Download 2. ic operation of each circuit and pin description

Transcript

KENWOOD

DP-1100 B

DP-1100II

COMPACT DISC PLAYER

NOTE: Please replace this service manual with the old DP-1100's manual (B51-1592-00). This manual

has all descriptions for DP-1100 and DP-110011.

Photo is DP-1100B

•Refer to Parts List on page 177.

Photo is DP-110011

'Refer to Parts List on page 1 9 1 ,

TRIO-KENWOOD Corp. certifies this

equipment conforms to DHHS Regula

tions No. 21 C F R 1 0 4 0 . 1 0 , Chapter I,

Subchapter J .

DANGER: Laser radiation when open

and interlock defeated.

AVOID DIRECT EXPOSURE TO BEAM.

DP-1100B II

MEANING OF ABBREVIATIONS

AFC:

Disc m o t o r s p e e d c o n t r o l signal o u t p u t f r o m IC8 o n

FOKG:

p r o c e s s PCB

F S R H or F S R C H :

APC:

Disc m o t o r phase c o n t r o l signal o u t p u t f r o m IC8 o n

BCK:

Clock pulse o n w h i c h m u s i c data is sent t o D/A c o n

p r o c e s s PCB

CK88:

KGC:

signal resultant f r o m 1/2 f r e q u e n c y division of X ' t a l

K I C F B or K C I F :

OSC 8 . 4 6 7 2 M H z )

LDC:

A b o u t 8 8 kHz signal w h i c h is identical w i t h signal

LRCK:

Refer to " I C 1 5 pin f u n c t i o n " o n p a g e 7 0 .

Refer t o " I C 1 5 pin f u n c t i o n " o n p a g e 6 9 .

Signal o u t p u t f r o m IC6 o n p r o c e s s PCB. It indicates

w h e t h e r o u t p u t data is f o r L-ch or R-ch.

MODE 4:

PCB or as p s e u d o EFM signal.

CLV:

Inversion signal of signal RFG in I C 1 5 . It is n o r m a l l y

" L " a n d " H " d u r i n g kick of m o t o r .

W D C K ( w o r d c l o c k pulse) o u t p u t f r o m IC6 o n p r o

CLS:

Interrupt c o n t r o l I/O pin b e t w e e n CPU 1 a n d CPU 2

(Interrupt request)

Clock signal of a b o u t 4 M H z f o r m i c r o p r o c e s s o r (the

cess PCB. It is used as c l o c k signal for IC15 o n servo

2 Hz signal t o d e t e c t j u s t f o c u s i n g p o i n t . It

m o v e s the p i c k u p a c t u a t o r u p a n d d o w n .

IRQ:

verter (Bit c l o c k pulse)

CK4M:

Refer t o " I C 1 5 pin f u n c t i o n " o n p a g e 6 9 .

IC15 c o n t r o l signal w h i c h is o u t p u t f r o m

S w i t c h t o i n f o r m o p e n e d or c l o s e d tray state. It is

M5P:

s h o r t e d w i t h tray c l o s e d . ( " L " w i t h tray closed)

MUTE:

M u s i c signal m u t i n g s i g n a l .

Circuit w h i c h m a k e s t h e linear v e l o c i t y of disc m o t o r

OPEN:

S w i t c h w h i c h t u r n s ON ( " L " ) w i t h tray o p e n t o i n

c o n s t a n t t o p r o v i d e c o n s t a n t reading rate of disc

data.

D A T A 1 2 and D A T A 2 1 :

Disc m o t o r O N / O F F c o n t r o l s i g n a l .

f o r m o p e n e d tray state.

OPNS:

Refer t o " I C 1 5 pin f u n c t i o n " o n page 6 8 .

Signals f o r data c o m m u n i c a t i o n

PLAY:

Refer t o " I C 1 5 pin f u n c t i o n " o n p a g e 6 9 .

Refer t o " I C 1 5 pin f u n c t i o n " o n page 7 1 .

( t r a n s m i s s i o n a n d reception) b e t w e e n CPU 1 a n d

PLCK:

CPU 2 .

P U or P . U :

DATA:

Signal line o n w h i c h data is s e n t f r o m process PCB

PUD:

t o D/A c o n v e r t e r .

PUFB:

Inversion signal of signal PUFF in I C 1 5 .

