Download OPERATIONS AND SERVICE MANUAL MR1300 HI FLOW SLOT

Transcript

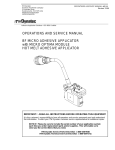

ITW Dynatec An Illinois Tool Works Company 31 Volunteer Drive Hendersonville, TN 37075 USA Telephone 615.824.3634 FAX 615.264.5222 OPERATIONS & SERVICE MANUAL #40-35 Revised 9/15/077 Adhesive Application Solutions • ISO 9001 Certified OPERATIONS AND SERVICE MANUAL MR1300 HI FLOW SLOT DIE HOT MELT ADHESIVE APPLICATOR HEADS* *Manufactured under U.S. Patent # 6,076,711 For an online copy of this manual, go to www.itwdynatec.com/manuals.htm IMPORTANT ! - READ ALL INSTRUCTIONS BEFORE OPERATING THIS EQUIPMENT It is the customer’s responsibility to have all operators and service personnel read and understand this information. Contact your ITW Dynatec customer service representative for additional copies. NOTICE! Please be sure to include the serial number of your application system each time you order replacement parts and/or supplies. This will enable us to send you the correct items that you need. ITW Dynatec Service Parts Direct Dial: 1-800-538-9540 ITW Dynatec Technical Service Direct Dial: 1-800-654-6711 Moving Forward Through Technology™ ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Revised 7/99 SAFETY INSTRUCTIONS GENERAL CONSIDERATIONS SERVICING EQUIPMENT 1. Read and follow these instructions. Failure to do this could result in severe personal injury or death. 1. Only trained personnel are to operate and service this equipment. 2. 2. Additional safety instructions and/ or symbols are located throughout this manual. They serve to warn maintenance personnel and operators about potentially hazardous situations. Never service or clean equipment while it is in motion. 3. Inspect the machine for unsafe conditions daily and replace all worn or defective parts. 4. Keep work area uncluttered and well lit. 5. All covers and guards must be in place before operating this equipment. For precautions and definitions of safety symbols, refer to the Safety Chapter of the service manual. Shut off the equipment and lock out all input power at the source before attempting any maintenance. 3. Follow the maintenance and service instructions in the manual. SIGNS 1. Read and obey all of the warning labels, signs and caution statements on the equipment. 2. Do not remove or deface any of the warning labels, signs and caution statements on the equipment. 3. Replace any warning labels, signs and caution statements which have been removed or defaced. Replacements are available from ITW Dynatec. ADDITIONAL CONSIDERATIONS ITW Dynatec An Illinois Tool Works Company Adhesive Application Solutions 1. To ensure proper operation of the equipment, use specified electrical and/ or air supply sources. 2. Do not attempt to alter the design of the equipment unless written approval is received from ITW Dynatec. 3. Keep all manuals readily accessible at all times and refer to it often for the best performance from your equipment. ITW Dynatec c. 1999 MR1300 HIGH FLOW SLOT DIE APPLICATOR Manual #40-35 Page iii Revised 11/01 TABLE OF CONTENTS Chapter - Page # Chapter 1 Safety Precautions Chapter 2 Description & Specifications Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 2-1 2-2 2-2 2-3 Chapter 3 Installation & Start Up Handling and Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 Service Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 Chapter 4 Maintenence Maintenence Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Stroke Limit Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Replacement of the Filter in the Optional Filter Block Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Shim Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 4-1 4-2 4-3 Chapter 5 Troubleshooting & Service In General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Replacement of the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Module Assembly Instructions for the High Flow Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Testing Resistance of Heater Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Testing Resistance of RTD Temperature Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Replacement of the Heater Cartridge or RTD Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Re-Assembly Procedures and General Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 5-1 5-3 5-3 5-5 5-6 5-6 5-8 Chapter 6 Component Illustrations & Bills of Material Bill of Materials: MR1300 Hi-Flow Module Assembly PN 106480 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2 Component Illustration: MR1300 Hi-Flow Module Assembly PN 106480 . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3 Bill of Material: MR1300 Hi-Flow, Hi-Temperature Module Assembly PN 108789 . . . . . . . . . . . . . . . . . . 6-4 Component Illustration: MR1300 Hi-Flow, Hi-Temperature Module Assembly PN 108789 . . . . . . . . . . . 6-5 Bill of Material: MR1300 Hi-Flow Slot Die Applicator Assembly PN 106500 DCL & 106485 MTC/CV . 6-6 Component Illustration: MR1300 Hi-Flow Slot Die Applicator Assembly PN 106500 & 106485 . . . . . . . 6-7 Bill of Material: MR1300 Hi-Temperature, Hi-Flow Slot Die Applicator Right, Down Apply, 240V PN 108790 DCL/ PN 108791 MTC/CV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8 Component Illustration: MR1300 Hi-Temperature, Hi-Flow Slot Die Applicator Right, Down Apply, 240V PN 108790 DCL/ PN 108791 MTC/CV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9 Bill of Material: MR1300 Hi-Flow Applicator Bracket Assembly PN 106653 . . . . . . . . . . . . . . . . . . . . . . . 6-10 Component Illustration: Bracketry Configutation for Down Apply, Right . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11 Component Illustration: Bracketry Configutation for Up Apply, Right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12 Component Illustration: Bracketry Configutation for Up Apply, Left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13 Component Illustration: Bracketry Configutation for Down Apply, Left . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14 Page iv Revised 11/01 ITW Dynatec c. 1999 MR1300 HIGH FLOW SLOT DIE APPLICATOR Manual #40-35 Bill of Material & Component Illustration: High Flow Slot Die Applicator Options . . . . . . . . . . . . . . . . . . 6-15 Chapter 7 Ordering Guides Applicator Heater Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Applicator RTD Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Module Seal Repair Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Recommended Service Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Recommended Service Parts List for Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 7-1 7-1 7-2 7-2 Chapter 8 Engineering Drawings & Schematics DynaControl (DCL) or PLC Control Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1 Microprocessor Temperature Control or CompuVision (MCV) Control Scheme . . . . . . . . . . . . . . . . . . . . . 