Download 100/200V Single-phase Sigma II Servo Systems

Transcript

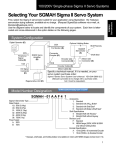

100/200V Single-phase Sigma II Servo Systems Flat Series SGMPH Servomotors - With Incremental / Absolute Encoder Rated Output: 100W, 200W, 400W, 750W, 1500W SGMPH Ratings & Specifications SGMPH Speed/Torque Curves SGMPH Dimensions SGMPH Selection/Ordering Information SGDH Ratings & Specifications SGDH Dimensions Page(s) 30 31 32 41 99 101 - 40 - 45 - 100 - 112 Design Features 1. Compact ! The length is about 1/2 of conventional motors ! Enhanced withstand load since motor output shaft bearing size is upgraded ! Up to 5000rpm maximum speed 2. Enhanced Environmental Resistance ! Water resistance (not including the shaft), IP67 standard ! Optional shaft seals available ! Reinforced lead-out cable access 3. Encoders (reduced wiring serial encoder) ! 13-bit (2,048ppr x 4) incremental encoder (standard) ! 16-bit (16,384ppr x 4) absolute encoder (option) 4. Application Emphasis ! Chip mounters ! PCB drilling machines ! Robots ! Conveyor ! Packaging 5. Certified International Standards ! UL, cUL recognized, (File #: E165827), CE compliance 27 SGMPH Servomotors For Additional Information 100/200V Single-phase Sigma II Servo Systems Servomotor Ratings and Specifications Applied Voltage Time Rating: Insulation: Vibration: Withstand Voltage: Insulation Resistance: 100Vac 200Vac SGMPH Servomotors 100Vac 200Vac System Voltage * ** * 28 MOTORS: SGMPH01A 02A 04A 08A 15A 01B 02B 04A** Continuous Class B 15µm or less 1500Vac 500VDC 10MΩ or more Excitation: Permanent magnet Drive Method: Direct drive Mounting: Flange-mounted Applicable Encoder: 13-bit Incremental and 16-bit Absolute encoder Enclosure: Totally-enclosed, self-cooled Ambient Temperature: 0 to 40ºC Ambient Humidity: 20 to 80% (non-condensing) Rated Rotation Speed: 3000rpm Maximum Rotation Speed:5000rpm Rated Output Rated Torque Instantaneous Peak Torque Continuous Rated Current* Maximum Peak Current* Rated Angular Acceleration Rated Power Rate W (hp) oz • in N•m oz • in N•m A rms A rms rad/s2 kW/s 100 (0.13) 200 (0.27) 400 (0.54) 750 (1.01) 1500 (2.01) 100 (0.13) 200 (0.27) 400 (0.54) 45.1 90.1 180 338 676 45.1 90.1 180 0.318 0.637 1.27 2.39 4.77 0.318 0.637 1.27 135 270 542 1010 2027 135 270 542 0.96 1.91 3.82 7.1 14.3 0.96 1.91 3.82 0.89 2.0 2.6 4.1 7.5 2.2 2.7 2.6 2.8 6.0 8.0 13.9 23.0 7.1 8.4 8.0 64800 33000 38500 11400 11900 64800 33000 38500 20.4 21.0 49.0 27.0 56.7 20.4 21.0 49.0 Holding Brake (at 20°C) Coil Rated Capacity Resistance Current Allowable Load Inertia * Values are calculated when the servomotor is combined with an SGDH servo amplifier. When combined with an SGDH-04FE Moment of Inertia MOTORS SGMPH- Motor without Brake oz • in • s2 × 10-3 Motor with Brake KG • m2 × 10-4 oz • in • s2 × 10-3 KG • m2 × 10-4 W Ω A KG • m2 × 10-4 01A 02A 04A 08A 15A 01B 02B 0.695 2.73 4.69 29.7 56.9 0.695 2.73 0.0491 0.193 0.331 2.10 4.02 0.0491 0.193 1.106 4.274 6.234 42.09 69.29 1.106 4.274 0.0781 0.302 0.44 2.975 4.895 0.0781 0.302 6 5 7.6 7.5 10 6 5 96 115 76 77 58 96 115 0.25 0.21 0.32 0.31 0.42 0.25 0.21 1.20 3.69 3.82 13.4 24.1 1.20 3.69 04A 4.69 0.331 6.234 0.44 7.6 76 0.32 3.82 Allowable load inertia (JL) shows the range requiring no exterior regenerative unit. When these values are exceeded, application may be restricted or a regenerative unit may be required. Values are calculated when the servomotor is combined with an SGDH servo amplifier. MOTORS SGMPH- Servomotor Capacity W 01' 02' 04A 08A 15A 100 200 400 750 1500 Holding Brake Holding Torque KG · cm oz-in 69.5 5.0 139 10 279 20 514 37 1015 73 100/200V Single-phase Sigma II Servo Systems Speed / Torque Curves 200V SGMPH-02A SGMPH-04A 5000 5000 4000 4000 4000 B A 2000 3000 A 2000 B 1000 1000 1000 0 0.5 TORQUE (N m) 1 1.5 0 150 100 200 TORQUE (oz/in) 300 5000 4000 4000 SPEED (rpm) SPEED (rpm) 1 B A 2 3 4 0 200 400 TORQUE (oz/in) 600 SGMPH15A 5000 3000 A 2000 B 1000 1000 0 0 TORQUE (N m) SGMPH-08A 2000 0 2 TORQUE (N m) 50 100 TORQUE (oz/in) 3000 B A 2000 0 0 0 0.25 0.5 0.75 1.0 0 3000 SGMPH Servomotors 3000 SPEED (rpm) 5000 SPEED (rpm) SPEED (rpm) SGMPH-01A 0 2 4 6 0 8 0 4 8 0 12 16 TORQUE (N m) TORQUE (N m) 0 400 800 1200 TORQUE (oz/in) 800 1600 2400 TORQUE (oz/in) 100V SGMPH-02B SGMPH-04A* 5000 5000 5000 4000 4000 4000 SPEED (rpm) SPEED (rpm) SGMPH-01B 3000 A 2000 B 1000 3000 2000 A 3000 B 0 0 0 0.25 0.5 0.75 1.0 TORQUE (N m) 0 50 100 TORQUE (oz/in) 0.5 1 1.5 0 2 0 TORQUE (N m) 150 0 B 1000 1000 0 A 2000 100 200 TORQUE (oz/in) 1 2 3 4 TORQUE (N m) 300 0 200 400 TORQUE (oz/in) 600 A : CONTINUOUS DUTY ZONE B : INTERMITTENT DUTY ZONE *When combined with SGDH-04FE amplifier. 29 100/200V Single-phase Sigma II Servo Systems Dimensions in inches (mm) (1) 13-Bit Incremental or 16-Bit Absolute Encoder, w/o Brake Note: • 1. The keyway complies with JIS B1301-1976 (precision). A straight key is supplied. 2. Conforms to the IP67 enclosure, excluding the shaft (optional shaft seal available). 