DCON:

Signal w h i c h is o u t p u t f r o m I d 5 o n servo PCB. It is

RES:

CPU initialize signal

DIN:

DOCK:

RFES:

Refer t o " I C 1 5 pin f u n c t i o n " o n p a g e 6 9 .

l o w e r e d in level d u e t o disc f l a w . ( D r o p o u t c o n t r o l )

RFG:

Refer t o " I C 1 5 pin f u n c t i o n " o n page 7 0 .

Signal line o n w h i c h positional data of disc f l a w is

RFOK:

This o u t p u t b e c o m e s

Clock pulse o u t p u t f r o m IC15 o n servo PCB t o disc

position

memory

circuit.

It

is a six

times

o n m e c h a n i s m PCB.

SCK:

SLT:

1

and

EFM

These

0:

are

Eight-to-Fourteen-Modulation

high-frequency

signals or

RF

P r e - e m p h a s i s signal o u t p u t f r o m

Focusing

S V C (A, B, C and INH):

process

and tracking

coils

control

signals.

F E or F . E : Focus error signal

resultant f r o m

I C 1 2 c o n t r o l signal t o enable SVC opera

Servo c o n t r o l

T E or T . E : T r a c k i n g error signal or t r a c k i n g m o n i t o r pin

Refer t o " I C 1 5 pin f u n c t i o n " o n page

68.

T E O P and T E O N :

F . C O I L and T . C O I L :

Refer t o " I C 1 5 pin f u n c t i o n " o n page 6 8 .

TEP:

Refer t o " I C 1 5 pin f u n c t i o n " o n p a g e 6 8 .

TES:

Refer t o " I C 1 5 pin f u n c t i o n " o n page 6 8 .

T R A Y or T R Y : Disc t r a y or t r a y drive signal

1/30

frequency

division

of

signal DOCK. It c o n t r o l s disc m o t o r drive s i g n a l .

FOK:

most track.

T E G 1 and T E G 2 :

IC8 o n

PCB.

FGS:

S w i t c h w h i c h t u r n s ON ( " L " ) w i t h p i c k u p at inner

t i o n by m a i n C P U . ( I C 1 2 O N at " H " )

signals given f r o m optical p i c k u p .

Signal

Clock pulse f o r c o m m u n i c a t i o n b e t w e e n CPU1 a n d

S T A R T or S T A T :

Refer t o " I C 1 5 pin f u n c t i o n " o n p a g e 6 8 .

EFM

O u t p u t signal f r o m r e m o t e c o n t r o l signal amplifier

CPU 2 . (Serial c l o c k pulse)

W i t h disc p r o v i d e d , t h i s pulse o u t p u t is " L " . Q1 o n

signals.

FG4:

from

RMC:

(Disc OK)

EMPH:

RF signal

S1 and S 2 : Pickup o u t p u t signals e m i t t e d f r o m p r e a m p l i f i e r

servo PCB d e t e c t s t h e p r e s e n c e or a b s e n c e of disc.

EFM,

when

Disc m o t o r drive signal

a m p l i f i e d signal of FGS. ( D r o p o u t c l o c k pulse)

DSG:

"L"

p i c k u p is i n p u t t o IC10 ( V 2 ) .

c u i t a n d IC15 o n servo PCB.

flaw

DOK:

Pickup.

Refer t o " I C 1 5 pin f u n c t i o n " o n p a g e 6 8 .

n o r m a l l y " H " a n d b e c o m e s " L " w h e n RF signal is

t r a n s m i t t e d b e t w e e n disc f l a w position m e m o r y cir

DISK:

main

CPU. (Refer t o page 7 0 . )

IC15 i n p u t pin of FG signal f r o m disc m o t o r .

Focus servo c o n t r o l s i g n a l . Servo ON w i t h

TTAC:

WDCK:

Refer t o " I C 1 5 pin f u n c t i o n " o n page 6 8 .

Signal o u t p u t f r o m

IC6 o n

process

PCB. Its fre

q u e n c y is t w i c e t h a t of signal LRCK.

signal

FOK " L " .