8-1 Appendix Air Control FIlter Coalescing Kit for Applicator Heads Installation Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Pneumatic Drawing for Head Air Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Component Illustration & Bill of Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Page 1-1 Revised 1/07 ITW Dynatec c. 1997 ALL MODELS Chapter 1 SAFETY PRECAUTIONS All operators and service personnel must read and understand this manual before operating or servicing equipment. All maintenance and service on this equipment must be performed by trained technicians. Electrical DANGER HIGH VOLTAGE Dangerous voltages exist at several points in this equipment. To avoid personal injury, do not touch exposed connections and components while input power is on. Disconnect, lockout and tag external electrical power before removing protective panels. A secure connection to a reliable earth ground is essential for safe operation. A disconnect switch with lockout capability must be provided in the line ahead of the unit. Wiring used to supply electrical power should be installed by a qualified electrician. High Temperatures WARNING HOT SURFACE Severe burns can occur if unprotected skin comes in contact with molten adhesive or hot application system parts. Safety glasses, gloves and long- sleeved clothing must be worn whenever working with or around adhesive application systems. High Pressure WARNING HIGH PRESSURE PRESENT To avoid personal injury, do not operate the equipment without all covers, panels and safety guards properly installed. To prevent serious injury from molten adhesive under pressure when servicing the equipment, disengage the pumps and relieve the adhesive system’s hydraulic pressure (e.g., trigger the heads, hand-held applicators, and/or other application devices into a waste container) before opening any hydraulic fittings or connections. IMPORTANT NOTE: Even when a system’s pressure gauge reads “0” psig, residual pressure and trapped air can remain within it causing hot adhesive and pressure to escape without warning when a filter cap or a hose or hydraulic connection is loosened or removed. For this reason, always wear eye protection and protective clothing. Either of the two High Pressure symbols shown may be used on equipment. Page 1-2 Revised 3/97 ITW Dynatec c. 1997 ALL MODELS Protective Covers WARNING DO NOT OPERATE WITHOUT GUARDS IN PLACE Keep all guards in place! To avoid personal injury, do not operate the application system without all covers, panels and safety guards properly installed. Eye Protection & Protective Clothing WARNING EYE PROTECTION REQUIRED PROTECTIVE CLOTHING REQUIRED It is very important that you PROTECT YOUR EYES when working around hot melt adhesive equipment! Wear safety glasses with side shields which conform to ANSI Z87.1 or EN166. Failure to wear safety glasses could result in severe eye injury. It is important to protect yourself from potential burns when working around hot melt adhesive equipment. Wear protective gloves and long-sleeved, protective clothing to prevent burns that could result from contact with hot material or hot components. Always wear steel-reinforced safety shoes. Safe Installation and Operation To avoid possible failure of hoses, make sure all hoses are routed to avoid kinking, tight radius turns (8” or less) and abrasive contact. Hot-melt hoses should not have prolonged contact with heat-absorbing surfaces such as cold floors or metal troughs. These heat-absorbing surfaces can alter adhesive flow and cause incorrect calibration. Hoses should never be covered with materials that prevent heat dissipation, such as insulation or sheathing. Read this manual before applying electrical power to the equipment. Equipment may be damaged by incorrect electrical connections. Do not use adhesive that is dirty or that may be chemically contaminated. Doing so can cause system clogging and pump damage. When adhesive hand-held applicators or other movable applicators are used, never point them at yourself or at any other person. Never leave a hand-held applicator’s trigger unlocked when not actually in use. Do not operate the hopper or other system components without adhesive for more than 15 minutes if the temperature is 150 degrees C (300 degrees F) or more. To do so will cause charring of the residual adhesive. Never activate the heads, hand-held applicators and/ or other application devices until the adhesive’s temperature is within the operating range. Severe damage could result to internal parts and seals. Treatment for Burns From Hot Melt Adhesives Burns caused by hot melt adhesive must be treated at a burn center. Care should be used when working with hot melt adhesives in the molten state. Because they rapidly solidify, they present a unique hazard. Even when first solidified, they are still hot and can cause severe burns. When working near a hot melt application system, always wear safety gloves, safety glasses and long-sleeved, protective clothing. Page 1-3 Revised 1/07 ITW Dynatec c. 1997 ALL MODELS Always have first-aid information and supplies available. Call a physician and/or an emergency medical technician immediately. Service Refer all servicing to qualified personnel only. Explosion/ Fire Hazard Never operate this unit in an explosive environment. Use cleaning compounds recommended by ITW Dynatec or your adhesive supplier only. Flash points of cleaning compounds vary according to their composition, so consult with your supplier to determine the maximum heating temperatures and safety precautions. Lockout/ Tagout Follow OSHA 1910.147 (Lockout/ Tagout Regulation) for equipment’s lockout procedures and other important lockout/ tagout guidelines. Be familiar with all lockout sources on the equipment. Even after the equipment has been locked out, there may be stored energy in the application system, particularly in the capacitors within the panel box. To ensure that all stored energy is relieved, wait at least one minute before servicing electrical capacitors. Use of PUR (Polyurethane) Adhesives PUR adhesives emit fumes (MDI and TDI) that can be dangerous to anyone exposed to them. These fumes cannot be detected by the sense of smell. ITW Dynatec strongly recommends that an exhaust hood or system be installed over any PUR system. Consult with your adhesive manufacturer for specifics about required ventilation. CAUTION: Because of the nature of PUR adhesives to strongly bond in the presence of moisture, care must be taken to prevent them from curing inside Dynatec equipment. If PUR adhesive solidifies in a unit, the unit must be replaced. Always purge old PUR adhesive from the system per your adhesive manufacturer’s instructions and timetable. ALLOWING PUR ADHESIVE TO CURE IN A UNIT VOIDS ITW DYNATEC’S WARRANTY. In This Manual WARNINGS and CAUTIONS are found throughout this manual. WARNINGS mean that failure to observe the specific instructions may cause injury to