Download Rexroth Frequency Converter

Transcript

Electric Drives

and Controls

Hydraulics

Linear Motion and

Assembly Technologies

Pneumatics

Rexroth Frequency Converter

VFC x610 Series

VFC 3610 / VFC 5610

Operating Instructions

Service

R912005516

Edition 01

Bosch Rexroth AG

VFC x610 Series

Record of Revision

Edition

Release Date

Notes

DOK-RCON04-VFC-x610***-IT01-EN-P

2014.07

First release

Copyright

© Bosch Rexroth (Xi'an) Electric Drives and Controls Co., Ltd. 2014

This document, as well as the data, specifications and other information set

forth in it, are the exclusive property of Bosch Rexroth (Xi'an) Electric Drives

and Controls Co., Ltd. It may not be reproduced or given to third parties without its consent.

Liability

The specified data is intended for product description purposes only and shall

not be deemed to be a guaranteed characteristic unless expressly stipulated in

the contract. All rights are reserved with respect to the content of this documentation and the availability of the product.

RS-c63a6cfb1e23a43a0a6846a500ffb920-1-en-US-24

VFC x610 Series

Deutsch

Bosch Rexroth AG

English

Français

Lebensgefahr bei

Danger to life in

Nichtbeachtung der nachstehenden case of non‑compliance with the

Sicherheitshinweise!

below-mentioned safety

Nehmen Sie die Produkte erst dann instructions!

Danger de

mort en cas de non‑respect des

consignes de sécurité figurant ciaprès !

in Betrieb, nachdem Sie die mit dem

Produkt gelieferten Unterlagen und

Sicherheitshinweise vollständig

durchgelesen, verstanden und

beachtet haben.

Do not attempt to install or put these

products into operation until you

have completely read, understood

and observed the documents

supplied with the product.

Ne mettez les produits en service

qu’après avoir lu complètement et

après avoir compris et respecté les

documents et les consignes de

sécurité fournis avec le produit.

Sollten Ihnen keine Unterlagen in

Ihrer Landessprache vorliegen,

wenden Sie sich an Ihren

zuständigen RexrothVertriebspartner.

If no documents in your language

were supplied, please consult your

Rexroth sales partner.

Si vous ne disposez pas de la

documentation dans votre langue,

merci de consulter votre partenaire

Rexroth.

Only qualified persons may work

with drive components.

Seul un personnel qualifié est autorisé

à travailler sur les composants

For detailed explanations on the

safety instructions, see chapter 1 of d’entraînement.

Nähere Erläuterungen zu den

this documentation.

Vous trouverez des explications plus

Sicherheitshinweisen entnehmen

détaillées relatives aux consignes de

Sie Kapitel 1 dieser Dokumentation.

sécurité au chapitre 1 de la présente

documentation.

Nur qualifiziertes Personal darf an

Antriebskomponenten arbeiten.

Hohe elektrische

Spannung! Lebensgefahr durch

elektrischen Schlag!

High electrical

voltage! Danger to life by electric

shock!

Tensions

électriques élevées ! Danger de mort

par électrocution !

Betreiben Sie Antriebskomponenten Only operate drive components with N’exploitez les composants

nur mit fest installiertem

a permanently installed equipment d’entraînement que si un conducteur

Schutzleiter.

grounding conductor.

de protection est installé de manière

Schalten Sie vor Zugriff auf

Disconnect the power supply before permanente.

Antriebskomponenten die

Spannungsversorgung aus.

Beachten Sie die Entladezeiten von

Kondensatoren.

accessing drive components.

Observe the discharge times of the

capacitors.

Gefahrbringende

Bewegungen! Lebensgefahr!

Dangerous

movements! Danger to life!

Halten Sie sich nicht im

Bewegungsbereich von Maschinen

und Maschinenteilen auf.

Keep free and clear of the ranges of

motion of machines and moving

machine parts.

Avant d’intervenir sur les composants

d’entraînement, coupez toujours la

tension d’alimentation.

Tenez compte des délais de décharge

de condensateurs.

Mouvements entraînant une situation

dangereuse ! Danger de mort !

Ne séjournez pas dans la zone de

mouvement de machines et de

Verhindern Sie den unbeabsichtigten Prevent personnel from accidentally composants de machines.

Zutritt für Personen.

entering the range of motion of

Évitez tout accès accidentel de

machines.

personnes.

Bringen Sie vor dem Zugriff oder

Zutritt in den Gefahrenbereich die

Make sure that the drives are

Avant toute intervention ou tout accès

Antriebe sicher zum Stillstand.

brought to safe standstill before

dans la zone de danger, assurez-vous

accessing or entering the danger

de l’arrêt préalable de tous les

zone.

entraînements.

DOK-RCON04-VFC-x610***-IT01-EN-P

I

VFC x610 Series

Bosch Rexroth AG

Deutsch

Elektromagnetische / magnetische

Felder! Gesundheitsgefahr für

Personen mit Herzschrittmachern,

metallischen Implantaten oder

Hörgeräten!

English

Electromagnetic /

magnetic fields! Health hazard for

persons with heart pacemakers,

metal implants or hearing aids!

The above-mentioned persons are

not allowed to enter areas in which

Zutritt zu Bereichen, in denen

drive components are mounted and

Antriebskomponenten montiert und operated, or rather are only allowed

betrieben werden, ist für oben

to do this after they consulted a

genannten Personen untersagt bzw. doctor.

nur nach Rücksprache mit einem

Arzt erlaubt.

Français

Champs

électromagnétiques / magnétiques !

Risque pour la santé des porteurs de

stimulateurs cardiaques, d’implants

métalliques et d’appareils auditifs !

L’accès aux zones où sont montés et

exploités les composants

d’entraînement est interdit aux

personnes susmentionnées ou bien

ne leur est autorisé qu’après

consultation d’un médecin.

Heiße Oberflächen

Hot surfaces

(> 60 °C)! Verbrennungsgefahr!

(> 60 °C [140 °F])! Risk of burns!

Surfaces chaudes

(> 60 °C)! Risque de brûlure !

Vermeiden Sie das Berühren von

metallischen Oberflächen (z. B.

Kühlkörpern). Abkühlzeit der

Antriebskomponenten einhalten

(mind. 15 Minuten).

Do not touch metallic surfaces (e.g.

heat sinks). Comply with the time

required for the drive components to

cool down (at least 15 minutes).

Évitez de toucher des surfaces

métalliques (p. ex. dissipateurs

thermiques). Respectez le délai de

refroidissement des composants

d’entraînement (au moins 15

minutes).

Unsachgemäße

Handhabung bei Transport und

Montage! Verletzungsgefahr!

Improper handling

Manipulation

during transport and mounting! Risk incorrecte lors du transport et du

of injury!

montage ! Risque de blessure !

Verwenden Sie geeignete Montageund Transporteinrichtungen.

Use suitable equipment for mounting Utilisez des dispositifs de montage et

and transport.

de transport adéquats.

Benutzen Sie geeignetes Werkzeug

und persönliche Schutzausrüstung.

Use suitable tools and personal

protective equipment.

Utilisez des outils appropriés et votre

équipement de protection personnel.

Unsachgemäße

Handhabung von Batterien!

Verletzungsgefahr!

Improper handling

of batteries! Risk of injury!

Manipulation

incorrecte de piles! Risque de

blessure!

Do not attempt to reactivate or

Versuchen Sie nicht, leere Batterien recharge low batteries (risk of

zu reaktivieren oder aufzuladen

explosion and chemical burns).

(Explosions- und Verätzungsgefahr). Do not dismantle or damage

Zerlegen oder beschädigen Sie keine batteries. Do not throw batteries into

Batterien. Werfen Sie Batterien nicht open flames.

ins Feuer.

II

N’essayez pas de réactiver des piles

vides ou de les charger (risque

d’explosion et de brûlure par acide).

Ne désassemblez et n’endommagez

pas les piles. Ne jetez pas des piles

dans le feu.

DOK-RCON04-VFC-x610***-IT01-EN-P

VFC x610 Series

Español

Bosch Rexroth AG

Português

Italiano

Pericolo di

Perigo de vida em

caso de inobservância das seguintes morte in caso di inosservanza delle

seguenti indicazioni di sicurezza!

instruções de segurança!

