Download Yamaha TTR90(M) Service manual

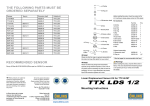

Transcript