5

DP-1100B II DP-1100B II

I. BLOCK DIAGRAM

DP-1100B II

II. FUNDAMENTALS

1-2

1 FUNDAMENTALS

1-1

SAMPLING

A n a n a l o g v o l t a g e is c o n t i n u o u s in respect t o t i m e , a n d has a

value at e a c h t i m e of t

QUANTIZATION

Fig. 1.3 i n d i c a t e s o n e e x a m p l e w h e r e a n a l o g signals r a n g i n g

1 (

t , t , etc. as s h o w n in Fig. 1.1 a n d as

2

f r o m O V t o 1 0 V are c o n v e r t e d t o 1 1 - s t e p v o l t a g e values of

0V, 1V, 2V

9 V a n d 1 0 V via r o u n d - o f f . W i t h t h i s c o n v e r

3

s i o n , p r e p a r a t i o n of o n l y 11 kinds of c o d e s is n e e d e d . T o c o n

w e l l a value at any t i m e b e t w e e n t a n d t .

x

2

vert an a n a l o g signal t o a kind of a digital signal w i t h t h e p r o

cess of r o u n d - o f f or t h e like is called " Q u a n t i z a t i o n " .

Voltage

Digital Voltage Converted by

Rounded-Off

Time

Fig.

1.1

Analog Voltage

If an a n a l o g v o l t a g e is represented c o r r e s p o n d i n g t o a c o d e

s y s t e m , t h e a n a l o g voltage over the definite t i m e range of t t o

t

t

2

is m a d e of the indefinite n u m b e r of c o d e s . In order t o

t r a n s m i t a digital signal c o r r e s p o n d i n g t o t h e voltage at t

1 (

it

needs a definite t i m e l e n g t h , b u t w h e n t r a n s m i t t i n g indefinite

c o d e s , t h e t r a n s m i s s i o n d o e s n o t e n d forever.

Time

Voltage (V)

Fig. 1 . 3

Voltage

Amplitude

t

Fig.

5

Time

1.2

Sampling

T h e r e f o r e , in case w h e r e an a n a l o g v o l t a g e is c o n v e r t e d t o a

c o d e d s y s t e m , a n a l o g v o l t a g e s at t i m i n g s w i t h s o m e interval

are o n l y c o n v e r t e d as s h o w n in Fig. 1.2. W i t h s u c h a p r o

c e s s , t h e definite n u m b e r of c o d e s c o r r e s p o n d i n g t o the

definite t i m i n g s , f o r e x a m p l e , five c o d e s f o r t h e t i m e interval t

t

t o t are p r o d u c e d .

5

W h e n h a v i n g t r a n s m i t t e d c o d e s d e s c r i b e d in Fig. 1.2, o n l y

five c o d e s c a n be received at the receive side b e t w e e n t

t

and

Quantization

t . T h e n u m b e r of v o l t a g e values r e p r o d u c e d t h e r e b y is only

5

f i v e , a n y v o l t a g e at t i m i n g s e x c e p t t

1 (

t , t , etc. c a n n o t be

2

3

determined.

H o w e v e r , if the f r e q u e n c y c o m p o n e n t ( 2 0 kHz) of the original

a n a l o g signal is less t h a n the value ( 4 4 . 1 kHz)

u p o n t h e t i m e interval b e t w e e n t i m i n g s t

1 (

depending

t , t , etc. at w h i c h

2

3

c o d i n g is s t a g e d , e v e n t h e value for n o n - t r a n s m i t t e d p o r t i o n s

c a n be r e p r o d u c e d . T o pick u p a n a l o g values at a fixed t i m e

interval by s u c h a process is called " s a m p l i n g " .

Fig.

1.4

DP-1100B II

II. FUNDAMENTALS

1-3

SAMPLING THEOREM

Signal Waveform

S/H

;

(

a

)

Measurings at a fixed time ( b)

interval (sampling)

Converts the measured

values to figures

(quantization)

A/D

f

Binary coded figures

(Offset Binary)

Recording

Reproduction

D/A

Demodulation

(PAM signal)

Fig. 1.5

T h e f r e q u e n c y of p i c k i n g u p an a n a l o g s i g n a l , for e x a m p l e ,

5 0 , 0 0 0 t i m e s per s e c o n d , is called " a s a m p l i n g f r e q u e n c y . It

is p r o v e n t h a t if s a m p l i n g is c o n d u c t e d at t h e rate larger t h a n a

c e r t a i n v a l u e , t h e original w a v e f o r m c a n be r e p r o d u c e d j u s t

the s a m e t o a n i n c h . T h i s is called " a s a m p l i n g t h e o r e m " .