personnel. CAUTIONS mean that failure to observe the specific instructions may damage the equipment. Page 1-4 Revised 3/97 ITW Dynatec An Illinois Tool Works Company Adhesive Application Solutions ITW Dynatec c. 1997 ALL MODELS ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Page 2-1 Revised 1/00 Chapter 2 DESCRIPTION AND SPECIFICATIONS Description ITW Dynatec’s MR1300 High Flow Slot Die Applicator Head is an air-operated, single-module, hot melt adhesive applicator assembly commonly used in the pinch-bottom bag industry. A choice of bracketry allows setup for right- or left-hand or up- or down-apply applications, depending on requirements. The applicator is heated by replaceable cartridge heating elements which are controlled by an integrated RTD sensor and electronic control. High Flow applicators are available configured for ITW Dynatec’s DynaControl, MTC/ CompuVision or Allen-Bradley PLC controls. Theory of Operation Each applicator features one MR1300 high flow slot die adhesive valve mounted to a single service block. The valve (module) is opened and closed by air pressure. Springs are used to keep the stem closed when no air pressure is supplied to the head. The rate of adhesive flow from the applicator is determined by the adhesive pressure applied by the adhesive application system’s (ASU’s) pump and the stem stroke adjustment. As shown in the illustration below, the heated adhesive supply hose may be connected at either side of the applicator or at the hose connect at the back. Adhesive flows from the hose into the service block and then to the module. Air pressure opens the adhesive valve, allowing adhesive to flow through the module’s seat and into the slot die. MR1300 High Flow Slot Die Applicator Air Inlets Electrical Connection Hi Flow Module Piston Slot Die Nozzle Glue Inlet/ Hose Connect Die Adapter Glue Inlet/ Hose Connect (one on each side of applicator) Page 2-2 Revised 11/01 ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Specifications Environmental: Storage/ shipping temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -40°C to 70°C (-40°F to 158°F) Ambient service temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -7°C to 50°C (20°F to 122°F) Physical: Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . see dimensional layout on following page Weight (including module and solenoid valve) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.52 kg (7.75 lb.) Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M6 x 1 screws with insulators Performance: Temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38°C to 218°C (100°F to 425°F) Warm-up time . . . . . . . . . . . . . . . . . . . 15 minutes for cold start/ 5 minutes for module change only Adhesive viscosity . . . . . . . . . . . . . . . . . . . . . . . . 100 to 30000 mPa. sec. (100 to 30000 centipoise) Adhesive pressure range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150 to 650 psi typical* Noise emission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 dB(A) Air Requirements: Air pressure range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1 to 6.9 bar (70 to 100 psi) Electrical: Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200-240 VAC/ 1p/ 50-60 Hz Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . service block: 500 watts die adapter: 90 watts Options Filter Block Assembly PN 106720 (Hi Temperature Filter Block Assembly PNs 108892 &108893) A filter block assembly allows adhesive to be filtered prior to entering the applicator’s service block. Filter baskets are available in either 80 or 100 mesh and can be easily accessed for replacement or cleaning. Pressure Gauge Assembly PN 101175 Installation of a pressure gauge allows monitoring of adhesive pressure inside the service block. * Dependant on adhesive viscosity, hose length and diameter, and shim thickness. Page 2-3 Revised 1/00 ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Dimensions 248 mm/ 9.75” 50-150mm/ 2-6” adjustable 177.8mm/ 7” 136.4mm/ 5.37” 101.6mm/ 4.00” Page 2-4 Revised 11/01 ITW Dynatec An Illinois Tool Works Company Adhesive Application Solutions ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Page 3-1 Revised 1/00 Chapter 3 INSTALLATION & START UP Note: Re-read Chapter 1 “Safety Precautions” before performing any installation or start-up procedures. All installation and start-up procedures must be performed by qualified, trained technicians. Handling and Shipping MR1300 Hi Flow Slot Die applicator head assemblies are packaged within protective cushioning material in a fiber packing carton. This package may be shipped inside another carton along with other individual boxes containing components of the system. Service Requirements The service block’s incoming electrical power and temperature control is supplied through the flexible cable exiting the adhesive supply hose cuff. The applicator has a circular, plastic connector which mates with the connector attached to this cable. Incoming (operating) air is supplied through a solenoid valve. It must be clean and unlubricated. It is controlled by a four-way solenoid valve and should be separately regulated and maintained at a pressure between 4.1 to 6.9 bar (60 to 100 psi). Head air inlet ports are G 1/8 threads (1/8 NPT). Installation Instructions The applicator head has been tested at the factory and is ready for installation and operation. Note: air lines and fittings must be capable of withstanding temperatures up to 218°C (425°F). ITW Dynatec supplies Air Control Filter Coalescing Kits (PN 100055) to be used with air-operated applicators (see the Air Control Filter Coalescing Kit Manual in the appendix of this manual). See the diagram on the following page for location of the components referred to in the following section. 1. The applicator should be supported from brackets that permit lateral and vertical adjustments. Mount the applicator on bracketry using the M6 screws and insulators provided. Allow access to the (optional) filter, if installed. Be sure that the stroke limit adjustment screws are accessible and that the “weep” holes are visible for periodic inspection. 2. Before making the adhesive connection to the applicator, align the adhesive supply hose with its electrical connector oriented in relation to the electrical connector on the top of the applicator. Connect the swivel fitting of the hot melt hose to the adapter on the service block, using either one of the inlet ports located on either side of the applicator or the port located on the back of the applicator. When tightening the hose fitting, hold the hose cuff to prevent the hose core from rotating. cont. Page 3-2 Revised 1/00 ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Installation Diagram Electrical connection to aux heating zone in ASU’s Panel Box Air Inlet Port Pressure Gauge located on the opposite side of optional filter block Electrical connection to Head/ Hose Muffler To Timer or Limit Switch Purge Button B Solenoid Stroke Limit Adjustment A Filter nut on optional filter block Adhesive Inlet, either side or at back Mounting Bracket or Weep Hole Slot die Nozzle 45° hose fitting 90° hose fitting Plug in alternate glue inlet position. 