Download Mettler Toledo ID7-Base2000 Technical data

Transcript

Industrial Terminal

Technical Manual

15896200A

9/00.01

This manual describes the operation and functionality of the JAGXTREME terminal. The software number is

displayed during the power-up sequence.

Copyright 2000 Mettler-Toledo, Inc. This documentation contains proprietary information of Mettler-Toledo, Inc.

It may not be copied in whole or in part without the express written consent of Mettler-Toledo, Inc.

METTLER TOLEDO reserves the right to make refinements or changes to the product or manual without notice.

U.S. Government Restricted Rights Legend: This software is furnished with Restricted Rights. Use, duplication, or

disclosure of the Software by the U.S. Government is subject to the restrictions as set forth in subparagraph (C)

(1) (ii) of the Rights in Technical Data and Computer Software clause at 40 C.F.R. Sec. 252.227-7013 or in

subparagraphs (c) (1) and (2) of the Commercial Computer Software-Restricted Rights clause at 40 C.F.R. Sec.

52-227-19, as applicable.

CUSTOMER FEEDBACK

If you have a problem with this product, or just a suggestion on how we can serve you better, please fill out this form and send it to

us. Your feedback will help us to improve product performance, quality and service. Mail to the address on the reverse, or fax to

(614) 438-4355.

Your Name:

Organization Name:

Address:

Phone Number: (

E-mail Address:

)

Fax Number: (

How well did this product meet your

expectations in its intended use?

Met and exceeded my needs

Met all needs

Met most needs

Met some needs

Did not meet my needs

PROBLEM:

UNACCEPTABLE DELIVERY:

Shipped late

Shipped early

Shipped to incorrect location

Other (Please Specify)

)

Date:

Mettler Toledo Order Number

Part / Product Name:

Part / Model Number:

Serial Number:

Company Name of Installation:

Contact Name:

Phone Number:

Comments:

OUT OF BOX ERROR:

Wrong item

Wrong part

Missing equipment

Equipment failure

Wrong documentation

Missing documentation

Incorrectly calibrated

Other (Please specify)

Comments:

DO NOT WRITE IN SPACE BELOW; FOR METTLER TOLEDO USE ONLY

Retail

Light Industrial

RESPONSE: Include Root Cause Analysis and Corrective Action Taken.

Heavy Industrial

Systems

FOLD THIS FLAP FIRST

NO POSTAGE

NECESSARY IF

MAILED IN THE

UNITED STATES

BUSINESS REPLY MAIL

FIRST CLASS

PERMIT NO. 414

COLUMBUS, OH

POSTAGE WILL BE PAID BY ADDRESSEE

Mettler-Toledo, Inc.

Quality Manager - MTWI

1150 Dearborn Drive

Worthington, OH 43085

USA

Please seal with tape.

DECLARATION OF CONFORMITY

Konformitätserklärung

Déclaration de conformité

Declaración de Conformidad

Conformiteitsverklaring

Dichiarazione di conformità

We/Wir/Nous/Wij/Noi:

Mettler-Toledo, Inc.

1150 Dearborn Drive

Worthington, Ohio 43085

USA

declare under our sole responsibility that the product,

erklären, in alleiniger Verantwortung, daß dieses Produkt,

déclarons sous notre seule responsabilité que le produit,

declaramos, bajo nuestra sola responsabilidad, que el producto,

verklaren onder onze verantwoordelijkheid, dat het product,

dichiariamo sotto nostra unica responsabilitá, che il prodotto,

Model/Type:

Jaguar and JagXtreme

to which this declaration relates is in conformity with the following standard(s) or other normative document(s).

auf das sich diese Erklärung bezieht, mitder/den folgenden Norm(en) oder Richtlinie(n) übereinstimmt.

Auquel se réfère cette déclaration est conforme à la (aux) norme(s) ou au(x) document(s) normatif(s).

Al que se refiere esta declaración es conforme a la(s) norma(s) u otro(s) documento(s) normativo(s).

Waarnaar deze verklaring verwijst, aan de volende norm(en) of richtlijn(en) beantwoordt.

A cui si riferisce questa dichiarazione è conforme alla/e sequente/i norma/e o documento/i normativo/i.

in combination with a weighing platform produced by Mettler-Toledo is in conformity with the following directives and standards.

Council directive on the harmonization of the laws of the Member states:

standards:

relating to non-automatic weighing instruments (90/384/EEC) amended by

directive (93/68/EEC)

EN 45501

relating to electromagnetic compatibility (89/336/EEC) amended by directive

(93/68/EEC; 92/31/EEC)

EN 55022-1

relating to electrical equipment designed for use within certain voltage limits

(73/23/EEC amended by directive (93/68/EEC)

EN 60950

Worthington, Ohio USA,

May, 2000

Darrell Flocken, Manager - Weights & Measures

Office of Weights and Measures

Original issue:

Revised:

July, 1995

October, 1996

May, 2000

added compliance to Low Voltage Directive

added JagXtreme

Mettler-Toledo, Inc.

INTRODUCTION

This publication is provided solely as a guide for individuals who have received Technical Training in

servicing the METTLER TOLEDO product.

Information regarding METTLER TOLEDO Technical Training may be obtained by writing to:

METTLER TOLEDO

1900 Polaris Parkway

Columbus, Ohio USA 43240

Phone (US and Canada): 614-438-4511

Phone (International): 614-438-4888

FCC Notice

This device complies with Part 15 of the FCC Rules and the Radio Interference Requirements of the

Canadian Department of Communications. Operation is subject to the following conditions: (1) this device

may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be required to correct

the interference at his or her own expense.

ORDERING INFORMATION

It is most important that the correct part number is used when ordering parts. Parts orders are machine

processed, using only the part number and quantity as shown on the order. Orders are not edited to determine

if the part number and description agree.

COPYRIGHT

®

®

METTLER TOLEDO and JAGUAR are registered trademarks of Mettler-Toledo, Inc. JAGXTREME is a

trademark of Mettler-Toledo, Inc.

®

Allen-Bradley is a trademark of Allen-Bradley Company, Inc.

ARCnet™ is a trademark of Novell, Inc.

IPX™ is a trademark of Microsoft Corporation

All other brand or product names are trademarks or registered trademarks of their respective companies.

PRECAUTIONS

READ this manual BEFORE

operating or servicing this

equipment.

WARNING

DISCONNECT ALL POWER TO THIS UNIT BEFORE

INSTALLING, SERVICING, CLEANING, OR REMOVING THE

FUSE. FAILURE TO DO SO COULD RESULT IN BODILY

HARM AND/OR PROPERTY DAMAGE.

FOLLOW these instructions

carefully.

SAVE this manual for future

reference.

DO NOT allow untrained

personnel to operate, clean,

inspect, maintain, service, or

tamper with this equipment.

ALWAYS DISCONNECT this

equipment from the power

source before cleaning or

performing maintenance.

CALL METTLER TOLEDO for parts,

information, and service.