3. The quoted allowable radial load is the value at a position 5mm (0.2in) from the shaft end. 100W (0.13hp) Encoder cable UL20276 Φ0.24 (6) 11.81 (300) ±1.18 (30) Encoder plug SRUC 17GMRCN087 W Motor Plug U T Cross-section Y-Y SRUC 06JMSCN236 Motor cable 0.71 (18) SGMPH Servomotors Hexagonal nut 11.81 (300) ±1.18 (30) Opposite Side width: 0.55 (14) L 0.0016 (0.04) A LR LL LC LM Φ0.0016 (Φ0.04) A 0.83 (21) 0.42 (10.5) 0.12 (3) LG ΦLA ΦLB** Y Y LC QK 0.55 (14) 4 - ΦLZ ΦS* 0.35 (9.0) 0.51 (13) A 0.0008 (0.002) Serial encoder (absolute or incremental) Key Type SGMPH- L LL LM LR LG LC ΦLA ΦLZ ΦS* ΦLB** 01""E41D 01""E41D 3.43 (87) 2.44 (62) 1.67 (42.5) 0.98 (25) 0.24 (6) 2.36 (60) 2.76 (70) 0.21 (5.3) 0.315 (8) 1.97 (50) QK U W T Output W (hp) 0.55 (14) 0.071 (1.8) 0.12 (3) 0.12 (3) 100 (0.13) Torque in•lb (N•m) Time Rating Rated Speed (rpm) Approx Mass lb (kg) 2.81 (0.318) Continuous 3000 1.54 (0.7) Allowable Allowable Radial Thrust Load Load lb (N) lb (N) 17.5 (78) 11.0 (49) Note: The quoted allowable radial load is the value at a position 0.79in ( 20mm.) from the mounting surface. † Some motor dimensions vary for motors with the optional shaft seal: See p.38 for details. Specified Tolerances *Φ S Dimension Encoder Plug 1 2 3 11 10 12 13 17 5 16 15 14 4 6 9 8 7 SRUC 17GMRCN087 (Interconnectron) **ΦLB Unit Diameter Tolerance Diameter Tolerance in mm 0.3150 8.000 +0.0000-0.0004 +0.000 -0.009 1.9685 50.000 +0.0000 -0.0010 +0.000 -0.025 Incremental Terminal Specifications Pin No. Description Color 1* Battery — 2* Battery * (3.6V) — 3 Data + Blue 4 Data− Blue/White 5 - 7, 10 - 17 Free — 8 +5V (Power Supply) Red 9 0V (Power Supply) Black Connector Case FG (Frame Ground) Shield wire *Note: Incremental Terminal pins number 1 and 2 are connectors used for 16-bit absolute encoder option only. Mating Connector: SPNA17HFRON16900E3 (Interconnectron) 30 Motor Plug 1 6 2 5 3 4 SRUC 06JMSCN236 (Interconnectron) Motor Wiring Specifications Pin Number Description Color 1 2 3 6 Phase U Phase V Phase W FG (Frame Ground) Red White Blue Green/Yellow Mating Connector: SPNA06KFSDN169 (Interconnectron) 100/200V Single-phase Sigma II Servo Systems 200W (0.27hp), 400W (0.53hp) Encoder cable UL20276 Φ0.24 (6) 11.81 (300) ±1.18 (30) U Encoder plug W SRUC 17GMRCN087 Motor cable Motor Plug SRUC 06JMSCN236 T Cross-section Y-Y Hexagonal nut Opposite side width: 0.55 (14) LC 11.81 (300) ±1.18 (30) LR 0.0016 (0.04) 0.33 (8.5) LG 0.35 (9.0) Φ0.0016 (Φ0.04) A 0.12 (3) 4 - ΦLZ QK 0.55 (14) Y LC ΦLB** 0.51 (13) 0.83 (21) A SGMPH Servomotors 0.28 (7) 0.71 (18) maximum L LL LM ΦS* • Y ΦLA A 0.0008 (0.02) Serial encoder (absolute or incremental) Key Type SGMPH- 02""E41D 04""E41D L 3.82 (97) 4.61 (117) LL LM LR 2.64 1.89 (67) (48.1) 1.18 3.46 2.68 (30) (87) (68.1) LG 0.31 (8) LC 3.15 (80) ΦLA ΦLZ ΦS* ΦLB** 3.54 (90) 0.28 (7) 0.551 (14) 2.76 (70) QK U Voltage Output W T 0.63 0.12 0.20 0.20 (16) (3) (5) (5) V W (hp) Torque in•lb (N•m) 200 200 (0.27) 400 (0.53) 5.64 (0.637) 11.2 (1.27) Rated Approx Speed Mass (rpm) lb (kg) Time Rating Continuous 3000 3.09 (1.4) 4.63 (2.1) Allowable Allowable Radial Thrust Load Load lb (N) lb (N) 55.1 (245) 15.4 (68) Note: The quoted allowable radial load is the value at a position 0.98in (25mm) from the mounting surface. †Some motor dimensions vary for motors with the optional shaft seal: See p.38 for details. Specified Tolerances *Φ S Dimension **ΦLB Unit Diameter Tolerance Diameter Tolerance in mm 0.5512 14.000 +0.0000-0.0004 +0.000 -0.011 2.7559 70.000 +0.0000 -0.0012 +0.000 -0.030 Interconnection Connector Specifications: See p.30. 31 100/200V Single-phase Sigma II Servo Systems • 750W (1.01hp) Encoder cable UL20276 F0.24 (6) U 11.81 (300) ±1.18 (30) Encoder plug W SRUC 17GMRCN087 Motor Plug MOTOR CABLE T SRUC 06JMSCN236 Cross-section Y - Y 11.81 (300) ±1.18 (30) 0.28 (7) 0.0016 (0.04) LR LC 1.50 (38) Φ0.0016 (Φ0.04) A SGMPH Servomotors 0.14 (3.5) QK 0.51 0.75 (13) (19) Y ΦS* Y LC ΦLB** 0.35 (9.0) A 1.1 (28) maximum L LL LM 0.41 (10.5) LG Hexagonal nut Opposite side width: 0.67 (17) ΦLA 4 - ΦLZ A 0.0008 (0.002) Serial encoder (absolute or incremental) Key Type SGMPH- L LL LM LR LG LC ΦLA ΦLZ ΦS* ΦLB** QK U W T Voltage Output V W (hp) 750 4.98 3.41 2.63 1.57 0.39 4.72 5.71 0.39 0.63 4.33 0.87 0.12 0.20 0.20 200 (1.01) (126.5) (86.5) (66.7) (40) (10) (120) (145) (10) (16) (110) (22) (3) (5) (5) Note: The quoted allowable radial load is the value at a position 1.38in (35mm) from the motor mounting surface. †Some motor dimensions vary for motors with the optional shaft seal: See p.38 for details. 08""E41D Torque in•lb (N•m) Time Rating Rated Approx Speed Mass lb (rpm) (kg) 21.1 (2.39) Contin3000 uous 9.26 (4.2) Specified Tolerances *ΦS Dimension **ΦLB Unit Diameter Tolerance Diameter Tolerance in mm 0.6299 16.000 +0.0000-0.0004 +0.000 -0.011 4.3307 110.000 +0.0000 -0.0014 +0.000 -0.035 Interconnection Connector .Specifications: See p.30. 32 Allowable Allowable Radial Thrust Load Load lb (N) lb (N) 88.1 (392) 33.0 (147) 100/200V Single-phase Sigma II Servo Systems • 1500W (2.0hp) Encoder cable UL20276 Φ0.24 (6) U 11.81 (300) ±1.18 (30) W Encoder plug SRUC 17GMRCN087 Motor cable T Motor Plug SRUC 06JMSCN020 Cross-section Y - Y 11.81 (300) ±1.18 (30) LL LR LC 1.50 (38) LM 0.41 (10.5) LG 4 - ΦLZ Φ0.0016 (Φ0.04) A 0.14 (3.5) 1.1 (28) 0.28 (7) SGMPH Servomotors L Hexagonal nut Opposite side width: 0.67 (17) A maximum 0.0016 (0.04) ΦLA 0.35 (9.0) 0.51 0.75 (13) (19) QK ΦS* Y LC ΦLB** Y A 0.0008 (0.002) Serial encoder (absolute or incremental) Key ΦLA ΦLZ ΦS* ΦLB** 6.08 4.51 3.73 1.57 0.39 4.72 5.71 0.39 (154.5) (114.5) (94.7) (40) (10) (120) (145) (10) 0.75 (19) 4.33 (110) Type SGMPH- L 15""E41D LL LM LR LG LC QK U W Voltage Output V W (hp) T 0.87 0.14 0.24 0.24 (22) (3.5) (6) (6) Torque in•lb (N•m) Time Rating 42.1 (4.77) Continuous 1500 (2.0) 200 Rated Approx Speed Mass (rpm) lb (kg) 3000 14.55 (6.6) Allowable Allowable Radial Thrust Load Load lb (N) lb (N) 110 (490) 33.0 (147) Note: The quoted allowable radial load