Download RCAVICTOR 721TS Specifications

Transcript

^

rcaVictor

TELEVISION RECEIVER

MODEL

Chassis No.

KCS

721TS

26-1 (60 cycles) KCS 26-2 (50 cycles)

Mfr. No. 274

,

Service

—

Data

1947 No. T4

RADIO CORPORATION OF AMERICA

RCA VICTOR DIVISION

CAMDEN, N.)., U.S.A.

Model 7 2 ITS

Walnut or Mahogany

GENERAL DESCRIPTION

Model 721TS

is

a twenty-one tube, direct-viewing, table-model

Television Receiver having a 10" picture tube (kinescope). The

receiver

is

complete

seven front-panel

in

one

controls.

unit

and

Features

is

operated by the use

of

the

receiver

ELECTRICAL

PICTURE

r

of

include:

Full

thirteen

picture

channel coverage; f-m sound system: improved

two stages of video amplification; A-F-C

brilliance:

improved sync ampliand separator; and reduced-hazard high-voltage supply.

horizontal hold, stabilized vertical hold;

fier

AND MECHANICAL SPECIFICATIONS

ELECTRICAL

72 ITS

AND MECHANICAL SPECIFICATIONS

PICTURE INTERMEDIATE FREQUENCIES

(Continued)

Horizontal (Picture Horizontal Hold)

-i

.Dual Control Knobs

'

Picture

Carrier

Accompanying

Frequency

25.75

Sound

21.25

Traps

Mc

Mc

Vertical

Picture

(Picture

Vertical

Hold)

J

(Contrast)

..Dual Control

Knobs

Brightness (Brilliance)

SOUND INTERMEDIATE FREQUENCIES

NON-OPERATING CONTROLS

Sound Carrier Frequency

21.25

Sound Discriminator Band Width (between peaks)

Mc

350 Kc

VIDEO RESPONSE

To

3

Mc

Horizontal

Centering

rear

Width

SWEEP DEFLECTION

Magnetic

Horizontal Linearity

Vertical

HORIZONTAL SCANNING FREQUENCY

15,750

cps

and

i-f

ad-

chassis

adjustment

rear chassis screwdriver adjustment

Height

525 line

r-f

rear chassis adjustment

Vertical Centering

Magnetic

Interlaced,

including

justments)

FOCUS

SCANNING

(not

J

rear

top

rear

Linearity

chassis

adjustment

screwdriver adjustment

chassis

chassis

adjustment

rear chassis screwdriver adjustment

Horizontal Drive

Horizontal Frequency (Fine)

rear chassis screwdriver

adjustment

VERTICAL SCANNING FREQUENCY

60 cps

FRAME FREQUENCY

30 cps

(Picture

Repetition Rate)

Horizontal Oscillator Frequency (coarse)

bottom chassis

screwdriver adjustment

Horizontal Locking Range. ...rear chassis screwdriver adjustment

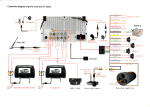

OPERATING CONTROLS

Station Selector

Fine Tuning

(front

panel)

Focus

)

L

^^

i

.

i

Ion

J

Sound Volume and On-Off

S'witch

Single

Control

Knob

rear

Focus Coil

t^

t^

i_

Control Knobs

Dual

top chassis

Trup Magnet

top

chassis

chassis

wing

adjustment

screw^ adjustment

thumb screw adjustment

wing nut adjustment

top chassis

Deflection Coil

HIGH VOLTAGE WARNING

OPERATION OF THIS RECEIVER OUTSIDE THE CABINET OR WITH THE

COVERS REMOVED INVOLVES A SHOCK HAZARD FROM THE RECEIVER

POWER SUPPLIES. WORK ON THE RECEIVER SHOULD NOT BE ATTEMPTED

BY ANYONE WHO IS NOT THOROUGHLY FAMILIAR WITH THE PRECAUTIONS NECESSARY WHEN WORKING ON HIGH- VOLTAGE EQUIPMENT. DO

NOT OPERATE THE RECEIVER WITH THE HIGH-VOLTAGE COMPARTMENT

SHIELD REMOVED.

KINESCOPE HANDLING PRECAUTIONS

DO NOT OPEN THE KINESCOPE SHIPPING CARTON, INSTALL, REMOVE, OR

HANDLE THE KINESCOPE IN ANY MANNER UNLESS SHATTERPROOF

GOGGLES AND HEAVY GLOVES ARE WORN. PEOPLE NOT SO EQUIPPED

SHOULD BE KEPT AWAY WHILE HANDLING KINESCOPES. KEEP THE

KINESCOPE AWAY FROM THE BODY WHILE HANDLING.

lo its large surface area, is subjected

considerable air pressure. For these reasons, kinescopes must be handled with more care

The kinescope bulb encloses a high vacuum and, due

to

than ordinary receiving tubes.

The large end

ol the

kinescope bulb

struck, scratched, or subjected to

—particularly

the rim of the viewing surface

more than moderate pressure

at

any

time.

—must not be

In installation,

if

smoothly through the deflecting yoke, investigate and remove

force the tube. Refer to the Receiver Installation section for

trouble.

Do

not

the cause of the

detailed instructions on kinescope installation. All RCA kinescopes are shipped in special carthe tube sticks or fails to slip

tons

and should be

left

in the cartons until

carton for possible future use.

ready

for installation in the

receiver.

Keep

the

J

RECEIVER OPERATING INSTRUCTIONS

The following adjustments are necessary when turning the

receiver on ior the first time:

Turn

1.

volume

"ON"

receiver

the

control

the

SOUND

desired

channel.

advance

and

Adjust the

8.

Set

3.

Turn the PICTURE

the

to

hold control

Adjust the PICTURE control

9.

for suitable picture contrast.

necessary

some time, it may be

FINE TUNING control slightly for

improved sound fidelity.

readjust the

to

counter-

fully

one

Turn

4.

BRIGHT-

the

.^^=^

control fully coun-

then clock-

terclockwise,

a

wise

until

just

appears

station

may

it

repeat

and

the

\==J^

Turn the PICTURE

control

approximately

Adjust

6.

TUNING

sound

and

fidelity

control

for

positions

the

6

suit-

CAL

hold

control

should not

it

repeat

to

the

of

generally

is

13.

VERTI-

Adjust the

is

the

if

controls

have not been changed.

any adjustment is

If

necessary, step number

able volume.

7.

set

adjustments

the

control for best

SOUND

the

be necessary

FINE

the

6

idle period,

clockwise.

three-fourths

to

number

turned on again after an

screen.

5.

be necessary

steps

When

12.

on

another,

to

9.

glow

faint

from

In switching

11.

clockwise.

NESS

the picture

until

After the receiver has been on for

10.

STATION SELECTOR

2.

control

HORIZONTAL

appears on the screen.

approximately mid-position.

to

the

72 ITS

the

the positions of

If

PICTURE

the pattern stops vertical

essary

I

BRIGHTNESS

IN SOME RECEIVERS "BRIGHTNESS" IS

movement.

FINE TUNING

ON-OFF SOUND'

STATION SELECTOR

THE OUTER KNOB AND 'PICTURE' THE INNER

Fig/iie

I

— Receiver

have been

controls

changed,

until

sufficient.

may

it

be necsteps

to

repeat

1

through

number

9.

Operating Controls

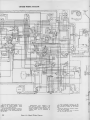

CIRCUIT DESCRIPTION

provided

divider

new and

on the positive peaks

be described

will

briefly.