CAUTION

OBSERVE PRECAUTIONS FOR HANDLING

ELECTROSTATIC SENSITIVE DEVICES.

WARNING

ONLY PERMIT QUALIFIED PERSONNEL TO SERVICE THIS

EQUIPMENT. EXERCISE CARE WHEN MAKING CHECKS,

TESTS AND ADJUSTMENTS THAT MUST BE MADE WITH

POWER ON. FAILING TO OBSERVE THESE PRECAUTIONS

CAN RESULT IN BODILY HARM.

WARNING

FOR CONTINUED PROTECTION AGAINST SHOCK

HAZARD, CONNECT TO PROPERLY GROUNDED OUTLET

ONLY. DO NOT REMOVE THE GROUND PRONG.

CONTENTS

1

Introduction........................................................................................................................ 1-1

Model Identification............................................................................................................ 1-1

Accessories .............................................................................................................. 1-2

Specifications..................................................................................................................... 1-5

Display and Keypad .................................................................................................. 1-6

Physical Dimensions ................................................................................................. 1-7

Custom Applications................................................................................................ 1-11

Power Requirements................................................................................................ 1-11

Controller PCB ........................................................................................................ 1-12

Temperature and Humidity ....................................................................................... 1-12

Environmental Protection.......................................................................................... 1-12

Standards Compliance ...................................................................................................... 1-13

UL and cUL Listing .................................................................................................. 1-13

Weights and Measures Approval ............................................................................... 1-13

CE Conformity......................................................................................................... 1-13

Conducted and Radiated Emissions (RFI) .................................................................. 1-13

Radio Frequency Interference Susceptibility ................................................................. 1-14

AC Power Line Voltage Variation................................................................................ 1-14

2

Installation......................................................................................................................... 2-1

Unpacking and Inspection ................................................................................................... 2-1

Installing the General Purpose Model .................................................................................. 2-2

Installing the Panel Mount Model ........................................................................................ 2-3

Installing the Harsh Environment Enclosure.......................................................................... 2-4

Opening the Enclosure ............................................................................................... 2-4

Mounting the Enclosure.............................................................................................. 2-5

Electrical Connections ........................................................................................................ 2-5

Connect the Load Cell ................................................................................................ 2-5

Connect the Power Cable ......................................................................................... 2-13

Serial Port Connections— Controller PCB ................................................................... 2-15

Discrete Wiring ....................................................................................................... 2-18

Optional Multifunction I/O PCB Serial and Discrete Connections..................................... 2-19

Keyboard and Ethernet Connections ................................................................................... 2-20

JAGXTREME Terminal Jumper and Switch Settings ............................................................. 2-21

Controller ............................................................................................................... 2-21

Analog Load Cell..................................................................................................... 2-22

Single Channel Analog Load Cell............................................................................... 2-23

Dual Channel Analog Load Cell................................................................................. 2-24

Allen-Bradley RIO PCB ............................................................................................. 2-24

POWERCELL PCB.................................................................................................... 2-25

MMR (IDNET) PCB .................................................................................................. 2-26

Multifunction I/O PCB............................................................................................... 2-27

Installing Options ............................................................................................................. 2-27

Apply Power..................................................................................................................... 2-28

Power-up Sequence .......................................................................................................... 2-29

Scale Build Determination................................................................................................. 2-29

Minimum Increment Size for Bench and Portable Single DLC Scale Bases ...................... 2-29

Minimum Increment Size For Optional Analog Scale Input............................................. 2-29

Sample Calculation ................................................................................................. 2-31

Seal the Enclosure - Weights and Measures Applications .................................................... 2-31

Panel Mount Enclosure ............................................................................................ 2-31

General Purpose Enclosure....................................................................................... 2-32

Harsh Environment Enclosure ................................................................................... 2-32

3

Programming and Calibration.............................................................................................. 3-1

General Information............................................................................................................ 3-1

Style Conventions...................................................................................................... 3-1

Front Panel Display ................................................................................................... 3-1

Key Functions........................................................................................................... 3-2

Accessing Setup........................................................................................................ 3-2

Navigating ............................................................................................................... 3-3

Audible Messages ..................................................................................................... 3-3

Reset to Factory ........................................................................................................ 3-4

Configuring JAGXTREME Terminals With Multiple Scales and a Summing Scale ................ 3-4

Program Block Overview ..................................................................................................... 3-6

Scale Interface Program Block............................................................................................. 3-7

1. Market Sub-block .................................................................................................. 3-8

2. Scale Type Sub-block ............................................................................................ 3-8

3. Calibration Unit Sub-block .................................................................................... 3-10

4. Capacity Sub-block ............................................................................................. 3-10

5. Increment Size Sub-block ..................................................................................... 3-11

6. Shift Adjustment Sub-block ................................................................................... 3-12

7. Linearity Correction Sub-block............................................................................... 3-12

8. Calibration Sub-block .......................................................................................... 3-12

9. Zero Adjustment Sub-block ................................................................................... 3-13

10. Span Adjustment Sub-block................................................................................ 3-14

11. Add in Sum ...................................................................................................... 3-14

12. Gravity Adjustment Sub-block ............................................................................. 3-14

13. Reset to Factory Sub-block ................................................................................. 3-14

Service Mode for MMR (IDNET) Bases ............................................................................... 3-15

NATION Program Sub-block...................................................................................... 3-15

RESET Program Sub-block ....................................................................................... 3-15

SCALE PARAMETERS Program Sub-block ................................................................... 3-16

LINEARITY Program Sub-block .................................................................................. 3-16

CALIBRATION Program Sub-block.............................................................................. 3-17

SAVE PARAMETERS Program Sub-block ..................................................................... 3-17

RETURN Program Sub-block..................................................................................... 3-17

Application Environment Program Block ............................................................................. 3-18

1. Character Set Sub-block ....................................................................................... 3-19

2. Language Sub-block............................................................................................ 3-19

3. Keyboard Type Sub-block..................................................................................... 3-19

4. Scale ID Sub-block .............................................................................................. 3-20

5. Time and Date Sub-block ..................................................................................... 3-20

6. Alternate Weight Units Sub-block ........................................................................... 3-21

7. Power Up Operation Sub-block ............................................................................. 3-23

8. Tare Operation Sub-block ..................................................................................... 3-23

9a. Zero Operation Sub-block ................................................................................... 3-25

9b. Zero Operation Sub-block for MMR (IDNET) Bases................................................ 3-26

10a. Stability Detect Sub-block ................................................................................. 3-26

10b. Stability Detect Sub-block for MMR (IDNET) Bases............................................... 3-27

11. Beeper Operation Sub-block ............................................................................... 3-27

12. Inhibit Memory Sub-Block .................................................................................. 3-27

13. Application Type Sub-block ................................................................................ 3-28

14. Vibration Rejection Sub-block ............................................................................. 3-28

14a. Vibration Rejection Sub-block for MMR ............................................................... 3-30