is the value at a position 1.38in (35mm) from the motor mounting surface. † Some motor dimensions vary for motors with the optional shaft seal: See p.38 for details. Specified Tolerances *ΦS Dimension **ΦLB Unit Diameter Tolerance Diameter Tolerance in mm 0.7480 19.000 +0.0000-0.0005 +0.000 -0.013 4.3307 110.000 +0.0000 -0.0014 +0.000 -0.035 Interconnection Connector Specifications Encoder Plug 1 2 3 4 11 10 12 13 17 5 16 15 14 6 9 8 7 SRUC 17GMRCN087 (Interconnectron) Incremental Terminal Specifications Pin Number Description Color 1* Battery — 2* Battery * (3.6V) — 3 Data + Blue 4 Data− Blue/White 5 - 7, 10 - 17 Free — 8 +5V (Power Supply) Red 9 0V (Power Supply) Black Connector Case FG (Frame Ground) Shield wire *Note: Incremental Terminal pins number 1 and 2 are connectors used for 16-bit absolute encoder option only. Motor Plug 1 6 2 5 3 4 SRUC 06JMSCN020 (Interconnectron) Motor Wiring Specifications Pin No. Description Color 1 2 3 6 Phase U Phase V Phase W FG (Frame Ground) Red White Blue Green/Yellow Mating Connector: SPNA06KFSDN169 (Interconnectron) Mating Connector: SPNA17HFRON16900E3 (Interconnectron) 33 100/200V Single-phase Sigma II Servo Systems (2) 13-Bit Incremental or 16-Bit Absolute Encoder, with Brake Note: • 1. The keyway complies with JIS B1301-1976 (precision). A straight key is supplied. 2. The electromagnetic brake is only to hold the load in position and cannot be used to stop the motor. 3. Conforms to the IP67 enclosure, excluding the shaft (optional shaft seal available). 100W (0.13hp) 11.81 (300) ±1.18 (30) Encoder plug Encoder cable UL20276 Φ0.24 (6) SRUC 17GMRCN087 W U Motor Plug MOTOR cable Φ0.0016 (Φ0.04) A ΦLA ΦLB** LC QK Y 0.90 (23) Y Serial encoder (Absolute or Incremental) 4 - ΦLZ ΦS* 0.51 (13) A A Magnetic brake: Non-excitation operation DC power supply: 24V 0.0008 (0.002) Key LC ΦLA ΦLZ ΦS* ΦLB** 4.57 3.58 1.67 0.98 0.24 2.36 (116) (91) (42.5) (25) (6) (60) 2.76 (70) 0.22 0.315 (5.5) (8) 1.968 (50) Type SGMPH- L 01""E4CD LL LM LR LG maximum. 0.0016 (0.04) 0.12 (3) LG 0.35 (9.0) LC 0.83 (21) LR 0.71 (18) SGMPH Servomotors L LL LM 0.41 (10.5) Cross-section Y - Y Hexagonal nut Opposite side width: 0.67 (17) 11.81 (300) ±1.18 (30) 0.28 (7) T SRUC 06JMSCN236 QK U W T Voltage Output (V) W (hp) Torque in•lb (N•m) Time Rating Rated Approx Speed Mass (rpm) lb (kg) 100 (0.13) 2.81 (0.318) Continuous 3000 0.55 0.071 0.12 0.12 (14) (1.8) (3) (3) 200 1.5 (0.7) Allowable Radial Load lb (N) Allowable Thrust Load lb (N) 17.5 (78) 11.0 (49) Note: The quoted allowable radial load is the value at a position 0.79in (20mm) from the motor mounting surface. †Some motor dimensions vary for motors with the optional shaft seal: See p.38 for details. Specified Tolerances *Φ S Dimension **ΦLB Unit Diameter Tolerance Diameter Tolerance in mm 0.3150 8.000 +0.0000-0.0004 +0.000 -0.009 1.9685 50.000 +0.0000 -0.0010 +0.000 -0.025 Interconnection Connector Specifications Encoder Plug 1 2 3 4 11 10 12 13 17 15 14 5 16 6 9 8 7 SRUC 17GMRCN087 (Interconnectron) Motor Plug Incremental Terminal Specifications Pin Number Description Color 1* Battery 2* Battery * (3.6V) 3 Data + Blue 4 Data− Blue/White 5 - 7, 10 - 17 Free 8 +5V (Power Supply) Red 9 0V (Power Supply) Black Connector Case FG (Frame Ground) Shield wire *Note: Incremental Terminal pins number 1 and 2 are connectors used for 16-bit absolute encoder option only. 6 3 4 2 5 SRUC 06JMSCN236 (Interconnectron) Mating Connector: SPNA17HFRON16900E3 (Interconnectron) 34 1 Motor Wiring Specifications Pin Number Description Color 1 2 3 4 5 6 Phase U Phase V Phase W Holding Brake Holding Brake FG (Frame Ground) Red White Blue Black Black Green/Yellow Mating Connector: SPNA06KFSDN169 (Interconnectron) 100/200V Single-phase Sigma II Servo Systems • 200W (0.27hp), 400W (0.53hp) Encoder cable UL20276 Φ0.24 (6) 11.81 (300) ±1.18 (30) U Encoder plug W SRUC 17GMRCN087 T Motor cable Motor Plug SRUC 06JMSCN236 0.71 (18) maximum Φ0.0016 (Φ0.04) A 0.51 (13) 0.90 (23) SGMPH Servomotors 0.35 (9.0) HEXAGONAL NUT Opposite side width: 0.67 (17) 0.0016 (0.04) A LC 0.83 (21) 11.81 (300) ±1.18 (30) L LR LL LM LG 0.12 (3) 0.28 (7) 0.33 (8.5) Cross-section Y-Y QK Serial encoder (Absolute or Incremental) ΦLA ΦS* Y LC ΦLB** Y ΦLZ A Magnetic brake: Non-excitation operation DC power supply: 24V 0.0008 (0.002) Key Type SGMPH- 02""E4CD 04""E4CD L LL LM LR LG LC ΦLA ΦLZ 5.06 3.88 1.89 (128.5) (98.5) (48.1) 1.18 0.31 3.15 3.54 5.85 4.67 2.68 (30) (8) (80) (90) (148.5) (118.5) (68.1) ΦS* ΦLB** 0.28 0.551 (7) (14) 2.756 (70) QK U W T 0.63 0.12 0.20 0.20 (16) (3) (5) (5) Voltage Output V W (hp) Torque in•lb ( N•m) Time Rating Rated Speed (rpm) Approx Mass lb (kg) 200 (0.27) 400 (0.53) 5.64 (0.637) 11.2 (1.27) Continuous 3000 4.2 (1.9) 5.7 (2.6) 200 400 Allowable Allowable Radial Thrust Load lb Load (N) lb (N) 55.1 (245) 15.29 (68) Note: The quoted allowable radial load is the value at a position 0.98in (25mm) from the motor mounting surface. †Some motor dimensions vary for motors with the optional shaft seal: See p.38 for details. Specified Tolerances *Φ S Dimension **ΦLB Unit Diameter Tolerance Diameter Tolerance in mm 0.5512 14.000 +0.0000-0.0004 +0.000 -0.011 2.7559 70.000 +0.0000 -0.0012 +0.000 -0.030 Interconnection Connector Specifications: See p.33. 