Utilize apenas os produtos depois de Mettere in funzione i prodotti solo

Los productos no se pueden poner ter lido, compreendido e tomado em dopo aver letto, compreso e

en servicio hasta después de haber consideração a documentação e as osservato per intero la

leído por completo, comprendido y instruções de segurança fornecidas documentazione e le indicazioni di

sicurezza fornite con il prodotto.

tenido en cuenta la documentación y juntamente com o produto.

las advertencias de seguridad que se

Se non dovesse essere presente la

Se não tiver disponível a

incluyen en la entrega.

documentação na sua língua, dirija- documentazione nella vostra lingua,

siete pregati di rivolgervi al

Si no dispusiera de documentación se ao seu parceiro de venda

rivenditore Rexroth competente.

en el idioma de su país, diríjase a su responsável da Rexroth.

distribuidor competente de Rexroth.

Solo personale qualificato può

Apenas pessoal qualificado pode

eseguire lavori sui componenti di

Solo el personal debidamente

trabalhar nos componentes de

comando.

cualificado puede trabajar en

acionamento.

componentes de accionamiento.

Per ulteriori spiegazioni riguardanti le

Explicações mais detalhadas

indicazioni di sicurezza consultare il

Encontrará más detalles sobre las

relativamente às instruções de

capitolo 1 di questa documentazione.

indicaciones de seguridad en el

segurança constam no capítulo 1

capítulo 1 de esta documentación. desta documentação.

¡Peligro de

muerte en caso de no observar las

siguientes indicaciones de

seguridad!

¡Alta tensión

Alta tensão elétrica!

eléctrica! ¡Peligro de muerte por

Perigo de vida devido a choque

descarga eléctrica!

elétrico!

Active sólo los componentes de

Opere componentes de acionamento

accionamiento con el conductor

apenas com condutores de proteção

protector firmemente instalado.

instalados.

Desconecte la alimentación eléctrica Desligue a alimentação de tensão

antes de manipular los componentes antes de aceder aos componentes

de accionamiento.

de acionamento.

Tenga en cuenta los tiempos de

Respeite os períodos de descarga

descarga de los condensadores.

dos condensadores.

Alta tensione

elettrica! Pericolo di morte in seguito

a scosse elettriche!

¡Movimientos

Movimentos

peligrosos! ¡Peligro de muerte!

perigosos! Perigo de vida!

No permanezca en la zona de

Não permaneça na área de

movimiento de las máquinas ni de

movimentação das máquinas e das

sus piezas.

peças das máquinas.

Impida el acceso accidental de

Evite o acesso involuntário para

personas.

pessoas.

Antes de acceder o introducir las

Antes de entrar ou aceder à área

manos en la zona de peligro, los

perigosa, imobilize os acionamentos

accionamientos se tienen que haber de forma segura.

parado con seguridad.

Movimenti

pericolosi! Pericolo di morte!

DOK-RCON04-VFC-x610***-IT01-EN-P

Mettere in esercizio i componenti di

comando solo con conduttore di

messa a terra ben installato.

Staccare l'alimentazione prima di

intervenire sui componenti di

comando.

Osservare i tempi di scarica del

condensatore.

Non sostare nelle zone di manovra

delle macchine e delle loro parti.

Impedire un accesso non autorizzato

per le persone.

Prima di accedere alla zona di

pericolo, arrestare e bloccare gli

azionamenti.

III

VFC x610 Series

Bosch Rexroth AG

Español

Português

Italiano

¡Campos

electromagnéticos/magnéticos!

¡Peligro para la salud de las personas

con marcapasos, implantes

metálicos o audífonos!

Campos

eletromagnéticos / magnéticos!

Perigo de saúde para pessoas com

marcapassos, implantes metálicos

ou aparelhos auditivos!

Campi

elettromagnetici / magnetici! Pericolo

per la salute delle persone portatrici

di pacemaker, protesi metalliche o

apparecchi acustici!

El acceso de las personas arriba

mencionadas a las zonas de montaje

o funcionamiento de los

componentes de accionamiento está

prohibido, salvo que lo autorice

previamente un médico.

Acesso às áreas, nas quais os

componentes de acionamento são

montados e operados, é proibido

para as pessoas em cima

mencionadas ou apenas após

permissão de um médico.

L'accesso alle zone in cui sono

installati o in funzione componenti di

comando è vietato per le persone

sopra citate o consentito solo dopo un

colloquio con il medico.

¡Superficies

calientes (> 60 °C)! ¡Peligro de

quemaduras!

Superfícies quentes

Superfici bollenti

(> 60 °C)! Perigo de queimaduras! (> 60 °C)! Pericolo di ustioni!

¡Manipulación

inadecuada en el transporte y

montaje! ¡Peligro de lesiones!

Manejo incorreto no

Manipolazione

transporte e montagem! Perigo de

inappropriata durante il trasporto e il

ferimentos!

montaggio! Pericolo di lesioni!

Utilice dispositivos de montaje y de

transporte adecuados.

Utilize dispositivos de montagem e

de transporte adequados.

Utilizzare dispositivi di montaggio e

trasporto adatti.

Utilice herramientas adecuadas y

equipo de protección personal.

Utilize ferramentas e equipamento

de proteção individual adequados.

Utilizzare attrezzi adatti ed

equipaggiamento di protezione

personale.

¡Manejo

inadecuado de las pilas! ¡Peligro de

lesiones!

Manejo incorreto de

Utilizzo

baterias! Perigo de ferimentos!

inappropriato delle batterie! Pericolo

di lesioni!

Não tente reativar nem carregar

Evite tocar superfícies metálicas (p.

Evite el contacto con las superficies ex. radiadores). Respeite o tempo de

arrefecimento dos componentes de

calientes (p. ej., disipadores de

acionamento (mín. 15 minutos).

calor). Observe el tiempo de

enfriamiento de los componentes de

accionamiento (mín. 15 minutos).

Evitare il contatto con superfici

metalliche (ad es. dissipatori di

calore). Rispettare i tempi di

raffreddamento dei componenti di

comando (almeno 15 minuti).

No trate de reactivar o cargar pilas baterias vazias (perigo de explosão e

descargadas (peligro de explosión y de queimaduras com ácido).

cauterización).

Não desmonte nem danifique as

No desarme ni dañe las pilas. No tire baterias. Não deite as baterias no

fogo.

las pilas al fuego.

Non tentare di riattivare o ricaricare

batterie scariche (pericolo di

esplosione e corrosione).

IV

DOK-RCON04-VFC-x610***-IT01-EN-P

Non scomporre o danneggiare le

batterie. Non gettare le batterie nel

fuoco.

VFC x610 Series

Svenska

Bosch Rexroth AG

Dansk

Livsfara om följande

Livsfare ved

säkerhetsanvisningar inte följs!

manglende overholdelse af

nedenstående

Använd inte produkterna innan du

sikkerhedsanvisninger!

har läst och förstått den

dokumentation och de

Tag ikke produktet i brug, før du har

säkerhetsanvisningar som medföljer læst og forstået den dokumentation

produkten, och följ alla anvisningar. og de sikkerhedsanvisninger, som

Kontakta din Rexroth-återförsäljare følger med produktet, og overhold

om dokumentationen inte medföljer de givne anvisninger.

på ditt språk.

Endast kvalificerad personal får

arbeta med drivkomponenterna.

Nederlands

Levensgevaar bij niet-naleving van

onderstaande veiligheidsinstructies!

Stel de producten pas in bedrijf nadat

u de met het product geleverde

documenten en de

veiligheidsinformatie volledig gelezen,

begrepen en in acht genomen heeft.

Mocht u niet beschikken over

Kontakt din Rexroth-forhandler, hvis documenten in uw landstaal, kunt u

dokumentationen ikke medfølger på contact opnemen met uw plaatselijke

dit sprog.

Rexroth distributiepartner.

Se kapitel 1 i denna dokumentation

för närmare beskrivningar av

säkerhetsanvisningarna.

Det er kun kvalificeret personale, der Uitsluitend gekwalificeerd personeel

må arbejde på drive components.

mag aan de aandrijvingscomponenten

werken.

Nærmere forklaringer til

Hög elektrisk

spänning! Livsfara genom elchock!

Elektrisk

højspænding! Livsfare på grund af

elektrisk stød!

Använd endast drivkomponenterna

med fastmonterad skyddsledare.

sikkerhedsanvisningerne fremgår af Meer informatie over de

kapitel 1 i denne dokumentation.

veiligheidsinstructies vindt u in

hoofdstuk 1 van deze documentatie.

Drive components må kun benyttes

Koppla bort spänningsförsörjningen med et fast installeret jordstik.

före arbete på drivkomponenter.

Sørg for at koble

Var medveten om kondensatorernas spændingsforsyningen fra, inden du

rører ved drive components.

urladdningstid.