Serial Interface Program Block .......................................................................................... 3-31

1. Configure Port Sub-block...................................................................................... 3-32

2. Configure Template Sub-Block .............................................................................. 3-37

Configure Discrete Program Block ..................................................................................... 3-41

1. Discrete Inputs Sub-block..................................................................................... 3-42

2. Discrete Outputs Sub-block................................................................................... 3-43

3. Assign Setpoints Sub-block .................................................................................. 3-44

Configure Memory Program Block...................................................................................... 3-45

1. Configure Literals Sub-block ................................................................................. 3-45

2. Configure Prompts Sub-block ............................................................................... 3-46

3. Configure Consecutive Numbering Sub-block.......................................................... 3-47

Configure JagBASIC Program Block ................................................................................... 3-48

1. Keyboard Sub-block ............................................................................................ 3-48

2. Display Sub-block ............................................................................................... 3-49

3. Auto Start Sub-block ............................................................................................ 3-49

4. Manual Start Sub-block........................................................................................ 3-49

5. Send RAM Files Sub-block.................................................................................... 3-50

6. Initialize RAM Disk Sub-block................................................................................ 3-50

7. Password Maintenance Sub-block......................................................................... 3-50

Configure Network Program Block...................................................................................... 3-51

Network Overview............................................................................................................. 3-52

General Networking Considerations ................................................................................... 3-53

IP addresses .......................................................................................................... 3-53

Clustering JAGXTREME Terminals...................................................................................... 3-54

1. Ethernet ............................................................................................................. 3-62

2. Modem .............................................................................................................. 3-63

3. Name-Password ................................................................................................. 3-63

4. PPP .................................................................................................................. 3-63

5. Cluster IP ........................................................................................................... 3-64

6. PC Data Access .................................................................................................. 3-64

7. Email................................................................................................................. 3-64

8. Web Server......................................................................................................... 3-65

9. FTP Server.......................................................................................................... 3-65

10. PLC SP Control Sub-block .................................................................................. 3-65

Diagnostics Program Block................................................................................................ 3-66

1. Memory Test Sub-block........................................................................................ 3-67

2. Display Test Sub-block ........................................................................................ 3-67

3. Keyboard Test Sub-block...................................................................................... 3-67

4. Scale Test Sub-block ........................................................................................... 3-68

5. Serial Test Sub-block ........................................................................................... 3-71

6. Parallel I/O Test Sub-block ................................................................................... 3-72

7. Network Test Sub-block........................................................................................ 3-73

8. Ethernet Send BRAM Sub-block ............................................................................. 3-73

9. Zmodem Send BRAM Sub-block............................................................................ 3-74

10. Print Setup Sub-block ........................................................................................ 3-74

11. Reset to Factory Sub-block ................................................................................. 3-75

Options Program Block...................................................................................................... 3-76

Maintenance .................................................................................................................... 3-77

1. Calibration Management ...................................................................................... 3-78

2. Calib Chk Parms................................................................................................. 3-79

3. Calib Mon Parms ................................................................................................ 3-80

Predictive Failure (Only for RAAD Box and POWERCELL Platforms) ............................... 3-82

Calibrate Check....................................................................................................... 3-83

Maintenance Reports ............................................................................................... 3-84

Network Stats ......................................................................................................... 3-84

Reset to Factory ...................................................................................................... 3-84

4

Programming and Calibration Using the Web Server............................................................. 4-1

System Requirements ......................................................................................................... 4-1

Navigation Bar Menu .......................................................................................................... 4-1

Home ...................................................................................................................... 4-2

Scale ....................................................................................................................... 4-3

Application ............................................................................................................... 4-3

Terminal .................................................................................................................. 4-4

Communication ........................................................................................................ 4-4

Maintenance............................................................................................................. 4-5

Documentation ......................................................................................................... 4-6

Help ........................................................................................................................ 4-6

5

Installing and Launching JagXFILES ..................................................................................... 5-1

Installing JagXFILES ........................................................................................................... 5-1

Browser and JAGXTREME Setup........................................................................................... 5-1

Operating JagXFILES........................................................................................................... 5-1

Menu Items........................................................................................................................ 5-2

Open ....................................................................................................................... 5-2

Save........................................................................................................................ 5-2

Restore .................................................................................................................... 5-2

Backup .................................................................................................................... 5-2

All Other Menu Items.................................................................................................. 5-2

6

JAGXTREME Terminal Operations......................................................................................... 6-1

Overview............................................................................................................................ 6-1

Keypad Operation ............................................................................................................... 6-1

Alphabetic and Special Character Entry ........................................................................ 6-2

Using a PC Keyboard ................................................................................................ 6-2

Normal Operating Mode ...................................................................................................... 6-3

Operator Functions.............................................................................................................. 6-3

Zero the Scale........................................................................................................... 6-3

Tare Operations ........................................................................................................ 6-4

Print Operations ........................................................................................................ 6-6

MEMORY Key Operations ........................................................................................... 6-7

FUNCTION Key Operations.......................................................................................... 6-9

Scale Selection........................................................................................................ 6-10

7

Service and Maintenance .................................................................................................... 7-1

Tools and Supplies ............................................................................................................. 7-1

Cleaning and Regular Maintenance...................................................................................... 7-1

Troubleshooting.................................................................................................................. 7-1

Status Lights............................................................................................................. 7-2

Error Codes and Actions...................................................................................................... 7-2

Diagnostic Tests ............................................................................................................... 7-18

AC Power Test ........................................................................................................ 7-18

Voltage Test............................................................................................................ 7-18

Backup Battery Test ................................................................................................. 7-20

Ground Test............................................................................................................ 7-21

External Equipment Test ........................................................................................... 7-21

Internal Testing ....................................................................................................... 7-21

20 mA /RS-232 Printer Tests .................................................................................... 7-21

Replacing the Power Supply .............................................................................................. 7-22

Replacing the Battery Back-up ........................................................................................... 7-23

8

Parts and Accessories......................................................................................................... 8-1

Panel Mount Parts .............................................................................................................. 8-2

General Purpose Parts (Front View) ..................................................................................... 8-4

General Purpose Parts (Rear View)...................................................................................... 8-6

Harsh Environment Parts..................................................................................................... 8-7

Line Cord Assemblies ......................................................................................................... 8-9

Controller PCB ................................................................................................................. 8-10

Analog Load Cell PCB ....................................................................................................... 8-11

Dual Analog Load Cell PCB ............................................................................................... 8-12

Power Supply ................................................................................................................... 8-13

Allen-Bradley RIO Option................................................................................................... 8-14

PROFIBUS Option.............................................................................................................. 8-15

MODBUS Plus PCB ........................................................................................................... 8-16

Dual Analog Output Option ................................................................................................ 8-17

POWERCELL PCB .............................................................................................................. 8-18

Multifunction PCB............................................................................................................. 8-19

High Precision (IDNET) PCB .............................................................................................. 8-20