3. Make the two electrical connections: a. Make one connection from the hose to the applicator by connecting the female connector of the hose to the male connector of the applicator. b. Make the other connection (to heat the slot die nozzle) from the applicator to an auxillary heating zone in the ASU’s panel box by connecting the male connector of the applicator to the female connector on the auxilliary cable, which adapts to the female connection at the panel box. 4. Install the air line onto the air inlet port on the solenoid valve. CAUTION: Do not use lubricating oil with the air supply as applicators are lubricated at the factory and do not require lubrication when used in production. Where oil is present in the air supply, a coalescing filter (Dynatec PN 100055) must be installed between the standard air regulator/ filter and the applicator. 5. If an (optional) pressure gauge is to be utilized, remove the plug in the pressure gauge port and thread the gauge into the port. 6. It is advisable to check the temperature of the applicator. This can be done through the temperature readout of the adhesive supply unit. Surface temperature may be checked with a cont. ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Page 3-3 Revised 1/00 separate pyrometer and surface probe or with a dial thermometer. Turn the system power switch ON. Permit the applicator to warm up at least 15 minutes (5 minutes for module change) before reading temperature. 7. Purge the applicator of air and oil. Turn the applicator ON electrically and pneumatically. WARNING HIGH PRESSURE During the purging procedure, hot adhesive and oil can come out of the head under high pressure. Wear safety glasses, gloves and protective clothing. WARNING Use a stable, deep container to collect hot-melt adhesive and/ or oil. 8. Place a heat resistant container under the module to collect the material that drains from the applicator. Manually open the solenoid by pushing (with a small screwdriver or other tool) the purge button located on the solenoid coil. Continue to hold in the purge button until all air and oil have drained and only adhesive flows from the module. Page 3-4 Revised 1/00 ITW Dynatec An Illinois Tool Works Company Adhesive Application Solutions ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Page 4-1 Revised 7/99 ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Chapter 4 MAINTENENCE Note: Re-read Chapter 1 “Safety Precautions” before performing any maintenance procedures. All maintenance procedures must be performed by qualified, trained technicians. The MR1300 High Flow Slot Die modular applicator requires no regular maintenance. Wipe the applicator clean of adhesive with a clean cloth while still hot at the end of each shift. Inspect the applicator periodically as outlined in the following table. Maintenence Schedule ITEM CHECK FREQUENCY ACTION Adhesive supply hose fitting connection Inspect for leaks As required Tighten if loose Air supply connections Inspect for leaks As required Tighten if loose Weep holes Inspect for adhesive As required Replace seal cartridge or valve module Nozzle performance Inspect all nozzles for proper operation As required Clean nozzle or re-adjust stroke limiter Optional filter block assembly Inspect for cleanliness Monthly or as required by use Replace filter element Stroke Limit Adjustment All applicators are equipped with a stroke limit adjustment. Whenever the module is disassembled, the stroke limit must be adjusted using the following procedure (see next page for illustration): 1. Bring applicator up to operating temperature. 2. Loosen the lock nut located on the top of the module. 3. Bottom the stroke adjustment screw lightly. CAUTION: Tightening the stroke adjustment to shut OFF the nozzle will cause damage to the applicator. 4. Back off the screw one-half to one turn. cont. Page 4-2 Revised 7/99 ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 5. While holding the screw in positon, tighten the lock nut. Replacement of the Filter in the Optional Filter Block Assembly WARNING HIGH PRESSURE WARNING HOT SURFACE During this procedure, hot adhesive can come out of the applicator under high pressure. Wear safety glasses, gloves and protective clothing. The applicator must be at operating temperature. Turn the ASU’s pump/ motor OFF. 1. Place a heat-resistant container under the die lips. 2. Relieve the adhesive pressure by manually opening the modules. This is done by pushing the purge button located on the side of the air solenoid coil. Or, if the ASU is equipped with a drain, adhesive pressure may be relieved at the ASU. 3. Unscrew and remove the filter nut. 4. With needle nose pliers, pull the filter basket out of the manifold. Filter Nut Stroke Adjustment Screw Lock Nut O-ring 5 Replace the o-ring on the filter nut. Apply o-ring lubricant (PN N07588) to the new o-ring. Filter Basket 6. Apply a coat of anti-seize to the threads of the filter nut. 7. Re-install the filter basket and the filter nut. Tighten the filter nut until it is seated firmly, taking care not to cut the o-ring. Extruder Shim Clamp ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Page 4-3 Revised 7/99 Shim Replacement All slot die heads are equipped with shims, located between the clamp and the body of the extruder. To replace a shim: WARNING HOT SURFACE During this procedure, the applicator will be at operating temperature. Wear safety glasses, gloves and protective clothing to avoid injury from hot parts or adhesive. 1. Bring applicator up to operating temperature. 2. Loosen the M5 screws which attach the clamp and shim to the body of the extruder. 3. Wipe the body and clamp clean of all adhesive and char using a liquid cleaning solvent. Pay special attention to the surfaces that clamp the shim. 4. Inspect the new shim for any burrs or rough edges. Using 400 grit paper on a flat surface, sand as required to insure flatness. 5. Re-attach shim and clamp to the body, keeping the screws loose. 