Overhold kondensatorernes

afladningstider.

Livsfara!

Farliga rörelser!

Farlige

bevægelser! Livsfare!

Uppehåll dig inte inom maskiners

och maskindelars rörelseområde.

Du må ikke opholde dig inden for

maskiners og maskindeles

Förhindra att obehöriga personer får bevægelsesradius.

tillträde.

Sørg for, at ingen personer kan få

utilsigtet adgang.

Innan du börjar arbeta eller vistas

inom drivsystemets riskområde

måste maskinen vara stillastående.

DOK-RCON04-VFC-x610***-IT01-EN-P

Stands drevene helt, inden du rører

ved drevene eller træder ind i deres

fareområde.

Hoge

elektrische spanning! Levensgevaar

door elektrische schok!

Bedien de aandrijvingscomponenten

uitsluitend met vast geïnstalleerde

aardleiding.

Schakel voor toegang tot

aandrijvingscomponenten de

spanningsvoorziening uit.

Neem de ontlaadtijden van

condensatoren in acht.

Risicovolle

bewegingen! Levensgevaar!

Houdt u niet op in het

bewegingsbereik van machines en

machineonderdelen.

Voorkom dat personen onbedoeld

toegang verkrijgen.

Voor toegang tot de gevaarlijke zone

moeten de aandrijvingen veilig tot

stilstand gebracht zijn.

V

VFC x610 Series

Bosch Rexroth AG

Svenska

Dansk

Elektromagnetiska/

magnetiska fält! Hälsofara för

Elektromagnetiske/magnetiske

personer med pacemaker, implantat felter! Sundhedsfare for personer

av metall eller hörapparat!

med pacemakere, metalliske

implantater eller høreapparater!

Det är förbjudet för ovan nämnda

Nederlands

Elektromagnetische / magnetische

velden! Gevaar voor de gezondheid

van personen met pacemakers,

metalen implantaten of

hoorapparaten!

personer (eller kräver överläggning

med läkare) att beträda områden där

drivkomponenter är monterade och i

drift.

For disse personer er der adgang

forbudt eller kun adgang med

tilladelse fra læge til de områder,

hvor drive components monteres og

drives.

Varma ytor

(> 60 °C)! Risk för brännskador!

Varme overflader

Hete

(> 60 °C)! Risiko for forbrændinger! oppervlakken (> 60 °C)!

Verbrandingsgevaar!

Undgå at berøre metaloverflader

Undvik att vidröra metallytor (t.ex.

kylelement). Var medveten om att

(f.eks. køleelementer). Overhold

det tar tid för drivkomponenterna att drive components nedkølingstid

svalna (minst 15 minuter).

(min. 15 min.).

Toegang tot gebieden, waarin

aandrijvingscomponenten worden

gemonteerd en bediend, is verboden

voor voornoemde personen of

uitsluitend toegestaan na overleg met

een arts.

Voorkom contact met metalen

oppervlakken (bijv. Koellichamen).

Afkoeltijd van de

aandrijvingscomponenten in acht

nemen (min. 15 minuten).

Felaktig

hantering vid transport och

montering! Skaderisk!

Fejlhåndtering

ved transport og montering! Risiko

for kvæstelser!

Onjuist gebruik

bij transport en montage!

Letselgevaar!

Använd passande monterings- och

transportanordningar.

Benyt egnede monterings- og

transportanordninger.

Gebruik geschikte montage- en

transportinrichtingen.

Använd lämpliga verktyg och

personlig skyddsutrustning.

Benyt egnet værktøj og personligt

sikkerhedsudstyr.

Gebruik geschikt gereedschap en een

persoonlijke veiligheidsuitrusting.

Felaktig

hantering av batterier! Skaderisk!

Fejlhåndtering af

batterier! Risiko for kvæstelser!

Onjuist gebruik

van batterijen! Letselgevaar!

Försök inte återaktivera eller ladda

upp batterier (risk för explosioner

och frätskador).

Forsøg ikke at genaktivere eller

oplade tomme batterier

(eksplosions- og ætsningsfare).

Batterierna får inte tas isär eller

skadas. Släng inte batterierna i

elden.

Undlad at skille batterier ad eller at

beskadige dem. Smid ikke batterier

ind i åben ild.

Probeer nooit lege batterijen te

reactiveren of op te laden

(explosiegevaar en gevaar voor

beschadiging van weefsel door

cauterisatie).

VI

Batterijen niet demonteren of

beschadigen. Nooit batterijen in het

vuur werpen.

DOK-RCON04-VFC-x610***-IT01-EN-P

VFC x610 Series

Suomi

Bosch Rexroth AG

Polski

Näiden

turvaohjeiden noudattamatta

jättämisestä on seurauksena

hengenvaara!

Zagrożenie

życia w razie nieprzestrzegania

poniższych wskazówek

bezpieczeństwa!

Ota tuote käyttöön vasta sen jälkeen,

kun olet lukenut läpi tuotteen

mukana toimitetut asiakirjat ja

turvallisuusohjeet, ymmärtänyt ne ja

ottanut ne huomioon.

Nie uruchamiać produktów przed

uprzednim przeczytaniem i pełnym

zrozumieniem wszystkich

dokumentów dostarczonych wraz z

produktem oraz wskazówek

bezpieczeństwa. Należy

przestrzegać wszystkich zawartych

tam zaleceń.

Jos asiakirjoja ei ole saatavana

omalla äidinkielelläsi, ota yhteys

asianomaiseen Rexrothin

myyntiedustajaan.

W przypadku braku dokumentów w

Państwa języku, prosimy o

Käyttölaitteiden komponenttien

parissa saa työskennellä ainoastaan skontaktowanie się z lokalnym

partnerem handlowym Rexroth.

valtuutettu henkilöstö.

Lisätietoa turvaohjeista löydät tämän Przy zespołach napędowych może

pracować wyłącznie

dokumentaation luvusta 1.

wykwalifikowany personel.

Český

Nebezpečí života v

případě nedodržení níže uvedených

bezpečnostních pokynů!

Před uvedením výrobků do provozu si

přečtěte kompletní dokumentaci a

bezpečnostní pokyny dodávané s

výrobkem, pochopte je a dodržujte.

Nemáte-li k dispozici podklady ve

svém jazyce, obraťte se na

příslušného obchodního partnera

Rexroth.

Na komponentách pohonu smí

pracovat pouze kvalifikovaný

personál.

Podrobnější vysvětlení k

bezpečnostním pokynům naleznete v

kapitole 1 této dokumentace.

Bliższe objaśnienia wskazówek

bezpieczeństwa znajdują się w

Rozdziale 1 niniejszej dokumentacji.

Voimakas

sähköjännite! Sähköiskun

aiheuttama hengenvaara!

Wysokie

napięcie elektryczne! Zagrożenie

życia w wyniku porażenia prądem!

Käytä käyttölaitteen komponentteja Zespoły napędu mogą być

ainoastaan maadoitusjohtimen

eksploatowane wyłącznie z

ollessa kiinteästi asennettuna.

zainstalowanym na stałe przewodem

ochronnym.

Katkaise jännitteensyöttö ennen

käyttölaitteen komponenteille

Przed uzyskaniem dostępu do

suoritettavien töiden aloittamista.

podzespołów napędu należy

odłączyć zasilanie elektryczne.

Huomioi kondensaattoreiden

purkausajat.

Zwracać uwagę na czas

rozładowania kondensatorów.

Hengenvaara!

Vaarallisia liikkeitä!

Älä oleskele koneiden tai

koneenosien liikealueella.

Niebezpieczne ruchy! Zagrożenie

życia!

Nie wolno przebywać w obszarze

pracy maszyny i jej elementów.

Pidä huolta siitä, ettei muita

henkilöitä pääse alueelle vahingossa. Nie dopuszczać osób niepowołanych

do obszaru pracy maszyny.

Pysäytä käyttölaitteet varmasti

ennen vaara-alueelle koskemista tai Przed dotknięciem urządzenia/

menemistä.

maszyny lub zbliżeniem się do

obszaru zagrożenia należy zgodnie z

zasadami bezpieczeństwa wyłączyć

napędy.

DOK-RCON04-VFC-x610***-IT01-EN-P

Vysoké elektrické

napětí! Nebezpečí života při zasažení

elektrickým proudem!

Komponenty pohonu smí být v

provozu pouze s pevně

nainstalovaným ochranným vodičem.

Než začnete zasahovat do komponent

pohonu, odpojte je od elektrického

napájení.

Dodržujte vybíjecí časy kondenzátorů.