Optional Accessories ........................................................................................................ 8-21

Optional Panels ................................................................................................................ 8-22

Recommended Spare Parts ............................................................................................... 8-22

9

Appendices ........................................................................................................................ 9-1

Appendix 1: Serial Interface Reference ................................................................................ 9-1

Hardware Connections............................................................................................... 9-2

Output Modes and Formats ........................................................................................ 9-3

Standard Status Bytes A, B, and C............................................................................... 9-4

4-Setpoint Status Bytes A, B, and C ............................................................................. 9-5

Multi Cont 1 ............................................................................................................. 9-7

Multi Cont 2 ............................................................................................................. 9-8

Default Template Formats......................................................................................... 9-10

Input Modes ........................................................................................................... 9-13

ASCII Characters ..................................................................................................... 9-18

Appendix 2: Discrete I/O Reference.................................................................................... 9-22

Inputs .................................................................................................................... 9-22

Outputs.................................................................................................................. 9-23

Appendix 3: Network Reference......................................................................................... 9-24

Keyboard/Display Sharing ........................................................................................ 9-24

Redirecting Serial Output .......................................................................................... 9-25

A-B RIO / PROFIBUS / MODBUS+ Option Sharing......................................................... 9-26

Appendix 4: Loading JAGXTREME Software ........................................................................ 9-26

Flash the Software ................................................................................................... 9-26

Appendix 5: JAGXTREME Default Values ............................................................................ 9-30

Appendix 6: Gravity Factors............................................................................................... 9-37

Appendix 7: Multiple Range and Multi-Interval Operation.................................................... 9-38

Multiple Range Operation ......................................................................................... 9-38

Multi-Interval Operation ............................................................................................ 9-39

Appendix 8: Market Destination (Finish) Codes .................................................................. 9-41

Chapter 1: Introduction

Model Identification

1

Introduction

Model Identification

The JAGXTREME Internet-enabled scale terminal is designed to help companies provide

cost-effective, flexible methods of production while maximizing engineering time and

effort. It offers connectivity to all METTLER TOLEDO technologies, as well as open

connectivity to the leading industry technologies, to facilitate communication and data

exchange with companies’ control, manufacturing execution, and enterprise systems.

The JAGXTREME terminal is available with various operator interfaces and enclosure

types. Please refer to the following Factory Number Reference chart to identify the

JAGXTREME terminal with which you will be working. A detailed description of each

designation is given to help you determine the specifications for each model. A brief

description of the optional accessories appears on the next page.

If you are upgrading an existing METTLER TOLEDO JAGUAR terminal to a new

JAGXTREME terminal, refer to the instructions provided with your upgrade kit.

For users of the JAGXTREME terminal’s predecessor, METTLER TOLEDO’s JAGUAR

terminal, please pay special attention to the programming and calibration section.

Programming and calibration of the JAGXTREME terminal can be performed via the

embedded web server as well as through the front panel of the unit.

FACTORY NUMBER REFERENCE CHART

JAGXTREME TERMINAL MODEL CONFIGURATION

Example: JXPB-1600-000

JX

Terminal

JAGXTREME

Terminal

XX

Enclosure

Display

PB=Panel, Blind

PA=Panel, A/N

GA=General

Purpose A/N

HA=Harsh, A/N

X

Slot #1

Accessory

0=Cover Plate

1=Analog Scale

2=R E* Analog Scale

3=POWERCELL

4=MMR Base

7=Multifunction I/O

A=Dual Analog Scale

B=Dual R E* Analog

Scale

X

Slot #2

Accessory

0=Cover Plate

1=Analog Scale

2= R E*Analog Scale

3=POWERCELL

4=MMR Base

7=Multifunction I/O

A=Dual Analog Scale

B=Dual R E Analog

Scale

X

Slot #3

Accessory

0=Cover Plate

5=Modbus Plus

6=Allen Bradley RIO

7=Multi-function I/O

8=Dual Channel

Analog Output

9=PROFIBUS DP

X

Application

Software

0=Standard

JagBASIC

(included)

XXX

Destination

Market

000=USA

See the Market

Codes in the

Appendix for

additional

destination

codes

* RE – Reduced Excitation. JAGXTREME terminals with harsh environment enclosures

are not approved for use in hazardous areas.

(9-00)

1-1

METTLER TOLEDO JAGXTREME Terminal Technical Manual

Accessories

A number of accessories are available for the JAGXTREME terminal. Please contact your

authorized METTLER TOLEDO representative for more detailed information.

Cover Plate (0)

This thin metal plate is used to cover the opening in the back of the regular or blind

chassis panel-mount JAGXTREME terminal if an optional PCB is not installed at this

location.

Analog Scale (1)

This option is required when interfacing analog type load cells. A 15-volt excitation

voltage is used to power up to 16 350-ohm load cells from one Analog PCB. A jumper

is provided to select operation with 2 mV/V or 3 mV/V load cells. The JAGXTREME

terminal will operate with load cells of impedances other than 350 ohms or other mV/V

specifications, but the total scale resistance must not be less than 22 ohms. A quiet

analog signal section, combined with a proprietary analog-to-digital converter and

coprocessor implementing METTLER TOLEDO proprietary TraxDSP filters, provides

weighing and vibration rejection performance unequaled in the industry.

The zero temperature coefficient is 0.15 µV/degree C. The span temperature coefficient is

6 ppm/degree C. When using the analog scale option, the display update rate is limited

to 10 updates per second. The actual A/D conversion rate exceeds 300 cycles per

second. This high-speed process allows the JAGXTREME terminal to filter out noise while

providing a weight update rate of up to 50 updates per second for setpoint control and

other scale functions.

Each analog scale option board has a removable EEPROM that stores calibration

parameters for the scale. If an EEPROM is transferred to another board, all calibration

parameters transfer. A detachable seven-position terminal strip is used to terminate the

analog load cell cable on the rear of the PCB. Signal, excitation, sense, and shield

connections are provided with easy-to-read descriptions. Two LEDs are visible through

holes in the rear panel of the PCB to indicate the status of the Analog PCB.

Reduced Excitation Analog Scale (2)

This option, when used with a protective load cell barrier, allows operation of the

JAGXTREME terminal with analog load cells located in an area classified as hazardous

by the National Electrical Code. The excitation voltage is lowered to 5 volts for this

option. A METTLER TOLEDO Reduced Excitation module is required for these

applications. The standard JAGXTREME terminal cannot be located inside the hazardous

area. Purged enclosures are available from METTLER TOLEDO.

The zero temperature coefficient is 0.15 µV/degree C. The span temperature coefficient is

6 ppm/degree C. When using the analog scale option, the display update rate is limited

to 10 updates per second. The actual A/D conversion rate exceeds 300 cycles per

second. This high-speed process allows the JAGXTREME terminal to filter out noise while

providing a weight update rate of up to 50 updates per second for setpoint control and

other scale functions.

