Download Bunn Espress ES.1AF Service manual

Transcript

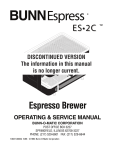

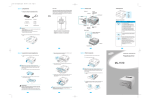

BUNNEspress ® ES•1AF DISCONTINUED VERSION The information in this manual is no longer current. G LE SI N CL 2 OPERATING & SERVICE MANUAL Designs, materials, weights, specifications, and dimensions for equipment or replacement parts are subject to change without notice. BUNN-O-MATIC CORPORATION POST OFFICE BOX 3227 SPRINGFIELD, ILLINOIS 62708-3227 PHONE: (217) 529-6601 FAX: (217) 529-6644 26691.0000C 6/97 ©1995 Bunn-O-Matic Corporation BUNN Espress® WARRANTY Model ES•1AF User notices......................................................................................................................... 3 Site Requirements ............................................................................................................... 4 Installation ........................................................................................................................... 5 Operating Controls............................................................................................................... 6 Adjustments ........................................................................................................................ 7 Operation ............................................................................................................................. 8 Brewing tips ...................................................................................................................... 10 Alarms ............................................................................................................................... 11 Wiring Diagram ................................................................................................................. 12 INTRODUCTION This compact, easy-to-operate equipment produces consistently fine espresso and related beverages with the push of a button. The brewer is selectable to deliver one of eight different programmed amounts of beverage. All of the critical functions of the brewer are electronically controlled. WARRANTY Bunn-O-Matic Corp. (“Bunn”) warrants the equipment manufactured by it to be commercially free from defects in material and workmanship existing at the time of manufacture and appearing within one year from the date of installation. This warranty does not apply to any equipment, component or part that was not manufactured by Bunn or that, in Bunn’s judgement, has been affected by misuse, neglect, alteration, improper installation or operation, improper maintenance or repair, damage or casualty. THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of Bunn are not authorized to make modifications to this warranty or to make additional warranties that are binding on Bunn. Accordingly, statements by such individuals, whether oral or written, do not constitute warranties and should not be relied upon. The Buyer shall give Bunn prompt notice of any claim to be made under this warranty by telephone at (217) 5296601 or by writing to Post Office Box 3227, Springfield, Illinois, 62708-3227. If requested by Bunn, the Buyer shall ship the defective equipment prepaid to an authorized Bunn service location. If Bunn determines, in its sole discretion, that the equipment does not conform to the warranty, Bunn shall repair the equipment with no charge for parts during the one year warranty period and no charge for labor by a Bunn Authorized Service Representative during the one year warranty period. If Bunn determines that repair is not feasible, Bunn shall, at its sole option, replace the equipment or refund the purchase price for the equipment. THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AS SPECIFIED HEREIN, TO REPAIR OR, AT BUNN’S SOLE OPTION, REPLACEMENT OR REFUND.Bunn shall not be liable for any other damage or loss, including, but not limited to, lost profits, lost sales, loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute equipment, facilities or services, or any other special, incidental or consequential damages. 