Sampling T h e o r e m : If s a m p l i n g

ble the m a x i m u m f r e q u e n c y ( 2 0 kHz)

in a s p e c t r u m of a s i g n a l , t h e original

w a v e f o r m c a n be c o m p l e t e l y r e p r o d u c

ed.

8

is c o n d u c t e d at the f r e

q u e n c y ( 4 4 . 1 kHz) w h i c h is over d o u

DP-1100B II

II. FUNDAMENTALS

1-4

QUANTIZING NOISES

Transmitted signal waveform in passing

Signal Waveform

through a demodulation filter

3-digit figure

(decimal code)

9-bit figure

(Binary code)

Sampling point

Fig.

1.6

A r o u n d i n g error is c a u s e d by q u a n t i z a t i o n at s a m p l i n g points

noise is of t h e nature different f r o m noises e m i t t e d f r o m an

as d e s c r i b e d in 1-2, a n d seeing Fig. 1.6 it c a n be t h o u g h t

a n a l o g s y s t e m , being called " a q u a n t i z a t i o n n o i s e " .

t h a t this r o u n d i n g error is c r e a t e d as a distortion or noise. This

Max. Signal Amplitude

Sampling Quantization

Sampling

Frequency

44.1 kHz

Fig.

1.7

T h e ratio of a q u a n t i z i n g noise against t h e m a x i m u m value of

W h e n m a k i n g t h e a m p l i t u d e of 0 t o V c o r r e s p o n d i n g t o t h i s ,

the

the w i d t h E of o n e quantization step is given by:

signal

in a b i n a r y - c o d e d

1 6 - b i t system

is plotted

in

0

r e s p e c t t o a sinusoidal w a v e i n p u t as s h o w n in Fig. 1.7.

E = V/(N

0

-1)

If a 1 6 - b i t c o d e is used in q u a n t i z i n g o n e s a m p l e d v a l u e , the

n u m b e r of steps w h i c h c a n be t a k e n , i.e., the

n u m b e r N is given as f o l l o w s :

N = 2

1 6

quantizing

T h e r e f o r e , t h e a m p l i t u d e of a q u a n t i z i n g noise is E at t h e

0

p e a k - t o - p e a k v a l u e , so t h a t the noise p o w e r N

Q

is:

= 65536

9

DP-1100B II

II. FUNDAMENTALS

On t h e o t h e r

hand, supposing

t h a t an i n p u t signal is a

T h e r e f o r e , the p o w e r ratio is:

sinusoidal w a v e w h o s e a m p l i t u d e at the p e a k - t o - p e a k value is

V , the signal p o w e r S is:

1-5

E F M (EIGHT T O FOURTEEN MODULATION)

T o c o n v e r t a level of an a n a l o g signal at every interval of a fix

Role of Margin Bits

ed p e r i o d ( 1 / 4 4 . 1 kHz = 2 2 . 7 /is), as d e s c r i b e d in 1-4, t o a

T h e p u r p o s e of t h e m a r g i n bits is t o r e d u c e a DC c o m p o n e n t

binary c o d e (1 a n d 0 ) after q u a n t i z a t i o n is called a " P C M "

a n d l o w f r e q u e n c y c o m p o n e n t s by a d d i n g three additional

(Pulse Code M o d u l a t i o n ) .

bits t o t h e signals c o n v e r t e d into EFM.

PCM has v a r i o u s kinds of m o d u l a t i o n s y s t e m s , b u t here a

C h a n n e l Bits

S o n y a n d Philips j o i n t l y d e v e l o p e d n e w s y s t e m , called E F M ,

One of 1 4 bits c o n v e r t e d f r o m 8 bits is called a c h a n n e l bit.

used f o r D A D is d e s c r i b e d .

One word

Sample

A

L S B

MSB

Symbol 1 ( = 8 bits)

Symbol 2 ( = 8 bits)

EFM

Margin bits

added

Symbol 2 { = 17 channel bits)

Symbol 1 ( = 17 channel bits)

Fig.