6. Hold a flat bar (steel or aluminum) against the leading edge of the extruder. This will align the shim to the clamp and the body. All components must be parallel for the entire length of the assembly. Tighten the screws to hold the components together. Remove the flat bar. 7. If required, wrap a piece of 400 grit sandpaper around a flat file and, going from end to end, sand the entire leading edge surface to remove any shim edges that are not in parallel with the clamp and body. 8. Test the applicator for proper performance. Adjust as required. Page 4-4 Revised 7/99 ITW Dynatec An Illinois Tool Works Company Adhesive Application Solutions ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Page 5-1 Revised 1/00 ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Chapter 5 TROUBLESHOOTING & SERVICE Note: Re-read Chapter 1 Safety Precautions” before performing any troubleshooting or repair procedurs. All troubleshooting or repair procedures must be performed by qualified, trained technicians. In General If failure occurs, first check all the electrical and pneumatic connections. Verify that the main power switch is ON at the ASU. Verify that the pump is ON and the application heads have sufficient air pressure. Verify that the temperature controller is in operation and that the setpoints are correct for the application. Check to see if all components are heating properly. Troubleshooting Guide Problem Possible Cause Solution Module does not open 1. Temperature adjustment of head is too low. 1. Check temperature adjustment. 2. Inoperative solenoid. 2. Push the solenoid’s manual button. If it opens, the problem is electrical. 1. Nozzle is clogged. 1. Clean or replace nozzle. 2. Optional filter element is dirty. 2. Replace filter, see instructions in Ch. 4 Maintenence. 3. Module seals (o-rings) are inoperative. 3. Check module o-rings, see instructions in this chapter: “Module Assembly Instructions.” 4. ASU’s hopper is empty. 4. Re-fill hopper. 5. Adhesive is too cold. 5. Adjust temperature, see ASU manual. 6. Solenoid valve is not opening. 6. Check solenoid valve. 7. Piston stroke is too low. 7. Adjust the stroke limit, see Ch. 4 Maintenence. No adhesive flowing out of module Page 5-2 Revised 1/00 ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Problem Possible Cause Solution Hot melt is coming out of the module’s “weep” holes 1. Module seals are damaged. 1. Replace seal cartridge or module, see instructions in this chapter. Applicator does not reach operating temperature 1. Hopper temperature setpoint is too low. 1. Change setpoint, see ASU manual. 2. Inoperative heater cartridge. 2. Check/ replace heater cartridge, see instructions in this chapter. 3. Inoperative temperature sensor. 3. Check/ replace sensor, see instructions in this chapter. 1. Applicator temperature setpoint is too high. 1. Change setpoint, see ASU manual. 2. Inoperative temperature sensor. 2. Check/ replace sensor, see instructions in this chapter. 1. Inoperative piston o-ring. 1. Replace o-ring, see instructions in this chapter. 2. O-rings located between module and service block are inoperative. 2. Remove module from block (see instructions in this chapter: “Replacement of Module”) and replace o-rings. 1. Adhesive pressure is too low. 1. a. For units without speed control: increase adhesive pressure at ASU. Applicator is too hot Air escapes from module Application pattern is erratic b. For units with speed control (tach follower): adjust pump speed control. Adhesive is bubbling 2. Adjust pattern controller or solenoid firing mechanism. 2. See pattern controller manual for proper adjustment. 3. Finger pressure is incorrect. 3. Re-adjust finger pressure and/ or finger location over the slot. 1. Adhesive is too hot. 1. Lower adhesive temperature. 2. Adhesive is below the pressure relief setting. 2. Add adhesive and allow time for it to melt. 3. Moisture in the adhesive. 3. Drain the ASU and fill with new batch of adhesive. ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Page 5-3 Revised 1/00 Replacement of the Module Turn the ASU OFF. Turn all adhesive and air pressure OFF. WARNING HIGH PRESSURE During this procedure, hot adhesive can come out of the applicator under high pressure. Wear safety glasses, gloves and protective clothing. 1. Place a heat-resistant container under the manifold. 2. Relieve the adhesive pressure by manually opening the modules. This is done by pushing the purge button located on the side of the air solenoid coil. Or, if the ASU is equipped with a drain, adhesive pressure may be relieved at the ASU. 3. Remove the module from the service block by removing the two mounting screws on the front of the module with a hex key screwdriver (allen wrench). Make sure that the old o-rings located on the back of the module are also removed (the new module will include new o-rings). 4. Mount the new module using a 4mm (5/32”) hex key on the mounting screws. Module Assembly Instructions for the PN 106480 Hi Flow Module Use the component illustration and parts list on pages 6-2 and 6-3 as a reference with the following instructions for the MR1300 Hi Flow module. ITW Dynatec has a Module Seal Kit available (PN 106722) which contains the components necessary to rebuild one module, including the seal cartridge assembly, all o-rings, springs and seal lubricant. 1. During re-assembly, coat all o-rings with a liberal amount of High Temp Lube (PN N07588). CAUTION: DO NOT SUBSTITUTE! Failure to use High Temp Lube (N07588) may result in premature seal breakdown and leakage of glue from the applicator. 2. Insert the new seal cartridge assembly into the module body. Align the roll pin in the seal cartridge with the corresponding hole in the top of the module body. Press the seal cartridge into position. The air hole in the seal cartridge must align with the air hole in the module body for the valve to function properly. 3. Place a new piston o-ring onto the stem assembly and slowly insert the stem assembly into the seal cartridge. 4. After applying locktite to the coupling nut, install the coupling nut onto the stem (on top of the lower piston). 5. Put the stem extension on the opposite side of the coupling nut. 6. Insert the mid air cylinder anti-rotation plate onto the top of the piston. cont. Page 5-4 Revised 1/00 ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 7. Install the seals (o-rings) into the mid air cylinder cap. Slide the cap down over the piston. 8. Install the upper piston and piston seals (o-rings). 9. Place the two new springs on top of the upper piston. The smaller spring will nest inside the larger spring. 10. Place the air cylinder over the springs and piston and press down into place. Take care not to dislodge the springs or damage may result. Secure the air cylinder with the four mounting screws. 11. Place a new o-ring on the seat assembly and insert the seat assembly into the bottom of the module body. Secure with the four mounting screws. Spring resistance will be felt as the screws are tightened. Tighten the screws evenly to avoid binding. 12. Thread the adjusting screw into the sealing washer and insert this assembly into the top of the air cylinder. Do not adjust the stem stroke at this time. 13. Place new o-rings into the grooves on the rear face of the module and mount the module onto the service block. 14. Allow five minutes for the module to heat. Adjust the stem stroke to the desired setting. To disassemble, reverse above order. Page 5-5 Revised 1/00 ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Testing Resistance of Heater Cartridges 1. Turn the ASU OFF or disable the head (applicator) at the control panel. Turn all pumps OFF and relieve system pressure before proceeding. 