35 100/200V Single-phase Sigma II Servo Systems 750W (1.01hp) Encoder cable UL20276 Φ0.24 (6) 11.81 (300) ±1.18 (30) Encoder plug U SRUC 17GMRCN087 W • Motor cable Motor Plug SRUC 06JMSCN236 T 11.81 (300) ±1.18 (30) 0.0016 (0.04) A 1.5 (38) Φ0.0016 (Φ0.04) 0.14 (3.5) A 4 - ΦLZ QK 0.51 (13) 1.0 (25.5) Y ΦS* Y ΦLC ΦLB** SGMPH Servomotors 0.35 (9.0) LR 1.1 (28) 0.28 (7) Hexagonal nut Opposite side width: 0.55 (14) LC maximum. L LL LM 0.41 (10.5) LG Cross-section Y - Y ΦLA A Serial encoder (Absolute or Incremental) Magnetic brake: Non-excitation operation DC power supply: 24V 0.0008 (0.002) Key Type SGMPH- 08""E4CD L LL LM LR LG LC ΦLA ΦLZ ΦS* ΦLB** 6.42 4.84 2.63 1.57 0.39 4.72 5.71 0.39 (163) (123) (66.7) (40) (10) (120) (145) (10) 0.63 (16) 4.33 (110) QK U W T 0.87 0.12 0.20 0.20 (22) (3) (5) (5) Voltage V Output W (hp) Torque in•lb (N•m) Time Rating Rated Speed (rpm) Approx Mass lb (kg) 200 750 (1.01) 21.15 (2.39) Continuous 3000 12.6 (5.7) Note: The quoted allowable radial load is the value at a position 1.38in (35mm) from the motor mounting surface. † Some motor dimensions vary for motors with the optional shaft seal: See p.38 for details. Specified Tolerances *Φ S Dimension **ΦLB Unit Diameter Tolerance Diameter Tolerance in mm 0.6299 16.000 +0.0000-0.0004 +0.000 -0.011 4.3307 110.000 +0.0000 -0.0014 +0.000 -0.035 Interconnection Connector Specifications: See p.33. . 36 Allowable Allowable Radial Thrust Load lb Load (N) lb (N) 88.1 (392) 33.0 (147) 100/200V Single-phase Sigma II Servo Systems • 1500W (2.0hp) Encoder cable UL20276 Φ0.24 (6) 11.81 (300) ±1.18 (30) U Encoder plug W SRUC 17GMRCN087 T Motor Plug Motor cable SRUC 06JMSCN020 Cross-section Y - Y 11.81 (300) ±1.18 (30) 0.0016 (0.04) LR LC 1.50 (38) LG 0.41 (10.5) 0.14 (3.5) Φ0.0016 (Φ0.04) A QK 1.00 (25.5) ΦLB** ΦS* Y LC 0.35 (9.0) 0.51 (13) 1.1 (28) Maximum 0.28 1.30 (33) (7) Hexagonal nut Opposite side width: 0.55 (14) A SGMPH Servomotors L LL LM Y Serial encoder (Absolute or Incremental) A Magnetic brake: Non-excitation operation DC power supply: 24V 0.0008 (0.002) Key Type SGMPH- L LL 15""E4CD 7.40 (188) 5.83 (148) ΦLA ΦLZ ΦS* ΦLB** 3.73 1.57 0.39 4.72 5.71 (94.7) (40) (10) (120) (145) 0.39 (10) 0.75 (19) 4.33 (110) LM LR LG LC QK U W T 0.87 0.14 0.24 0.24 (22) (3.5) (6) (6) Voltage Output V W (hp) Torque in•lb ( N•m) Time Rating Rated Approx Speed Mass (rpm) lb (kg) 1500 (2.02) 42.1 (4.77) Continuous 3000 200 17.9 (8.1) Allowable Allowable Radial Thrust Load Load lb (N) lb (N) 110 (490) 33.0 (147) Note: The quoted allowable radial load is the value at a position 1.38in (35mm) from the motor mounting surface. †Some motor dimensions vary for motors with the optional shaft seal: See p.38 for details. Specified Tolerances *ΦS Dimension **ΦLB Unit Diameter Tolerance Diameter Tolerance in mm 0.7480 19.000 +0.0000-0.0005 +0.000 -0.013 2.7559 70.000 +0.0000 -0.0014 +0.000 -0.035 Interconnection Connector Specifications Encoder Plug 1 2 3 4 11 10 12 13 17 15 14 5 16 6 9 8 7 SRUC 17GMRCN087 (Interconnectron) Incremental Terminal Specifications Pin Number Description Color 1* Battery — 2* Battery * (3.6V) — 3 Data + Blue 4 Data − Blue/White 5 - 7, 10 - 17 Free — 8 +5V (Power Supply) Red 9 0V (Power Supply) Black Connector Case FG (Frame Ground) Shield wire *Note: Incremental Terminal pins number 1 and 2 are connectors used for 16-bit absolute encoder option only. Motor Plug 1 6 2 5 3 4 SRUC 06JMSCN020 (Interconnectron) Motor Wiring Specifications Pin No. Description Color 1 2 3 4 5 6 Phase U Phase V Phase W Holding Brake Holding Brake FG (Frame Ground) Red White Blue Black Black Green/Yellow Mating Connector: SPNA06KFSDN169 (Interconnectron Mating Connector: SPNA17HFRON16900E3 (Interconnectron) 37 100/200V Single-phase Sigma II Servo Systems Dimension Modifications for Motors with Optional Shaft Seal LR LE LD ΦLB LP ΦS QK SGMPH Servomotors Shaft Seal Type SGMPH01 02 04 08 15 QK 0.55 (14) ΦLB* ΦS* 1.97 (50) 0.31 (8) LE 0.64 (16) 2.76 (70) 0.55 (14) 0.87 (22) 4.33 (110) 0.63 (16) 0.75 (19) 0.12 (3) 0.14 (3.5) ΦLP LR 0.98 (25) LD 0.28 (7) 1.54 (39) 1.18 (30) 0.39 (10) 1.93 (49) 1.57 (40) 0.41 (10.5) 3.03 (77) *Refer to the following table for tolerances for diameters LB and S. Specified Tolerances * ΦS Dimension Unit in mm **ΦLB Diameter Tolerance Diameter Tolerance 0.3150 0.5512 0.6299 0.7480 8.000 14.000 16.000 19.000 +0.0000-0.0004 +0.0000-0.0004 +0.0000-0.0004 +0.0000-0.0005 +0.000 -0.009 +0.000 -0.011 +0.000 -0.011 +0.000 -0.013 1.9685 2.7559 4.3307 +0.0000 -0.0010 +0.0000 -0.0014 +0.0000 -0.0014 50.000 70.000 110.000 +0.000 -0.025 +0.000 -0.035 +0.000 -0.035 Torque Reduction Factor for SGMPH motors equipped with a shaft seal: Servo Motor Model Torque Reduction Factor 01 02 04 08 15 90% 90% 95% 95% 95% For Example: The SGMPH-01 continuous and peak torque rating should be reduced to 90% of the listed catalog specification. To specify a motor with a shaft seal, refer to the motor part number explanation on the following page. 38 100/200V Single-phase Sigma II Servo Systems Selecting Your SGMPH Sigma II Servo System First, select the Sigma II servomotor suited for your application using SigmaSize: the Yaskawa servomotor sizing software, available at no charge. (Request SigmaSize software via e-mail, at: [email protected]). Use the diagram below to locate and identify the components of your system. Each item is lettercoded and cross-referenced in the option tables on the following pages. System Configuration Digital Operator (E) Optional Holding Brake 5CN Shaft Keyway For Monitor (D) SGDH Servo Amplifier (B) Connector Encoder (D) Shaft Seal Encoder side Connector (D) SGMPH Servomotors 3CN Peripheral Signal Cable (E) SGMPH Servomotor (A) Motor side Connector (D) 2CN 1CN Encoder Cable (C) Motor Cable (C) I/O Signal Connector (D) Specify a technical manual, if it is needed, on your servo system purchase order: Regenerative Unit (E) Sigma II Series Servo System User’s Manual: YEA-SIA-S800-32.2 (Manual is provided at no charge with a purchase order, but it must be requested). Model Number Designation SGMPH - 01 A A E 4 1D Sigma Servomotor Type Rated Output 01: 100W (0.13hp) 02: 200W (0.25hp) 04: 400W (0.5hp) 08: 750W (1hp) 15: 1.5kW (2hp) Power Supply A: 200V UL Recognized B: 100V UL Recognized Accessories 1D: Standard CD: Standard with 24VDC Holding Brake SD: Standard with Shaft Seal ED: Standard with Brake & Shaft Seal Shaft Specifications 4: Straight Shaft with Keyway Revision Level Encoder Specifications A: 13-Bit (2048 x 4) Incremental Encoder 1: 16-Bit (16,384 x 4) Absolute Encoder 39 100/200V Single-phase Sigma II Servo Systems Servomotor & Amplifier Selection Use the table below to select the appropriate SGMPH Sigma II servomotor and amplifier. (Refer to the motor model # designation on the previous page specifying the available modification to motor construction/features.) Description Peak Torque (oz • in) 135 SGMPH Servomotors 200V 13-Bit Incremental Encoder Straight Shaft with Keyway 270 542 Rated Torque (oz • in) 1010 2027 100V, 1-Phase 135 270 0.917 SGMPH-01AAE41D 1.46 SGMPH-01AAE4CD 2.96 SGMPH-02AAE41D 4.35 SGMPH-02AAE4CD 4.92 SGMPH-04AAE41D 6.31 SGMPH-04AAE4CD 29.9 SGMPH-08AAE41D 181 338 35.7 SGMPH-08AAE4CD 57.1 SGMPH-15AAE41D 67.8 SGMPH-15AAE4CD 0.917 SGMPH-01BAE41D 676 45.1 1.46 SGMPH-01BAE4CD 2.96 SGMPH-02BAE41D 90.1 5000rpm Pre-wired with Heavy Duty Connectors 542 Motor MODEL # (A) 90.1 13-Bit Incremental Encoder Straight Shaft with Keyway Amplifier MODEL # (B)* 45.1 5000rpm Pre-wired with Heavy Duty Connectors Motor Inertia (oz • in • s2x10-3) 4.35 SGMPH-02BAE4CD 4.92 SGMPH-04AAE41D 181 6.31 1-Phase SGDH- 3-Phase SGDH- 01AE — 02AE — 04AE — 08AE-S 08AE Motor & Amplifier Item Class Stock 15AE-S 15AE 01BE — 02BE — 04FE — SGMPH-04AAE4CD Notes: 24VDC brakes for SGMPH Sigma II servomotors are standard. Contact a local source for 24VDC power supplies. Motor power and encoder cables are factory pre-wired with approximately 13” lead length with heavy duty mating connectors. Use the tables on the following page to specify mating connectors and/or various cable lengths. For technical information, request Yaskawa manual number YEA-SIA-S800-32.2. * For more detailed SGDH amplifier specifications and dimensions, refer to pages 99 to 112. 40 100/200V Single-phase Sigma II Servo Systems Pre-wired Cable Selection Use the table below to select pre-wired cables for your SGMPH Sigma II servomotor. Power Cable with Interconnectron Connectors (without Brake) Power Cable with Interconnectron Connectors (with Brake) (IP67) Motor Size (kW) Part Number* 0.1, 0.2, 0.4, 0.8 B4ICE-''(A) 1.5 B5ICE-''(A) 0.1, 0.2, 0.4, 0.8 B4IBCE-''(A) 1.5 B5IBCE-''(A) Encoder Cable with Interconnectron Connector (incremental or absolute) (IP67) A1ICE-''(A) Encoder Cable (for applications up to 20m) Only for Solder Connections FR-RMCT-SB Encoder Cable (for applications from >20 to <50m) Only for Solder Connections UL20276-SB Comments Item Class These UL and CE compliant cables are available in five lengths. Use two digits in the part number’s last place: 03: 3m 05: 5m 10: 10m (standard) 15: 15m 20: 20m SGMPH Servomotors Cable Description (C) These cables are available in any length. For example, to order one FR-RMCT-SB cable, 16m long, specify: quantity:16 part no.: FR-RMCT-SB Stock** All Input/Output 1CN Cable & Transition Terminal Block Input/Output 1CN Cable with Pigtail Leads Input/Output 1CN Cable Cable with Female D-Sub output Connector*** * ** *** JUSP-TA50P 35mm DIN rail mountable; the cable length is 0.5 meters. JZSP-CKI01-'(A) Use the following key to specify required cable length (last digit of part number): 1: 1m (standard) 2: 2m 3: 3m Use the following key to specify required cable length (last two digits of the part number): JZSP-CKI0D-'' D50: 01: 02: 03: 0.5m 1m (standard) 2m 3m The “(A)” at the end of the cable part number is the revision level. Revision level may be changed prior to catalog reprinting. Standard cable lengths are Stock items; non-standard cable lengths are Limited Stock items. 50 Pin Female D-Sub output connector mates to customer supplied third party terminal block. (e.g., Wago #289-449, Weidmuller #919658, Phoenix #2283647, Amphenol/Sine #20-51039, and many others) 41 100/200V Single-phase Sigma II Servo Systems Connector Selection Use the table below to select mating connectors or kits for your SGMPH Sigma II servomotor. Connector Description (D) Motor Size (kW) Interconnectron Connector for Motor Power Cable (with or without Brake) (IP67) Part Number FIN07S-B2 SGMPH Servomotors 0.1, 0.2, 0.4, 0.8, 1.5 2CN Amplifier Mating Connector JZSP-CMP9-1 Comments Item Class Solder Cup — Stock Interconnectron Connector for Encoder Cable (incremental or absolute encoder) (IP67) 1CN Mating Connector FIN17C-A2 Gauge: 24 - 18AWG Requires Crimp Tool B150 and positioner. JZSP-CKI9 – All Interconnectron Crimp Tool — B150 — Positioner — B055/A — 42 Limited Stock 100/200V Single-phase Sigma II Servo Systems Peripheral Device Selection Use the table below to select peripheral devices for your SGMPH Sigma II servomotor. Component Description (E) Comments Item Class Absolute Encoder Battery JZSP-BA01 Software Interface Cable — SigmaWin+ Software YS-12 JZSP-WP0001 For: Individual External Regenerative Unit For: For 200V: DC Reactor (for suppressing harmonics in the power supply) For 100V: SGDH-01AE SGDH-02AE SGDH-04AE SGDH-08AE SGDF-08AE-S amps SGDH-15AE SGDH-15AE-S SGDH-01AE SGDH-02AE SGDH-04AE SGDH-08AE SGDF-08AE-S SGDH-15AE SGDH-15AE-S SGDH-01BE SGDH-02BE 3.6V, 1000mAh (lithium battery) SGMPH Servomotors JUSP-OP02A-1 Portable unit with 1m adapter cable for and JZSP-CMS00-1 Sigma II Hand-held Digital Operator Panel * Part Number Stock Pre-wired 2.0m cable with 9-pin connector Minimum Recommended System Requirements Pentuim 200 MHz, 64MB RAM, 200MB hard drive, CDROM Drive, RS-232 or RS-422 port, Screen rsolution 800x600 w/ 256 colors, and Windows 95,98,NT4.0,2000,ME. (Windows XP planned) are general purpose regeneraRH12050ohmJ These tive units.