Download AC/DC True RMS Power Clamp Meter

Transcript

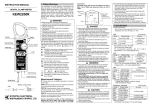

AC/DC True RMS Power Clamp Meter ELECTRONIC TEST INSTRUMENTS MODEL 325 CONTENTS 1. FEATURES ................................................ 2 2. Safety precaution ........................................ 2 Symbols Description .................................... 3 3. Specifications.............................................. 4 4. Electrical Specifications ................................ 4 800A rms ........................................... 4 800Arms (60 second).............................. 4 DC 500V AC500V rms ............................ 5 600V rms ........................................... 6 DC600V ........................................... 6 AC600V rms.......................................... 6 5. Instrument Description (fig.1)......................... 6 6. Alignment marks ......................................... 8 7. Measurement .............................................. 8 7-1. DC Current (DCA) measurement ............. 8 7-2. AC Current (ACA) measurement .............. 9 7-3. DC Voltage (DCV) measurement ............. 10 7-4. AC Voltage (ACV) measurement .............. 10 7-5.AC+DC Watt Measurement ...................... 11 7-6.Resistance measurements....................... 11 7-7.Continuity Tests ..................................... 12 7-8.Frequency measurements ....................... 13 7-9.Function key descriptions ........................ 13 ? HOLD function.................................... 13 ? ZERO relative function......................... 14 ? MAX MIN function ............................... 14 ? PEAK –H (PEAK HOLD) function........... 15 ? AUTO POWER OFF function ................ 16 7-10. Measuring non-sinusoidal quantity ......... 16 ? TRUE RMS MEASUREMENT ............... 16 ? WAVEFORM COMPARISON ................ 17 ? Battery Replacement ........................... 18 ? Maintenance and Cautions ................... 19 325 1. FEATURES Thank you for purchasing this instrument. Please read this instruction manual carefully and completely before using the digital clamp meter. Correct operation will insure the best performance and decrease the possibility of damages. 2. SAFETY PRECAUTION CAUTION Take extreme care for the conditions while measuring following 1. Measuring voltage over 20V as it may cause human body electricity conduction. 2. Measure AC power. 3. Do not measure voltage, current under humid or wet environment. 4. If any unusual condition (such as: breakage, deformation, fracture, foreign substance, no display, etc.) of the test leads end (metal part) and attachment of the meter, please do not conduct any measurement. 5. Do not contact any exposed metal (conductive) parts, such as : end of test lead, jack, fixing object, circuit, etc . 6. Keep you insulated from the object waiting for being measured. 7. Do not operate the meter under the environment with explosive gas (material), combustible gas (material) steam or filled with dust. EN-2 325 8. In order to avoid reading incorrect data, replace the battery immediately when the symbol “ ” appears on the LCD. 9. In order to avoid the damage caused by contamination or static electricity, do not touch the circuit board before you take any adequate action. 10. Operating Environment: Indoors use. This instrument has been designed for being used in an environment of pollution degree 2. 11. Operation Altitude: Up to 2000M. 12. Operating Temperature & Humidity: 5 ? ~ 40 ? ,below 80%RH. 13. Storage Temperature & Humidity: -10? ~ 60? , below 70%RH. 14. Fingers should hold under the protection guard of test probe. 15. Category: EN 61010-1(2001) and EN 61010-2032(2002) CAT ? 600V & CAT ? 1000V 16.SYMBOLS DESCRIPTION DC Voltag e or Current AC Voltage or Current DC/AC Voltage or Current Ground Meter Double insulated Caution Danger high voltage: risk of electric shock Application around and removal from hazardous live conductors is permitted EN-3 325 3. SPECIFICATIONS 1. Display: 3 3/4 digits LCD with max. reading 3999, plus decimal point, unit symbol indication. 2. Overload Indication: LCD will show “OL” in the left highest position. 3. Low Battery Indication: Replace battery immediately when LCD displays “ ”. 4. Sampling Rate: 2 times per second for digital display. 5. Power Supply: 9V NEDA 1604 IEC 6F22 JIS 006P battery x 1pc. 6. Battery Life: About 200 hours. 