Fundamentally the horizontal

oscillator

plied to the control tube grid.

a bias

plies

A

If

and phase

to the oscillator to

tube

control

cut

on the slope

off

except

the grid

of

the two voltages are not in

relations, the control tube ap-

bring

it

into sync.

and

when

the

is

sync pulse

waveform as shown

applied

keep the

to

sufficient

is

high

is

Figure 2-A.

in

slides

the slope, the plate conduction time decreases as

down

shown

in

up the slope, then the plate

conduction time increases as shown in Figure 2-C. When the

and CI67 in its

control tube conducts capacitors C16I

Figure

2-B.

cathode

the

oscillator

and pulling

The

charge to a d-c potential proportional to the

circuit

effect

of

adjustments

effect

fine

thus

grid

into

it

LI2I

is

adjustments

is

is

of the

and hence

is

is

a

The horizontal drive

and

is

of

coefficients

oscillator

the

or

and

characteristics

control

and

circuits

case

in

should be replaced only by exact replacement.

a special

pro-

sawtooth voltage on the VI 09

of

control for picture linearity.

components

Several

have special

waveform.

part of a capacity voltage divider

vided to vary the amount

grid

waveform

lube so that conduction occurs only

resistor

capable

of

stability

of

1%

or

of

RI73

better.

a high negative coefficient resistor to compensate for

warm up drift. It is mounted within about Vi inch of the

power transformer and chassis for good heat transfer. The

R191

is

dress of this component should not be disturbed.

Strains or excessive heat should not be applied to the leads or

bodies

and

of the resistors

control

changes

page

circuits.

of resistance

associated with the horizontal oscillator

Such conditions may cause excessive

See "Critical Lead Dress" on

with age.

18.

applied as a bias

oscillator

frequency

tuned with a slug to

frequency.

in

C136C

RI56

frequency.

effect

is

VIOBA GRID CUTOFF

coarse

provided

the

is

by varying

to

horizontal

provided on the front panel to permit a

variation of frequency

CI 36 A

the

C136B

the amplitude of the

to set

phase with the sync pulses.

oscillator

in

hold control

shifting

is

control

is

of the control

the various controls associated with the circuit

are as follows.

age.

This potential

conduction time.

plate

to

the pulse slides

If

on the grid

failure,

changes phase so that the pulse

the oscillator

is

waveform and ap-

portion of the bias from the blocking oscillator

to the grid of the control tube

If

The incoming sync

circuit.

superimposed on the horizontal

the proper freguency

a free running block-

oscillator is

and discharge

ing oscillator

c

and

The general design features of the 721TS television receiver

are conventional. However, the a-f-c horizontal hold circuit is

5%

SYNC TOO EARLY

SYNC TOO LATE

NORMAL CONTROL

SHADED AREA IS PORTION OF W/AVEFORM EFFECTIVE IN PRODUCING

OSCILLATOR CONTROL VOLTAGE,

the control tube plate volt-

a variable portion

of

a

capacity

voltage

Figure 2

—Horizontal Control Waveforms

INSTALLATION INSTRUCTIONS

721TS

The Model 72 ITS television receiver is shipped complete in

one carton except for the 10BP4 kinescope. The kinescope is

shipped in a special carton and should not be unpacked until

ready ior installation.

—

are worn. People not so equipped should be kept away while

handling the kinescope. Keep the kinescope away from the

body while handling. The shipping carton should be kept for

use in case of future moves.

UNPACKING To unpack

the receiver, tear open the carton

pick the receiver up from under the bottom of the cabinet and lift it out of the shipping carton.

INSTALLATION OF KINESCOPE— The kinescope second anode

flaps,

contact is a recessed metal well in the side of the bulb. The

tube must be installed so that this contact is approximately on

grill off the back of the cabinet.

Remove the

panel from the cabinet as indicated in Figure 3.

lop.

The final orientation of the tube will be determined by

the position of the ion trap flags.

Looking at the kinescope

Take the metal

front

gun structure, it will be observed that the second cylinder from

the base inside the glass neck is provided with two small

metal flags, as shown in Figure 5. The kinescope must be

installed so that when looking down on the chassis, the two

flags will be seen as shown in Figure 4.

TO REMOVE CABINET FRONT

TAKE OUT SCREWS UNDER CABINET

LOOSEN WING NUTS INSIDE CABINET

TURN PLATES AND REMOVE FRONT

T

"S'3^

FLAGS

Figure 5

—Ion Trap

Flags

the neck of the kinescope through the

deflection and

focus coils as shown in Figure 6 until the

base of the tube

protrudes approximately two inches beyond

the focus coil.

If the tube sticks, or fails to

slip into place

Insert

smoothly, investiDo not force the

gate and remove the cause of the trouble.

tube.

Figure 3

Cabinet, Front

View

The operating control knobs are packed in a paper bag which

is tied to the focus coil mounting bracket inside the cabinet.

3-

Remove the bag.

Remove the protective cardboard shield from the 5U4G rectifier.

Make sure all tubes are in place and are firmly seated

in their sockets.

Loosen the two kinescope cushion adjustment wing screws and

Loosen the

slide the cushion toward the rear of the chassis.

deflection yoke adjustment, slide the yoke toward the rear

See Figure 4 for the location of

of the chassis and tighten.

the cushion

and yoke adjustments.

Figure 6

—Kinescope

Insertion

Early production receivers employed an

magnet

/

FLAGS

Ml

justment thumbscrews sufficiently to hold

free enough to permit adjustment.

Coil Adjustments

not in line, loosen the three focus coil adjustment wingnuts and raise, lower, or rotate the coil until alignment is obtained. Tighten the wingnuts with the coil in this

is

position.

Loosen the two lower kinescope face centering slides, and set

them at approximately mid position. See Figure 3 for location of the slides and their adjustment screws.

Loosen the

ion trap magnet adjustment thumb screws.

KINESCOPE HANDLING PRECAUTION—Do

not

open the

kine-

scope shipping carton, install, remove, or handle the kinescope

any manner, unless shatterproof goggles and heavy gloves

in

in position

but

still

the

PM

of the

From the front of the cabinet, look through the deflection yoke

and check the alignment of the focus coil with the yoke. If

the focus coil

it

type is employed, slip the assembly over the neck

kinescope with the large magnet towards the base of

the tube and with the arrow on the assembly up as shown in

Figure 4. The front magnet is movable on the assembly. The

If

— Yoke and Focus

type of ion trap

the neck of the kinescope with the coils down and the large

coil towards the base of the tube.

Tighten the magnet ad-

FRONT MACNET GAP

ON THIS SIDE AND EVEN

WITH REAR MAGNET GA»

Figure 4

EM

model 630TS receiver. Late production

receivers employed a PM type magnet as shown in Figure 4.

If an EM type of magnet is applied, slip the

assembly over

like that in the

correct position of the front magnet

side (from the rear of the cabinet)

the rear magnet.

is with the gap on the left

and even with the gap of

Connect the kinescope socket to the tube base.

Insert the

kinescope until the face of the tube protrudes approximately

one-eighth of an inch outside the front of the cabinet. Adjust

the four centering slides until the face of the kinescope is in

the center of the cabinet opening.

Tighten the four slides

securely.

Wipe the kinescope screen surface and front panel

safety glass clean of all dust and finger marks with a soft cloth

moistened with the Drackett Co.'s "Windex" or similar cleaning

agent. Install the cabinet front panel by reversal of the removing process as shown in Figure 3.

Install the control knobs

on the proper control shafts.

INSTALLATION INSTRUCTIONS

the kinescope as lar forward as possible. Slide the

kinescope cushion firmly up against the flare of the tube and

Slide the deflection

tighten the adjustment wing screws.

yoke as far forward as possible. Connect the high voltage

lead to the kinescope second anode socket.

Slip

C

The antenna and power connections should now be made.