* Caution: Proper set-up is necessary to avoid equipment damage. RH500N25_ohmΚ X5071 X5070 X5069 X5061 X5079 X5060 X5078 X5063 X5062 — Limited Stock For an alternate solution, specify the individual resistor part number RH500N25_OHMK in necessary series or parallel connection. Refer to the SGDH servo amplifier section of this catalog for additional specifications, and the Sigma II Series Servo System User’s Manual (YEA-SIA-S800-32.2) for proper resistor sizing guidelines. 43 100/200V Single-phase Sigma II Servo Systems NOTES: SGMPH Servomotors 44 100/200V Single-phase Sigma II Servo Systems SGMPH Gearmotors - With Incremental / Absolute Encoder Rated Output : 100W, 200W, 400W, 750W, 1500W For Additional Information SGMPH Gearmotor Ratings & Specifications SGMPH Gearmotor Dimensions SGMPH Gearmotor Selection/Ordering Information SGDH Ratings & Specifications SGDH Dimensions Page(s) 48 50 52 99 101 - 49 - 51 - 55 - 100 - 112 Design Features SGMPH Gearmotors 1. Compact Construction ! Easy to install - pre-engineered and pre-assembled ! Ideal for cyclic and reversing applications ! Fits in limited mounting space ! Planetary gear geometry allowing high output torques in a compact package 2. Torque ! 40.9 to 3540in • lb peak torque ! Cost-effective solution for low speed and high torque applications ! Gear ratios - 5:1 to 100:1 in some sizes ! High torsional stiffness and low backlash ! Lubrication is self-replenishing to ensure long life 3. Encoders ! 13-Bit (2,048ppr x 4) incremental encoder (standard) ! 16-Bit (16,384ppr x 4) absolute encoder (option) 4. Enclosure ! Motor is totally enclosed, self-cooled IP67 (not including shaft) 5. Application Emphasis ! PCB drilling machines ! Robots ! Conveyors ! Packaging machines 6. Certified International Standards ! UL, cUL recognized (File #: E165827), CE compliance 45 100/200V Single-phase Sigma II Servo Systems Gearmotor Ratings and Specifications GEARMOTOR Part Number SG05SA-PE01"" SG10SA-PE01"" SG25SA-PE01"" SG50SA-PE01"" SG1ASA-PE01"" SG05SA-PE02"" SG10SA-PE02"" SG25SA-PE02"" SG50SA-PE02"" SG1ASAPE02"" SG05SA-PE04"" SG10SA-PE04"" SG25SA-PE04"" SG50SA-PE04"" SG1ASA-PE04"" SG05SA-PE08"" SG10SA-PE08"" SG25SA-PE08"" SG50SA-PE08"" SG05SA-PE15"" SG10SA-PE15"" SG25SA-PE15"" SG50SA-PE15"" Rated Torque (in • lb) Peak Torque (in • lb) Rated Maximum Speed Speed (rpm) (rpm) 13.67 27.34 66.95 133.89 267.78 27.34 54.68 133.89 267.78 535.56 54.81 109.61 268.38 536.75 1073.50 102.34 204.67 501.13 1002.25 205.16 410.31 1004.63 2009.25 40.93 81.84 200.39 283.00 637.00 81.84 163.69 283.00 708.00 1593.00 164.42 283.00 708.00 1610.25 2832.00 306.04 612.07 1498.63 2997.25 614.50 1228.99 3009.13 3540.00 600 300 120 60 30 600 300 120 60 26 600 300 120 52 20 600 300 104 40 520 260 80 40 1000 500 200 100 50 1000 500 200 100 48 1000 500 200 96 36 1000 500 192 72 960 480 144 72 Speed N1 (rpm) Torque T1 (in • lb) Torque T2 (in • lb) 900 450 180 90 45 1000/600 500/300 200/120 100/60 50/30 640 320 128 64 32 640 320 128 64 640 320 128 64 8.59 17.17 42.04 84.08 168.16 17.17 34.34 84.08 168.16 336.32 34.34 68.68 168.16 336.32 672.65 51.51 103.02 252.24 504.48 103.02 206.04 504.48 1008.97 34.34 68.68 168.16 336.32 672.65 81.8/36.2* 163.7/72.4* 283/177* 708/354.7* 1593/704.4* 77.27 154.53 378.36 756.73 1513.45 51.51 103.02 252.24 504.48 103.02 206.04 504.48 1008.97 Amplifier Model Number Analog Input SGDH- 01"" 02"" 04"" 08"" 15"" SGMPH Gearmotors * Values for 100V Gearmotor Note: 1. These performance ratings apply when duty cycles are 60% or less, and when the gearmotor runs for 1,000 cycles per hour or less. Contact your Yaskawa representative when duty cycles exceed 60%, and when the gearmotor runs for more than 1,000 cycles per hour. 2. Rated Speed is at 20°C ambient temperature. Reduce Rated Speed by 20% at 40°C ambient temperature. 3. For right-angle gearmotors, please consult the factory for availability. Torque A = Continuous Duty B = Intermittent Duty Peak Torque T2 B Rated Torque A T1 Rated Speed N1 Maximum Speed 46 Speed 100/200V Single-phase Sigma II Servo Systems Gearmotor Mechanical Ratings SG05SA-PE01"" SG10SA-PE01"" SG25SA-PE01"" SG50SA-PE01"" SG1ASA-PE01"" SG05SA-PE02"" SG10SA-PE02"" SG25SA-PE02"" SG50SA-PE02"" SG1ASA-PE02"" SG05SA-PE04"" SG10SA-PE04"" SG25SA-PE04"" SG50SA-PE04"" SG1ASA-PE04"" <10 Gearhead Maximum Radial Load (lbf) Gearhead Maximum Axial Load (lbf) Gearhead Inertia (in • lb • s2) Gearmotor Weight (lb) 146 158 0.000052 3.24 326 349 0.00025 6.39 540 428 0.0016 12.79 326 349 0.00025 <10 <10 SG05SA-PE08"" SG10SA-PE08"" SG25SA-PE08"" SG50SA-PE08"" <10 SG05SA-PE15"" SG10SA-PE15"" SG25SA-PE15"" SG50SA-PE15"" <10 7.28 540 1035 428 900 0.0016 0.0049 7.94 14.34 27.79 326 349 0.00025 