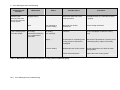

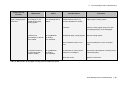

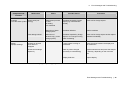

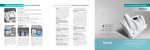

Download Osmomat 030

Transcript