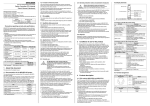

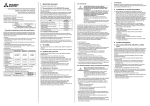

Download UE4140 PROFIBUS PROFIsafe, UE4740 PROFINET IO

Transcript