intoadjacent under-counter cabinetry whenawallovenisinstalledbelow thisappliance. Joina 1/2"NPTpipeelbow(locally available) tothe malethreads at the manifold entrance.Whenjoined,causetheopenthreads of theelbowto facetowardtheleftsideoftheappliance. Installtheappliance inkscounter cutout. Joina 1/2"NPTpipenipple totheelbowusinga pipesection ofsufficient lengthtoextend,horizontally, beyond the leftsideof thewalloven.(To accomplish thisitmaybenecessary toextend thepipesection intoadjacent cabinetry.)Join additional1/2" NPT elbow(s)and pipe nipples,as necessary, to accomplish thefollowing: Jointhe outletof the appliancepressure regulatorsuppliedwiththis appliance tothemalethreadsof the newlyinstalledgassupplypiping. InstaU theappliance regulator ina location whichwillbeaccessible beside orbelowthewalloven.Insuretheappliance regulator is installed withits directional arrowpointing inthedirection ofgasflow.Tightentheappliance regulator to20to30ft-lbsoftorque. IMPORTANT ] NevertJghtan tomorethan35ft-lbsof torque. Always useanapproved I pipejointcompound resistant to theaction ofLPgas. ] Locate andjoina manualshut-off valveinanaccessible location inthegas lineaheadoftheapplianceregulator andexternal totheappliance forthe purpose ofturningonorshuttingoffgasto theappliance, Makeadditional pipeconnections asnecessaryahead oftheshut-off valve tothegassupplysource.Assureall pipejointconnections aregastight, IMPORTANT Applya non-corrosive leakdetection fluidtoalljointsandfittings inthe gasconnection between thesupply lineshut-offvalveandthe range, include gasfittings andjointsintherangeifconnections weredisturbed duringinstallation. Checkforleaks!Bubbles appearing aroundfittings andconnections willindicate a leak.If aleakappears, turnoffsupply line 'gasshut-off valve,tighten connections, turnonthesupplylinegasshut Ioffvalve,and retestforleaks.Nevertestforgasleakswithan open i flame. ILLUSTRATNE GASSUPPLY PIPING (WALL OVEN INSTALLED BELOW 30"COOKTOP) j 7 _ =_'_EReox (Rz,_oF_a I I _"¢" lr,.N.p.,. ] I t_="_ [ ALL _PEao_xrs __. _N_ L- _ .,%._ ,_FgCO_MA_ SZC'nU_ pROFILE OFCROSS WALL OVEN FIGURE4 Note,regarding Figure4, above: • Forconvenience in service a groundjointunion(notshown:locally available) should be included in thepipingillustrated infigure4, in location mostpracticed fortheinstallation. Generally, a practical iccatlor isinthe_binet belowthisappliance, nearthemanifold entrance, rathe thaninan adjoiningcabinet. • If the alternativepipingmethodshownin figure5 is selectedforthe installation, no groundjoint unionis required.(Theflexibleapplianc_ connector illustrated provides theunionjointsnecessary forservicing. I Whena dividing wallis presentanda flexibleconnector is usedit i= recommended for convenJanse, in bethinstallation and service, th_ flexibleconnector, itself,passthrough thedividing wall.Anyflexlbl connector usedwith thisappliance mustsatisfyall requirement statedinthetextaccompanying figureS. ALTERNATIVE PIPINGMETHODS TOCONNECT APPUANCE TOGASSUPPLY A TRAINEDSERVICEMAN ORGASAPPLIANCEINSTALLERMUST MAKETHEGASSUPPLY CONNECTION.LeakIasting oftheappliance shallbe conductedby the installeraccordingto the instruation8 given. Unlessprohibited bylocalcodesorordinances, a newA.G.A.- Certified, flexiblemetalapplianceconnector maybeusedto connectthisappliance to itsgassupply.Theconnector musthavean internaldiameternotless thannominal1/2" NPTpipeandbe nomorethan5 feetin length.A 1/2" NPTx 1/2" flare unionadapteris requiredat eachendof the flexible connector, ff a flexibleconnector is usedassurethat b_h theappliance pressureregulatorand manualshut-offvalvearejoinedsolidlyto other permanent hardpiping(eithergassupply ortheappliance manifold) soas tobe physically stationary. Seaillustrations below: CAU11ON: Donot_empt toattachtheflexible connector directly toan external pipethread.Connection