2 BUNN Espress® USER NOTICES Model ES•1AF The notices on this brewer should be kept in good condition. Replace unreadable or damaged labels. WARNING This equipment is to be installed to comply with the Basic Plumbing Code of the Building Officials and Code Administrators International, Inc. (BOCA) and the Food Service Sanitation Manual of the Food and Drug Administration (FDA). • DO NOT OVERLOAD CIRCUIT. • ALWAYS ELECTRICALLY GROUND THE CHASSIS OR ADAPTOR PLUG. • DO NOT DEFORM PLUG OR CORD. • FOLLOW NATIONAL AND LOCAL ELECTRICAL CODES. • KEEP COMBUSTIBLES AWAY. FAILURE TO COMPLY RISKS EQUIPMENT DAMAGE, FIRE OR SHOCK HAZARD. READ THE ENTIRE OPERATING MANUAL INCLUDING THE LIMIT OF WARRANTY AND LIABILITY BEFORE BUYING OR USING THIS PRODUCT 00656.0000 CAUTION 00986.0000C 3/94 © 1994 Bunn-O-Matic Corporation HOT Liquid-Steam-Surfaces 00986.0002 24246.0000 F SM 26602.0000 26602.0001 NOTICE 160 psig max operating pressure 24247.0000 Must wet o-ring with clean water before installing. WARNING 26625.0000 HAZARDOUS VOLTAGE ! WARNING UNPLUG BREWER BEFORE REMOVING! The milk supply hose and milk container must be refrigerated after use in compliance with state and local health codes. 12652.0000 26868.0000 1. Place a pod in the filter holder. 2. Lock the filter holder into the group head. 3. Place an empty cup below the dispensing nozzles. 4. Press your drink selection. 5. Carefully remove the cup after the flow has stopped. 1. Place an empty cup below the dispensing nozzle. 2. Press the button indicating your selection. 3. Press any button to stop the cycle. 1. For complete instructions, see the operators manual. When CLEAN FROTHER light flashes, rinse the frother as follows: 2. Place the end of the milk supply tube in a container of clean hot water. 3. Press the "CLEAN FROTHER" button. 4. Carefully remove the cup & discard contents after flow has stopped. 5. Disassemble and thoroughly clean the milk frother according to local sanitation codes, at least every four (4) hours. 226601.0000 25551.0001 3 (Revised January 1996) BUNN Espress® SITE REQUIREMENTS Model ES•1AF PHYSICAL The brewer is for indoor use only on a sturdy counter or cart. It is 16” (40.5 cm) wide, 20” (50.8 cm) tall and 19.25” (48.9 cm) deep. The brewer weighs approximately 88 pounds (40 kg) with the water tank filled. ADJUSTABLE LEGS Remove the four rubber feet from the brewer and install the four 4” adjustable legs supplied with the brewer. Place the brewer on a counter or cart having sufficient space for easy access to water, electricity and drainage. PLUMBING The brewer must be connected to a cold water source with operating pressure between 20 and 90 psi (1.5-6.5 bar) from a .5” or larger supply line. Install a shutoff valve in the water line before the brewer. Install a regulator before the brewer when the pressure is greater than 90 psi (6.3 bar) to reduce it to 45-60 psi ( 3-4 bar). The enclosed water strainer, water inlet hose assembly and drain hose must be installed. NOTE-Only softened or demineralized water should be used in this espresso brewer to reduce the service problems caused by naturally occurring elements in your local water supply. A polyphosphate feeder is not recommended because it does not remove minerals. NOTE-Bunn-O-Matic recommends .375” copper tubing for no more than 25 feet from the .5” water supply line. Bunn-O-Matic does not recommend the use of a saddle valve to install the brewer. The size and shape of the hole made in the supply line by this type of device may restrict water flow. ELECTRICAL The brewer is equipped with an attached cordset and requires a 2-wire, grounded mating receptacle rated 120 volts ac, 20 amp, single phase, 60 hz. An electrician must properly install a NEMA 5-20R connector to the appropriate electrical service on an individual branch circuit to install this brewer. CAUTION- The brewer must be