Each analog scale option board has a removable EEPROM that stores calibration

parameters for the scale. If an EEPROM is transferred to another board, all calibration

parameters transfer as well. A detachable seven-position terminal strip is used to

terminate the analog load cell cable on the rear of the PCB. Signal, excitation, sense,

and shield connections are provided, each with an easy-to-read description. Two LEDs

are visible through holes in the rear panel of the PCB to indicate its operating status.

1-2

(9/00)

Chapter 1: Introduction

Model Identification

POWERCELL (3)

The POWERCELL interface must be used when the JAGXTREME terminal is used with a

METTLER TOLEDO load cell. The POWERCELL I/O option supports up to 24 cells (an

external power supply is needed for scales with more than 14 cells). The POWERCELL

I/O PCB can be used with the METTLER TOLEDO Hazardous Area Barrier Box. Please

contact your METTLER TOLEDO representative for more information about applications in

hazardous environments.

MMR (IDNET) (4)

The IDNET Interface Module allows you to interface a METTLER TOLEDO Multi-Range

base or lab balance with IDNET option with the JAGXTREME terminal. When utilizing this

interface, the JAGXTREME terminal acts as a “front end” for the base. Setup and

calibration of the base is identical to the procedure used by the ID family of indicators.

Scale related information is stored in the scale base as well as the JAGXTREME terminal,

allowing its access by external devices such as a PLC.

Modbus Plus (5)

The Modbus Plus interface enables the terminal to directly interface with Modbus Plus

devices such as PLCs manufactured by MODICON. The JAGXTREME terminal interface

acts as a single Modbus Plus node, which can support up to four scales, and has been

fully certified by the Modicon Test Center.

Allen-Bradley RIO (6)

This option allows the JAGXTREME terminal to exchange data with an Allen-Bradley PLC

like a remote 1771 module on the Allen-Bradley remote I/O. A direct connection to an

Allen-Bradley controller is possible via this “blue hose” connection. If the terminal has

two or more scales installed, all share the same RIO option board. If multiple terminals

are combined in a “cluster” using Ethernet, up to four scales can share the RIO option.

Each scale requires one-quarter rack of RIO address space. JAGXTREME terminals

support quarter rack addressing.

JAGXTREME terminals support discrete and block transfer modes of data interface. Both

are bi-directional. Discrete mode is used for data, status, and command exchange.

Block transfer allows more extensive data exchange and allows the PLC to write

messages to the terminal’s lower alphanumeric display. Connection to the RIO option is

made via a detachable three-position terminal strip on the rear of the RIO option.

Multifunction I/O (7)

The Multifunction PCB option expands the number of serial and discrete input and output

ports supported by the JAGXTREME terminal. The Multifunction PCB adds two serial

ports. COM3 can be used for RS-232 communications. COM4 can be used for RS-232

or RS-422/RS-485 communications. COM4 can be used for a single DigiTOL or

UltraRes understructure interface. The Multifunction PCB adds eight programmable

discrete inputs (PAR 3). Eight programmable discrete outputs (PAR 4). PAR 3 and PAR

4 assignments are user-configurable.

Dual Channel Analog Output (8)

The Analog Output Module provides two channels of analog output, one for each of up

to two scales connected to the terminal. The channels may be selected to provide either

a 0 to 10 V or a 4 to 20 mA analog output signal. The output is the result of a 16-bit

digital to analog conversion.

(9-00)

1-3

METTLER TOLEDO JAGXTREME Terminal Technical Manual

PROFIBUS Interface (9)

The JAGXTREME terminal with the PROFIBUS Interface Module is a fully L2-DP compliant

device which can be used with a wide range of PROFIBUS compatible devices. This

module provides the process control engineer with the ability to access weight

information, status of the scale, and to download a setpoint or tare weight. The Profibus

option has been fully certified by the Siemens Profibus Test Center.

Dual Analog Scale (A)

An analog scale option is required when interfacing analog type load cells. A 15-volt

excitation voltage is used to power up to 16 350-ohm load cells from one analog

channel. The dual channel card can support a maximum of 20 load cells. A jumper is

provided to select operation with either 2mV/V or 3mV/V load cells. The JAGXTREME

terminal will operate with load cells of impedances other than 350 ohms or other mV/V

specifications, but the total scale resistance must not be less than 22 ohms.

A quiet analog signal section, combined with a proprietary analog-to-digital converter

and co-processor that use METTLER TOLEDO’s proprietary TraxDSP filters, provides

weighing and vibration rejection performance unequaled in the industry. The zero

temperature coefficient is 0.15 uV/degree C. The span temperature coefficient is 6

ppm/degree C.

When using the analog scale option, the display update rate is limited to 10 updates per

second. The actual A/D conversion rate exceeds 300 cycles per second. The high-speed

process allows the terminal to filter out noise while providing a weight update rate up to

50 updates per second for setpoint control and other functions.

The dual channel analog scale option board has a removable EEPROM for each scale

channel that stores calibration parameters for that scale channel. If an EEPROM is

transferred to another board, all calibration parameters transfer as well.

A detachable seven-position terminal strip is used to terminate each analog load cell

cable on the rear of the PCB. Signal, excitation, sense, and shield connections are

provided with easy-to-read descriptions. Two LEDs are visible through holes in the rear

panel of the PCB to indicate the status of the Analog PCB. The JAGXTREME terminal

supports up to two dual analog scale cards.

Reduced Excitation Dual Analog Scale (B)

The analog scale option is used with a protective load cell barrier to permit operation of

the JAGXTREME terminal with analog load cells located in an area classified as

hazardous by the National Electrical Code. The excitation voltage is lowered to 5 volts

for this option. A METTLER TOLEDO Reduced Excitation module is required for these

applications. The standard JAGXTREME terminal cannot be located inside the hazardous

area as is. Purged enclosures are available from METTLER TOLEDO if the terminal must

be located inside the hazardous area. Note: The Reduced Excitation module can only

support up to 12 analog load cells or a total resistance of 58 ohms.

Jumpers are provided to select operation with 2mV/V or 3mV/V load cells. The terminal

will operate with load cells of impedances other than 350 ohms or other mV/V

specifications, but the total scale resistance must not be less than 22 ohms.

The zero temperature coefficient is 0.15 uV/degree C. The span temperature coefficient is

6 ppm/degree C. When using the analog scale option, the display update rate is limited

to 10 updates per second. The actual A/D conversion rate exceeds 300 cycles per

second. The high-speed process allows the JAGXTREME terminal to filter out noise and

still provide a weight update rate up to 50 updates per second for setpoint control and

other scale functions.

1-4

(9/00)

Chapter 1: Introduction

Specifications

The dual channel analog scale option board has a removable EEPROM for each scale

channel that stores calibration parameters for that scale channel. If an EEPROM is

transferred to another board, all calibration parameters transfer as well.