requiresflareunionadapters. IMPORTANT Applya non-corrosive leakdetection fluidtoalljointsandfittingsinthe gasconnection betweenthesupplylineshut-offvalveandthe range. Include gasfittingsandjointsintherangeif connections weredisturbed duringinstallation. CheckforleakalBubblesappearingaroundfittings andconnectionswill indicatealeak. Ifaleakappears, tumoffsuppiyline gasshut-o_1 valve,tightenconnections, turnonthesupldylinegasshut offvalve,andretestfor leaks.Nevertestfor gasleakswith an open flame. PRESSURE TESTING ILLUSTRATIVE ALTERNATIVE PIPING Theappliance mustbe isolated #orethegassupplypipingsystemby thegassupplypipingsystemattest pressures equalto or lessthan1/2 PSIG (3.5kPa). I I t e.-..- .._ m ! R I jCalt I I NOAPPL.JANOE THISCOOKTOP MOUI/11_D BELOW _ _ Guut._ vz_ I WALL OVENMOUNTED IN CABINETRY BELOW THIS COOK_OP _-_NPTP_ _ II ] (_ _[!,ml supply pipe) FIGURE5 This appliance,as wall as its individualshut-offvalve, mustbe disconnected fromthegassupplypipingsystemduringany pressure testingofthesystem attestpressures inexcess of 1/2PSIG(3.5kPa). closingits individual manualshut-off valveduringanypressure testingof Whencheckingapplianceregulatorfunction,makecertainpressureof naturalgas supplyis between6 and14 inchesof watercolumnor,if converted forLPgas,between 11and14inches. ELECTRICAL WIRINGINFORMATION Thisappliance isequipped witha grounded typepowercord.Agrounded outletmustbeprovided. Itisrecommended, forconvenience, theoutletbe located (withreference tofigure6) asinAor8, below: A. If nootherappliance istobeinstalledbelowthisappliance: within _ther theshaded areaorthecrosshatched areashown infigure6. B. If a ModelW30XXXorW131electric ovenistobeinstalled below this appliance, either: 1. withintheorosshatched areaoffigure6,or, 2. withinanadjacent cabinet, I 91.44crn I cAeiNs'r BO'r'rou T FIGURE6 DimenalonA: W30XXX:5-1/2"(13.97cm) Wt31:4"(tO.16cm) If a wallovenisto beinstalledbelowthisapplianceandthecounterunit's outletis tobe mounted withinthecrosshatched areaof figure6: 1. The cabinet'slowerfrontpanel,belowthe oven,must be made removable foraccessto theoutlet. 2. A clearanceholefor the powercord'splug(1-1/4"(3.18cm)dia is recommended) mustbeprovided throughtheoven'sfloorsupportshelf and,if necessary, throughtheslatssupporting theshelf.Theclearance holeshould belocated asnearaspractical totherearoftheshelfand (iftheovenismodel W30XXX) asnearaspractical totheleftrearcomer. 3. WhenmodelW3OXXX ismounted belowthisappliance, andifthepower outletforthisappliance is tobelocated inthecrosshatched areaof figure6, it is recommended thepowercordbe routedthroughthe externalvertical clearance channel at the left rearof theoven.The channel's crosssection isapproximately 4.2" x 2.25"(10.7x 5.7cm), extending thefull heightoftheoven.(ModelW131provides a similar, butlarger, vetticalchannel nearthecenter ofthemainbackoftheoven.) Iftheoutletis tobe mounted ineithera leftorrightadjacent cabinet, a clearance hole,asdescribed above,mustbeprovided inthedividing wall betweenthecabinets. Figure4; page3, illustrates a typical(leftside) is convenient in thisleftwallorinthecorresponding rightwall. dividing wall.Theclearance hole(notshowninfigure4) canbelocatedas In planning anyinstallation, notethat thefreelengthofthisappliance's centeroftherearwalloftheburnerbox,whenviewedfromthefrontofthe powercord,extending unit,isapproximately 46" beyond (117 acm). point3-3/4"(9.53cm)leftofthenominal WARNING ELECTRICAL GROUNDING INSTRUCTIONS THIS APPLIANCEIS EQUIPPEDWITH A THREE PRONG GROUNDING PLUGFOR YOURPROTECTION AGAINSTSHOCK HAZARDAND SHOULDBE PLUGGEDDIRECTLYINTO A PROPERLYGROUNDEDRECEPTACLE.DO NOT CUT OR REMOVE THEGROUNDING PRONGFROMTHISPLUG. i WARNING I ]! THIS APPUANCE MUST BE DISCONNECTEDFROM ITS] ELECTRICAL SUPPLYAT THE WALL RECEPTACLE BEFORE] SERVICING THEAPPLIANCE. CONVERTING APPLIANCE FORUSE INSTALLATION OFLP ORIFICE SPUDS WITH LP GAS 