properly grounded. A plumbing line will not provide an adequate ground. FROTHER DISCONNECT ASSEMBLY When installing frother assembly thoroughly wet O-rings with water. Using the slide bracket on the front panel as a guide, slide frother assembly into the frother manifold as far as it will go. Secure frother assembly with attached thumb screw. an cle ith gw -rin in to we fore st be Mu ater N w IO UT CA T s face HO -Sur team id-S Liqu P911 4 BUNN Espress® INSTALLATION Model ES•1AF PLUMBING Install the brewer as indicated below: 5 3 1. Inlet Hose 2. Strainer Assy. 3. Filter/Softener 4. Water Supply Hose 5. Drain Hose 6. Drain Cup BOM 90 psig Straine BUN max r operat N ing pressu re FLOW L E G 0,5 1 SIN 0 0 4 8 1,5 CL 2 2 2,5 12 16 bar s: ow foll water. l. r as hot nua ma frotheclean d. rs ppe rato e the er of sto local ope , rins tain has to the hes con ing see flas in a r flow ord ns, light tube afte r acc ts ctio tru THER ply ton. ten frothe sup ins te FRO milk " but d conmilk rs. ER car the ple AN com CLE of the TH & dis an (4) hou FRO For en end y cle r Wh the EAN the cupghl ry fou "CL rou eve ce Pla ss the remove tho st 2. lea Pre efully ble and at 3. es, Car em cod ass 4. Dis itation 5. san 4 1 2 1. g noz sin . ion pen dis ect the r sel ow you le. bel cup icatingthe cyc p sto zle. pty ind em an button to ce ton Pla ss the but 1. Pre ss any 2. Pre 3. . zles d. hea noz . d. der up sing ppe r holthe gro pen sto dis filte has into the the in der ow flow hol bel . a pod r cup ion r the filte ce ect afte Pla k the empty k sel cup 1. Loc an r drin the 2. ce Pla ss youremove 3. Pre efully 4. Car 5. 66 1 P907 NOTE: For cart applications, unit will function with inlet hose suspended into a container of water. Be sure not to run the container dry, damage to the pump will occur. ELECTRICAL CAUTION- The brewer must be disconnected from the power source until specified. Improper electrical installation will damage electronic components. 1. Using a voltmeter, check the voltage and color coding of each conductor at the electrical source. 2. When Instructed to proceed, connect the brewer to the power source. CAUTION- The brewer must be properly grounded. A plumbing line will not provide an adequate ground. INITIAL FILL AND HEAT CAUTION- The brewer must be disconnected from the power source until specified. Improper electrical installation will damage electronic components. Plumbing must be connected to the brewer before proceeding. 1. Make sure the brewer ON/OFF toggle switch is in the off position. The toggle switch is located on the upper left side of the front panel, just above the pressure gauge 2. Connect brewer to the power source. 3. Place the brewer ON/OFF switch in the “ON” position. The tank will automatically fill. When full the heater will begin heating the water in the tank. NOTE: The tank heater switch is shipped in the “ON” position, and during normal operation should stay there. This switch is located on the DBC control board behind the right hand side panel. If service is required this switch may be turned off to disable the heating circuit. During initial fill, using a bottled water source, a fault may occur. The controller will detect that the tank is not filling fast enough. If this occurs power down the unit. Reinitiate start-up procedures and the unit will complete filling. The unit will begin heating after filling. If necessary, repeat until tank is properly filled. 4. When the steam side of the pressure gauge is in the green area the brewer is ready for selection of one of the four drinks and the size drink desired.. 