(1)

1.8

EFM is t h e m o d u l a t i o n t o first divide a 1 6 - b i t d a t u m (data

bit) into t w o 8 - b i t data a n d t h e n c o n v e r t e a c h of these

T w o or m o r e b u t 10 or less Os (zeros) s h o u l d be a l w a y s i n

8 - b i t d a t a t o a 1 4 - b i t d a t u m ( c h a n n e l bit) as s h o w n in

serted b e t w e e n c h a n n e l bits 1 a n d 1 4 .

Fig. 1.8. T h e c o n v e r s i o n is t o select patterns of 2

a m o n g p a t t e r n s of 2

1 4

8

kinds

k i n d s , m e e t i n g the f o l l o w i n g c o n

d i t i o n . C h a n n e l bits of 2

8

m e e t i n g this c o n d i t i o n have

(2)

T h r e e c h a n n e l bits are a l w a y s inserted b e t w e e n

14-bit

b l o c k s . T h e role of these 3 bits is t o m a k e a d j u s t m e n t so

b e e n p r e d e t e r m i n e d by a c o m p u t e r as indicated in Tables

t h a t the a b o v e c o n d i t i o n (enclosed in t h e box) is m e t

1-1 a n d 1-2:

e v e n at t h e c o n n e c t i o n of b l o c k s .

DP-1100B II

II. FUNDAMENTALS

8 bits - 1 4 bits

8 b i t s - 1 4 bits

Order

Order

0

i

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

data bits

channel bits

00000000

00000001

00000010

00000011

00000100

00000101

00000110

00000111

00001000

00001001

00001010

00001011

00001100

00001101

00001 110

0 0 0 0 1 111

00010000

00010001

00010010

00010011

00010100

00010101

00010110

0 0 0 1 01 11

00011000

00011001

00011010

00011011

00011 100

00011101

00011110

00011111

00100000

00100001

00100010

00100011

00100100

00100101

00100110

00100111

00101000

00101001

00101010

00101011

00101100

00101101

00101110

00101111

00110000

00110001

00110010

00110011

00110100

00110101

00110110

00110111

00111000

00111001

00111010

00111011

00111100

00111101

00111110

00111111

01001000100000

10000100000000

10010000100000

10001000100000

01000100000000

00000100010000

00010000100000

00100100000000

01001001000000

10000001000000

10010001000000

10001001000000

01000001000000

00000001000000

00010001000000

00100001000000

10000000100000

10000010000000

10010010000000

00100000100000

01000010000000

00000010000000

00010010000000

00100010000000

01001000010000

10000000010000

10010000010000

10001000010000

01000000010000

00001000010000

00010000010000

00100000010000

00000000100000

10000100001000

00001000100000

00100100100000

01000100001000

00000100001000

01000000100000

00100100001000

01001001001000

10000001001000

10010001001000

10001001001000

01000001001000

00000001001000

00010001001000

00100001001000

00000100000000

10000010001000

10010010001000

10000100010000

01000010001000

00000010001000

00010010001000

00100010001000

01001000001000

10000000001000

10010000001000

10001000001000

01000000001000

00001000001000

00010000001000

00100000001000

d1

d8

C1

C14

C1 is first cut.

EFM Conversion table 0 to 127

(NRZ-1 represantation)