Nebezpečné

pohyby! Nebezpečí života!

Nezdržujte se v dosahu pohybu strojů

a jejich součástí.

Zabraňte náhodnému přístupu osob.

Před zásahem nebo vstupem do

nebezpečného prostoru bezpečně

zastavte pohony.

VII

VFC x610 Series

Bosch Rexroth AG

Suomi

Sähkömagneettisia/magneettisia

kenttiä! Terveydellisten haittojen

vaara henkilöille, joilla on

sydämentahdistin, metallinen

implantti tai kuulolaite!

Polski

Pola

elektromagnetyczne / magnetyczne!

Zagrożenie zdrowia dla osób z

rozrusznikiem serca, metalowymi

implantami lub aparatami

słuchowymi!

Yllä mainituilta henkilöiltä on pääsy

kielletty alueille, joilla asennetaan tai

käytetään käyttölaitteen

komponentteja, tai heidän on ensin

saatava tähän suostumus

lääkäriltään.

Wstęp na teren, gdzie odbywa się

montaż i eksploatacja napędów jest

dla ww. osób zabroniony względnie

dozwolony po konsultacji z lekarzem.

Kuumia pintoja

(> 60 °C)! Palovammojen vaara!

Gorące

powierzchnie (> 60 °C)!

Niebezpieczeństwo poparzenia!

Vältä metallipintojen koskettamista

(esim. jäähdytyslevyt). Noudata

Unikać kontaktu z powierzchniami

käyttölaitteen komponenttien

metalowymi (np. radiatorami).

jäähtymisaikoja (väh. 15 minuuttia). Przestrzegać czasów schładzania

podzespołów napędów (min. 15

minut).

Český

Elektromagnetická/

magnetická pole! Nebezpečí pro

zdraví osob s kardiostimulátory,

kovovými implantáty nebo

naslouchadly!

Výše uvedené osoby mají zakázán

přístup do prostorů, kde jsou

montovány a používány komponenty

pohonu, resp. ho mají povolen pouze

po poradě s lékařem.

Horké povrchy

(> 60 °C)! Nebezpečí popálení!

Nedotýkejte se kovových povrchů

(např. chladicích těles). Dodržujte

dobu ochlazení komponent pohonu

(min. 15 minut).

Epäasianmukainen

käsittely kuljetuksen ja asennuksen

yhteydessä! Loukkaantumisvaara!

Niewłaściwe

Nesprávné

obchodzenie się podczas transportu zacházení při přepravě a montáži!

i montażu! Ryzyko urazu!

Nebezpečí zranění!

Käytä soveltuvia asennus- ja

kuljetuslaitteita.

Stosować odpowiednie urządzenia

montażowe i transportowe.

Používejte vhodná montážní a

dopravní zařízení.

Käytä omia työkaluja ja

henkilökohtaisia suojavarusteita.

Stosować odpowiednie narzędzia i

środki ochrony osobistej.

Používejte vhodné nářadí a osobní

ochranné vybavení.

Paristojen

epäasianmukainen käsittely!

Loukkaantumisvaara!

Niewłaściwe

Nesprávné

obchodzenie się z bateriami! Ryzyko zacházení s bateriemi! Nebezpečí

urazu!

zranění!

Älä yritä saada tyhjiä paristoja

toimimaan tai ladata niitä uudelleen

(räjähdys- ja syöpymisvaara).

Nie próbować reaktywować i nie

ładować zużytych baterii

(niebezpieczeństwo wybuchu oraz

Älä hajota paristoja osiin tai vaurioita poparzenia żrącą substancją).

niitä. Älä heitä paristoja tuleen.

Nie demontować i nie niszczyć

baterii. Nie wrzucać baterii do ognia.

Nepokoušejte se znovu aktivovat nebo

dobíjet prázdné baterie (nebezpečí

výbuchu a poleptání).

VIII

DOK-RCON04-VFC-x610***-IT01-EN-P

Nerozebírejte ani nepoškozujte

baterie. Neházejte baterie do ohně.

VFC x610 Series

Slovensko

Bosch Rexroth AG

Slovenčina

Română

Življenjska

nevarnost pri neupoštevanju

naslednjih napotkov za varnost!

Nebezpečenstvo

Pericol de

ohrozenia života pri nedodržiavaní moarte în cazul nerespectării

nasledujúcich bezpečnostných

următoarelor instrucţiuni de

siguranţă!

Izdelke začnite uporabljati šele, ko v pokynov!

celoti preberete, razumete in

Výrobky uvádzajte do prevádzky až Punerea în funcţiune a produselor

upoštevate izdelkom priloženo

potom, čo ste úplne prečítali,

trebuie efectuată după citirea,

dokumentacijo in varnostne

pochopili a zobrali do úvahy

înţelegerea şi respectarea

napotke.

podklady a bezpečnostné pokyny

documentelor şi instrucţiunilor de

dodané s výrobkom.

siguranţă, care sunt livrate împreună

Če priložena dokumentacija ni na

voljo v vašem maternem jeziku, se

Ak by ste nemali k dispozícii žiadne cu produsele.

obrnite na pristojnega distributerja

Rexroth.

podklady v jazyku svojej krajiny,

obráťte sa prosím na svojho

Samo kvalificirano osebje sme delati príslušného predajcu Rexroth.

na pogonskih komponentah.

Na komponentoch pohonu smie

Podrobnejša pojasnila o varnostnih pracovať iba kvalifikovaný personál.

navodilih najdete v poglavju 1 v tej

dokumentaciji.

În cazul în care documentele nu sunt

în limba dumneavoastră maternă, vă

rugăm să contactaţi partenerul de

vânzări Rexroth.

Numai un personal calificat poate

Bližšie vysvetlenia k bezpečnostným lucra cu componentele de acţionare.

pokynom zistite z kapitoly 1 tejto

Explicaţii detaliate privind

dokumentácie.

instrucţiunile de siguranţă găsiţi în

capitolul 1 al acestei documentaţii.

Visoka električna

Vysoké elektrické

Tensiune

napetost! Življenjska nevarnost

napätie! Nebezpečenstvo ohrozenia electrică înaltă! Pericol de moarte prin

zaradi električnega udara!

života v dôsledku zásahu elektrickým electrocutare!

Pogonske komponente uporabljajte prúdom!

Exploataţi componentele de acţionare

samo s fiksno nameščenim zaščitnim Komponenty pohonu prevádzkujte numai cu împământarea instalată

vodnikom.

iba s pevne nainštalovaným

permanent.

ochranným vodičom.

Pred dostopom do pogonske

Înainte de intervenţia asupra

komponente odklopite napajanje.

Upoštevajte čase praznjenja

kondenzatorjev.

Pred prístupom na komponenty

pohonu odpojte zdroj napätia.

Rešpektujte časy vybitia

kondenzátorov.

Nevarni premiki!

Pohyby

Življenjska nevarnost!

prinášajúce nebezpečenstvo!

Ne zadržujte se v območju delovanja Nebezpečenstvo ohrozenia života!

strojev.

Preprečite nenadzorovan dostop

oseb.

Pred prijemom ali dostopom v

nevarno območje varno zaustavite

vse gnane dele.

DOK-RCON04-VFC-x610***-IT01-EN-P

Nezdržiavajte sa v oblasti pohybu

strojov a častí strojov.

Zabráňte nepovolanému prístupu

osôb.

componentelor de acţionare,

deconectaţi alimentarea cu tensiune

electrică.

Ţineţi cont de timpii de descărcare ai

condensatorilor.

Mişcări

periculoase! Pericol de moarte!

Nu staţionaţi în zona de mişcare a

maşinilor şi a componentelor în

mişcare a maşinilor.

Împiedicaţi accesul neintenţionat al

persoanelor în zona de lucru a

maşinilor.

Pred zásahom alebo prístupom do

nebezpečnej oblasti uveďte pohony Înainte de intervenţia sau accesul în

bezpečne do zastavenia.

zona periculoasă, opriţi în siguranţă

componentele de acţionare.

IX

VFC x610 Series

Bosch Rexroth AG

Slovensko

Elektromagnetna / magnetna polja!

Nevarnost za zdravje za osebe s

spodbujevalniki srca, kovinskimi

vsadki ali slušnimi aparati!

Dostop do območij, v katerih so

nameščene delujoče pogonske

komponente, je za zgoraj navedene

osebe prepovedan oz. dovoljen

samo po posvetu z zdravnikom.

Vroče površine

(> 60 °C)! Nevarnost opeklin!

Izogibajte se stiku s kovinskimi

površinami (npr. hladilnimi telesi).