5 BUNN Espress® OPERATING CONTROLS Model ES•1AF 10 44 5 11 6 13 78 12 9 12 14 15 L E G 0,5 8 1 1,5 CL 2 16 2 2,5 12 16 17 SIN 0 0 4 bar 2 s: low ter. fol as t wa al. nu ther an ho . s ma fro cle ed tor the of pp al era se iner s stoto loc op , rin ha the shes a conta w flo rding see er co s, ht fla e in aft r ac on cti R lig tub tru HE pply tton. ntentsfrothe co lk e ins OT su bu mi urs. let N FR milk R" card HE the mp EA the OT & dis an (4) ho r co CL of cle r Fo hen end N FR cup W the EA the ughly fou ery "CL e ce ov thoro st ev Pla the 2. ess y rem and lea at Pr 3. refullemble des, Ca 4. sass on co Di 5. nitati sa 1. e. zzl no ing ns n. pe dis lectio the se low your . cle p be g cu icatin cy pty ind p the em n sto an butto n to ce tto Pla the 1. ess y bu an Pr 2. ess Pr 3. . . zzles ad r. . p he ing no ed lde ou pp ho gr pens er s sto filt o the dis ha the r int the w flo d in holde below a po er cup tion. er the filt ce pty seleccup aft Pla 1. ck the em ink the an dr Lo 2. ce ur ove Pla yo 3. ess y rem Pr 4. refull Ca 5. 19 20 ON 1 OFF 0 0 0,5 1 4 8 118 1,5 CL 2 3 2 2,5 12 16 bar P908 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. ON/OFF Toggle Switch Power LED Pressure Gauge Stop Button Tall/Short Button & LEDS Cappuccino Button & LED Espresso Button & LED Latte Button & LED Special Button & LED Froth Button 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 6 Clean Frother Button & LED Steamed Milk Button Hot Water Button Frother Disconnect Assembly Group Head Filter Holder Syphon Tube, Milk Cup Tray Drip Tray Grate Drip Tray Wireform BUNN Espress® ADJUSTMENTS Model ES•1AF INFUSION Water The brewer is factory set to yield these approximate amounts of water: Short Coffee Volume - 1.5 oz (44 cc) Tall Coffee Volume - 1.8 oz (53 cc) To change the factory set amounts: 1. Place the program switch in the “Program” (right) position. The P912 program switch is located behind the switch/LED panel. See Fig. 1 FIG. 1 2. Place the desired quantity of pods into the appropriate filter holder (1 pod or 2 pod). Lock the filter holder into the group head. 3. Place a measuring vessel beneath the filter holder dripout. The amounts may be set from 0 to 500 cc. 4. Hold button of desired drink for three flashes, then release the button. 5. When enough coffee is dispensed hit button to stop coffee. This hit also starts milk flow. NOTE- To change steamed milk temperature adjust needle valve. Rotate counterclockwise to increase temperature, clockwise to decrease temperature. See Fig. 2 6. Hit button the third time to complete drink. NOTE- Three hits of button will program a milk drink, two hits of a button for espresso only. 7. Place the program switch in the “RUN” left position, when done. 4 F 2 C L 8 10 4 2 L 8 SM C 10 Air 1. Remove the three screws securing the top cover. Remove the top cover. P913 FIG. 2 CAUTION- The inside of this machine is very hot. C F 2 4 8 10 4 10 2 SM C 8 L L 2. To change the steamed milk adjustment, turn the knob closest to you marked “SM”. A lower number means less steam. See Fig. 3 3. To change the frothed milk adjustment, turn the knob farthest from you marked “F”. The adjustment is added to the “SM” adjustment, so any change made to “SM” will also change “F”. See Fig. 3 NOTE- Factory settings are SM-1; F-5. These settings are for 2% milk. FIG. 3 P909 3. The milk frother is designed to pull cold milk from counter height at the most. If milk will be pulled from below the counter, the metering jet at the end of the tube must be drilled out with a .125” drill. Make sure all burrs are removed. DO NOT use connector to lengthen the hose. The maximum height this frother will pull is 24.0” PREINFUSION- Refer to the DBC instruction manual for additional adjustments and settings. 7 BUNN Espress® OPERATION Model ES•1AF BREWING 1. Place a pod in the filter holder. 2. Lock the filter holder into the group head. Make sure it is tight. 3. Place an empty cup in position. The factory settings are for an 8 oz cup. NOTE- Install the cup tray, as shown in the operating controls illustration (Page 6). This can be used when brewing into shorter cups, or swung out of the way when using taller cups. The height may be adjusted by moving the slide up or down, as desired. 4. If brewing a milk based drink, place the milk supply hose in milk. 5. Press the button indicating your selection. NOTE- If you press the wrong selection, or want to stop brewing at any time, simply press the “STOP” button or any button on the panel. 