Turn the power switch

to

control fully clockwise,

and

the "on" position, the brightness

picture control counter-clockwise.

MAGNET ADJUSTMENT—The ion trap rear magnet

poles should be placed over the ion trap flags as shown in

Figure 4.

Starting from this position adjust the magnet by

ION TRAP

moving

lorward or backward at the same time rotating

it

around the neck of the kinescope for the brightest

raster on the screen.

Reduce the brightness control setting

until the raster is slightly above average brilliance.

Adjust

the focus control (R129 on the chassis rear apron) until the

it

slightly

line structure of the raster is clearly visible.

magnet

trap

for

maximum

raster brilliance.

Readjust the ion

final touches

The

adjustment should be made with the brightness control

position with which good line focus can be

maintained.

on

this

maximum

at the

FOCUS COIL ADJUSTMENTS—Turn

and R166

to

rear apron

mid

the centering controls R152

for location of these

See Figure 7

position.

controls.

shadowed, it indicates that the

neck of the tube. Loosen the

electron beam is

focus coil adjustment wing nuts and rotate the coil about its

vertical and horizontal axes until the entire raster is visible,

approximately centered and with no shadowed corners. Tighten

the focus coil adjustment wing nuts with the coil in this

If

a corner

of

the raster

721TS

(Continued)

should show from

3'/2

to 4'/2

bars sloping

downward

to the

right.

the receiver passes the above checks and the picture is

normal and stable, the horizontal oscillator is properly aligned.

Skip "Alignment of Horizontal Oscillator" and proceed with

"Focus" adjustment.

If

ALIGNMENT OF HORIZONTAL OSCILLATOR— If

in the

above

check the receiver failed to hold sync with the hold control

at the extreme counterclockwise position or failed to hold

sync at least 60 degrees of clockwise rotation of the control

from the pull in point, it will be necessary to make the following adjustments.

—

Horizontal Frequency Adiustment Turn the horizontal hold

control to the extreme clockwise position. Tune in a television

station and adjust the rear apron horizontal frequency trimmer C136C until the picture is out of sync and shows 3Vi to

41/2 bars sloping downward to the right.

If the trimmer has

insufficient range, set the trimmer to mid-position (1 turn out

from max. capacity) and adjust the L121 horizontal frequency

adjustment until this condition is obtained. See figure 22 for

the location of L121.

—

Horizontal Locking Range Adjustment Set the horizontal

hold control to the full counter-clockwise position. Momentarily

remove the signal by switching off channel and, then back.

Slowly turn the horizontal hold control clockwise and note

the least number of diagonal bars obtained just before the

picture pulls into sync.

is

striking the

position.

c

WIDTH

a

CONTROL

more than

bars are present just before the picture pulls

range trimmer C136A

slightly clockwise.

If less than 3'/2 bars are present, adjust

C136A slightly counterclockwise. Turn the horizontal hold

control counterclockwise, momentarily remove the signal and

recheck the number of bars present at the pull in point. Repeat this procedure until 3V2 to 4'.^ bars are present.

If

4'/2

into sync, adjust the horizontal locking

Repeat the adjustments under "Horizontal Frequency Adjustment" and "Horizontal Locking Range Adjustment" until the

When the horiconditions specified under each are fulfilled.

zontal hold operates as outlined under "Check of Horizontal

Oscillator Alignment" the oscillator is properly adjusted.

HEIGHT AND VERTICAL LINEARITY ADJUSTMENTS— Adjust

HOR.

LINEARITY

RI48

VERT.

LINEARITY

a.

FOCUS

q;^

HOR.

(OX

(CIX

*il>/VERT.

^CjpHOR.

HOR. DRIVE

CENTERING CENTERING

Figure 7

— Rear

Ct36A

LOCKING^

CI36C

«

e

HOR.FREa.''

Chassis Adjustments

the lines of the raster

are not horizontal or squared with the picture mask, rotate

the deflection yoke until this condition is obtained. Tighten

the yoke adjustment wing screw.

PICTURE ADJUSTMENTS— It

will now be necessary to obtain a

pattern picture in order to make further adjustments. See

steps 2 through 9. of the receiver operating instructions on

test

3.

Vary

the

horizontal

hold control to the extreme counter-clockwise

The picture should remain in horizontal sync. Momentarily remove the signal by switching off channel and

position.

Normally the picture will be out of sync. Turn

clockwise slowly. The number of diagonal bars

will be gradually reduced and when only 3'/2 to iVi bars

sloping downward to the left are obtained, the picture will pull

into sync upon slight additional clockwise rotation of the control.

Pull in should occur when the control is approximately

90 degrees from the extreme counterclockwise position.

The

picture should remain in sync for approximately 90 degrees

of additional clockwise rotation of the control.

At the extreme

clockwise position, the picture should be out of sync and

then back.

the control

c

to the maximum clockwise posithe horizontal drive trimmer C136B to yield the

width control LI 12

Adjust

best compromise between brightness and linearity.

the horizontal linearity control LI 13 for best linearity of the

Readjust the width control until the

right half of the picture.

Adjust horizontal centering to

picture just fills the mask.

align the picture with the mask.

FOCUS— Adjust

of the vertical

the focus control R129 for

of the test pattern.

maximum

definition

wedge

Check to see that all cushion, yoke, focus coil and ion trap

magnet thumb screws are light. Replace the cabinet back

Make sure that the back is on tight, otherwise it may

grille.

rattle

CHECK OF HORIZONTAL OSCILLATOR ALIGNMENT—Turn

AND HORIZONTAL LINEARITY ADJUSTMENTS

WIDTH. DRIVE

—Turn the

tion.

DEFLECTION YOKE ADJUSTMENT— If

page

the height control (R141 on chassis rear apron) until the picture

Adjust vertical linearity

fills the mask vertically (6% inches).

(R148 on rear apron), until the test pattern is symmetrical from

top to bottom. Adjustment of either control will require a readAdjust vertical centering to align the

justment of the other.

picture with the mask.

at

high volume.

R-F OSCILLATOR ADJUSTMENTS— With a crystal

calibrated test oscillator or heterodyne frequency meter, check

the proper

to see if the receiver r-f oscillator is adjusted to

frequency on all channels. If adjustments are required, these

should be made by the method outlined in the alignment procedure on page 10. The adjustments for channels 1 through 5

CHECK OF

and 7 through 12 are available from the front of the cabinet

by removing the station selector escutcheon as shown in Figure

Adjustments for channels 6 and 13 are under the chassis.

8.

available Television Stations, Observe the picture

proper interlacing and for the presence of

see the

interference or reflections. If these are encountered,

Tune

for

in all

detail,

section

for

on antennas on page

6.

INSTALLATION INSTRUCTIONS

72 ITS

(Continued)

The stock #226 antenna

is bi-directional on channels one

through six (44 to 88 Mc). When used on these channels, the

maximum signal is obtained when the antenna rods are broadside toward the transmitting antenna.

The stock #225 antenna with reflector is unidirectional on

channels one through six. When used on these channels, the

maximum signal is obtained when the antenna rods are broadside toward the transmitting antenna, with the antenna element between the reflector and the transmitting antenna.

When

Figure

—R-F

8

operated on channels seven through thirteen, (174 to

216 Mc), both types of antennas have side lobes. On these

channels, the maximum signal will be obtained when the

antenna is rotated approximately 35 degrees in either direction from its broadside position toward the transmitting an-

Oscillator Adjustments

tenna.