Upoštevajte čas hlajenja pogonskih

komponent (najm. 15 minut).

Slovenčina

Elektromagnetické/magnetické

polia! Nebezpečenstvo pre zdravie

osôb s kardiostimulátormi, kovovými

implantátmi alebo načúvacími

prístrojmi!

Prístup k oblastiam, v ktorých sú

namontované a prevádzkujú sa

komponenty pohonu, je pre hore

uvedené osoby zakázaný resp. je

dovolený iba po konzultácii s

lekárom.

Română

Câmpuri

electromagnetice / magnetice! Pericol

pentru sănătatea persoanelor cu

stimulatoare cardiace, implanturi

metalice sau aparate auditive!

Intrarea în zone, în care se montează

sau se exploatează componente de

acţionare, este interzisă pentru

persoanele sus numite respectiv este

permisă numai cu acordul medicului.

Horúce

Suprafeţe fierbinţi

povrchy (> 60 °C)! Nebezpečenstvo (> 60 °C)! Pericol de arsuri!

popálenia!

Nu atingeţi suprafeţele metalice (de

Zabráňte kontaktu s kovovými

ex. radiatoare de răcire). Respectaţi

povrchmi (napr. chladiacimi

timpii de răcire ai componentelor de

telesami). Dodržiavajte čas

acţionare (min. 15 minute).

vychladenia komponentov pohonu

(min. 15 minút).

Nestrokovno ravnanje

med transportom in namestitvijo!

Nevarnost poškodb!

Neodborná

manipulácia pri transporte a

montáži! Nebezpečenstvo

Uporabljajte ustrezne pripomočke za poranenia!

nameščanje in transport.

Používajte vhodné montážne a

Uporabite ustrezno orodje in osebno transportné zariadenia.

Manipulare

necorespunzătoare la transport şi

montaj! Pericol de vătămare!

Nepravilno ravnanje z

baterijami! Nevarnost poškodb!

Neodborná

manipulácia s batériami!

Nebezpečenstvo poranenia!

Manipulare

necorespunzătoare a bateriilor!

Pericol de vătămare!

Nepokúšajte sa reaktivovať alebo

nabíjať prázdne batérie

(nebezpečenstvo výbuchu a

poleptania).

Nu încercaţi să reactivaţi sau să

încărcaţi bateriile goale (pericol de

explozie şi pericol de arsuri).

zaščitno opremo.

Ne poskušajte ponovno aktivirati ali

napolniti praznih baterij (Nevarnost

zaradi eksplozij ali jedkanja).

Ne razstavljajte ali poškodujte

nobenih baterij. Baterij ne mečite v

ogenj.

X

Utilizaţi dispozitive adecvate de

montaj şi transport.

Folosiţi instrumente corespunzătoare

Používajte vhodné náradie a osobné şi echipament personal de protecţie.

ochranné prostriedky.

Nu dezasamblaţi şi nu deterioraţi

Batérie nerozoberajte ani

bateriile. Nu aruncaţi bateriile în foc.

nepoškodzujte. Nehádžte batérie do

ohňa.

DOK-RCON04-VFC-x610***-IT01-EN-P

VFC x610 Series

Magyar

Bosch Rexroth AG

Български

Latviski

Az

alábbi biztonsági útmutatások

figyelmen kívül hagyása

életveszélyes helyzethez vezethet!

Turpinājumā

Опасност за живота при

doto drošības norādījumu

неспазване на посочените по-долу neievērošana var apdraudēt dzīvību!

инструкции за безопасност!

Sāciet lietot izstrādājumu tikai pēc

Използвайте продуктите след като tam, kad esat pilnībā izlasījuši,

Üzembe helyezés előtt olvassa el,

сте се запознали подробно с

értelmezze, és vegye figyelembe a

sapratuši un ņēmuši vērā kopā ar

приложената към продукта

csomagban található

izstrādājumu piegādātos dokumentus.

документация и указания за

dokumentumban foglaltakat és a

безопасност, разбрали сте ги и сте Ja dokumenti nav pieejami Jūsu valsts

biztonsági útmutatásokat.

valodā, vērsieties pie pilnvarotā

се съобразили с тях.

Amennyiben a csomagban nem talál

Rexroth izplatītāja.

az Ön nyelvén írt dokumentumokat, Ако текстът не е написан на Вашия Darbus pie piedziņas komponentiem

език, моля обърнете се към Вашия

vegye fel a kapcsolatot az illetékes

drīkst veikt tikai kvalificēts personāls.

компетентен търговски

Rexroth-képviselővel.

представител на Rexroth.

Detalizētus paskaidrojumus attiecībā

A hajtás alkatrészein kizárólag

uz drošības norādījumiem skatiet šī

Със задвижващите компоненти

képzett személy dolgozhat.

dokumenta 1. nodaļā.

трябва да работи само

A biztonsági útmutatókkal

квалифициран персонал.

kapcsolatban további magyarázatot

Подробни пояснения към

ennek a dokumentumnak az első

инструкциите за безопасност

fejezetében találhat.

можете да видите в Глава 1 на тази

документация.

Високо

Augsts

електрическо напрежение!

elektriskais spriegums! Dzīvības

Опасност за живота от удар от

apdraudējums elektriskā trieciena dēļ!

електрически ток!

A hajtás alkatrészeit csak véglegesen

Piedziņas komponentus darbiniet tikai

Работете със задвижващите

telepített védővezetővel

ar fiksēti uzstādītu zemējumvadu.

компоненти само при здраво

üzemeltesse!

закрепен заземяващ проводник. Pirms darba pie piedziņas

Mielőtt hozzányúl a hajtás

komponentiem atslēdziet

Преди работа по задвижващите

alkatrészeihez, kapcsolja ki az

elektroapgādi.

компоненти, изключете

áramellátást.

Ņemiet vērā kondensatoru izlādes

захранващото напрежение.

Ügyeljen a kondenzátorok kisülési

laikus.

Обърнете внимание на времето за

idejére!

разреждане на кондензаторите.

Magas

elektromos feszültség! Életveszély

áramütés miatt!

Опасни

Bīstamas

движения! Опасност за живота!

kustības! Dzīvības apdraudējums!

Не стойте в обсега на движение на Neuzturieties mašīnu un mašīnas

Ne tartózkodjon a gépek és a

машините и частите на машините. detaļu kustību zonā.

gépalkatrészek mozgási területén

belül!

Не допускайте непреднамерен

Novērsiet nepiederošu personu

Illetéktelen személyeket ne engedjen достъп на хора.

piekļūšanu.

a gép közelébe!

Преди работа или влизане в

Pirms darba bīstamajās zonās pilnībā

Mielőtt beavatkozik, vagy a veszélyes опасната зона, спрете надеждно

apstādiniet piedziņu.

приводния механизъм.

zónába belép a hajtásokat

biztonságosan állítsa le.

Veszélyes mozgás! Életveszély!

DOK-RCON04-VFC-x610***-IT01-EN-P

XI

VFC x610 Series

Bosch Rexroth AG

Magyar

Elektromágneses / mágneses mező!

Káros hatással lehet a szívritmusszabályozó készülékkel,

fémbeültetéssel vagy

hallókészülékkel rendelkezők

egészségére!

Azokra a területekre, ahol hajtások

alkatrészeit szerelik és üzemeltetik, a

fent említett személyeknek tilos a

belépés, illetve csak orvosi

konzultációt követően szabad az

adott területekre lépniük.

Български

Latviski

Електромагнитни / магнитни

полета! Опасност за здравето на

хора със сърдечни стимулатори,

метални импланти или слухови

апарати!

Elektromagnētiskais / magnētiskais

lauks! Veselības apdraudējums

personām ar sirds stimulatoriem,

metāliskiem implantiem vai dzirdes

aparātiem!

Достъпът за гореспоменатите лица

до зони, в които ще се монтират и

ще работят задвижващи

компоненти се забранява, или

разрешава само след консултация

с лекар.

Tuvošanās zonām, kurās tiek montēti

un darbināti piedziņas komponenti,

iepriekš minētajām personām ir

aizliegta, respektīvi, atļauta tikai pēc

konsultēšanās ar ārstu.

Горещи

Karstas virsmas

повърхности (> 60 °C)! Опасност от (> 60 °C)! Apdedzināšanās risks!

изгаряне!

Ne érjen hozzá fémfelületekhez (pl.