4 BURNER MODEL (30" WIDE) WARNING Propane conversion isto beperformed bya JENN-AIR AUTHORIZED SERVICER(or otherqualifiedagency)in accordance withthe manufacturer's instructions and all codesandrequirements of the authority having jurisdiction. Failure tofollow instructions could resultin serious injury orproperty damage. Thequalified agency performing this workassumes responsibility forthisconversion. Electrical power andgasmust beturned offprior to conversion. WARNING I _ O (_) convert itforusewithLPgas(propane orbutane),eachofthefollowing modifications mustbeperformed: A. Replaceallorificespuds Step1: Remove thegratesandburner heads. Thisappliance w asadjusted at thefactory Step2: Remove aluminum venturi tube.forusewithnaturalgas.To _T _Z19-,O-O _ OFIGURE (_ 8 Step3: Trima smallpieceofmasking tapetothesizeofa dimeand a_fixitovertheendofa 5/16"nutdriver. Step4: Firmlypressthenutdriverovertheorificespud(figure7)and loosenspudby turningcounterclockwise. Carefully lift nut driveroutofburner throat.Odficespudshould becaptured in therecess.Repeatthisstepforeachburner. 5 BURNER MODEL (36"WIDE) _ / ,_--J.___\ f..l---._-__ /,--"'_--_ REMOVAL OF ORIRCE SPUD o FIGURE9 FIGURE7 Step6: Withthe masking tapestillin placeintherecessof thenut driver,pressanLPorificespudintotherecesssothat it is snugly captured. Step5: LocatetheLPorificespudpackettapedtotheundersideoftheStep7: Carefullyinstalltheorificespudintheappropriatebumerthroa byturningclockwise totighten. Tighten toa torqueof15to20 burnerbox.Thespuds havesmallnumbers stamped on the inch-lbs. side.Thisnumbercodestheorificediameter anditscorrect burnerlocation. Thefollowing illustrations showcorrect LP Step8: Replacecylindrical aluminum venturitubes.Replaceburner orificespudlocation for 4 burnerand5 burnermodels, headsandgrates.Indexeachgratetoitsburner pan. respectively. Step9: Savetheorifices removed fromtheappliance forfutureuse. B. Invertmp In appliancepresaureregulator (Seefigures10and11.) Withtheappliance installed, theapplience regulator shouldbelocated 3. Inserta slender,thin-blade screwdriver intotherecessatcenterof valvesternendengagebladewithslotin adjusting screw. asshownin figure3or4.Identifythetypeof appliance regulator onthe unitandfollowtheinstructions intheappropriate illustration. 4. Turncenterstemadjusting screwto setflamesize. ... clockwise toreduce ... counterclockwise toincrease 5. Replacecontrolknobwhenadjustment is completed. CONVERSION OF MAX1TROLAPPLIANCE PRESSURE REGULATOR APPLY DO_IWN_ RN_R PRESSURE AT DISC ED6ESTO CO_IVERTE ¢/# PiN ,j. J APPLY SI_'A_ fJqqPTORB_OVE RN CL_j RK_ICAP Proper adjustment willproduce a stable,steadyblueflameof minimum size.Thefinaladjustment shouldbecheckedbyturningknobfromhighto lOWsever_timeswithout extinguishing theflame. _w.,v Thisadjustment, atlowsetting, willautomaticaJly provide theproper flame _ sizeatmediumsetting. SIZE TO INCREASEFLAME CLOCk3NISE REDUCE FLAMESIZE _ FIGURE10 COUNTERCLOCk3NISE ..""'-1 [----_ ..WLVE CONVERSION PRESSURE OFHARPER-WYMAN REGULAToRAPPUANCE _ :_:, _u After Conversion StepsA, B and C havebeencornpleted, checkthe appearance ofeachburner's flameattheHiandLosettingsagainstfigure 13.If theflamesappeartoo (argeor toosmall,revieweachstepto make FIGURE12 sureit wascompleted correctly. _ Natural Setting _LP FIGURE11 FLAME APPEARANCE ATHIANDLO ,Setting (Seefigure12.) Thisappliance isshipped fromthefactory withlowandmedium flame C, LOW FlameAdjustment settings adjustedfor usewithnatura)gas.If furtheradjustment is necessary, orto readjust forusewithLP,proceed asfollows: =_" L, _ , o,,, ,,,,., (_ _ o, 1, Lightburner andsetcontrol knowforlowflame. 