A detachable seven-position terminal strip is used to terminate each analog load cell

cable on the rear of this PCB. Signal, excitation, sense, and shield connections are

provided, each with an easy-to-read description. Two LEDs are visible through holes in

the rear panel of this PCB to indicate the status of the Analog PCB. The JAGXTREME

terminal will support one or two Reduced Excitation dual analog scale cards.

Specifications

Model

Dimensions

Construction

Mounting Options

Degree of

Protection

Ethernet

Connection

Attachable

Platforms

Display

Keypad

Interfaces

A/D Rate

Digital

Input/Output

Maintenance

Monitoring

Signal Processing

Power

Requirements

Setup

Scripting

Language

Operating

Temperature

Storage

Temperature

Options

Approvals

General Purpose

12.45 in (25 cm) wide x 7.86

in (20 cm) high x 10.6 in (27

cm) deep

Column, desktop

NEMA 4

Panel Mount

10.05 in (25.5 cm) x 5.6 in

(14 cm) at front of terminal

9.5 in (24 cm) x 4.91 in (12.5

cm) at the rear

8.03 in (21 cm) deep

Aluminum

Panel

NEMA 4 (front panel)

Panel Mount – Blind Chassis

10.75 in (27 cm) x 4.31 in

(10.9 cm) at base

10.25 in (26 cm) x 3.91 in

(10 cm) c-c mounting

9.5 in (24.1 cm) x 5.00 in (13

cm) chassis

Harsh Environment

12.62 in (32.1 cm) x 8.03 in

(21 cm) x 9.3 in (23.6 cm)

Blind panel

NEMA 1

Stainless steel

Wall, column

NEMA 4X (IP65)

10BASE-T. Uses crossover cable from RJ-45 Ethernet port on the back of the JAGXTREME terminal to a PC (point to-point connection) or

standard cable to connect to other equipment through a hub.

4 analog or 4 POWERCELL or 2 High Precision or 2 DigiTOL

Two vacuum fluorescent displays. Upper display: 7 segment 0.5" (13 mm); lower display: 16-character, 5 x 7 dot matrix display 0.25"

(6 mm)

4 x 5 matrix tactile-feel keypad with 0-9, letters A-Z, and function keys

Ethernet, serial, discrete, PLC, analog, network

>300 per second

Maximum 12 in/12 out

TraxEMT Embedded Maintenance Technician system for self-diagnosis and predictive failure analysis

TraxDSP three-stage filtering

85 to 264 VAC with a line frequency of 47 to 63 Hz

Via embedded web server, with the front keypad or using the JagXFILES tool box.

JagBASIC (standard)

14° F to 113° F (-10° C to 45° C) at 10% to 95% relative humidity, non-condensing

40° F to 140° F (-40° C to 60° C) at 10% to 95% relative humidity, non-condensing

Analog, Dual Analog, Analog Reduced Excitation Dual Analog Reduced Excitation Dual Analog Output, Modbus Plus, Profibus, A-B RIO,

Multifunction I/O, IDNet, POWERCELL, PCJagBASIC EDITOR

CE Conformity

90/384/EU – Non-automatic Balances and Scales

EN45501:1992 – Adopted European Standard

Weights and Measures (US)

Class III or IIIL devices

NTEP Certificate of Conformance No. 94-096

Weights and Measures (Australia)

Class III and IIIL non-automatic weighing instruments as defined in the National Standards Commission, Document 100

(9-00)

1-5

METTLER TOLEDO JAGXTREME Terminal Technical Manual

Display and Keypad

Alpha-numeric Display (xA)

The front of the JAGXTREME terminal contains two vacuum fluorescent displays and a 4

× 5 matrix tactile feel keypad in a diecast, zinc-aluminum alloy front housing.

The upper weight display is a seven-digit, seven-segment 0.5 in. (13 mm) high

vacuum fluorescent numeric display used to indicate weight values. Each of the seven

digits has a decimal point/comma and an annunciator associated with it. The

annunciators are used to indicate gross or net weights, a preset tare value, pound or

kilogram weights, the center of zero, and motion.

The lower display is a 16-character, 5×7 dot matrix, 0.25 in. (6 mm) high vacuum

fluorescent alphanumeric display. Each character has a period/comma and an

annunciator associated with it. This display is used to indicate tare, alternate weight

units, operator prompting, errors and other messages. The first 10 annunciators are

used to indicate which terminal number (1 through 6) and internal scale (A-D) are

currently displayed. The remainder indicates summation and weighing range.

The lens on both the general purpose and panel mount model lens are polycarbonate

with hardcoating. The harsh environment model lens is polyester with hardcoating.

The keypad consists of a tactile-feel membrane switch covered with a polyester overlay.

It is designed to give the operator positive feedback when pressing a key. Audible beeps

can be enabled to verify key depressions.

The keypad contains the numbers 0 -9 and the letters A - Z. Other function keys include

Escape, Memory, Tare, Select, Clear, space, decimal point, Zero, Enter, and Function.

These keys allow access to operator prompting, setup, and many other scale functions.

1-a: Display and keypad on panel-mount version of the JAGXTREME

1-6

(9/00)

Chapter 1: Introduction

Specifications

Physical Dimensions

Panel Mount Enclosure— Alpha-numeric (PA)

Two integral brackets are used to mount this unit through a flat panel. The front panel

and associated panel clamping mechanism are designed to provide a NEMA 4 (IP65)

seal and accommodate a panel thickness from 16 to 11 gauge.

The panel-mount model measures:

10.05 in. (25.5 cm) × 5.6 in. (14 cm) at the front of the terminal

9.5 in. (24 cm) × 4.91 in. (12.5 cm) at the rear

8.03 in. (21 cm) deep

4XR 0.25±.01

OPEN

Abra

5.12±.0

9.58±.06

Figure 1-b: JAGXTREME Panel Mount Model and Cutout Dimensions

(9-00)

1-7

METTLER TOLEDO JAGXTREME Terminal Technical Manual

Panel Mount Enclosure— Blind Chassis (PB)

The front of the panel mount enclosure has a blank plate to cover the electronics and to

provide a method of mounting. There is no keyboard or display on the front of the unit.

This allows the terminal’s use as a “blind” terminal (installed behind a panel,) sharing

another JAGXTREME terminal’s keyboard and display via the Ethernet connection. The

terminal enclosure designed to NEMA 1 or IP30 requirements with a “blind” front panel.

The blind chassis mount model measures:

!

10.75 in. (27 cm) × 4.31 in. (10.9 cm) at the base

!

10.25 in. (26 cm) × 3.91 in. (10 cm) c-c mounting

!

9.5 in. (24.1 cm) × 5.00 in. (13 cm) chassis

Figure 1-c: JAGXTREME Blind Chassis Model Dimensions

1-8

(9/00)

Chapter 1: Introduction

Specifications

General Purpose Enclosure (GA)

This enclosure, which provides NEMA 4 (IP65) protection, is a die-cast zinc-aluminum

alloy with an aliphatic urethane powder-coated finish. The unit is designed to sit on a

flat surface or may be wall- or column-mounted with an accessory bracket kit (09170209). The rear cover contains grip bushings to seal all cables entering the enclosure.