Neskarieties pie metāliskām virsmām

hűtőtestekhez)! Vegye figyelembe a Не докосвайте метални

(piemēram, dzesētāja). Ļaujiet

hajtás alkatrészeinek kihűlési idejét повърхности (например

piedziņas komponentiem atdzist (min.

радиатори). Съблюдавайте

(min. 15 perc)!

15 minūtes).

времето на охлаждане на

задвижващите компоненти (мин.

15 минути).

Forró felületek

(> 60 °C)! Égésveszély!

Szakszerűtlen

kezelés szállításkor és szereléskor!

Sérülésveszély!

A megfelelő beszerelési és szállítási

eljárásokat alkalmazza!

Használjon megfelelő szerszámokat

és személyes védőfelszerelést!

Akkumulátorok

szakszerűtlen kezelése!

Sérülésveszély!

Неправилно

Nepareizi veikta

боравене по време на транспорт и transportēšana un montāža! Traumu

монтаж!Опасност от нараняване! gūšanas risks!

Използвайте подходящо монтажно Izmantojiet piemērotas montāžas un

и транспортно оборудване.

transportēšanas ierīces.

Използвайте подходящи

Izmantojiet piemērotus instrumentus

инструменти и лични предпазни

un individuālos aizsardzības līdzekļus.

средства.

Неправилно

боравене с батерии! Опасност от

нараняване!

Üres akkumulátorokat ne aktiváljon Не се опитвайте да активирате

újra, illetve ne töltsön fel (robbanás- отново или да зареждате

разредени батерии (Опасност от

és marásveszély)!

експлозия и напръскване с

Az akkumulátorokat ne szedje szét, агресивен агент).

és ne rongálja meg! Az akkumulátort

Не разглобявайте и не

ne dobja tűzbe!

повреждайте батерии. Не

хвърляйте батерии в огън.

XII

Nepareiza bateriju

lietošana! Traumu gūšanas risks!

Nemēģiniet no jauna aktivizēt vai

uzlādēt tukšas baterijas (eksploziju un

ķīmisko apdegumu draudi).

Neizjauciet un nesabojājiet baterijas.

Nemetiet baterijas ugunī.

DOK-RCON04-VFC-x610***-IT01-EN-P

VFC x610 Series

Bosch Rexroth AG

Lietuviškai

Pavojus gyvybei

nesilaikant toliau pateikiamų

saugumo nurodymų!

Naudokite gaminį tik kruopščiai

perskaitę prie jo pridėtus aprašus,

saugumo nurodymus. Susipažinkite

su jais ir vadovaukitės naudodami

gaminį.

Eesti

Ελληνικά

Alljärgnevate

Κίνδυνος

ohutusjuhiste eiramine on eluohtlik! θανάτου σε περίπτωση μη

συμμόρφωσης με τις παρακάτω οδηγίες

Võtke tooted käiku alles siis, kui

ασφαλείας!

olete toodetega kaasasolevad

materjalid ning ohutusjuhised

täielikult läbi lugenud, neist aru

saanud ja neid järginud.

Kui Teil puuduvad emakeelsed

materjalid, siis pöörduge Rexrothi

kohaliku müügiesinduse poole.

Θέστε το προϊόν σε λειτουργία αφού

διαβάσετε, κατανοήσετε και λάβετε

υπόψη το σύνολο των οδηγιών

ασφαλείας που το συνοδεύουν.

Εάν δεν υπάρχει τεκμηρίωση στη

γλώσσα σας, απευθυνθείτε σε

Ajamikomponentidega tohib töötada εξουσιοδοτημένο αντιπρόσωπο της

Rexroth.

Prie pavaros komponentų leidžiama üksnes kvalifitseeritud personal.

Μόνο εξειδικευμένο προσωπικό

dirbti tik kvalifikuotam personalui.

Täpsemaid selgitusi ohutusjuhiste

επιτρέπεται να χειρίζεται στοιχεία

kohta leiate käesoleva

Išsamesnius saugumo nurodymų

μετάδοσης κίνησης.

dokumentatsiooni peatükist 1.

paaiškinimus rasite šios

Περαιτέρω επεξηγήσεις των οδηγιών

dokumentacijos 1 skyriuje.

ασφαλείας διατίθενται στο κεφάλαιο 1

της παρούσας τεκμηρίωσης.

Jei Jūs negavote aprašo gimtąja

kalba, kreipkitės į įgaliotus Rexroth

atstovus.

Kõrge elektripinge!

Aukšta elektros

įtampa! Pavojus gyvybei dėl elektros Eluohtlik elektrilöögi tõttu!

smūgio!

Käitage ajamikomponente üksnes

püsivalt installeeritud maandusega.

Pavaros komponentus

eksploatuokite tik su fiksuotai

Lülitage enne ajamikomponentidega

instaliuotu apsauginiu laidu.

tööde alustamist toitepinge välja.

Prieš prieidami prie pavaros

Järgige kondensaatorite

komponentų išjunkite maitinimo

mahalaadumisaegu.

įtampą.

Atsižvelkite į kondensatorių

išsikrovimo trukmę.

Pavojus gyvybei!

Pavojingi judesiai!

Θέτετε σε λειτουργία τα στοιχεία

μετάδοσης κίνησης μόνο εφόσον έχει

τοποθετηθεί καλά προστατευτικός

αγωγός γείωσης.

Πριν από οποιαδήποτε παρέμβαση,

αποσυνδέστε την τροφοδοσία των

στοιχείων μετάδοσης κίνησης.

Λάβετε υπόψη τους χρόνους

αποφόρτισης των πυκνωτών.

Eluohtlik!

Ohtlikud liikumised!

Nebūkite mašinų ar jų dalių judėjimo Ärge viibige masina ja masinaosade

liikumispiirkonnas.

zonoje.

Neleiskite netyčia patekti asmenims. Tõkestage inimeste ettekavatsematu

sisenemine masina ja masinaosade

Prieš patekdami į pavojaus zoną

liikumispiirkonda.

saugiai išjunkite pavaras.

Tagage ajamite turvaline seiskamine

enne ohupiirkonda juurdepääsu või

sisenemist.

DOK-RCON04-VFC-x610***-IT01-EN-P

Υψηλή

ηλεκτρική τάση! Κίνδυνος θανάτου από

ηλεκτροπληξία!

τάσεις! Κίνδυνος θανάτου!

Επικίνδυνες

Μην στέκεστε στην περιοχή κίνησης

μηχανημάτων και εξαρτημάτων.

Αποτρέπετε την τυχαία είσοδο ατόμων.

Πριν από την παρέμβαση ή πρόσβαση

στην περιοχή κινδύνου, μεριμνήστε για

την ασφαλή ακινητοποίηση των

συστημάτων μετάδοσης κίνησης.

XIII

VFC x610 Series

Bosch Rexroth AG

Lietuviškai

Elektromagnetiniai / magnetiniai

laukai! Pavojus asmenų su širdies

stimuliatoriais, metaliniais

implantais arba klausos aparatais

sveikatai!

Prieiga prie zonų, kuriose

montuojami ir eksploatuojami

pavaros komponentai, aukščiau

nurodytiems asmenims yra

draudžiama arba leistina tik

pasitarus su gydytoju.

Karšti

paviršiai (> 60 °C)! Nudegimo

pavojus!

Venkite liesti metalinius paviršius

(pvz., radiatorių). Išlaikykite pavaros

komponentų atvėsimo trukmę (bent

15 minučių).

Netinkamas

darbas transportuojant ir

montuojant! Susižalojimo pavojus!

Naudokite tinkamus montavimo ir

transportavimo įrenginius.

Eesti

Elektromagnetilised /

magnetilised väljad! Terviseohtlik

südamestimulaatorite,

metallimplantaatide ja

kuulmisseadmetega inimestele!

Ελληνικά

Ηλεκτρομαγνητικά/μαγνητικά πεδία!

Κίνδυνος για την υγεία ατόμων με

καρδιακούς βηματοδότες, μεταλλικά

εμφυτεύματα ή συσκευές ακοής!

Sisenemine piirkondadesse, kus

toimub ajamikomponentide

monteerimine ja käitamine, on

ülalnimetatud isikutele keelatud või

lubatud üksnes pärast arstiga

konsulteerimist.

Η είσοδος σε περιοχές όπου

πραγματοποιείται συναρμολόγηση και

λειτουργία στοιχείων μετάδοσης

κίνησης απαγορεύεται στα

προαναφερθέντα άτομα, εκτός αν τους

έχει δοθεί σχετική άδεια κατόπιν

συνεννόησης με γιατρό.

Kuumad

välispinnad (> 60 °C)! Põletusoht!