data bits

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

1 18

119

120

121

122

123

124

125

126

127

01000000

01000001

01000010

01000011

01000100

01000101

01000110

01000111

01001000

01001001

01001010

01001011

01001100

01001101

01001110

01001111

01010000

01010001

01010010

01010011

01010100

01010101

01010110

01010111

01011000

01011001

01011010

01011011

0101 1100

01011101

01011110

01011111

01100000

01100001

01100010

01100011

01100100

01100101

01100110

01100111

01101000

01101001

01101010

01101011

01101100

01101101

01101110

01101111

01110000

01110001

O i l 10010

O i l 10011

O i l 10100

01110101

01110110

01110111

0 1 1 1 1 0 00

01111001

01 1 1 1 0 1 0

01111011

01111100

01111101

01111110

01111111

channel bits

01001000100100

10000100100100

10010000100100

10001000100100

01000100100100

00000000100100

00010000100100

00100100100100

01001001000100

10000001000100

10010001000100

10001001000100

01000001000100

00000001000100

00010001000100

00100001000100

10000000100100

10000010000100

10010010000100

00100000100100

01000010000100

00000010000100

00010010000100

00100010000100

01001000000100

10000000000100

10010000000100

10001000000100

01000000000100

00001000000100

00010000000100

00100000000100

01001000100010

10000100100010

10010000100010

10001000100010

01000100100010

00000000100010

01000000100100

00100100100010

01001001000010

10000001000.010

10010001000010

10001001000010

01000001000010

00000001000010

00010001000010

00100001000010

10000000100010

10000010000010

10010010000010

00100000100010

01000010000010

00000010000010

00010010000010

00100010000010

01001000000010

00001001001000

10010000000010

10001000000010

01000000000010

00001000000010

00010000000010

00100000000010

DP-1100B II

II. FUNDAMENTALS

8 bits — 14 bits

8 bits — 14 bits

Order

Order

data bits

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

10000000

10000001

10000010

10000011

10000100

10000101

1 0 0 0 0 1 10

10000111

10001000

10001001

10001010

10001011

10001100

10001101

10001110

10001111

10010000

10010001

10010010

10010011

10010100

10010101

10010110

10010111

10011000

10011001

1001 1010

10011011

1001 1100

10011101

10011110

10011111

10100000

10100001

10100010

10100011

10100100

10100101

10100110

10100111

1010 1000

10101001

10101010

10101011

10101100

10101101

10101110

1010111 1

10110000

10110001

101 10010

10110011

10110100

10110101

10110110

10110111

10111000

10111001

10111010

10111011

10111100

10111101

10111110

10111111

channel bits

01001000100001

10000100100001

10010000100001

10001000100001

01000100100001

00000000100001

00010000100001

00100100100001

01001001000001

10000001000001

10010001000001

10001001000001

01000001000001

00000001000001

00010001000001

00100001000001

10000000100001

10000010000001

10010010000001

00100000100001

01000010000001

00000010000001

00010010000001

00100010000001

01001000000001

10000010010000

10010000000001

10001000000001

01000010010000

00001000000001

00010000000001

00100010010000

00001000100001

10000100001001

01000100010000

00000100100001

01000100001001

00000100001001

0100 0000100001

00100100001001

01001001001001

10000001001001

10010001001001

10001001001001

01000001001001

00000001001001

00010001001001

00100001001001

00000100100000

10000010001001

10010010001001

00100100010000

01000010001001

00000010001001

00010010001001

00100010001001

01001000001001

10000000001001

10010000001001

10001000001001

01000000001001

00001000001001

00010000001001

00100000001001

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

209

210

211

212

213

21*4

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

246

247

248

249

250

251

252

253

254

255

data bits

channel bits

11000000

11000001

11000010

11000011

11000100

11000101

11000110

11000111

11001000

11001001

11001010

11001011

11001100

11001101

11001110

11001111

11010000

11010001

11010010

11010011

11010100

11010101

1 1 0 1 0 1 10

11010111

11011000

11011001

11011010

11011011

11011100

11011101

11011110

11011111

11100000

11100001

11100010

11 1 0 0 0 1 1

11100100

11100101

11100110

1 1100111

11101000

11101001

11101010

11101011

11101100

11101101

11101110

1 1 1 0 1 1 11

11110000

11110001

11 1 1 0 0 1 0

11110011

111 1 0 1 0 0

1 1110101

11110110

111 1 0 1 1 1

111 1 1 0 0 0

111 1 1 0 0 1

11111010

11111011

111 1 1 1 0 0

11111101

11111110

11111111

01000100100000

10000100010001

10010010010000

00001000100100

01000100010001

00000100010001

00010010010000

00100100010001

00001001000001

10000100000001

00001001000100

00001001000000

01000100000001

00000100000001

00000010010000

00100100000001

00000100100100

10000010010001

10010010010001

10000100100000

01000010010001

00000010010001

00010010010001

00100010010001

01001000010001

10000000010001

10010000010001

10001000010001

01000000010001

00001000010001

00010000010001

00100000010001

01000100000010

00000100000010

10000100010010

00100100000010

01000100010010

00000100010010

01000000100010

00100100010010

10000100000010

10000100000100

00001001001001

00001001000010

01000100000100

00000100000100

00010000100010

00100100000100

00000100100010

10000010010010

10010010010010

00001000100010

01000010010010

00000010010010

00010010010010

00100010010010

01001000010010

10000000010010

10010000010010

10001000010010

01000000010010

00001000010010

00010000010010

00100000010010

data bits

d1

d8

C1

C14

C1 is first cut.