VIDEO PEAKING LINK

—A

provided to

permit changing the video response. This link is connected at

However, if transients are

the factory with the peaking in.

produced on high contrast pictures the peaking should be

taken out by removing the link on the terminal board under

the chassis near the VI 04 socket. See Figures 49 and 51 for

the connection

and

video peaking link

is

location of the link.

general, the stock #225 antenna should be

are encountered, if the signal strength is

the receiving location is noisy. If these conditions

countered, the stock #226 antenna will probably

In

flections

used if reweak, or if

are not en-

be

satisfac-

tory.

In

some

cases, the antenna should not be installed permanently

has been observed on

temporary transmission line can be

run between receiver and the antenna, allowing sufficient

slack to permit moving the antenna. Then, with a telephone

system connecting an observer at the receiver and an assistant

at the antenna, the antenna can be positioned to give the

most satisfactory results on the received signal. A shift of

direction or a few feet in antenna position may effect a treuntil the quality of the picture reception

ANTENNA TRAP—In some

a

series resonant trap across

the r-f amplifier grid circuit is provided to eliminate interference

stations on the image of channel 2, from interference

from

on channel 6 from a station on channel 10 or interference on

sets,

FM

channel 5 from a station on channel 7. In production, this

trap is adjusted to reject the channel 6-10' interference. However, in the field, it may be necessary to retouch the adjustments or to readjust the trap for channel 5-7 or FM image

a

television receiver.

mendous

A

difference in picture reception.

interference.

in the field, tune in the station on which

the interference is observed. Tune both cores of the trap for

minimum interference in the picture. See Figure 21 for the

location of the trap. Keep both cores approximately the same

by visual inspection. Then, turn one core V2 turn from the

original position and repeak the second for maximum rejecRepeat this process until the best rejection is obtained.

tion.

To adjust the trap

In severe cases of such interference,

reorient the antenna to eliminate this

it

may be

necessary

to

REFLECTIONS

—Multiple

images sometimes known as echoes

caused by the signal arriving at the antenna

by two or more routes. The second or subsequent image occurs when a signal arrives at the antenna after being reflected off a building, a hill or other object. In severe cases

of reflections, even the sound may be distorted.

In less severe

or ghosts, are

cases,

reflections

may

occur that are not noticeable as

flections but that will instead

cause a loss

re-

of definition in the

picture.

difficulty.

it may be possible to eliminate the reflections by rotating the antenna or by moving it

to a new location. In extreme cases, it may be impossible to

eliminate the reflection.

Depending upon the circumstances,

RECEIVER LOCATION—The owner should be advised

of

the importance of placing the receiver in the proper location

in the room.

The location

shjDuld

be chosen

— Away

from bright windows and so that no bright light

on the screen. {Some illumination in the

room is desirable, however.)

will fall directly

—To give easy access operation

—To permit convenient connection

—Convenient an electrical

—To allow adequate ventilation.

for

to

the

antenna.

outlet.

to

VENTILATION

and comfortable viewing.

—

INTERFERENCE Auto ignition, street cars, electrical maand diathermy apparatus may cause interference

which spoils the picture. Whenever possible, the antenna

chinery

CAUTION—The

receiver is provided with

adequate ventilation holes in the bottom and back of the

cabinet.

Care should be taken not to allow these holes to

be covered or ventilation to be impeded in any way.

ANTENNAS—The

finest television receiver built

to

be only as good as the antenna design and

is

therefore important to use

and

to

use care in

its

a

correctly

may

be said

installation.

It

designed antenna,

installation.

RCA

Television Antennas, stock No. 225 and No. 226, are designed for reception on all thirteen television channels. These

antennas use the 300-ohm RCA "Bright Picture" television

transmission line. Installation personnel are cautioned not to

make any changes in the antenna or to substitute other types

of transmission line as such changes may result in unsatisfactory picture reproduction.

Under certain extremely unusual conditions, it may be possible

to rotate or position the antenna so that it receives the cleanest

picture over a reflected path. If such is the case, the antenna

should be so positioned. However, such a position may give

variable results as the nature of reflecting surfaces may vary

with weather conditions. Wet surfaces have been known to

have different reflecting characteristics than dry surfaces.

location should be removed as far as possible from highways,

hospitals, doctors' offices, and similar sources of interference.

In mounting the antenna, care must be taken to keep the

antenna rods at least Vi wave length (at least 6 feet) away

from other antennas, metal roofs, gutters, or other metal objects.

Short-wave radio transmitting and receiving equipment may

cause interference in the picture in the form of moving ripples.

In some instances it may be possible to eliminate the interference by the use of a trap in the antenna transmission line.

However, if the Interfering signal is on the same frequency as

the television station, a trap will provide no improvement.

WEAK

PICTURE

—When the

near the limit of the

the picture may be

speckled, having a "snow" effect, and may not hold steady on

the screen. This condition is due to lack of signal strength

from the transmitter.

installation is

area served by the transmitting

station,

3

SERVICE SUGGESTIONS

Some

C

troubles

possible

the

of

may

that

be

encountered,

no raster can

of

effect

be caused by the following:

(2)

No

adjustment

assembly) being wrong value or open. These components are

mounted

SMALL RASTER

high

tubes and

(8016)

Check

voltage.

circuits.

V109

the

If

VI 10

and

(6BG6-G)

horizontal-deflection

circuits

are operating, as evidenced by the correct waveform measured

on terminal 4

winding

Either the high-voltage

the 8016 tube

high-voltage

If

on T105)

filament circuit

its

(VllO)

rectifier

(points 2 to 3

capacitor C142

filter

open;

tube

shorted.

is

and capacitors C139 and C140

Defective

(4)

circuit

No

(5)

Heater

kinescope.

plate

field

voltage

Plate

for short

circuit.

cathode

open;

Shorted electrolytic

voltage.

coil.

All

"return"

(1)

tector

(2)

Horizontal

osc.

Check

operative.

and

tube

control

tube (V109. 6BG6-G).

ages, and components in V108

horizontal

of

No

for

Check picture

signal on kinescope grid.

if amplifier

VlOl (6AG5), V102 (6AG5). V103 (6AG5), second de-

V104

V105 (12AU7).

(6AL5), and' video amplifier

Bad contact

ZONTALLY— A

to

kinescope grid.

(Lead

to

socket broken.)

condition of this nature can be caused by:

(1)

Defective sync amplifier

(2)

If

tube

is

and separator (V106, 6SN7-GT).

O.K., check voltages,

waveforms and associated

circuits.

in-

ONLY — If

output

check waveforms,

not present,

If

volt-

this condition is

integrating

Vertical

encountered, check:

network capacitors C164, C123, C124,

C125, and resistors R13B, R137, R138.

circuits.

PICTURE STABLE BUT WITH POOR RESOLUTION— If

HORIZONTAL DEFLECTION

only

is

ONLY—

horizontal

If

obtained, evidenced by a "straight

face of the kinescope,

it

deflection

across the

line"

ture resolution

of

and output tube (V107, 8SN7-GT)

inoperative. Check waveforms and voltages on grid and plate.

(1)

Vertical

(2)

Vertical output transformer (T103) open.

(L104,

(3)

Yoke

LI 06

oscillator

(3)

POOR VERTICAL LINEARITY—

adjustment

If

of

the

vertical

If

height and linearity controls will

of

the following

may

not

correct

this

condition,

Capacitors C128-C or C127-B defective.

(3)

V107 (6SN7-GT)

Check waveforms and

defective.

volt-

(5)

Low

plate

capacitors in

(6)

and bias

supply

-|-B

in

capacitor C130.

Check

voltages.

rectifier

have shunting

Leakage

in

Check adjustment

all potentials in

on either side

(1)

C

Check

this condition,

adjustment

If

of

controls

check the following:

or replace horizontal output tube (V109, 6BG6-G).