7. Jaws opening: Max. 36 mm. 8. Conductor size: Max. 35mm. 9. Dimension: 218mm(L)x75mm(W)x43mm(H). 10.Weight: About 375g. (Including battery) 11.Accessories : Test Leads ? manual? carrying case ? battery. 4. ELECTRICAL SPECIFICATIONS Accuracy: ±(..%rdg…dgt)at 23? ±5? , below 80? RH DCA Range Resolution Accuracy 400A 0.1A ± (1.5%+5) Overload Protection 800A rms (60 second) 600A 1A ± (2.0%+5) Range Resolution Accuracy 50Hz~60 Hz Overload Protection 400A 0.1A ± (2.0%+5) 600A 1A ± (2.5%+5) 800Arms (60 second) ACA EN-4 325 AC CURRENT (TRUE RMS:From 10% to 100% of range) Range 400A 600A Resolution 0.1A 1A Accuracy 40Hz~65Hz 65Hz~1kHz ± (2.0%+5) ± (3.0%+8) ± (2.0%+5) ± (3.0%+8) Overload Protection 800A rms (60 second) CURRENT 1 mS PEAK HOLD Range 400A 600A Resolution 0.1A 1A Overload Protection 600V rms Accuracy ± (1.5%+15) ± (2.5%+15) DC VOLTAGE Range 400V 600V Resolution 0.1V 1V Accuracy Overload Protection ± (1.0%+3) 600V rms AC VOLTAGE (TRUE RMS:From 10% to 100% of range) Range Resolution Accuracy Overload Protection 400V 0.1V 40Hz~400Hz 400Hz~2kHz 600V rms 600V 1V ± (1.2%+5) ± (2.0%+5) Input Impedance : 10M Ω// less than 100Pf.Crest factor : >3 :1. VOLTAGE 1 mS PEAK HOLD Range 400V 600V Resolution 0.1V 1V Accuracy ± (1.5%+15) ± (2.5%+15) Overload Protection 600V rms AC+DC WATT Range Resolution 40KW 0.01KW 400KW 0.1KW Accuracy ± (5.0+5) ± (5.0+5) Frequency Overload Protection 0~1KHz 600V rms Continuity Test Range Resolution 1Ω Max. Open Voltage Overload Protection About 1.2V DC 500V AC500V rms Lower 400Ω Buzzer RESISTANCE Range Resolution Accuracy Max. Open Voltage EN-5 Overload Protection 325 4000Ω 1Ω ± (1.0%+3) 0.4VDC Accuracy Max. Sensibility ± (0.5%+3) 5Vrms 600V rms Frequency Test Range Resolution 4KHZ 1HZ 40KHZ 10HZ 400KHZ 100HZ 5. Overload Protection DC600V AC600V rms INSTRUMENT DESCRIPTION (fig.1) 1. Inductive clamp jaw. 2. Safety guard. 3. HOLD button 4. Rotary switch Selector. 5. MAX/MIN key. 6. LCD 7. V/O Jack 8. COM Jack 9. PEAK-H 10. ZERO button. 11. Jaw Trigger. EN-6 325 Fig.2 EN-7 325 6. ALIGNMENT MARKS Put the conductor within the jaws on intersection of the indicated marks as much as possible (Figure 2) in order to meet the meter accuracy specifications. Fig.2 7. MEASUREMENT 7-1. DC CURRENT (DCA) MEASUREMENT WARNING Make sure that all the test leads are disconnected with the meter’s terminal for current measurement. 1. Set the rotary switch to A . 2. Check if the display shows zero in advance. If the display doesn’t show zero, press ZERO key. 3. Open the clamp and put the tested conductor in the center of the clamp jaw taking care to comply with the current flow shown in the label placed inside the Inductive clamp jaw and indicates. 4. The current value will be indicate on the display with automatic detection of the appropriate range. 5. If the reading is preceded by the "-" sign check if the current flow comply with consideration indicated. EN-8 325 6. If the reading is difficult, press the HOLD key to hold the obtained value. To exit from this function press HOLD key again. The analogy barograph isn’t affected of enabling of this function. CORRECT INCORRECT Current Flow Current Flow Fig.3 7-2. AC CURRENT (ACA) MEASUREMENT WARNING Make sure that all the test leads are disconnected with the meter’s terminal for current measurement. 1. Set the rotary switch to A ~ . 2. Open the clamp and put the tested conductor in the center of the clamp jaw. 3. The current value will be indicate on the display with automatic detection of the appropriate range. 4. If the reading is difficult, press the HOLD key to hold the obtained value. To exit from this function press HOLD key again. The analogy barograph isn’t affected of enabling of this function. EN-9 325 7-3. DC VOLTAGE (DCV) MEASUREMENT WARNING Max. input for DCV or ACV is 600V. Do not attempt to take any voltage measurement which exceeds the limits. Exceeding the limits could cause electrical shock and damage the clamp meter. 1. Set the rotary switch to V . 2. Plug the test leads into the jacks. The red test lead plugs into V/O jack, and the black test lead plugs into COM jack. 3. Connect the two long ends of test leads with the desired circuit, and then the reading will be displayed with automatic detection of the appropriate range. 4. If the reading is preceded by the "-" sign check if the Voltage polarity comply with consideration indicated. 