Download User Manual - sotralentz HABITAT

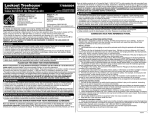

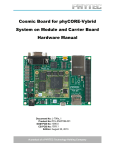

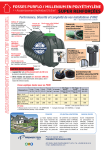

Transcript