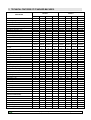

Download required periodic inspections by the owner

Transcript