Καυτές επιφάνειες

(> 60 °C)! Κίνδυνος εγκαύματος!

Vältige metalsete välispindade (nt

radiaatorid) puudutamist. Pidage

kinni ajamikomponentide

mahajahtumisajast (vähemalt 15

minutit).

Αποφεύγετε την επαφή με μεταλλικές

επιφάνειες (π.χ. μονάδες ψύξης).

Λάβετε υπόψη το χρόνο ψύξης των

στοιχείων μετάδοσης κίνησης

(τουλάχιστον 15 λεπτά).

Asjatundmatu

Ακατάλληλος

käsitsemine transportimisel ja

χειρισμός κατά τη μεταφορά και

montaažil! Vigastusoht!

συναρμολόγηση! Κίνδυνος

τραυματισμού!

Kasutage sobivaid montaaži- ja

Naudokite tinkamus įrankius ir

asmens saugos priemones.

transpordiseadiseid.

Kasutage sobivaid tööriistu ja

isiklikku kaitsevarustust.

Χρησιμοποιείτε κατάλληλους

μηχανισμούς συναρμολόγησης και

μεταφοράς.

Netinkamas

darbas su baterijomis! Susižalojimo

pavojus!

Patareide

asjatundmatu käsitsemine!

Vigastusoht!

Ακατάλληλος

χειρισμός μπαταριών! Κίνδυνος

τραυματισμού!

Χρησιμοποιείτε κατάλληλα εργαλεία

και ατομικό εξοπλισμό προστασίας.

Ärge üritage kunagi tühje patareisid

Nebandykite tuščių baterijų

reaktyvuoti arba įkrauti (sprogimo ir reaktiveerida või täis laadida

(plahvatus- ja söövitusoht).

išėsdinimo pavojus).

Neardykite ir nepažeiskite baterijų. Ärge demonteerige ega kahjustage

patareisid. Ärge visake patareisid

Nemeskite baterijų į ugnį.

tulle.

Μην επιδιώκετε να ενεργοποιήσετε

ξανά ή να φορτίσετε κενές μπαταρίες

(κίνδυνος έκρηξης και διάβρωσης).

XIV

DOK-RCON04-VFC-x610***-IT01-EN-P

Μην διαλύετε ή καταστρέφετε τις

μπαταρίες. Μην απορρίπτετε τις

μπαταρίες στη φωτιά.

VFC x610 Series

Bosch Rexroth AG

中文

如果不按照下述指定的安全说明使用,将会导致人身伤害!

在没有阅读,理解随本产品附带的文件并熟知正当使用前,不要安装或使用本产品。

如果没有您所在国家官方语言文件说明,请与 Rexroth 销售伙伴联系。

只允许有资格人员对驱动器部件进行操作。

安全说明的详细解释在本文档的第一章。

高电压!电击导致生命危险!

只有在安装了永久良好的设备接地导线后才可以对驱动器的部件进行操作。

在接触驱动器部件前先将驱动器部件断电。

确保电容放电时间。

危险运动!生命危险!

保证设备的运动区域内和移动部件周围无障碍物。

防止人员意外进入设备运动区域内。

在接近或进入危险区域之前,确保传动设备安全停止。

电磁场/磁场!对佩戴心脏起搏器、金属植入物和助听器的人员会造成严重的人身伤害 !

上述人员禁止进入安装及运行的驱动器区域,或者必须事先咨询医生。

热表面(大于 60 度)!灼伤风险!

不要触摸金属表面(例如散热器)。驱动器部件断电后需要时间进行冷却(至少 15 分钟)。

安装和运输不当导致受伤危险!当心受伤!

使用适当的运输和安装设备。

使用适合的工具及用适当的防护设备。

电池操作不当!受伤风险!

请勿对低电量电池重新激活或重新充电(爆炸和腐蚀的危险)。

请勿拆解或损坏电池。请勿将电池投入明火中。

DOK-RCON04-VFC-x610***-IT01-EN-P

XV

Bosch Rexroth AG

XVI

VFC x610 Series

DOK-RCON04-VFC-x610***-IT01-EN-P

VFC x610 Series

Bosch Rexroth AG

Table of Contents

Table of Contents

Page

1

1.1

1.2

1.3

1.3.1

1.3.2

1.3.3

1.4

1.4.1

1.4.2

1.4.5

1.4.6

Safety Instructions for Electric Drives and Controls.............................. 1

Definitions of Terms.............................................................................. 1

Explanation of Signal Words and the Safety Alert Symbol.................... 3

General Information............................................................................... 4

Using the Safety Instructions and Passing Them on to Others.............. 4

Requirements for Safe Use.................................................................... 4

Hazards by Improper Use....................................................................... 6

Instructions with Regard to Specific Dangers....................................... 7

Protection Against Contact With Electrical Parts and Housings............ 7

Protective Extra-Low Voltage as Protection Against Electric

Shock .................................................................................................... 8

Protection Against Dangerous Movements............................................ 8

Protection Against Magnetic and Electromagnetic Fields During Operation and Mounting........................................................................... 10

Protection Against Contact with Hot Parts.......................................... 11

Protection During Handling and Mounting.......................................... 11

2

2.1

2.2

Important Directions for Use............................................................... 12

Appropriate Use................................................................................... 12

Inappropriate Use................................................................................ 12

3

3.1

3.2

Documentation Information................................................................. 13

About this Documentation................................................................... 13

Reference............................................................................................. 13

4

4.1

4.1.1

4.1.2

4.2

4.3

4.4

4.5

Delivery and Storage............................................................................

Product Identification..........................................................................

Packing Nameplate..............................................................................

Product Nameplate..............................................................................

Visual Inspection..................................................................................

Scope of Supply...................................................................................

Transport of the Components.............................................................

Storage of the Components.................................................................

5

Drive System Overview........................................................................ 17

6

Frequency Converter Overview............................................................ 18

1.4.3

1.4.4

DOK-RCON04-VFC-x610***-IT01-EN-P

14

14

14

15

15

15

16

16

XVII

Bosch Rexroth AG

Table of Contents

VFC x610 Series

Page

6.1

6.1.1

6.1.2

6.1.3

6.1.4

6.1.5

6.1.6

6.1.7

6.1.8

6.1.9

6.2

6.2.1

6.2.2

Product Features.................................................................................

Input....................................................................................................

Output.................................................................................................

V/f Control Performance......................................................................

SVC Control Performance....................................................................

Main Functions....................................................................................

Communication....................................................................................

Operating Panel...................................................................................

Protection............................................................................................

Conditions...........................................................................................

Technical Data.....................................................................................

Electric Data........................................................................................

Derating of Electric Data......................................................................

Derating and ambient temperature.....................................................

Derating and mains voltage.................................................................

Derating and carrier frequency............................................................

18

18

18

18

18

19

19

20

20

20

21

21

22

22

23

24

7

7.1

7.2

7.3

7.3.1

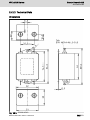

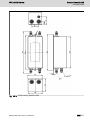

7.3.2

7.3.3

Frequency Converter Mounting...........................................................

Installation Conditions.........................................................................

Heat Dissipation..................................................................................

Figures and Dimensions.......................................................................

Figures.................................................................................................

Dimensions..........................................................................................

DIN Rail Mounting................................................................................

25

25

26

27

27

28

29

8

8.1

8.2

8.2.1

8.2.2

8.3

8.3.1

Frequency Converter Wiring................................................................

Wiring Diagram....................................................................................

Cable Specifications............................................................................

Power Cables.......................................................................................

Control Cables.....................................................................................

Terminals.............................................................................................

Power Terminals..................................................................................

Power Terminals Figure.......................................................................

Power Terminals Description...............................................................

Control Terminals................................................................................

Control terminals figure.......................................................................

Control terminals description..............................................................

Digital input X1...X5 NPN / PNP wiring................................................

Digital output DO1a, DO1b load pull-up / pull-down wiring................

30

30

31

31

32

32

32

32

33

34

34

35

37

38

8.3.2

XVIII

DOK-RCON04-VFC-x610***-IT01-EN-P

VFC x610 Series

Bosch Rexroth AG

Table of Contents

Page

Analog input terminals (AI1, AI2, +10 V, +5 V, Earth and GND)........... 38

9

9.1

9.1.1

Electromagnetic Compatibility (EMC).................................................

EMC Requirements..............................................................................

General Information.............................................................................

The electromagnetic compatibility (EMC) or electromagnetic interference (EMI) includes the following requirements:............................

Noise Immunity in the Drive System....................................................

Basic structure for noise immunity......................................................