8.82 540 1035 1687 428 900 1350 0.0016 0.0049 0.0047 15.88 29.33 50.83 540 428 0.0016 19.18 1035 1687 900 1350 0.0049 0.0047 34.84 56.34 1035 900 0.0048 34.40 1687 1350 0.0047 60.75 SGMPH Gearmotors Gearhead Backlash (arc min) GEARMOTOR Part Number CONVENTIONAL GEARMOTOR TORSIONAL ANGLE YASKAWA Sigma II GEARMOTOR REDUCER’S BACKLASH TORQUE 2% OF RATED TORQUE 47 100/200V Single-phase Sigma II Servo Systems Dimensions in inches (mm) Q QK T W KD Motor leads extend 11.81in (300mm) from motor U T LC LL LL3 LR (4) Holes 90° apart MT threaded MD deep LE øLA øGD øLB øS GEARMOTOR LL3 LL LE LR LB GD S LC 1.988 (50) 5.177 (131.5) 0.158 (4) 0.965 (24.5) 1.378 (35) 1.969 (50) 0.472 (12) 2.362 (60) 3.465 (88) 6.858 (174.2) 1.417 (36) 2.047 (52) 2.756 (70) 0.630 (16) SG1ASA-PE01"A 4.193 7.500 (106.5) (190.5) 1.811 (46) 2.677 (68) 3.543 (90) SG05SA-PE02"A SG10SA-PE02"A 2.677 (68) 6.181 (157) SG25SA-PE02"A 3.465 (88) 6.969 (177) 1.417 (36) 2.047 (52) SG50SA-PE02"A 4.193 7.697 (106.5) (195.5) 1.811 (46) SG1ASA-PE02"A 5.295 9.036 (134.5) (229.5) SG05SA-PE01"A SG10SA-PE01"A SG25SA-PE01"A SG50SA-PE01"A SGMPH Gearmotors SG05SA-PE04"A SG10SA-PE04"A 2.677 (68) 6.969 (177) 0.197 (5) 0.236 (6) 0.197 (5) LA MT MD Q QK 1.732 M4 0.315 (44) x 0.7 (8) 0.709 (18) 2.756 (70) 2.441 M5 0.394 (62) x 0.8 (10) 0.866 (22) 3.543 (90) 2.756 (70) 0.630 (16) 2.677 (68) 3.543 (90) 2.756 (70) 3.543 (90) 1.417 (36) KD W T U 0.551 (14) 0.158 (4) 0.158 (4) 0.098 (2.5) 1.102 (28) 0.984 (25) 0.197 (5) 0.197 (5) 0.118 (3) 3.150 M6 0.472 (80) x 1.0 (12) 1.417 (36) 1.260 (32) 0.236 (6) 0.236 (6) 0.138 (3.5) 3.150 (80) 2.441 M5 0.394 (62) x 0.8 (10) 1.102 (28) 0.984 (25) 0.197 (5) 0.197 (5) 0.118 (3) 0.866 (22) 3.543 (90) 3.150 M6 0.472 (80) x 1.0 (12) 1.417 (36) 1.260 (32) 0.236 (6) 0.236 (6) 0.138 (3.5) 4.724 (120) 1.260 (32) 4.724 (120) 4.252 (108) M8 x 1.25 0.630 (16) 2.284 (58) 1.969 (50) 0.394 (10) 0.315 (8) 0.197 (5) 2.047 (52) 2.756 (70) 0.630 (16) 3.150 (80) 2.441 M5 0.394 (62) x 0.8 (10) 1.102 (28) 0.984 (25) 0.197 (5) 0.197 (5) 0.118 (3) 1.811 (46) 2.677 (68) 3.543 (90) 0.866 (22) 3.543 (90) 3.150 M6 0.472 (80) x 1.0 (12) 1.417 (36) 1.260 (32) 0.236 (6) 0.236 (6) 0.138 (3.5) M8 x 1.25 0.315 (8) 0.197 (5) 0.236 (6) 0.138 (3.5) 0.315 (8) 0.197 (5) 0.079 (2) 0.158 (4) 0.079 (2) SG25SA-PE04"A 4.193 8.484 (106.5) (215.5) SG50SA-PE04"A 5.295 9.823 (134.5) (249.5) 0.236 (6) 2.756 (70) 3.543 (90) 4.724 (120) 1.260 (32) 4.252 (108) 0.630 (16) 2.284 (58) 1.969 (50) 0.158 (4) 0.394 (10) SG1ASA-PE04"A 6.024 (153) 10.551 (268.0) 0.315 (8) 3.819 (97) 4.724 (120) 6.102 (155) 1.575 (40) 5.512 M10 0.787 (140) x 1.5 (20) 3.228 (82) 2.756 (70) 0.236 (6) 0.472 (12) 3.150 (80) 7.815 (198.5) 0.197 (5) 1.811 (46) 2.677 (68) 3.543 (90) 0.866 (22) 3.150 M6 0.472 (80) x 1.0 (12) 1.417 (36) 1.260 (32) 0.079 (2) 0.236 (6) SG25SA-PE08"A 5.295 (134.5) 9.803 (249) 0.236 (6) 2.756 (70) 3.543 (90) 4.724 (120) 1.260 (32) M8 x 1.25 0.630 (16) 2.284 (58) 1.969 (50) 0.158 (4) 0.394 (10) SG50SA-PE08"A 6.024 (153) 10.532( 267.5) 0.315 (8) 3.819 (97) 4.724 (120) 6.102 (155) 1.575 (40) 5.512 M10 0.787 (140) x 1.5 (20) 3.228 (82) 2.756 (70) 0.236 (6) 0.472 (12) 4.016 (102) 9.626 (244.5) 0.236 (6) 2.756 (70) 3.543 (90) 4.724 (120) 1.260 (32) 4.252 (108) M8 x 1.25 0.630 (16) 2.284 (58) 1.969 (50) 0.158 (4) 0.394 (10) 6.024 (153) 11.634 (295.5) 0.315 (8) 3.819 (97) 4.724 (120) 6.012 (155) 1.575 (40) 5.512 M10 0.787 (140) x 1.5 (20) 3.228 (82) 2.756 (70) 0.236 (6) 0.472 (12) SG05SA-PE08"A SG10SA-PE08"A SG05SA-PE15"A SG10SA-PE15"A SG25SA-PE15"A SG50SA-PE15"A 48 4.724 (120) 4.252 (108) 100/200V Single-phase Sigma II Servo Systems Tolerances for standard (SG) gearmotors Unit in mm Diameter ΦLB Tolerance 0.472, 0.630 +0.00047 +0.00004 0.866 +0.00059 +0.00008 1.25984, 1.57480 +0.00071 +0.00008 12, 26 +0.012 +0.001 22 +0.015 +0.002 32, 40 +0.018 +0.002 Diameter 1.378 2.047, 2.677 3.5433, 4.724 35 52, 68 90, 120 W Tolerance Width Tolerance +0.00000 -0.00063 0.158, 0.197, 0.236 +0.00000 -0.00118 +0.00000 -0.00075 0.39370 +0.00000 -0.00142 +0.00000 -0.00087 0.47244 +0.00000 -0.00169 +0.000 -0.016 4, 5, 6 +0.000 -0.030 +0.000 -0.019 10 +0.000 -0.036 +0.000 -0.022 12 +0.000 -0.043 SGMPH Gearmotors ΦS Dimension 49 100/200V Single-phase Sigma II Servo Systems Selecting Your SGMPH Gearmotor System First, select the Sigma II servomotor suited for your application using SigmaSize: the Yaskawa servomotor sizing software, available at no charge. (Request SigmaSize software via e-mail, at: [email protected]). Use the diagram below to locate and identify the components of your system. Each item is lettercoded and cross-referenced in the option tables on the following pages. System Configuration Digital Operator (E) 5CN Shaft w/Keyway For Monitor (D) 3CN Peripheral Signal Cable (E) SGDH Servo Amplifier (B) 1CN SGMPH Gearmotor (A) Connector for Encoder Signal (D) Encoder side Connector (D) Motor side Connector (D) 2CN Encoder Cable (C) I/O Signal Connector (D) Regenerative Unit (E) Motor Cable (C) Specify a technical manual, if it is needed, on your servo system purchase order: SGMPH Gearmotors Sigma II Series Servo System User’s Manual: YEA-SIA-S800-32.2 (Manual is provided at no charge with a purchase order, but it must be requested). Model Number Designation SG 05 S A-PE 02 A A C Sigma II Gearmotor Series G: Standard (<10 arc min) Reduction Ratio 05: 5:1 10: 10:1 25: 25:1 50: 50:1 1A: 100:1 Construction S: Standard Revision Level Motor Series PE: SGMPH 50 Accessories C: 24VDC Brake Blank:Standard YEA