2. Unplug the electrical cable from the adhesive supply hose to expose the pins in the cable. 3. With an ohmmeter or multimeter, contact pins 7 and 8 and measure resistance. Compare the reading with the values given in the charts below. Service Block Heaters The service block of the High Flow applicators contains two heaters wired in parallel. The individual and parallel resistance values of these heaters is listed below: Applicator Model Individual Resistance Parallel Resistance High Flow 230.4 Ohms each 97.6 Ohms Die Adapter Heater The die adapter contains one heater, wired in parallel with the two heaters in the service block. The resistance value of this heater is listed below: Applicator Model Individual Resistance Parallel Resistance High Flow 640 Ohms n.a. If one of the heaters is not functional, the parallel resistance measured at the contact pins will be higher than the range given in the chart. To determine which heater is not functional, remove the cover plate and test each heater independently. Page 5-6 Revised 1/00 ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Testing Resistance of the RTD Temperature Sensor All M1300 applicators use platinum temperature sensors. The resistance value (Ohms) of the temperature sensor depends on the temperature of the sensor at the time it is being tested. At 25°C (77°F), the resistance of the sensor should be 110 Ohms. With an ohmmeter or multimeter, contact pins 5 and 6 and measure the sensor resistance. A tolerance range of ± 5% is allowed. A sensor that tests outside of this range must be replaced. Replacement of Heater Cartridge or Sensor Replacement of Service Block Heater Cartridges 1. Turn OFF the ASU and relieve all system pressure before proceeding. Terminal Block 2. Disconnect the service block’s electrical cable assembly from the hose. Ground Screw Heater 3. Remove the four screws holding the cover plate. Remove the plate. Pull the ceramic terminal blocks from the wiring cavity and disconnect the heater leads from the terminal blocks. 4. Locate the non-functioning heater with a multimeter. Remove and replace the heater. Apply a thin film of thermal paste to the new heater before installation. 5. Reconnect the heaters to the terminal blocks, making sure that no strands of wire are protruding from the terminal blocks. 6. Place the terminal blocks back into the wiring cavity. Replace the cover plate. RTD Sensor RTD Sensor Heater Heater/ RTD Sensor Replacement Diagram ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Page 5-7 Revised 1/00 Replacement of Die Adapter Heater Cartridge See illustration on page 5-6 for parts locations. 1. Turn OFF the ASU and relieve all system pressure before proceeding. 2. Disconnect the service block’s electrical cable assembly from the hose. 3. Remove the three M4 screws from the wire cover. Remove the wire cover. 4. Disconnect the heater leads from the ceramic terminal block. 5. Check the heater with a multimeter. 6. If the heater is non-functioning, remove and replace it at this time. Apply a thin film of thermal paste to the new heater before installation. 7. Reconnect the heater to the terminal block, making sure that no strands of wire are protruding from the terminal block. 8. Replace the wire cover. Replacement of Temperature Sensors See illustration on page 5-6 for parts locations. There are two temperature sensors. One is located in the die adapter. The other is located in the service block. To Replace the Die Adapter Sensor: 1. Disconnect the service block’s electrical cable assembly from the hose. 2. Disconnect the die adapter’s electrical cable assembly from the adapter cable. 3. Remove the three screws holding the die adapter cover plate. Remove the plate. 4. Pull the sensor out of the die adapter and disconnect its leads from the ceramic terminal block. 5. Apply a thin film of thermal paste to the new sensor and place it in the die adapter. 6. Wire the new sensor to the ceramic terminal block, making sure that no strands of wire are protruding from the terminal block. 7. Replace the die adapter cover. 8. Re-connect all cable assemblies. To Replace the Service Block Sensor: 1. Disconnect the service block’s electrical cable assembly from the hose. cont. Page 5-8 Revised 1/00 ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 2. Disconnect the die adapter’s electrical cable assembly from the adapter cable. 3. Remove the top cover plate where the electrical cables are mounted. 4. Pull the sensor out of the service block and disconnect its leads from the ceramic terminal block. 5. Apply a thin film of thermal paste to the new sensor and place it in the service block. 6. Wire the new sensor to the ceramic terminal block, making sure that no strands of wire are protruding from the terminal block. 7. Replace the wiring cover. 8. Re-connect all cable assemblies. Re-Assembly Procedures and General Cautions Unless noted, head re-assembly is simply the reverse sequence of the disassembly procedures. However, the following “cautions” should be followed (whenever they apply) for proper re-assembly: CAUTION: In general, all O-RINGS AND SEALS must be replaced whenever hot-melt equipment is re-assembled. All new o-rings must be lubricated with o-ring lube (PN N07588). CAUTION: TAPERED PIPE THREADS are found on air line fittings used with the pump air supply and on the outlet filter manifold. Apply thread sealant (PN N02892) whenever tapered pipe threaded parts are re-assembled. CAUTION: SOME FITTINGS used for adhesive on hot melt equipment have straight threads and o-ring seals. Use of thread sealant is not necessary with these parts, but the o-ring seals should be clean and lubricated. Tighten straight-threaded parts and fittings until their shoulders are firmly seated. Excessive torque may damage straight-threaded parts and the use of power wrenches is not recommended. CAUTION: HOT-MELT RESIDUE must be cleaned from parts before they are re-assembled, particularly from threaded parts. As a precaution against adhesive residue preventing proper re-assembly, threaded parts must always be re-tightened at operating temperature. ITW Dynatec c. 1999 MR1300 HI-FLOW, SLOT DIE APPLICATOR Manual #40-35 Page 6-1 Revised 3/05 Chapter 6 COMPONENT ILLUSTRATIONS & BILLS OF MATERIAL WARNING All parts must be periodically inspected and replaced if worn or broken. Failure to do this can affect equipment’s operation and can result in personal injury. The following pages provide exploded-view reference drawings to assist users of MR1300 Hi-Flow Slot Die applicators to identify parts and aid in servicing the equipment. Note: most common nuts, bolts and fasteners can be obtained locally at your hardware store. Specialty fasteners are available by contacting Dynatec’s Customer Service. Page 6-2 Revised 11/03 ITW Dynatec c. 1999 MR1300 HI-FLOW, SLOT DIE