Download MR-J3 - Oceania Automation

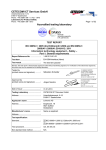

Transcript