6. Carefully remove the cup after the flow has stopped. WARNING - The milk supply hose and milk container must be refrigerated after use in compliance with state and local Health Codes. 7. Disconnect the milk supply hose from the frother assembly. 8. Place the milk supply hose into a separate storage container or secure it to the milk container being careful not to allow contamination by contact with other foods or the refrigeration storage compartment. DISPENSING HOT WATER OR FROTHED/STEAMED MILK 1. Place an empty cup in position. 2. Press the button indicating your selection. 3. Press any button to stop the cycle. CLEANING General 1. The use of a damp cloth rinsed in any mild, non-abrasive, liquid detergent is recommended for cleaning all surfaces on Bunn-O-Matic equipment. 2. Clean the gasket that seals the filter & group head, located under the group head. Ground coffee buildup on this gasket will result in a bad seal of the filter holder, and will leak brewed coffee onto the outside of the filter holder when brewing. This is why it is important to wipe excess coffee off of the rim of the filter prior to insertion of the group head. 3. Clean the drip tray components nightly. Remove the grate, wireform, drip tray and drain hose. Clean drain cup thoroughly. Wash the grate, wireform and drip tray thoroughly. Run clean water through the drain hose. Reinstall drain hose, drip tray, wireform and grate. Filter Cup 1. Place the pressure test cup into the filter holder. 2. Put a teaspoon of any granular espresso cleaner or automatic dish washing detergent into the filter cup. 3. Lock the filter holder into the group head, as if you were brewing coffee. 4. Press the expresso brew button and repeat for four cycles. 5. Remove the filter holder from the group head. 6. Rinse the group head thoroughly by repeating step 4 a few times without a filter holder installed. 7. Remove the cup filter and filter support wire from the filter holder. 8. Use a damp cloth rinsed in any mild non-abrasive liquid detergent to wipe the inside and outside surfaces of the cup filter, filter support wire and the filter holder. 9. Rinse all parts in hot water and reassemble. Insure your hands are clean before reassembling the filter holder. 10. Repeat steps 2 through 9 with the double cup filter. (Revised January 1996) 8 BUNN Espress® Model ES•1AF OPERATION Milk Frother NOTE- The milk frother parts need to be cleaned as described below at least every four to six hours depending upon use. See the DBC instruction manual for changing the clean warning alarm. It is factory set at 25 drinks. Daily Milk Frother Cleaning Instructions 1. Dispense 10 oz. of hot water from the espresso machine into a separate container. Add 1/2 packet Of Kay-5 sanitizing cleaner or any brand of sanitizing cleaner that contains 3%-5% chlorine based sanitizer. 2. Place milk supply hose into the container. 3. Push the frother clean button. The frother clean button must be actuated as many times as needed to empty the container. 4. After the container has been emptied, rinse the container out with hot water. 5. Dispense 10 oz. of hot water from the espresso machine into the container. 6. Repeat steps 2 and 3. 7. Rinse the frother by running clear water through it. Nightly Milk Frother Cleaning Instructions 1. Follow items 1 through 6 of the Daily Milk Frother Cleaning Instructions. 2. Loosen the frother disconnect assembly thumb screw (A) and gently tug downward on the frother assembly (B). 3. Remove the deflector tube (C), dispense tube (D) and focusing laminator (E). 4. Disconnect the milk supply hose assembly (F) and air tube assembly (G) from the venturi body assembly (H). 5. Remove the two end fittings from the milk supply hose assembly (F). 6. Remove the end fitting from the air tube assembly (G). 7. Remove the venturi body assembly (H). 