APPLICATOR Manual #40-35 MR1300 Hi-Flow Module Assembly # 106480 Item No. Part Number Description Qty. 1 C78A204 6-32 x 2 1/2 SHC Screw 4 2 3 N00178 N00198 O-ring, -011 O-ring, -113 4 2 4 5 057E409 057E410 Inner Compression Spring Outer Compression Spring 1 1 6 7 057F139 069X197 Air Cylinder Stem Seal 1 1 8 N02680 6-32 x 3/8 BHC Screw 4 9 10 078A384 078C085 10-32 x 3/4 SHS Screw Washer, .25 x .16 x .032 1 1 11 12 078D078 078F034 10-32 Sealing Hex Nut Internal Ring 1 1 13 14 106515 106487 2-56 Hex Nut Mid Air Cylinder Cap 1 1 15 16 106489 108753 Piston, Threaded Extension Stem 2 1 17 18 110584 106493 Body Stem & Ball Assembly 1 1 19 20 084B1361 N00176 Seal Cartridge Assembly O-ring, -009 1 1 21 22 057E429 057I260 Seal Cartridge Gasket 1 1 23 069X197 Stem Seal 2 24 25 069X198 078C085 Seal Back Up Washer, .25 x .16 x .032 2 2 26 27 078F034 078G028 Internal ring 1/16 Dia. x 3/8 LG Roll Pin 2 18 28 29 106496 N00195 Die To MR1300 High Flow Adapter O-ring, #-110 1 1 30 31 N05044 110587 O-ring, -109 Die Adapter Assembly 1 1 Page 6-3 Revised 11/03 ITW Dynatec c. 1999 MR1300 HI-FLOW, SLOT DIE APPLICATOR Manual #40-35 1 11 2 9 26 6 25 23 Assembled View 24 5 4 27 21 13 15 19 20 3 22 24 12 10 2 7 23 25 26 2 14 17 16 15 18 29 3 31 30 MR1300 Hi-Flow Module Assembly # 106480 8 Page 6-4 Revised 11/03 ITW Dynatec c. 1999 MR1300 HI-FLOW, SLOT DIE APPLICATOR Manual #40-35 MR1300 Hi-Flow, Hi-Temp. Module Assembly # 108789 Item No. Part Number Description Qty. 1 110613 Adapter Assembly, Die, MR13HF, Hi Temp 2 3 106493 110584 Stem Hi Flow Module Body 4 5 108753 102289 Stem Extension Primer, Loctite, 7649 1 A/R 6 7 106489 108669 Piston Threaded Thread Sealant 2 A/R 8 106487 Cylinder, Mid, Air 1 9 10 084B1457 078F034 Seal Cartridge Assembly, Hi-Temp. Ring, Ret, Internal 1 1 11 12 078D078 078C085 10-32 Hex Nut Washer, .25 x .16 x .32 THK 1 1 13 14 078A384 N02680 10-32 x 3/4 SHC Screw 6-32 x 3/8 BSHC Screw 1 4 15 16 069X197 057F139 Stem Seal Air Cylinder 1 1 17 18 057E410 057E409 Outer Compression Spring Inner Compression Spring 1 1- 19 20 N07079 069X222 O-ring, -011 O-ring, -113 4 2 21 22 C78A204 106515 6-32 x 2.5 SHC Screw 2-56 Hex Nut 4 4 23 001U002 Lube 1 1 ITW Dynatec c. 1999 MR1300 HI-FLOW, SLOT DIE APPLICATOR Manual #40-35 MR1300 Hi-Flow, Hi-Temp. Module Assembly # 108789 Page 6-5 Revised 10/02 Page 6-6 Revised 02/08 ITW Dynatec c. 1999 MR1300 HI-FLOW, SLOT DIE APPLICATOR Manual #40-35 MR1300 Hi-Flow Slot Die Applicator Assembly # 106500 DCL & 106485 MTC/ CV Item No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 see 57 see 59 Part Number Description N00099 Fitting, Elbow, 90° 106645 Cover Plate, Die Adapter 105113 Screw, Cover Plate, Die Adapter N00175 O-ring,#-008 (This part appears with106481) N00178 O-ring, #-011 104663 M6-1,0 x 25mm SHC Screw 108699 Heater, Cartridge, 250w, 240v, 3/8 x 2 N06435 Fitting connector, Push-in 107881 Terminal block, 2 Pos, Ceramic N07677 Tubing Teflon, .25OD x .125 ID 109402 Valve Solenoid, Mac 45, 1/8, 24DC 030B108 1/8 NPT Breathing Vent 113365 Heater, 1/4 x 3, 240v, 200w N07958 Temperature Sensor (106500 DCL) 104912 Temperature Sensor (106485 MCV) N07864 Temperature Sensor (113288 Upgrade) 048J049 1/4 Conduit Fitting 072X254 2.5” Solenoid Nipple, 1/8 NPT 072X383 3/16 Tube Support 105162 M3-0,5 x 6mm Phil. Screw 102466 M4-07 x 10mm SHC Screw 078A111 10-24 x 1 1/4 SHC Screw 106242 M5-0,8 x 16mm SHC Screw 106648 Cable Assembly, 240v, DCL (106500 DCL) 106655 Cable Assembly, 240v, MTC (106485 MCV) 113287 Cable Assembly, (Upgrade 113288) 106477 Service Block, MR13HF N02540 Wire Nut 106478 Solenoid Adapter,1 port, MR13HF 106479 Die Adapter, 1 port, MR13HF 106481 Nozzle, 1 port, MR13HF (This part appears on earlier models) 107132 Nozzle, 1 Port, MR13HF 107133 Die (To be used with Shim Pack) 106952 Plug (This part appears with106481) 106483 Pressure Screw (This part appears with106481) 106486 Wire Cover, Service Block 106480 Module, MR13HF, Slot 101691 M4-0,7 x 40mm SHC Screw SHC Screw 107461 Machinable Die (optiion) 103944 1/4 BSPP, #8 101625 Fitting, Plug, 1/4 BSPP L00006 Insulated Spacer 106508 Mounting Plate 104663 M6-1,0 x 25mm SHC Screw 078A055 10-24 x 3/16 SH Set Screw 106245 M3 Lock Washer, Int Tooth N06883 Nut, Hex, Jam, 9/16-18 069X024 O-ring, -014 N00196 Oring, -111 N07430 Terminal Ring 107144 Dowel Pin, 1/8 Dia. x 3/16 107138 Shim Kit (to be modified with customers pattern) 107134 Shim, Blank, .020 107135 Shim, Blank, .015 111682 Shim, Blank, .025 111683 Shim, Blank, .031 Note: the following parts are shown with the bracket assembly pages 6--10 107031 Shim Slide 106509 Skid Plate Qty. 2 1 3 3 1 4 2 1 2-3 4” 1 1 1 2 2 2 2 1 2 1 4 2 4 2 2 1 4-6 1 1 1 1 1 1 1 1 1 2 1 2 4 1 4 2 1 2 2 1 2 2 1 1 1 1 1 1 1 Page 6-7 Revised 6/03 ITW Dynatec c. 1999 MR1300 HI-FLOW, SLOT DIE APPLICATOR Manual #40-35 12 22 8 11 39 15 1 Up and down, left and right configuration for nozzle and nozzle mouth piece. 17 10 16 41 33 19 Up Apply, Right 25 31 4 24 37 18 7 Down Apply, Right 40 44 35 38 36 42 Up Apply , Left 34 32 43 23 14 20 Down Apply, Left 9 42 35 26 21 28 14 46 27 45 5 6 These items only appear on models which include 106481 Nozzles. 13 2 4 30 29 21 3 MR1300 Hi-Flow Slot Die Applicator # 106500/ 106485 ITW Dynatec c. 1999 MR1300 HI-FLOW, SLOT DIE APPLICATOR Manual #40-35 Page 6-8 Revised 08/07 MR1300 Hi Temp, Hi-Flow Slot Die Applicator, Right Down Apply, 240V PN’s # 108790 DCL, 108791 MTC/CV Item No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 Part Number Description 106477 106478 106479 107132 106509 106470 107031 106486 105113 106645 078C137 105162 N07077 N07079 109402 102446 106508 108789 078A111 104663 107881 N07081 107138 072X254 030B108 N06435 072X383 106242 101691 036A016 N00099 N07677 107133 107461 101625 103944 N07430 L00006 104912 048J049 106655 108699 078A055 106245 N02540 105282 100097 N08036 107144 Service Block, MR13HF Solenoid Adapter,1 port, MR13HF Die Adapter, 1 port, MR13HF Nozzle, 1 Port, MR13HF Skid Plate M4 x 8mm,FH Screw Shim Slide Wire Cover, Service Block Screw, Cover Plate, Die Adapter Wire Cover, Die Adapter Washer M3-0,5 x 6mm Phil. Screw 0-ring, -008 (Hi-Temp.) 0-ring, -011 Valve Solenoid M4-07 x 10mm SHC Screw Mounting Plate Module,MR13HF, Hi Temp.Slot M5 x 35mm SHC Screw M6-1,0 x 25mm SHC Screw Terminal Block, 2 Pos, Ceramic 0-ring, -014 Shim Kit (to be modified with customers pattern) 2.5” Solenoid Nipple, 1/8 NPT 1/8 NPT Breathing Vent Fitting connector, Push-in 3/16 Tube Support M5-0,8 x 16mm SHC Screw M4-0,7 x 40mm SHC Screw SHC Screw Heater, 1/4 x 3, 240v, 90w Fitting, Elbow, 90° Tubing Teflon, .25OD x .125 ID Die Machinable Die (Option) Fitting, Plug, 1/4 BSPP 1/4 BSPP, #8 Terminal Ring Insulated Spacer Temperature Sensor (106485 MCV) 1/4 Conduit Fitting Cable Assembly, 240v, MTC (106485 MCV) Heater,, Cartridge, 250w, 240V, 3/8 x 2” 10-24 x 3/16 SH Set Screw M3 Lock Washer, Int Tooth Wire Nut, Ceramic Marker, Tie 0-ring, -111 (Hi Temp.) Ferrule ( Not Shown) Dowel Pin, 1/8 