Download A Series Panelboard - GH Phipps Construction Companies

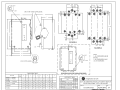

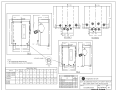

Transcript