Check and

Check

(3)

Check waveform on

(4)

Check

(5)

Check capacitors C139 and C140

or replace

damper tube

linearity coil

be defective, check the

grid

realign,

circuit

circuits.

for

poor or dirty contact.

focus control (R129).

of

of

video

It

should be

proper focus.

if

necessary, the picture if and

r-f

SMEAR—

to

phase

shift at

the

This

can be

caused by improper values of R and C in the video

Check for grid current on video amplifier tube V105.

circuits.

(2)

This

of

the

video characteristic.

can originate in either the transmitter

Check reception from another station.

trouble

or

(1)

1!

regular sections at the

left of

the picture are displaced,

replace the horizontal output tube (V109, 6BG6-G).

for defects.

(2)

This condi

Vertical instability

may be due

to

loose connections or

"noise" received with the signal.

can be caused by:

(3)

Defective yoke.

coils

PICTURE JITTER—

for short circuit.

TRAPEZOIDAL OR NON-SYMMETRICAL RASTER

lion

peaking

(VI 11, 5V4-G).

grid of V109.

L113

to

Normally, smear can be attributed

the receiver.

(2)

all

Note that L105 and

circuits.

low-frequency end

does not correct

Check

coil.

resistors.

(3)

effective

(1)

POOR HORIZONTAL LINEARITY

the pic-

caused by any

V105 grid capacitor CI 15.

Check kinescope

PICTURE

Capacitor CI 29 defective.

peaking

Check

tube and

circuits.

video

L105, L106, L107) for continuity.

(2)

(4)

Excess leakage or incorrect value

Open

(1)

ages.

(4)

may be

Defective picture detector (V104, 6AL5) or video amplifier

above components are not found

be the cause:

(2)

it

following:

Vertical output transformer (T103) defective.

(1)

not up to standard,

(V105, 12AU7).

(2)

vertical coils open.

is

the following:

can be caused by the following:

(1)

any

Vi09

SIGNAL ON KINESCOPE GRID AND HORIZONTAL SYNC

6SN7-GT)

(V108,

sawtooth on grid

for

tube

output

horizontal

SIGNAL APPEARS ON KINESCOPE GRID BUT IMPOSSIBLE TO

SYNCHRONIZE THE PICTURE VERTICALLY AND HORI-

open

capacitor;

measurements are accessible

-j-B

measurement by removing cover from bleeder box.

(6)

from

output

Replace tube.

condition can be caused by:

open.

speaker

Insufficient

tubes

O.K., check LI 13 (horizontal linearity coil) for con-

is

(2)

This condition can be caused by:

or line voltage.

RASTER— NO IMAGE, BUT ACCOMPANYING SOUND— This

open; or the

is

5V4-G) inoperative.

(VI 11,

circuit.

is

for

tinuity,

Low +B

(6BG6-G).

6BG6-G horizontal output tube is obtained through

damper tube. Check tube, and heater winding on T106.

supply

the

defective;

is

Damper tube

(3)

high- voltage

the

to

(1)

output transformer T105, the trouble

of horizontal

can be isolated

yoke assembly.

in rear of

magnet.

trap

ion

of

condition can be

Defective yoke due to RlOl, H151. or C141 (internal in yoke

NO RASTER ON KINESCOPE— The

Incorrect

WRINKLES ON LEFT SIDE OF RASTER -This

caused by;

with their effects and causes, are listed below:

(1)

72 ITS

Horizontal instability

sync, or to "noise."

may

be due

to

unstable transmitted

ALIGNMENT PROCEDURE

721TS

TEST EQUIPMENT

recommended

— To

service

this

that the following test

receiver

properly,

it

is

equipment be available:

SERVICE PRECAUTIONS— Cutouts

make

possible to do

it

some

without removing the chassis.

Sweep Generator meeting

R-F

(a)

the

the following requirements:

when

Frequency ranges:

18 to 30 mc,

1

mc sweep

width

every

mc sweep width

If

Output adjustable with at least

(b)

Output constant on

(c)

all

.1

volt

maximum.

However,

"Flat"

output in

all

attenuator positions.

support

vertical deflection

and an

input calibrating source.

to

By

provide the following frequencies:

(Output on these ranges should be adjustable

volt

and

.1

maximum.)

(a)

to

See Figures

necessary

is

it

turning

and

rest

and

4

3,

to

6.

possible,

If

view the raster during servicing,

be inserted only

chassis

is

to

A

yoke.

bracket

viewing screen.

its

with the power transformer

made

conveniently available.

the only safe position in

is

after

in the deflecting

chassis on end

the

the

The kinescope should never be allowed

adjustments will be

all

rub finish and

1

finish.

remove the chassis from cabinet, the kinescope

weight by resting

its

preserve that

which the chassis

will

leave adjustments accessible, the trimmer location

still

drawings are oriented similarly

ease

for

of use.

Intennediate frequencies:

21.25

22.8

23.9

24.5

26.0

27.25

(b)

made

should then be serviced without the kinescope.

if

Since this

at least

If

should be used to support the tube at

"up,"

Signal Generator

to

turned on end.

Cathode-ray Oscilloscope, preferably one with a wide band

serviced in

the cabinet

kinescope should

the

(d)

is

be removed.

first

chassis

the

ranges.

the receiver

pad should be placed under

should be

effort

necessary

must

of the cabinet

inverted, in order to avoid scratching the surface.

is

it

soft

manufacture, the cabinet receives a Class

In

mc sweep width

40 to 90 mc, 10

170 to 225 mc, 10

a

cabinet,

bottom

in the

the servicing of the receiver

of

CAUTION:

mc sound M and sound traps

mc converter transformer

mc first picture i-f coil

mc third picture i-f coil

mc second picture i-f primary

mc second picture i-f secondary

Do

not permit

become "shorted"

to

kinescope second-anode lead

the

to the

To do so

chassis.

considerable overload on the high- voltage

ADJUSTMENTS REQUIRED

line

will

Normally,

only

the

HI 87.

oscillator

r-f

require the attention of the service technician.

other circuits are either broad or very stable

Radio frequencies:

cause a

will

resistor

filter

and hence

All

will

seldom require readjustment.

Picture

Channel

Carrier

Number

Freq.

Mc

Sound

Due

Carrier

Freq.

the

Mc

with practically any 6J6 tube in the

quency on channel

2

55.25

59.75

socket.

3

61.25

65.75

line to

4

67.25

71.75

5

77.25

81.75

However,

13

may

it

frequency on

all

can be adjusted

not then

of

adjust

the

line

to

to the

be possible

channels

7,

For an oscillator tube to be satisfactory,

to

8,

it

9,

proper

fre-

to adjust the

10,

11,

and

12.

should be possible

proper frequency with the fine-tuning

may

control in the

middle

of its

sary

a tube

for the oscillator socket.

range.

It

therefore be neces-

87.75

to select

7

175.25

179.75

the old tube can

8

181.25

185.75

new

9

187.25

191.75

it

be matched

ones, this practice

will

is

for

recommended.

probably be necessary

In replacing,

if

frequency by trying several

to

At best, however,

realign the

oscillator

line

completely after changing the tube.

193.25

197.75

11

199.25

203.75

Tubes which cannot be used as an

12

205.25

209.75

factorily

13

211.25

215.75

The detailed alignment procedure which follows

,

affected

line

49.75

10

and may be

is critical

by a tube change. The

45.25

83.25

adjustment

oscillator-line

1

6

which the receiver operates,

the high frequencies at

to

r-f

as an

r-f

oscillator

may work

satis-

amplifier or a converter.

is

intended

primarily as a discussion of the method used, precautions to

Heterodyne Frequency Meter with crystal calibrator

signal generator

is

if

the

not crystal controlled.

be taken, and the reasons

VoltOhmyst type" and a high

these precautions.