Dia. x 3/16 108878 Data Tag Qty. 1 1 1 1 1 1 1 3 1 2 1 2 1 1 4 1 1 2 4 2 2 1 1 1 1 2 4 2 1 2 4 1 2 1 2 4 2 2 2 2 2 1 4-6 2 1 8 2 1 ITW Dynatec c. 1999 MR1300 HI-FLOW, SLOT DIE APPLICATOR Manual #40-35 MR1300 Hi Temp, Hi-Flow Slot Die Applicator, Right Down Apply, 240V PN’s # 108790 DCL, 108791 MTC/CV Page 6-9 Revised 10/02 Page 6-10 Revised 10/02 ITW Dynatec c. 1999 MR1300 HI-FLOW, SLOT DIE APPLICATOR Manual #40-35 MR1300 Hi-Flow Applicator Bracket Assembly # 106653 Item No. Part Number Description Qty. 106653 Pinch Bottom Bracket Assembly 1 47 48 078A028 105278 3/8-16 x 1 1/4 FHSC Screw M4-0,7 x 6 FHSC Screw 1 2 49 50 N00732 078C012 5/16-18 x 3/4 HHC Screw 1/2” Flat Washer SAE 2 2 51 52 L00006 109848 Spacer, Insulating M12 Hex Nut, Flange Lock 2 2 53 106499 Guide, Finger 1, 54 55 106501 106502 Guide, Finger Finger, Bar 1 2 56 57 106504 107031 Base Plate Shim Slide (Part Of Head Assembly 106500) 1 1 58 59 106507 106509 Finger, Holdown Skid Plate (Part Of Head Assembly 106500) 2 1 60 61 106510 106657 T-Slotted, Stud T-Slot, Fastener 1 2 62 63 106656 101626 T-Slot End Cap M5-0,8 x 12 SHC Screw 1 2 64 65 107255 104663 Finger Guide Support M6 x 25mm SHC Screw 1 2 Note: The following pages show alternative bracketry set-ups for the Left and Right, Up and Down applicatons. Page 6-11 Revised 10/02 ITW Dynatec c. 1999 MR1300 HI-FLOW, SLOT DIE APPLICATOR Manual #40-35 49 37 56 61 62 60 38 alternative mounting position 36 Note: 37, 38, & 39 are not part of this assembly, shown for location purposes. 56 47 51 64 52 DOWN APPLY, RIGHT 50 54 63 50 58 52 55 53 57 59 48 Bracketry Configuration For Down Apply, Right (See page 6 of this chapter for BOM) 65 Page 6-12 Revised 10/02 ITW Dynatec c. 1999 MR1300 HI-FLOW, SLOT DIE APPLICATOR Manual #40-35 49 37 61 56 62 60 38 alternative mounting position 36 Note: 37, 38, & 39 are not part of this assembly, shown for location purposes. 50 52 64 51 47 56 65 50 52 UP APPLY, RIGHT 55 58 48 59 63 53 54 57 Bracketry Configuration For Up Apply, Right (See page 6 of this chapter for BOM) Page 6-13 Revised 10/02 ITW Dynatec c. 1999 MR1300 HI-FLOW, SLOT DIE APPLICATOR Manual #40-35 52 50 64 62 51 60 50 56 52 55 65 53 alternative mounting position 54 58 63 56 47 59 48 57 61 37 49 36 UP APPLY, LEFT 38 Bracketry Configuration For Up Apply, Left (See page 6 of this chapter for BOM) Note: 37, 38, & 39 are not part of this assembly, shown for location purposes. Page 6-14 Revised 10/02 ITW Dynatec c. 1999 MR1300 HI-FLOW, SLOT DIE APPLICATOR Manual #40-35 62 60 56 alternative mounting position 57 59 48 56 47 61 37 49 36 38 52 50 63 Note: 37, 38, & 39 are not part of this assembly, shown for location purposes. 50 58 54 52 64 53 51 55 65 DOWN APPLY, LEFT Bracketry Configuration For Down Apply, Left (See page 6 of this chapter for BOM) Page 6-15 Revised 10/02 ITW Dynatec c. 1999 MR1300 HI-FLOW, SLOT DIE APPLICATOR Manual #40-35 The optional Pressure Gauge Assembly can be mounted on either side of the applicator 8 9 or or 10 13 14 1 12 12 11 11 The optional Fliter Block Assembly can be mounted on either side of the applicator 6 5 7 2 3 4 MR1300 Hi-Flow Slot Die Applicator Options Item No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Part Number 106720 N00185 106721 006B121 069X058 006C024 101247 102693 102646 101175 101174 N00104 N00196 103330 N04531 101172 Description Optional Filter Block Assembly O-ring, #-018 M6 x 60mm SHCS Filter Block O-ring,# -028 Filter Nut Filter Basket, 100 mesh (standard) Filter Basket, 80 mesh (option) Filter Basket, 40 mesh (option) Optional Pressure Gauge Assembly Pressure Gauge Fitting Adapter, M, 37 JICM O-ring, -111 Fitting, Adapter,1/4 BPSS x 1/4 NPT Fitting, Street Tee, Brass, 1/4 NPT Fitting Adapter, 1/4 MPT x 1/4 FPT Qty. 1 1 4 1 1 1 1 1 1 1 1 1 1 1 1 1 Page 6-16 Revised 10/02 ITW Dynatec An Illinois Tool Works Company Adhesive Application Solutions ITW Dynatec c. 1999 MR1300 HI-FLOW, SLOT DIE APPLICATOR Manual #40-35 Page 7-1 Revised 5/07 ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Chapter 7 ORDERING GUIDES Hi Flow Applicator Heater Cartridges Part No. Description Location Qty. 036A016 108699 3” long, 90w 3/8x2”, 250w die adapter service block 1 2 Hi Flow Applicator RTD Sensors Applicator Part No. Description Location Qty. 106500 N07958 Pt 100 die adapter service block 1 1 106485 104985 Pt, dual die adapter service block 1 1 113288 N07864 Ni120 die adapter service block 1 1 Module Repair Kits PN 106722 Hi-Flow Seal Repair Kit The Hi-Flow module seal repair kit contains all the parts necessary to rebuild one High Flow MR1300 module, including the seal cartridge, high temperatue lubricant, springs and all o-rings. PN 113709 Hi-Flow, Hi--Temp Seal Repair Kit The Hi-Flow, Hi-Temp module repair kit contains all the parts necessary to rebuild one High Flow, High Temp MR1300 module, including the seal cartridge, high temperatue lubricant, springs and all o-rings. MR1300 High Flow Shim Kit PN 107138 All slot die applicators require that a shim be modified (cut) per the user’s application pattern. The shim kit contains four shims of various widths (0.015, 0.020, 0.025 and 0.031), one of which should be selected for the modification. Important note: No other shim on the applicator should be cut. Page 7-2 Revised 5/07 ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Recommended Service Parts List Part Number Description 106722 113709 084B1361 Hi-Flow Module Seal Kit Hi-Flow, Hi-Temp Module Seal Kit Seal Cartridge Assembly Heaters RTD Sensor Solenoid Valve O-ring 110 O-ring 011 O-ring 014 O-ring 113 O-ring 008 O-ring 010 O-ring 111 O-ring 009 Lubricant Thermal Paste See Ordering Guide See Ordering Guide 030A035 N00195 N00178 069X024 N00198 N00175 N00177 N00196 N00176 N07588 001V061 Qty. per Applicator as required as required as required as required 1 1 1 1 2 1 3 1 1 1 1 1 Recommended Service Parts List for Options 069X058 N00185 102693 101247 N00196 O-ring 028 (filter block option) O-ring 018 (filter block option) Filter Basket, 80 mesh (filter block option) Filter Basket, 100 mesh (filter block option) O-ring 111 (pressure gauge option) 1 1 2 2 1 Page 8-1 Revised 1/00 ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Chapter 8 ENGINEERING DRAWINGS & SCHEMATICS Pin Connectors & Electrical Schematics Note: Pin connectors are viewed from the exposed end. Pins not shown on schematics are not used. DynaControl (DCL) or PLC Control Scheme PN 103117 5 6 7 4 3 9 8 1 7 8 5 6 9 VVV 2 Microprocessor Temperature Control or CompuVision (MCV) Control Scheme PN 045X144 1 2 VVV 3 6 6 8 7 4 5 8 9 10 11 3 5 12 13 14 10 12 13 Symbols Used: RTD Sensor VVV Heater Ground ITW Dynatec c. 1999 MR1300 HI FLOW SLOT DIE APPLICATOR Manual #40-35 Page 8-2 Revised 11/06 Upgrade (Nickel RTD) Control Scheme PN 104551 VVV 5 4 2 6 3 1 Note: pin out numbers are not labeled on the Upgrade connector. ITW Dynatec An Illinois Tool Works Company Adhesive Application Solutions Heater RTD Sensor Ground 1 2 3 5 6