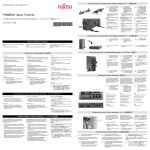

Download vcaution - Fujitsu manual server

Transcript