Then, for

more convenient reference during alignment, a tabulation

the

Electronic Voltmeter of "Junior

for

method

ment

is

is

given

given.

of

All the information necessary for align-

in the tables;

however, alignment by the tables

voltage probe for use with this meter to permit measurements

should not be attempted before reading the detailed instruc-

up

tions.

to 10 kr.

3

ALIGNMENT PROCEDURE

ORDER OF ALIGNMENT—When a

necessary,

is

complete receiver alignment

can be most conveniently periormed

it

the

in

following order:

Sound

Sound

not exceed the specified values otherwise the response curve

be broadened, permitting

will

Picture

i-f

Picture

i-f

on weak

distortion

signals.

PICTURE IF TRAP ADJUSTMENT—

transformers

i-f

misadjustment to pass

slight

and possibly causing

unnoticed

discriminator

721TS

(Continued)

Connect the "VoltOhmyst"

traps

R106 and R107

on the meter.

to the junction of

adjust the picture control for -3 volts

and

coils

R-F and converter lines

Set the channel switch to channel 13.

R-F oscillator line

Connect the "VoltOhmyst" across the picture second detector

Retouch picture

Sensitivity

load resistor RI18 and set

transformers

i-f

check

Connect the output

Set the signal generator for approximately

and connect

output at

volt

.1

second sound

to the

it

of

unit.

grid.

i-f

and check

Set the generator to 21.25 mc.

Detune T108 secondary

volt scale.

generator to the junction

C14 and R8. This connection is available on a terminal lug

through a hole in the side apron of the chassis, beside the r-f

SOUND DISCRIMINATOR ALIGNMENT—

21.25 mc.

on the 3

it

of the signal

(bottom).

calibrator to insure that the generator

Set the "VoltOhmyst" on the 10 volt scale.

r

Adjust T3

and TlOl

(top)

minimum

for

it

against a crystal

exactly on frequency.

is

indication on the "Volt-

Ohmyst."

Connect the meter

with a one

in series

megohm

resistor to the

Set the generator to 27.25

and R182.

junction of diode resistors R181

minimum

tom) for

Adjust the primary of T108

(top) for

maximum

output on the

ment

is

mc and

indication

adjust T104 secondary (boton the "VoltOhmyst" {this adjust-

omitted on some chassis).

meter.

Connect the "VoltOhmyst"

to

pin

1

V118 and

of

on the

set

3 volt scale.

will

It

be found

that

is

it

pos-

produce a positive or negative voltage on the meter de-

and peak

this adjustment. Obviously to pass from a posia negative voltage, the voltage must go through zero.

T108 (bottom) should be adjusted so that the meter indicates

zero output as the voltage swings from positive to negative.

oscillator to the grid of the

second sound

mc—T3

22.8

chassis)

—

—

26.0 mc.

primary

24.5 mc. — L103

chassis)

Oscillation— the receiver

Picture

the

approximately

to

frequency at approximately

center

output of approximately

mc. with

and with an

volt.

.1

Connect the oscilloscope

21.25

1

to

pin

V116.

of

chassis)

of

(top

I-F

If

of the

may

up as a voltage

If

The pattern obtained should be similar to that shown in

Figvure 13A. If it U not, adjust T108 (top) until the wave iorm

is symmetricaL

fall into

is

is

are tuned

badly misaligned and

to the

same frequency,

shows

I-F oscnllation

oscillation.

i-f

in excess of 3 volts at the picture detector

is

by

unaffected

r-f

independent of picture control

such a condition

stop oscillation

quency by

coils

i-f

This voltage

load resistor.

and sometimes

1

of

^T104

the receiver

sweep band width

(bottom)

LlOl (top

23.9 mc.

two or more

amplifier.

Adjust the

indication on

(top of

This point will be called discriminator zero output.

Connect the sweep

maximum

the specified adjustment for

the "VoltOhmyst."

pendent upon

tive to

i-f

COIL ADJUSTMENTS—

I-F

Set the signal generator to each of the following frequencies

Adjust T108 secondary (bottom).

sible to

PICTURE

is

by

encountered,

it

is

signal input

setting.

sometimes possible

adjusting the coils approximately to

setting

the

adjustment

extensions

stud

of

to

fre-

T3.

and LI03 to be approximately equal to those of

another receiver known to be in proper alignment. If this

does not have the desired effect, it may now be possible

to stop oscillation by increasing the grid bias. If so, it should

then be possible to align the coils by the usual method.

Once aligned in this manner, the i-f should be stable with

LlOl, T104

-

The peak

to

to 21.325

mc.

peak bandwidth of the discriminator should be

opproximotely 350 ke. and should be linear from 21.175 mc.

SOUND IF ALIGNMENT—

reduced bias.

Connect the sweep and signal generator

to the top

end

of the

If

trap winding of T3 (on top of the chassis).

Connect the oscilloscope

(terminal

A

T107) in series with

Connect a 5600

Insert

the second sound if grid return

to

ohm

resistor

a 33,000 ohm

to

ground.

a 21.25 mc. marker signal from the signal generator

first sound if grid.

(top

and bottom)

for

maximum

gain and sym-

metry about the 21.25 mc. marker. The pattern obtained should

be similar

80%

to that

shown

response from the

in Figure

first

sound

i-i

13B.

The band width

grid to the second

i-f

at

grid

Remove

Remove

i-f

above adjustment are

necessary that the sweep output voltage should

i-f

grid

and

adjust

the

r-i

first

i-f

to the junction of

and align T3

grid,

connect

all

i-f

i-f

C14 and R6

to frequency.

does not stop the osdllation, the

misaligiunent as the

Check

grid, connect

and align LlOl.

tuning luit)

erly aligned.

i-f

and align T104.

the shunting capacitor from the

Coimect the signal generator

this

the final touches on the

amplifiers to ground with

the shunting capacitor from the second

the signal generator

to

is

i-f

to the third

the signal generator to this grid

B

It

two

L103 to frequency.

The output level from the sweep should be set to produce

approximately .3 volt peak-to-peak at the second sound i-f grid

when

first

Connect the signal generator

(in

return

cannot be stopped in the above matmer,

1000 mmf. capacitors.

should be approximately 250 kc.

made.

os<dllation

isolating resistor.

from terminal A, T107

into the

Adjust T107

the

shunt the grids of the

difficulty is not

section is very stable

by-pass condensers,

resistors, tubes, socket voltages, ete.

when

coil

due

prop-

loading

ALIGNMENT PROCEDURE

721TS

H-F

AND CONVERTER

Connect the

minals.

output,

sweep

sweep

r-f

the

If

shown

connecting as

Check channels 5 down through channel 1 by switching the

receiver, sweep oscillator and marker oscillator to each channel and observing the response obtained. In all cases, the

markers should be above the 70% response point. If this is

not the case, Lll, L12, L37 and L38 should be retouched. On

9.

D

BO OUM

UNBALANCED

SWEEP OUTPUT

CABLE

response curve located symmetrically between the markers.

ter-

balanced output by

obtain

to

Figure

in

Adjust Lll, LI2, L37 and L38, for an approximately flat-topped

receiver antenna

has a 50 ohm single-ended

oscillator

be necessary

will

it

ADJUSTMENT—

LINE

oscillator to the

IZO A.

—

(Continued)

adjustment,

final

(/VA/"

<S)

RECEIVER

all

Coupling between

and converter

r-f

a link between L12 and L37.

db

and should

factory

Sweep Cable Termination

response

slightly

is

By-pass the

capacitor.