5. If the reading is difficult, press the HOLD key to hold the obtained value. To exit from this function press HOLD key again. The analogy barograph isn’t affected of enabling of this function. 7-4. AC VOLTAGE (ACV) MEASUREMENT WARNING Max. input for DCV or ACV is 600V. Do not attempt to take any voltage measurement which exceeds the limits. Exceeding the limits could cause electrical shock and damage the clamp meter. 1. Set the rotary switch to V~ . EN-10 325 2. Plug the test leads into the jacks. The red test lead plugs into V/O jack, and the black test lead plugs into COM jack. 3. Connect the two long ends of test leads with the desired circuit, and then the reading will be displayed with automatic detection of the appropriate range. 4. If the reading is difficult, press the HOLD key to hold the obtained value. To exit from this function press HOLD key again. The analogy barograph isn’t affected of enabling of this function. 7-5.AC+DC WATT MEASUREMENT 1. Set the rotary switch to KW. 2. Plug the test leads into the jacks. The red test lead plugs into V/O jack, and the black test lead plugs into COM jack. 3. Connect the two long ends of test leads with the desired circuit, Inductive clamp jaw on to the active line, then reading will be displayed with automatic detection of the appropriate range. 4. If the reading is difficult, press the HOLD key to hold the obtained value. To exit from this function press HOLD key again. The analogy barograph isn’t affected of enabling of this function. 7-6.RESISTANCE MEASUREM ENTS WARNING Before measuring the resistance, please be sure to remove power from the circuit being tested and discharge all the capacitors. If the reading is over range, the symbol ”OL” will be displayed. EN-11 325 1. Set the rotary switch to O . 2. Plug the test leads into the jacks. The red test lead plugs into V/O jack, and the black test lead plugs into COM jack. 3. Connect the two long ends of test leads with the desired circuit, then the reading will be displayed with automatic detection of the appropriate range. 4. If the reading is difficult, press the HOLD key to hold the obtained value. To exit from this function press HOLD key again. The analogy barograph isn’t affected of enabling of this function. 7-7.CONTINUITY TESTS WARNING Before measuring the resistance, please be sure to remove power from the circuit being tested and discharge all the capacitors. If the reading is over range, the symbol ”OL” will be displayed. 1. Set the rotary switch to O . 2. Plug the test leads into the jacks. The red test lead plugs into V/O jack, and the black test lead plugs into COM jack. 3. Connect the two long ends of test leads with the desired circuit, then the reading will be displayed while the buzzer sounds when the resistance value lower then 300O approximately. 4. If the reading is difficult, press the HOLD key to hold the obtained value. To exit from this function press HOLD key again. The analogy barograph isn’t affected of enabling of this function. EN-12 325 7-8.FREQUENCY MEASUREMENTS WARNING Max. input for DCV or ACV is 600V. Do not attempt to take any voltage measurement which exceeds the limits. Exceeding the limits could cause electrical shock and damage the clamp meter. 1. Set the rotary switch to Hz. 2. Plug the test leads into the jacks. The red test lead plugs into V/O jack, and the black test lead plugs into COM jack. 3. Connect the two long ends of test leads with the desired circuit, then the reading will be displayed with automatic detection of the appropriate range. 4. If the reading is difficult, press the HOLD key to hold the obtained value. To exit from this function press HOLD key again. The analogy barograph isn’t affected of enabling of this function. 7-9.FUNCTION KEY DESCRIPTIONS ? HOLD function 1. The HOLD function allows operator to hold the displayed digital values. When this function is enabled the display shows the "H" symbol. 2. The HOLD function will be disabled if: l The HOLD key is pressed again. l The position of the rotary switch is changed. 3. The analogy barograph isn’t affected of enabling of this function so it continues showing present readings. EN-13 325 ? ZERO relative function 1.The ZERO relative function subtracts an OFFSET (stored when the key has been pressed) from the present measurements and displays the result. 