2. Removecontrol knobfromvalvestem. _,["/ "_ HI CAUTION: NEVERUSEAMETALBLADE TOPRYKNOBOFF.IF KNOBCANNOT BEEASILYREMOVED, TUCKTHEFOLDSOFA CLOTHDISHTOWEL UNDERTHEKNOBANDPULLTHETOWEL UPWARD WITHSTEADY, EVENPRESSURE. ow FIGURE13 TOCONVERT APPLIANCE FORUSEWITH NATURAL GAS WARNING Electrical power andgasmust beturned offprior to conversion. INSTALLATION OFNATURAL GAS ORIFICE SPUDS I 4 BURNER MODEL J If this appliancehasbeenconverted forusewithLPgas,eachofthe following modifications mustbe performed toconverttheunitbackto natural gas. A. Replaceallorificespuds Perform Steps1 through 4 onpage5. ForStep5:Locate thecolored brassnatural gasorifice spuds thatwere originally installed inthis beforeitsconversion foruse with LP gas.Observe thecolor oappliance feachofthespuds andnotethe correct burner (_ Complete Steps6spud through 9 onpage 5 tocomplete the installation of location foreach as shown infigures 14and15. natural gasmainspudsintheircorrectlocations. Savetheorifices removed fromtheappliance forfutureuse.Theywill be needed if thisappliance isagainconverted forusewithLPgas. B. Invertcapin applianceprassumregulator. (Seefigures10and11.) Withtheappliance installed theappliance regulator should belocated as shownin eitherfigure3 or figure4 (page3). Identify thetypeof applianceregulator and followthe instructions in the appropriate illustration. C. Adjustlowflameasinstructed on page6 itemC. AfterStepsA,BandChavebeencompleted, checktheappearance of eachburner'sflameat theHi andLo settingsagainstfigure13.If the flamesappeartoo largeor too small, makesure all stepswere completed correctly. _ _ (_ (_ (_ ,,RT _2_,,-,9_-.0 // FIGURE14 5 BURNER MODEL (36"WIDE) k _RT t_21W-993-_ FIGURE15 (_ BURNERIGNITIONANDAUTO-REIGNITION TOPGRATEREPLACEMENT Thisappliance is equipped forelectronic auto-raignition by meansof a sparkigniterlocated attherearofeachburner. Theburners aredesigned tolightatanyvaJve rotation thatadmitssufficient gesflowtosupport aflame andtoautomatically relightfollowing a lessofflameduetoa draftorother adversecondition.Thisfeatureis providedas a convenience andis not intendedasa safetyfeature. Thetopgrates onthiscooktop haveunderside projection lugsdesigned nestinmatching depressions inthesplllnver trays.Duringgratepleceme elwayspesition gratestomakethisengagement. Correct indexing ofgrat_ aboveburnerportswill preserve thegrates'appearance and helpassut longlife. CAUTION:Neverusea metalbladeto pryoff a controlknob.If a knob cannotbe easilyremovedtuckthefoldsof a clothdishtowelunderand aroundtheknobandpullthetowelupwardwithsteadyevenpressure. CAUTION: Nevercovercontrolknobsor surrounding controlsurfacewith utensils, towels,orotherobjects.Neverobstruct freeairpassagepastthe controlknobs.Theknobopeningshavebeensizedtoproperlycontrolair entrytothe interior oftheappliance duringoperation. This appliancehas no air shutters.Primaryair adjustments are unnecessary. Theburners aredesigned toprovide optimum aer_ionforall gaseswithoutair shutters. Whenoperatingproperty, burnersshould produce clearly defined,evenblueflames.If theflameshaveyellow tipsor arehazyandotherwise appeartohaveinsufficient air,obtaintheservices ofa qualified service technician. Specified inputr=esare asshowninfigures16and17,below. REQUIREDADJUSTMENTSATTIME OF INSTALLATION 4 BURNER MODEL E_ _ absenceof lecelcodes,withthe latesteditionof theNationalFuelGas CodeANSI Z223.1USA or currentCAN/CGA-Bf49INSTALLATION Theinstail=ienofthisappliancemustconform CODE. withIo_ codes,orinthe FIGURE16 BURNER LOCATION RightFront RightRear LeftFront LeftRear INPUTRATES- NATURAL GAS(BTU/HR) Hi Lo 12,000 1,500 9,100 1,050 6,500 830 10,500 1,500 5BURNER MODEL FIGURE17 BURNER LOCATION RightFront RightRear Center LeftFront LeftRear INPUTRATES. NATURAL GAS(BTU/I'IR) Hi Lo 12,000 9,100 6,500 9,100 10,500 1,5_ 1,050 830 1,050 1,500 f0 [] Thisappliance wasmanufactured forusewithNaturalGas.If LPgas isthefuelofchoice, followtheconversion toLPprocedure foundinthe installation instructions. [] Testallexternal connections forgasleaks.Nevertestforgasleaks withanopenflame. [] Testallelectrical connections.