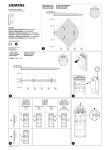

Download s200+ series infra-red flame detection flame detectors user manual

Transcript