If

to this

and cause an

cursion

may

incorrect picture of the

Connect the "VoltOhmyst"

to

fall

in

the

Remove

range

r-f

response.

r-f

the junction of R170

and R171

picture control for -1 volt on the meter.

and adjust the

Connect the signal generator loosely

to

the receiver antenna

has the narrowest response

high frequency channels,

of

should be adjusted

it

any

switch shaft

Insert

sweep

of

channel

channel

picture carrier

7

R-F

OSCILLATOR LINE ADJUSTMENT—

The

r-f

oscillator line

of

the

18

and sound

carrier

If

16) for

an

and the markers occur

See Figure

channel

17,

of all

7.

at

In

90%

approximately

making these

If

oscillator to

each

of

See Figure

obtained.

be found that

all

aligned by adjusting

it

i-f

grid.

to

beat

to

is

oscillator

of

be

alignment

be adjusted by the heterodyne

is

adjusted by feeding

in

the

r-f

under "R-F Sound

R-F Sound

Receiver

R-F Osc.

Carrier

Number

Freq. Mc.

Freq. Mc.

channels

It

oscillator

Channel

switch,

response curves.

receiver

under "R-F

must be available.

carrier signal, the frequencies listed

adjust-

cores should be kept approxi-

17 for typical

in the table

used,

is

crystal controlled or calibrated.

Carrier" must be available.

1

71

49.75

2

81

59.75

3

87

65.75

4

93

71.75

5

103

81.75

6

109

87.75

7

201

179.75

8

207

185.75

9

213

191.75

10

219

197.75

II

225

203.75

12

231

209.75

13

237

215.75

should

these channels have the proper shaped

re-

sponse with the markers above 70% response. If the markers

do not fall within this requirement on one or more high frequency channels, since there are no individual channel adjustments, it will be necessary to readjust L25, L26, LSI and

L52, and possibly ^compromise some channel slightly in order

up on other channels. Normally however,

no difficulty of this type should be experienced since the

higher frequency channels become comparatively broad and

to

picture

re-

8 through 13 by switching

sweep oscillator and marker

these channels and observe the response

of

channel

receiver

the

sound

mately equal.

Check the response

which method

the receiver oscillator

Osc. Freq."

approxi-

flat topped response curve located symmetrically between the markers. Normally this curve appears somewhat

overcoupled or double humped with a 10 or 15% peak to val-

ments, the stud extension

of

the frequency standard must

7.

mately

the

may be

first

frequency meter method, the frequencies listed

Adjust L25, L26, L51 and L52 (see Figure

sponse.

capacitor from the

r-f sound carrier frequency and adjusting the oscillator for zero output from the

sound discriminator. In this latter case the sound discriminator

must first have been aligned to exact frequency. Either method

of adjustment will produce the same results. The method used

will depend upon the type of test equipment available.

and 179.75 mc.

ley excursion

mmf

location versus channel).

flat

oscillator to cover

markers

175.25 mc.

maximum,

is

the 1000

Regardless

Set the

at

feeding a signal into the receiver at the

first.

Set the receiver channel switch to channel 7 (see Figure

for

10%

overcoupled with approximately a

With the coupling

On

field.

position, the

with a crystal calibrated heterodyne frequency meter, or by

terminals.

Since channel 7

the

approximately 40%.

is

by-pass as short as possible.

done, lead resonance

adjusted in the

somewhat broader and the peak-to-valley exThe amount of coupling permissible is limited by the peak-to-valley excursion which should

not be greater than 30 °o on any channel.

the response

the

picture if grid to ground through a 1000 mmfd.

first

Keep the leads

this is not

(in

augmented by

is

is

minimum coupling

in the

excursion from peak-to-valley.

Connect the oscilloscope to the junction of C14 and R6

r-f tuning unit) through a 10,000 ohm resistor.

lines

This link

not require adjustment in

channel 6 with the link

— Unbalanced

spec-

ANTENNA

TERMINALS

MSa2T

figure 9

70%

channels must be within the

ification.

get the markers

the markers easily

Channel

6

is

fall

within the required range.

next aligned

in the

Set the receiver to channel

same manner.

6.

If

Set the

sweep

Set the

marker

oscillator to cover

oscillator to

channel

the heterodyne frequency meter

meter probe loosely

6.

channel 6 picture and sound car-

If

the

r-f

Ohmyst"

rier frequencies.

10

sound

to pin

carrier

1

of

method

is

used, couple the

to the receiver oscillator.

method

V116.

is

used,

connect the

"Volt-

3

ALIGNMENT PROCEDURE

Connect the signal generator

method

is

same regardless

inductance,

frequencies

necessary

is

it

by adding

obtained

are

align channel 13

to

steps

and

first

mately

flat

mately

90%

If

Set the receiver channel switch to channel 13.

is to

response.

adjust-

i-f

response point.

low frequency video response, of

and of sync may occur. If the

picture brilliance, of

picture carrier oper-

ates too high on the response curve, the picture definition

for the signal

impaired by loss

generator).

its

45%

blanking,

the correct frequency (237

Set the fine tuning control to the middle of

making the

in

get the picture carrier at the

the picture carrier operates too low on the response curve,

loss of

mc. for heterodyne frequency meter or 215.75 mc.

The curve must be approxi-

response.

The most important consideration

con-

ments

to

45%

topped and with the 23 mc. marker at approxi-

of

tinue in reverse numerical order.

Adjust the frequency standard

adjustment the picture carrier marker must be at

final

approximately

which

of

used.

lower

Since

On

antenna terminals.

to the receiver

The order of alignment remains the

72 ITS

(Continued)

range while mak-

CHECK — A

SENSITIVITY

ing the adjustment.

Adjust L77 and L78 for an audible beat on the heterodyne

frequency meter or zero voltage from sound discriminator. The

core stud extensions should be maintained equal by visual

is

high frequency video response.

of

comparative sensitivity check can be

made by

operating the receiver on a

television

station

tained to

that

weak

signal from

a

and sound obreceivers under the same

and comparing

the

obtained on other

picture

conditions.

inspection.

weak

This

Switch the receiver

channel

to

antenna

Set the frequency standard to the proper frequency as listed

in

shown

Adjust L76 for indications as above.

what

frequency on

to

Figure

through an attenuator pad

The number

10.

stages

of

in

type

of the

pad

the

de-

pends upon the signal strength available at the antenna. A

sufficient number of stages should be inserted so that a some-

the alignment table.

Adjust the oscillator

to the receiver

in

obtained by connecting the shop

signal can be

12.

channels by switch-

all

normal contrast picture

less than

picture control

and the frequency standard to each channel

and adjusting the appropriate oscillator trimmer for the specified indication. It should be possible to adjust the oscillator

the

is at

maximum

is

obtained

when

the

clockwise position.

ing the receiver

to the

correct frequency

on

been

After the oscillator has

c

channels with the fine tuning

all

control in the middle third of

its

all

RECEIVER

ANTENNA

TERMINALS

I

channels, start back at

I

channel 13 and recheck

to

make

sure that all adjustments are

correct.

-vwwRETOUCHING OF PICTURE

The

picture

and

of bias

I-F

If

response curve varies somewhat with change

i-f

for this

reason

should be aligned with approxi-

it

the receiver

is

it

located at the edge of the service area,

normal conditions, (signals

for

or greater),

it

recommended

is

with a grid bias of —3

at the junction of

Connect the

r-f

volts.

-JWSA/V-

Vigure 10

i-f

1000

of

that the picture

i-f

it

Only carbon type

grid bias.

microvolts

it

advisable

is

sistor

R106 and R107.

antenna

to the receiver

ter-

used

in

to

of

the low

wire

of

to

construct the

value moulded

wound

—The

its

re-

construction,

break and examine one of each type

order to determine

RESPONSE CURVES

minals.

should be used

many

generally available are

sistors

be aligned

resistors

Since

attenuator pad.