The general-purpose JAGXTREME terminal model measures:

12.45 in. (25 cm) wide × 7.86 in. (20 cm) high x 10.6 in. (27 cm) deep

In figure 1-d, the top views show optional wall/column brackets (P/N 0917-0209).

12.45

12 4

12.31

12 3

29°

2 °

115°

°

11

10.05

10 0

39°

3 °

7.85

78

10.59

10 5

Figure 1-d: JAGXTREME General Purpose Model Dimensions

(9-00)

1-9

METTLER TOLEDO JAGXTREME Terminal Technical Manual

Harsh Environment Enclosure (HA)

The harsh environment enclosure provides NEMA 4X (IP65) protection and is intended

for applications in which the terminal is exposed to high humidity, direct washdown, or

corrosive environments. It is constructed of 304L stainless steel and meets all US FDA

and comparable European requirements.

A full 4-slot JAGXTREME terminal chassis is mounted inside the enclosure. All field

wiring enters into the unit through cable seals that maintain the washdown protection of

the enclosure. The cable seals are located at the bottom rear of the unit. Two brackets

are provided for wall mount applications. An interface adapter (0917-0233) is available

for column mount applications.

The harsh environment enclosure model measures: 12.62 in (32.1 cm) x 8.03 in (21

cm) x 9.3 in (23.6 cm)

12.62

8.25

0.50

11.62

11.12

0.84

0.56

ABC

7

JKL

4

STU

1

$#%

0

DEF

8

MNO

5

VWX

2

-/=

GHI

9

PQR

6

YZ?

3

*()

SP

FUNCTI

F

MEMO

M

SELE

S

ZER

ESC

TA

T

CLE

C

5.75

9.42

ENT

0

* Shown with wall mount brackets

(included with enclosure) installed.

Figure 1-e: Harsh Environment Model Dimensions

1-10

(9/00)

Chapter 1: Introduction

Specifications

Custom Applications

JagBASIC

JagBASIC provides for the development of easy-to-use custom applications. JagBASIC

programs reside along side the standard JAGXTREME terminal program. The JagBASIC

interpreter runs as a separate task using the terminal’s multi-tasking operating system.

This allows the custom JagBASIC program to interact with the other JAGXTREME terminal

tasks and resources using the terminal’s exclusive shared memory design. For example,

to monitor a scale gross weight, the JagBASIC program relates a BASIC variable to the

terminal shared data variable for gross weight then uses the BASIC variable as desired.

All of the shared memory in the terminal may be accessed by the JagBASIC program

using this construct.

The high level of integration permits the programmer to exploit the standard functions in

the JAGXTREME terminal, making it easier to implement solid solutions in record time.

To print a standard ticket or report, a JagBASIC program can load data into a

JAGXTREME terminal shared data variable then print by using a standard template that

is designed in the terminal setup. Rather than monitoring setpoint coincidence in the

JagBASIC program, a standard setpoint shared data variable can be loaded in the

program then monitored by an associated JAGXTREME terminal scale task.

Power Requirements

!

85 to 264 VAC with a line frequency of 47 to 63 Hz.

!

Power consumption -- 20 Watts maximum.

!

Power termination -- single three-position removable terminal strip.

!

The wire size range -- 16 to 12 AWG.

Note: The integrity of the power ground for equipment is important for both safety and

dependable operation of the JAGXTREME terminal and it’s associated scale bases. A

poor ground can result in an unsafe condition if an electrical short develops in the

equipment. A good ground connection is needed to assure extraneous electrical noise

pulses are minimized. It is important that equipment does not share power lines with

noise generating equipment like heavy load switching, motor starter circuits, RF thermal

heaters, inductive loads and the like.

To confirm ground integrity, a commercial branch circuit analyzer is recommended. This

instrument uses a high amperage pulse to check ground resistance. It measures the

voltage from the neutral wire to the ground connection and will provide an assessment

of the line loading. Instructions with the instrument give guidelines about limits that

assure good connections. Visual inspections and a query of the user will provide

information about equipment sharing the power line.

The power line for the JAGXTREME terminal must not be shared with equipment such as

motors, relays, or heaters that generate line noise. If adverse power conditions exist, a

dedicated power circuit or power line conditioner may be required.

(9-00) 1-11

METTLER TOLEDO JAGXTREME Terminal Technical Manual

Controller PCB

!

Four discrete inputs (PAR1).

!

Four discrete outputs (PAR2)(5 to 30 Volts DC).

!

The output current is 35 mA per discrete output up to 115 mA maximum total current

draw on the +5 Volts DC supply.

!

Inputs can be defined as clear (return to gross), tare, print, zero, and other keyboard

functions.

!

Outputs can be defined for coincidence setpoints or a variety of scale conditions.

!

The COM1 serial port can be either RS-232 or 20 mA current loop active transmit.

Both are available simultaneously.

!

The COM2 serial port can be either RS-232 or RS-422/RS-485. This port is also

used to support a DigiTOL or UltraRes scale interface.

!

Keyboard input is a standard 6-pin PS2 type mini DIN connection for a compatible

keyboard.

!

The Ethernet network connection is accomplished using a RJ45 connection.

!

Connections to the Controller PCB are made using four removable terminal strips.

The wire size range for these terminal strips is 23 to 16 AWG.

!

The Controller PCB stores DigiTOL scale calibration parameters in its EEPROM. If

analog load cell scale(s) are installed, the calibration parameters for each scale are

stored in the EEPROM of its Analog PCB. IDNET calibration parameters are stored in

the base. POWERCELL parameters are stored on the POWERCELL PCB.

Temperature and Humidity

! Operating temperature: 14 to 113ºF (-10 to 45ºC) at 10% to 95% humidity, noncondensing.

! Storage temperature: -40 to 140ºF (-40 to 60ºC) at 10% to 95% humidity,

noncondensing.

! The optional Analog PCB zero temperature coefficient is 0.15 µV/ºC. Span

temperature coefficient is 6 ppm/° C maximum.

Environmental Protection

The JAGXTREME terminal is not intrinsically safe! In addition to the Reduced Excitation

Analog Scale option, a METTLER TOLEDO Hazardous Area Protection safety module is

required for JAGXTREME terminals operating with scales located in a hazardous area.

Contact your METTLER TOLEDO representative for information.

WARNING!

THE JAGXTREME TERMINAL IS NOT INTRINSICALLY SAFE! DO

NOT USE IN AREAS CLASSIFIED AS HAZARDOUS BY THE

NATIONAL ELECTRIC CODE (NEC) BECAUSE OF COMBUSTIBLE OR EXPLOSIVE ATMOSPHERES.

1-12

(9/00)

Chapter 1: Introduction

Standards Compliance

Standards Compliance

UL and cUL Listing

The JAGXTREME terminal has been tested and complies with UL 1950 and CSA 22.2

No. 950-M89. The JAGXTREME terminal carries the UL and cUL labels.