stock motor options Encoder Specifications A: 13-Bit Incremental Encoder 1: 16-Bit Absolute Encoder Power Supply A: 200V B: 100V Motor Output 01: 100W (0.13hp) 02: 200W (0.25hp) 04: 400W (0.5hp) 08: 750W (1hp) 15: 1.5kW (2hp) 100/200V Single-phase Sigma II Servo Systems Gearmotor & Amplifier Selection Use the table below to select the appropriate SGMPH Sigma II gearmotor and amplifier. (Refer to the motor model # designation on the previous page specifying the available modification to motor construction/features.) Gearhead only Rated Torque (in • lb) Peak Torque (in • lb) Rated Speed (rpm) Maximum Speed (rpm) SG05SA-PE01AA 13.67 40.93 600 1000 SG10SA-PE01AA 27.34 81.84 300 500 SG25SA-PE01AA 66.95 200.39 120 200 SG50SA-PE01AA 133.89 283.00 60 100 SG1ASA-PE01AA 267.78 637.00 30 50 SG05SA-PE02AA 27.34 81.84 600 1000 SG10SA-PE02AA 54.68 163.69 300 500 MODEL # Inertia (in • lb • s2) 0.000052 0.00025 Gear Ratio Amplifier MODEL # (B)* SGDH- Gear Motor Item Class Amplifier Item Class Normal leadtime 3-4 weeks for assembly Stock 5:1 10:1 25:1 01A" 50:1 0.0016 100:1 0.00025 10:1 5:1 SG25SA-PE02AA 133.89 283.00 120 200 SG50SA-PE02AA 267.78 708.00 60 100 0.0016 50:1 25:1 SG1ASA-PE02AA 535.56 1593.00 26 48 0.0049 100:1 SG05SA-PE04AA 54.81 164.42 600 1000 0.00025 5:1 SG10SA-PE04AA 109.61 283.00 300 500 SG25SA-PE04AA 268.38 708.00 120 200 SG50SA-PE04AA 536.75 1610.25 52 96 SG1ASA-PE04AA 1073.50 2832.00 20 36 SG05SA-PE08AA 102.34 306.04 600 1000 SG10SA-PE08AA 204.67 612.07 300 500 SG25SA-PE08AA 501.13 1498.63 104 192 0.0049 25:1 SG50SA-PE08AA 1002.25 2997.25 40 72 0.0047 50:1 0.0016 0.0047 0.0016 10:1 25:1 50:1 5:1 10:1 205.16 614.50 520 960 SG10SA-PE15AA 410.31 1228.99 260 480 SG25SA-PE15AA 1004.63 3009.13 80 144 0.0047 25:1 SG50SA-PE15AA 2009.25 3540.00 40 72 0.0047 50:1 SG05SA-PE01BA 13.67 40.93 600 1000 SG10SA-PE01BA 27.34 81.84 300 500 SG25SA-PE01BA 66.95 200.39 120 200 SG50SA-PE01BA 133.89 283.00 60 100 SG1ASA-PE01BA 267.78 637.00 30 50 SG05SA-PE02BA 27.34 81.84 600 1000 SG10SA-PE02BA 54.68 163.69 300 500 SG25SA-PE02BA 133.89 283.00 120 200 SG50SA-PE02BA 267.78 708.00 60 100 0.0016 50:1 SG1ASA-PE02BA 535.56 1593.00 26 48 0.0049 100:1 0.000052 0.00025 0.0016 04A" 100:1 SG05SA-PE15AA 0.0048 02A" 08A" 5:1 10:1 15A" 5:1 10:1 25:1 01B" 50:1 100:1 5:1 0.00025 10:1 25:1 02B" Notes:24VDC Brakes for SGMPH Sigma II gearmotors are standard. Contact a local source for 24VDC power supplies. Use the tables on the following page to specify mating connectors or pre-wired cables in different lengths. For technical information, request Yaskawa technical bulletin number YEA-TSA-S800-16.16 and Yaskawa manual number TSE-S800-15. 51 SGMPH Gearmotors Gearmotor (A) 100/200V Single-phase Sigma II Servo Systems * For more detailed 100/200V SGDH amplifier specifications and dimensions, refer to pages 99 - 112. . Pre-wired Cable Selection Use the table below to select pre-wired cables for your SGMPH Sigma II gearmotor. Motor Size (kW) Part Number* Comments Power Cable with Interconnectron Connectors (without Brake) 0.1, 0.2, 0.4, 0.8 B4ICE-''(A) 1.5 B5ICE-''(A) Power Cable with Interconnectron Connectors (with Brake) 0.1, 0.2, 0.4, 0.8 B4IBCE-''(A) 1.5 B5IBCE-''(A) These UL and CE compliant cables are available in five lengths.Use the following key to specify needed cable length (last two digits of the part number): 03: 3m 05: 5m 10: 10m (standard) 15: 15m 20: 20m Cable Description (C) Encoder Cable with Interconnectron Connector (incremental or absolute) A1ICE-''(A) Encoder Cable (for applications up to 20m) Only for Solder Connections FR-RMCT-SB Encoder Cable (for applications from >20 to <50m) Only for Solder Connections UL20276-SB Item Class These cables are available in any length. For example, to order one FR-RMCT-SB cable, 16m long, specify: quantity: 16 part no.: FR-RMCT-SB Stock** SGMPH Gearmotors Input/Output 1CN Cable & Transition Terminal Block Input/Output 1CN Cable with Pigtail Leads Input/Output 1CN Cable Cable with Female D-Sub output Connector*** * ** *** 52 All JUSP-TA50P JZSP-CKI01-'(A) JZSP-CKI0D-'' 35mm DIN rail mountable; the cable length is 0.5 meters. Use the following key to specify required cable length (last digit of part number): 1: 1m (standard) 2: 2m 3: 3m Use the following key to specify required cable length (last two digits of the part number): D50: 01: 02: 03: 0.5m 1m (standard) 2m 3m The “(A)” at the end of the cable part number indicates the revision level. Revision level may be subject to change prior to this catalog reprinting. Standard cable lengths are Stock items; non-standard cable lengths are Limited Stock items. 50 Pin Female D-Sub output connector mates to customer supplied third party terminal block. (e.g., Wago #289-449, Weidmuller #919658, Phoenix #2283647, Amphenol/Sine #20-51039, and many others) 100/200V Single-phase Sigma II Servo Systems Connector Selection Use the table below to select mating connectors or kits for your SGMPH Sigma II gearmotor. Connector Description (D) Motor Size (kW) Interconnectron Connector for Motor Power Cable (with or without Brake) Part Number FIN07S-B2 0.1, 0.2, 0.4, 0.8, 1.5 2CN Amplifier Mating Connector JZSP-CMP9-1 Comments Item Class IP67 Mated Solder Cup — Stock Interconnectron Connector for Encoder Cable (incremental or absolute encoder) FIN17C-A2 IP67 Mated Gauge: 24 - 18 AWG Requires Crimp Tool B150 and positioner. 1CN Mating Connector JZSP-CKI9 — Interconnectron Crimp Tool — B150 — Positioner — B055/A — Limited Stock 53 SGMPH Gearmotors All