Set the picture control for —3 volts

sweep generator

—Attenuator Pad

will receive in operation.

should be aligned with approximately —1 volt

However,

-WWAr-

ADJUSTMENTS—

mately the same signal input as

of re-

construction.

response curves shown on pages

feed in the 25.75 mc. if picture carrier marker and a 23 mc.

and 15 and referred to throughout the alignment procedure were taken from a production set. Although these

curves are typical, some variations can be expected. Chan-

marker.

nel 2

14

12,

Connect the signal generator

to

the

antenna terminals and

Connect the oscilloscope across the picture detector load

sistor,

to

response

the

r-f

1

and

and converter

6)

(not

shown)

is

the

found

left.

test set-up will

line ad-

sweep output to produce approximately

peak across the picture detector load resistor.

Set the

.3

volt peak-to-

sweep

Observe and analyze the response curve obtained.

sponse will not be ideal and the

i-f

flection

The

In

depend upon

i-f

classical

The curves may be seen independing on the dethe oscilloscope and the phasing of the

polarity of

to right

generator.

ALIGNMENT TABLE—Both methods

making

oscillation

of

the

the characteristics of the oscillo-

presented in the alignment table.

thereby choose the method

these adjustments, care should be taken that no two trans-

same frequency as

manner

in

re-

adjustments must be

retouched in order to obtain the desired curve.

3.

is

scope and the sweep generator.

verted and /or switched from left

justment.

similar to that of channel

with "response up" and low frequency to

The manner in which they will be seen in a given

presentation, that

have the best response during

formers are tuned to the

r-f

The response curves are shown

re-

R118.

Set the channel switch to channel (between

c

^

.^vvvvv-

range.

on

set

I20

1ZO

-vww-

may

is

found that the dual

can be easily erased.

result.

11

to

of oscillator

alignment are

The service technician may

suit

his test equipment.

listing is confusing, the

unwanted

If

it

listing

ALIGNMENT TABLE

721TS

THE DETAILED ALIGNMENT PROCEDURE BEGINNING

ON PAGE

8

SHOULD BE READ BEFORE ALIGNMENT BY USE OF THE TABLES

DISCRIMINATOR AND SOUND IF ALIGNMENT

STEP

No.

IS

ATTEMPTED.

ALIGNMENT TABLE

THE DETAILED ALIGNMENT PROCEDURE BEGINNING

ON PAGE

8

PICTURE IF

STEP

No.

(Continued)

SHOULD BE READ BEFORE ALIGNMENT BY USE OF THE TABLES

AND TRAP ADJUSTMENT

72 ITS

IS

ATTEMPTED.

721TS

ALIGNMENT TABLE

THE DETAILED ALIGNMENT PROCEDURE BEGINNING

ON PAGE

R-F

STEP

No.

8

(Continued)

SHOULD BE READ BEFORE ALIGNMENT BY USE OF THE TABLES

AND CONVERTER

LINE

ALIGNMENT

IS

ATTEMPTED.

ALIGNMENT TABLE

R-F

STEP

c

No.

(Continued)

OSCILLATOR ALIGNMENT

72 ITS

721TS

CHASSIS VIEWS

I

T106

POWER

TRANSFORMER

Figure 21

— Chassis Top

View (Showing Location

of

Major Components)

3

NOTE: IN

Figure 22

SOME RECEIVERS.

LI02

IS

USED

IN

PLACE OF TI04

— Chassis Bottom View (Showing Location of Major Components)

16

WAVEFORM PHOTOGRAPHS

Peak

to

peak voltages shown are nominal when

1

volt

peak

to

peak video signal

is

72 1 TS

applied to

Isl

video amplifier (V105).

c

Video Signal Input to 1st Video

Amplifier (At Pin 2 of V105)

Figure 25

— Vertical

(1.0 Volts,

P

to P)

.

'P-

ma

>

Figure 24

—Horizontal

(1.0 Volts,

P

to P)

'

'

S=

'

i

Output of

(Pin

Figure 25

—

(5.0 Volts,

1

Video Amplifier

of V105)

Vertical

P

Figure 26

to P)

to

P

Kinescope Socket)

—

Figure 28 Horizontal

(32 Volts, P to P)

to P)

Input to Grid Sync Amplifier

(Pin

1

ffl ffl

I

of V106)

—Vertical

Figure 29

P

to P)

Kinescope Grid

i^^WMIK

(8 Volts,

P

L106 and Green head

— Vertical

Figure 21

(32 Volts,

—Horizontal

(5.0 Volts,

Input to

(] unction of

c

1st

Figure 30

to P)

—Horizontal

(8 Volts,

P

to P)

Input to Sync Separator

(Pin 2 of VI 06)

—

—

Figure 31

Vertical

(90 Volts, P to P)

Figure 32 Horizontal

(90 Volts, P to P)

Output of Sync Separator

(Pin 6 of V106)

c

— Vertical

Figure 33

(10 Volts,

P

—

Figure 34 Horizontal

(10 Volts, P to P)

to P)

17

WAVEFORM PHOTOGRAPHS

72 ITS

— Vertical

Figure 35

(25 Volts,

PtoP)

Output of Integrating Network

(Junction of R138 and C125)

—

38 Plate of

Output Tube

(750 Volts, P to P)

(Pin 5 of V107)

Figure

Vertical

—

36 Grid of

Oscillator Tube

(175 Volts, P to P)

(Pin 1 of VI 07)

Figure

(Continued)

to

P)

(Junction of CI 29

—

to

P

(65 Volts,

Figure 39 Voltage Across Vertical Deflection

Coils (L108,

L109) (90 Volts, P to P) (At

Green Lead of T103

—

37 Input to Vertical

Output Tube

Figure

Vertical

Figure 40

and CI 30)

—Horizontal

Oscilla-

tor Waveforms and Sync Pulse

(20 Volts, P to P)

(Junction of C122 and C133)

Ground)

^Y

—

Figure 41

Horizontal Oscillator Control (45 Volts, P to P)

(Junction

Figure 44

R158 and R164)

— Grid of Horizontal

Output

(40 Volts, P to P)

(Pin 5 of V109)

—

Grid of Horizontal

Oscillator (400 Volts, P to P)

(Pin 4 of VI 08)

Figure 42

Figure

43

—Horizontal

Oscil-

Output (60 Volts, P to P)

(Junction of C135 and C163)

lator

—

—

Figure

46 Voltage

Across

Horizontal Deflection Coils

(Approx. 1100 Volts, P to P)

(Pin 4 or 6 of Vlll to

Figure 45 Plate of Horizontal

Output (Approx. 5000 Volts,

P to P) (Measured Through a

Capacity Divider

Connected

from Plate to Ground)

Ground)

CRITICAL LEAD DRESS

1.

Do not permit any strains

to

be

placed on the leads

2.

—

3.

Figure 47 Test Pattern Showing Out of Sync Condition

When Horizontal Hold Control

Is in a Counterclockwise Position Just Before Pulling Into

Figure 48 Test Pattern Showing Out Of Sync Condition

When Horizontal Hold Control

Is at the Maximum Clockwise

Sync

Position.

—

—

of R126, R157,

R158, R164, R165, R173, R188 and

R191. Do not permit these resistors to be exposed to the heat

of a soldering iron any more

than is absolutely necessary.

Dress the temperature compenapproxisating resistor R191

mately one-quarter inch from

the power transformer and the

chassis.

Dress all video coupling capaci-

and peaking coils up and

aivay from the chassis.

tors

4.