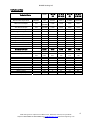

Download Procon 45 Technical data

Transcript