Download Catalogue - Ray

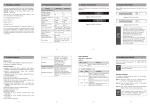

Transcript