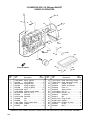

Download 191718 1365915167 8 1043 1 1-IN CLUDESIT EMS 3-16

Transcript