2.To enable this function press the ZERO key for less than 1 second. Consequently on the display will appear the message "ZERO" and the relative value. 3.Pressing the ZERO key again for less than 1 second the display will show the offset; and the message "ZERO" start blinking. ? MAX MIN function WARNING Before pressing MAX/MIN but ton, please take off test leads from circuit and/or Voltage / Ohm jack to prevent electric surge cause high MAX figures. 1. This function allows the instrument to store the MIN and MAX values of the quantity selected with the rotary switch. 2. To enable this function press the MAX/MIN key less than 1 second; consequently on the display will appear the message ”MAX”. In this mode the clamp measures and shows the maximum value of the selected quantity. This value will be automatically update if a bigger value will occur. 3. Pressing again the MAX/MIN key less than 1 second, the message “MIN” will appear on the display. In this mode the clamp measures and shows the minimum value of the selected quantity. EN-14 325 This value will be automatically update if a lower value will occur. 4. Pressing again the MAX/MIN key less than 1 second, the blinking message “MAX MIN” will appear on the display. In this mode the clamp measures and store the minimum and the maximum values of the selected quantity. To get the minimum or maximum stored value press less than 1 second the MAX/MIN key until the display shows the desired quantity. l l The MAX/MIN function will be disable if: The MAX/MIN is pressed for more than 1 second. The position of the rotary switch is changed. ? PEAK –H (PEAK HOLD) function 1. Set the rotary switch to V /A range. 2. Set the PEAK-H mode by pressing the PEAK-H >2 sec, The PEAK-H function will enter to calibration mode, the LCD will show “CAL” and the internal buffer will remember the internal OP offset voltage then back to the 600V or 600A range. 3. The display shows Pmax to indicate the PEAK MAX and shows Pmin to indicate the PEAK MIN. (See Fi g 4) * Under PEAK-H, the bargraph always show current value. EN-15 325 Fi g 4 The PEAK -H function will be disable if: l The PEAK-H is pressed for more than 1 second. l The position of the rotary switch is changed. ? AUTO POWER OFF function 1. In order to save the battery the clamp will be switched off 30 minutes later last selecting function or changing range operation. 2. If this function is enabled the symbol is displayed. 3. To disable this function select OFF position then select the V~ position while the MAX/MIN key is pressed. 4. Turning OFF and ON the clamp the AUTO POWER OFF will be re-enabled. 7-10. MEASURING NON-SINUSOIDAL QUANTITY ? TRUE RMS MEASUREMENT The meter measures the true RMS value of AC voltages and currents. In physical terms, the RMS (root-mean-square) value of a waveform is the EN-16 325 equivalent DC value that causes the same amount of heat to be dissipated in a resistor. True RMS measurement greatly simplifies the analysis of complex AC signals. Since the RMS value is the DC equivalent of the original waveform, it provides a reliable basis for comparing dissimilar waveforms. By contrast, many meters use average-responding AC converters rather than true RMS converters. The scale factor in these meters is adjusted so that they display the RMS value for a harmonic-free sine wave. However, However, if a signal is not sinusoidal, average-responding meters do not display correct RMS readings. ? WAVEFORM COMPARISON Table 1.illustrates the relationship between AC and DC components for common waveforms, and compares readings for true RMS meters and averageresponding meters. For example, consider the first waveform, a 1.414V (zero-to-peak) sine wave. Both the 325 and RMS-calibrated average-responding meters display the correct RMS reading of 1.000V(the DC component equals 0). However, consider the 2V (peak-to-peak) square wave. Both types of meter correctly measure the DC component (0V), but your TM-28E also correctly measures the AC component (1.000V) The average-responding meter measures 1.111V, which amounts to an 11% error. Table 1. WAVEFROM COMPARISON CHART Peak Value Metered Voltages AC Components only EN-17 Total RMS 325 AC coupled Input Waveform Peak Peak 0-Peak RMS CAL (*) 27E DC components only TRUE RMS 2 AC + DC 2 Sine Rectified sine (Full Wave) Rectified sine (Half Wave) 2.828 1.414 1.000 1.000 0.000 1.000 1.414 1.414 0.421 0.436 0.900 1.000 2.000 2.000 0.779 0.771 0.636 1.000 2.000 1.000 1.111 1.000 0.000 1.000 1.414 1.414 0.875 0.707 0.707 1.000 2.000 2.000 4.442K 2K 2D 2√D 3.464 1.732 0.962 1.000 0.000 1.000 Square Rectified square Rectangular pulse 2 Triangle Sawtooth (*) RMS CAL is the displayed value for average responding meter that are calibrated to display RMS for sine waves. Crest Factor = Peak value/True value ? Battery Replacement WARNING If the symbol “ ” appears on the LCD, please replace the battery immediately. 