Minimum immunity requirements for PDSs intended for use in the

second environment............................................................................

Evaluation criterion..............................................................................

Noise Emission of the Drive System....................................................

Ensuring the EMC Requirements.........................................................

EMC Measures for Design and Installation..........................................

Rules for Design of Installations with Drive Controllers in Compliance with EMC.....................................................................................

EMC-optimal Installation in Facility and Control Cabinet....................

Control Cabinet Mounting according to Interference Areas – Exemplary Arrangements..............................................................................

Design and Installation in Area A – Interference-free Area of Control

Cabinet................................................................................................

Design and Installation in Area B – Interference-susceptible Area of

Control Cabinet...................................................................................

Design and Installation in Area C – Strongly Interference-susceptible

Area of Control Cabinet.......................................................................

Ground Connections............................................................................

Installing Signal Lines and Signal Cables.............................................

General Measures of Radio Interference Suppression for Relays,

Contactors, Switches, Chokes and Inductive Loads............................

39

39

39

10

10.1

10.2

10.3

10.4

10.5

Operating Panel and Dust Cover.........................................................

LED Panel............................................................................................

LED Display..........................................................................................

Dust Cover...........................................................................................

LED Indicator.......................................................................................

Operating Descriptions........................................................................

58

58

58

59

60

61

11

11.1

Quick Start........................................................................................... 62

Checklist before Quick Start............................................................... 62

9.1.2

9.1.3

9.2

9.3

9.3.1

9.3.2

9.3.3

9.3.4

9.3.5

9.3.6

9.3.7

9.3.8

9.3.9

DOK-RCON04-VFC-x610***-IT01-EN-P

39

39

39

40

40

41

45

47

47

49

50

51

53

54

55

56

57

XIX

Bosch Rexroth AG

Table of Contents

VFC x610 Series

Page

11.1.1

11.1.2

11.1.3

11.2

11.3

11.4

11.5

11.6

Step 1: Check application conditions..................................................

Step 2: Check mounting conditions.....................................................

Step 3: Check the wiring.....................................................................

Quick Start Parameters.......................................................................

Control the Motor................................................................................

Motor Parameters Auto-Tuning............................................................

Possible Errors during Quick Start and Respective Solutions.............

Restoring Parameters to Factory Defaults...........................................

62

62

62

63

64

65

66

66

12

12.1

12.1.1

12.1.2

12.1.3

12.1.4

12.2

12.2.1

12.2.2

12.2.3

12.2.4

12.2.5

12.3

12.3.1

12.3.2

12.3.3

12.3.4

12.4

12.4.1

12.4.2

Functions and Parameters...................................................................

Basic Settings......................................................................................

Parameter Group Access Control........................................................

Parameter Initialization........................................................................

Parameter Replication.........................................................................

Password Protection...........................................................................

Input and Output Terminals Configuration..........................................

Digital Input Configuration..................................................................

X5 Pulse Input Configuration...............................................................

Analog Input Configuration..................................................................

Digital Output Configuration...............................................................

Analog Output Configuration...............................................................

Power Stage Configuration..................................................................

Set the Control Mode..........................................................................

Normal / Heavy Duty Setting................................................................

Carrier Frequency Setting....................................................................

Fan Maintenance Reminder.................................................................

Basic Frequency Setting Sources........................................................

Function Description...........................................................................

Select the Frequency Setting Source..................................................

General setting....................................................................................

Frequency setting source switching....................................................

Frequency setting sources combination..............................................

Adjust the setting frequency by panel potentiometer.........................

Adjust the setting frequency by panel button......................................

Adjust the setting frequency by analog input AI1, AI2.........................

Adjust the setting frequency by X5 pulse input...................................

Adjust the setting frequency by digital input Up / Down command....

Adjust the setting frequency by multi-speed function.........................

67

67

67

68

69

70

71

71

73

75

76

78

80

80

80

81

82

83

83

84

84

85

86

87

87

88

88

89

91

XX

DOK-RCON04-VFC-x610***-IT01-EN-P

VFC x610 Series

Bosch Rexroth AG

Table of Contents

Page

12.4.3 Acceleration and Deceleration Configuration...................................... 95

Acceleration and deceleration time configuration............................... 95

Acceleration and deceleration curve mode configuration................... 96

12.4.4 Output Frequency Limitation............................................................... 98

Direct output frequency limitation...................................................... 98

Behavior at low speed running............................................................ 98

12.4.5 Frequency Setting Saving.................................................................. 100

12.5

Run- / Stop- / Direction Command Source........................................ 101

12.5.1 Function Description......................................................................... 101

12.5.2 Run Command Source....................................................................... 102

First and second run command source configuration....................... 102

Switch between first and second run command source................... 102

Stop command via panel <Stop> button........................................... 102

12.5.3 Direction Control............................................................................... 103

Direction control via operation panel................................................ 103

Direction change dead time............................................................... 104

12.5.4 Start Behavior Setting....................................................................... 105

Start mode selection......................................................................... 105

Start directly...................................................................................... 105

DC-braking before start..................................................................... 106

Start with speed capture................................................................... 107

12.5.5 Stop Behavior Setting........................................................................ 108

Stop mode setting............................................................................. 108

DC-braking during deceleration to stop............................................. 109

Overexcitation braking....................................................................... 110

12.5.6 Resistor Braking................................................................................. 111

12.6

Special Running Behaviors................................................................ 113

12.6.1 Skip Frequency.................................................................................. 113

12.6.2 Jog Function...................................................................................... 115

12.6.3 2-wire / 3-wire Control (Forward / stop, reverse / stop)................... 117

2-wire control mode 1....................................................................... 117

2-wire control mode 2 (Forward / reverse, run / stop)..................... 118

3-wire control.................................................................................... 119

12.7

Special Functions.............................................................................. 121

12.7.1 Counter Function............................................................................... 121

12.7.2 Frequency Arrival............................................................................... 123

12.7.3 Frequency Level Detection................................................................ 124

12.7.4 High Resolution Current Display........................................................ 125

DOK-RCON04-VFC-x610***-IT01-EN-P

XXI

Bosch Rexroth AG

Table of Contents

VFC x610 Series

Page

12.8

Simple PLC........................................................................................

12.8.1 Function Description.........................................................................

12.8.2 Set the Simple PLC Mode..................................................................

12.8.3 Set Speed / Direction / Acceleration and Deceleration Time............

12.8.4 Stop and Pause Simple PLC Control.................................................

12.8.5 Indication of Simple PLC Status........................................................

12.9

PID Control........................................................................................

12.9.1 Function Description.........................................................................

12.9.2 Selecting the Reference and Feedback.............................................

12.9.3 Control Loop Configuration...............................................................

12.9.4 PID Regulation Mode Setting.............................................................

12.9.5 PID Deactivation by Digital Input.......................................................

12.9.6 PID Engineering Value Display...........................................................

12.9.7 PID Status Indication.........................................................................

12.9.8 Sleep / Wake Function.......................................................................

12.10 Protection Functions.........................................................................

12.10.1 Converter Protection.........................................................................

Overload pre-warning........................................................................

Stall overvoltage prevention..............................................................

Stall overcurrent prevention..............................................................

Phase loss protection........................................................................

12.10.2 Reaction to External Error Signals.....................................................

12.10.3 Motor Protection...............................................................................

Motor derating frequency at low speed.............................................

Motor thermal protection without temperature sensor.....................

Motor overload pre-warning..............................................................

Motor thermal protection with temperature sensor..........................

12.10.4 Resistor Braking Test.........................................................................

12.11 Motor Control....................................................................................

12.11.1 Motor Parameterization.....................................................................

Nameplate parameters configuration................................................

Motor slip frequency configuration....................................................

Motor parameter auto-tuning.............................................................

12.11.2 VFC 3610 - V/f Control.......................................................................

V/f curve selection.............................................................................

User-defined V/f curve configuration.................................................

Slip compensation factor configuration.............................................

Torque boost setting.........................................................................

XXII

126

126

127

128

129

130

132

132

133

134

135

136

136

137

138

140

140

140

141

142

144

145

146

146

147

147

148

150

151

151

151

152

153

155

155

156

158

159

DOK-RCON04-VFC-x610***-IT01-EN-P

VFC x610 Series

Bosch Rexroth AG

Table of Contents

Page

Optimization functions for V/f control...............................................

12.11.3 VFC 5610 - SVC Control.....................................................................

SVC control loop configuration..........................................................

Speed control mode..........................................................................

Torque control mode.........................................................................

162

164

164

164

165

13