Weights and Measures

Approval

United States

The JAGXTREME terminal meets or exceeds requirements for Class III or IIIL devices.

Certificate of Conformance No. 94-096A4 was issued under the National Type

Evaluation Program of the National Conference on Weights and Measures.

Canada

The JAGXTREME terminal meets or exceeds requirements for a 10,000 division rating

and approval AM-5041 has been issued by statutory authority of the Minister of

Industry, Science and Technology of Canada.

Australia

The JAGXTREME terminal meets or exceeds the requirements for Class III and IIIL nonautomatic weighing instruments as defined in the National Standards Commission,

Document 100. The National Standards Commission has approved the JAGXTREME

terminal for use with approved and compatible platforms.

Europe

The JAGXTREME terminal was submitted for approval to The Nederlands Meetindtituut

(NMi) in the Netherlands. After evaluation, the JAGXTREME terminal was found to meet

and/or exceed the requirements for a Class III weighing instrument. EC type approval

certificate TC2618 (Revision 5) was issued by the NMi in accordance to Council

Directive 90/384/EEC.

CE Conformity

The JAGXTREME terminal conforms to the following European Union regulations:

!

90/384/EU—Non-automatic Balances and Scales

!

EN45501:1992—Adopted European Standard

!

89/336/EU—EMC Directive

!

EN55022, A 01.04.87

(9-00) 1-13

METTLER TOLEDO JAGXTREME Terminal Technical Manual

Conducted and Radiated

Emissions (RFI)

The JAGXTREME terminal meets or exceeds FCC Part 15 for conducted and radiated

emissions requirements as a Class A digital device.

Radio Frequency

Interference Susceptibility

The JAGXTREME terminal meets US, Canadian, and European requirements for RFI

susceptibility as listed in the following table with a maximum of one display increment of

change when calibrated for recommended builds.

Radio Interference Frequency

26-1000 MHz

Field Strength

3 volts/meter

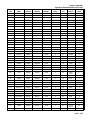

AC Power Line Voltage

Variation

The JAGXTREME terminal meets NIST H-44, Canadian Gazette Part 1, and OIMLSP7/SP2 line voltage variation specifications as listed in the following table.

AC Power Line Voltages

Specification

Line Voltage Variation

NIST H-44

Canadian

OIML-SP7/SP2

1-14

(9/00)

AC Line Voltage

Minimum

100

108

102

187

204

Nominal

120

120

120

220

264

Maximum

130

132

132

242

264

Line Frequency in Hz

Minimum

Nominal

59.5

60

58.8

60

58.8

60

49.0

50

49.0

50

Maximum

60.5

61.2

61.2

51

51

Chapter 2: Installation

Unpacking and Inspection

2

Installation

Unpacking and

Inspection

If upon delivery the shipping container for the JAGXTREME terminal appears damaged,

check for internal damage and file a freight claim with the carrier if required. If the

container is undamaged, unpack the JAGXTREME terminal from its protective package,

noting how it was packed, and inspect each component for damage. If it is necessary to

ship the terminal at any time, use the original shipping container if possible.

Package contents for all JAGXTREME terminals include:

•

JAGXTREME terminal

•

Screwdriver

•

Installation guide

•

Set of capacity labels

•

Weights and Measures sealing screws

•

Mating connectors for the I/O port

•

Cable tie wraps

•

JAGXTREME CD with documentation and ancillary software

Package contents for the panel mount and blind chassis JAGXTREME terminal include:

•

Six (6) nylon cable ties

•

2 mm Allen wrench (panel mount only)

Package contents for the harsh environment JAGXTREME terminal include:

Note: The (*) designation

before a part number indicates

that the part number may be

proceeded by a letter

designation such as A, B, C

and so on.

•

2 stainless steel wall mount brackets

•

4 stainless steel bolts for attaching the wall mount brackets

•

Hardware kit (*)15411500A

Package contents for the general purpose JAGXTREME terminal includes:

•

Hardware kit (*)15411400A

(9/00)

2-1

METTLER TOLEDO JAGXTREME Terminal Technical Manual

Installing the General

Purpose Model

Place the general purpose (desk top) model at the operating site.

•

Remove the four screws securing the rear access cover to the main housing

using a Phillips head screwdriver.

•

With the rear access cover removed, you are now ready to make connections

to the unit. Figure 2-a describes the recommended wiring connections.

C

D

Reference Letter

Suggested Cable

A

Serial I/O Cables (Except DigiTOL)

PLC I/F Cabling

Ethernet Wiring

B

Analog Load Cell Cabling

DigiTOL Load Cell Cabling

C

Ethernet Cable

D

QWERTY Keyboard

Figure 2-a: General Purpose Wiring Connections and Cable Chart

To connect the unit:

Be careful to select an opening

close to the terminal block you

are wiring to keep the wiring

neat and easy to connect.

1. Pass the cables that enter the general-purpose enclosure through an appropriately

sized cable grip before connecting the wires.

2. Tighten the cable grip to provide a water-tight seal around the cable after resecuring the back cover. This allows any internal cable slack to be received through

the cable grip.

3. Continue to the section entitled Electrical Connections.

2-2

(9/00)

Chapter 2: Installation

Installing the Panel Mount Model

Installing the Panel

Mount Model

Refer to Figure 2-b and the instructions below to install the panel mount terminal.

B

A

A

Figure 2-b: Panel Mount Installation Diagram

1. Cut an opening 9.58 in. (24.33 cm) × 5.12 in. (13.0 cm) to accommodate the

terminal. The tolerance for the panel cutout is ±0.06 in. (0.15 cm).

2. Using the Allen wrench included with the unit, remove the four retaining set screws

(A) located at the rear of the enclosure in the top and bottom mounting plate

grooves.

3. Remove both mounting plates (B).

4. Insert the terminal through the panel opening from the front until it is flush against

the panel. Confirm that the terminal is installed right side up.

5. Slide the top and bottom mounting plates back in the grooves and push them flush

against the panel from the back. The flared end of the plate should contact the back

of the panel.

6. Holding the unit in place, replace the four set screws and tighten until the unit is

secured and the front panel gasket is compressed.

7. Inspect the front of the JAGXTREME terminal for a good seal to the front of the

enclosure.

8. Continue to the section entitled Electrical Connections.

(9/00)

2-3

METTLER TOLEDO JAGXTREME Terminal Technical Manual

Installing the Harsh

Environment Enclosure

Opening the Enclosure

1. Disconnect power.

2. Locate the two slots on the bottom lip of the front of the harsh environment

enclosure.

3. Gently insert the blade of a slotted screwdriver into one of the slots and press

inward (toward the enclosure). This releases a pressure tab that allows the access

panel of the enclosure to open slightly.

4. Repeat steps 2 and 3 for the other slot.

5. Remove the access panel away from the enclosure. The access panel is connected

to the Controller PCB by a cable and cannot be removed without disconnecting the