1. Before operating the battery replacement, please remove all test leads and the conductor. 2. Set the range to OFF position. 3. Remove the screws from the battery cover with screwdriver, and detach the battery cover from the bottom cover. 4. Remove the battery from battery holder carefully, (replace it with new 9V NEDA 1604 IEC 6F22 JIS 006P battery x 1pc. EN-18 325 5. Put the battery cover back to its right place and tighten it with screws. ? Maintenance and Cautions 1. This meter is a precision digital instrument. Whether in use or in storage, please do not exceed the specification requirements to avoid any possible damage or danger 2. during in operation. 3. Do not use strong / abrasive detergents , water or wet cloth to clean the instrument. 4. Do not put the instrument in high temperature or in humid condition. Being exposed to direct sunlight is prohibited. 5. After finishing the measurement, please turn the rotary switch to off position. Remove the battery from battery holder if the instrument is not be used for a long period in order to avoid the liquid leakage from the battery. 6. Regarding to the other requirements for inspection and maintenance which are not stated in the manual, a qualified technician is necessary. EN-19 Limited One-Year Warranty B&K Precision Corp. warrants to the original purchaser that its product and the component parts thereof, will be free from defects in workmanship and materials for a period of one year from the data of purchase. B&K Preci sion Corp. will, without charge, repair or replace, at its’ option, defective product or component parts. Returned product must be accompanied by proof of the purchase date in the form a sales receipt. To obtain warranty coverage in the U.S.A., this product must be registered by completing and mailing the enclosed warranty card to B&K Precision Corp., 22820 Savi Ranch Parkway, Yorba Linda, CA 92887 within fifteen (15) days from proof of purchase. Exclusions: This warranty does not apply in the event of misuse or abuse of the product or as a result of unauthorized alternations or repairs. It is void if the serial number is alternated, defaced or removed. B&K Precision Corp. shall not be liable for any consequential damages, including without limitation damages resulting from loss of use. Some states do not allow limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you. This warranty gives you specific rights and you may have other rights, which vary from state -to-state. Model Number: ______________ Date Purchased: __________ 22820 Savi Ranch Parkway Yorba Linda, CA 9288 7 714.921.9095 714.921.6422 Facsimile Service Information Warranty Service: Please return the product in the original packaging with proof of purchase to the below address. Clearly state in writing the performance problem and return any leads, connectors and accessories that you are using with the device. Non-Warranty Service: Return the product in the original packaging to the below address. Clearly state in writing the performance problem and return any leads, connectors and accessories that you are using with the device. Customers not on open account must include payment in the form of a money order or credit card. For the most current repair charges contact the factory before shipping the product. Return all merchandise to B&K Precision Corp. with pre-paid shipping. The flat -rate repair charge includes return shipping to locations in North America. For overnight shipments and non -North America shipping fees contact B&K Precision Corp.. B&K Precision Corp. 22820 Savi Ranch Parkway Yorba Linda, CA 92887 Phone: 714- 921-9095 Facsimile: 714-921-6422 Email: [email protected] Include with the instrument your complete return shipping address, contact name, phone number and description of problem. B&K Precision 22820 Savi Ranch Parkway Yorba Linda, CA. 92887 P/N.481-525-9-001