8. Remove the steam tube (I) from the venturi body (H). 9. Remove the steam nozzle (J). 10. Thoroughly clean each part in accordance with local Health Department Codes, being careful not to damage any part. 11. Reassemble in reverse order, moisten all orings with clean water prior to assembly. I J G n clea ith g. g w allin o-rin inst et re t w befo Musater w N IO UT CA T HO -Sur Liqu id-S face s team milk NINGand ted WARhose gera ly refri with pp e s. su be ilk ust plianccode e m r m m th Th aine in co heal l nt co r use loca d aftee an stat ! F H E D A B C P910 9 (Revised June 1997) BUNN Espress® BREWING TIPS Model ES•1AF GENERAL Good espresso is identified by its taste, aroma, and the manner in which it is served. All of these elements can be improved-upon to serve your customers a better product. BEAN SELECTION The selection of a blend of coffee is a matter of personal choice. A blend with a high proportion of Central and/ or South American beans results in a beverage with a soft and agreeable flavor. A blend with a high proportion of African, Arabian, or Indonesian beans results in a beverage with a stronger flavor. BEAN STORAGE Roasted beans begin to lose their flavor and aroma shortly after roasting. It is not advisable to keep large quantities of coffee beans. Roasted beans should always be stored in an airtight container in a cool, dry place to retain these qualities for as long as possible. GRIND Make sure the grinder is functioning properly and delivering the correct grind. Place a small amount of ground coffee in the palm of your hand and spread it out. The particles should be small and for the most part, uniform in size. There should be almost no large grains. If the grind doesn’t look right, try adjusting the grinder. The true test of the grind, though, is when you brew. GROUND COFFEE STORAGE Do not store quantities of ground espresso coffee, even overnight. The use of freshly ground espresso coffee is always advisable for better flavor, extraction and aroma. ACCESSORIES & TOOLS Keep a supply of serving cups warming on top of the brewer, even when not a busy time. This assures the customer a hot cup of espresso each time. The cups will draw heat from the beverage if they are too thick. Mediumsized cups improve the presentation of the served beverage by allowing a slight amount of turbulence in the cup as the espresso falls from the filter holder. The crema can then rise easily to the surface. Store all mixing tools, ie: spoons, etc. in hot water so they will not draw the heat from the beverage. CLEANLINESS Keep all items used in the preparation of espresso and related beverages clean. It improves the presentation of the product served and it’s just a good sanitary practice. 10 BUNN Espress® ALARMS Model ES•1AF PROBLEMS When a fault occurs the following will happen: Fault 1 will appear on DBC screen. Power light will flash once every three seconds. This means a flowmeter error. Water is not flowing thru the flowmeter Fault 2 will appear on DBC screen. Power light will flash two flashes every three seconds. This means a refill error. The tank is not refilling with water fast enough. 11 WIRING DIAGRAM BUNN Espress® Model ES•1AF L1 N GRN BLK LIMIT T'STAT BLK LIMIT T'STAT PRESSURE SWITCH BLK BLK 1785W BLK K-N.O. WHI HOT WATER D I G I T A L B R E W E R C O N T R O L C I R C U I T B O A R D J2-1 J2-3 RED PUMP WHI WHI WHI TANK HEATER WHI BREW AIR WHI WHI SOL SOL PRIMARY STEAM SECONDARY STEAM SOL SOL SOL WHI J2-5 J2-7 J2-9 J2-11 J2-13 J2-15 BLK WHI/YEL WHI/RED ORA BLU WHI/BLU VIO WHI/ORA K WHI WHI REFILL WHI WHI SOL WHI J3-1 WHI GRN PNK J3-3 J3-5 J3-7 J3-9 J3-11 J3-13 J3-15 J3-17 J3-19 J3-21 J3-23 FLOW METER OUT + GRN - BLK RED GRY J3-25 J3-27 TANK LEVEL SENSING J3-29 P1 J3-31 J3-33 J3-35 J3-37 J3-39 VIO ORA BLU YEL WHI YEL P1 YEL P2 BLU P2 BLU P3 WHI P3 WHI P4 ORA P4 ORA P5 BLK P5 BLK P6 RED P6 RED 26564.0000B 11/95 © 1995 BUNN-O-MATIC CORPORATION 12 CONTROL PANEL, PROGRAM SWITCH, & DISPLAY INTERFACE 120 VOLTS AC 2 WIRE SINGLE PHASE