EFM Conversion table 128 to 2 5 5

(NRZ-1 represantation)

cf: NRZ Non Return to Zero

channel bits

DP-1100B II

II. FUNDAMENTALS

1-6

FRAME SYNCHRONIZATION AND FRAME

STRUCTURE

R e p r o d u c t i o n signals c a n n o t be r e c o v e r e d RF signals d o n o t

Channel bits

Margin bits

Total bits

Frame Synchro

nization

24

3

27

Users buts

14

3

17

c o m e o u t for a l o n g t i m e due t o d r o p o u t or o n e i n f o r m a t i o n bit

has b e e n shifted o w i n g t o jittering in digital r e c o r d i n g

or

p l a y b a c k . Because o n e bit shift of a digital signal m a k e s t h e

signal quite different in its signal level.

Data bits

T h e r e f o r e , by d i v i d i n g a r e c o r d e d signal t o m a n y small blockjs,

14 b i t x 2 4 = 336

408

14 b i t x 8 = 1 1 2

3 bit x 24

136

486

102

588

t h e s y s t e m is o r g a n i z e d so t h a t even w h e n a signal is d i s t u r b

ed d u e t o jittering or t h e like, a bit s y n c h r o n i z a t i o n is a l w a y s

Error correction

bits (Parity bits)

estabilished at the n e w block t o identify t h e j o i n t part b e t w e e n

3

b i t x 8 = 24 = 72

b l o c k s . S u c h a block is called a " F r a m e " . Frame Sync signals

are inserted t o indicate the b o u n d a r y of the f r a m e a n d t o

m a k e a bit s y n c h r o n i z a t i o n . Fig. 1.9 s h o w s the structure of

one frame.

Frame Structure

1-frame (588 Channel Bits)

• Margin Bit

User's Bit

Data Bits

I

2

4

3

5

14 14 14 14

3A

-3

:

6

14

:

:

7

Parity

9

10

14 14 14 14

14

8

.;

:

11

12

14

:i

14

13

14

15

14

14

14

:

2

Data Bits

16

17

14

14

:. 2

18

19

14

14

:

Parity

20

21

22

23

24

25

26

27

28

14

14

14

14

14

14

14

14

14

29

:i

Data Symbol 1 (14 Channel Bits)

Sync Pattern (24 Channel Bits)

Channel Bit Frequency = 4 . 3 MHz

Frame Frequency = 7 . 3 5 kHz

11

2 x Tmax

S T A R T FRAME

Fig.

1.9

14

32

14

:i

Control Display Symbol (14 Channel Bits) PQ Data Absolute Music

11 Channel Bits

31

30

24

14

:

;

:

DP-1100B II

II. FUNDAMENTALS

1-7

1.

2.

C O M P A C T D I S C (CD)

T h e r e are m a n y kinds of D A D s y s t e m s : C D , M D a n d

m o i s t u r e a b s o r p t i o n c a u s i n g b e n d is a big d e f e c t . (Refer

A H D . (Refer t o Fig. 1.10)

t o p r e c a u t i o n s o n h a n d l i n g t h e disc.)

7.

D P - 1 1 0 0 B / I I a d o p t s t h e CD s y s t e m . T h e CD system is

also c a l l e d

"a

light s y s t e m " .

A

light b e a m

from

Playback t i m e is 6 0 m i n u t e s w i t h a 1 2 0 m m disc.

D i m e n s i o n s are given in Fig. 1 . 1 2 .

a

s e m i c o n d u c t o r laser is c o n v e r g e d w i t h an objective lens

8.

t o hit pits inside a disc for using their reflected light.

T h e rotating s p e e d of t h e disc is n o t c o n s t a n t . Because of

a c o n s t a n t linear v e l o c i t y system e m p l o y e d , the rotating

3.

speed

T h e r e are no g r o o v e in t h e CD s y s t e m hit pits.

Size

of

Pit:

Width

0 . 5 fim,

Length: 0.9

to

is varied

between

(counterclockwise)

3.3 /im,

CLV

around

5 0 0 to 2 0 0

(constant

linear

r.p.m.

velocity):

c a p s t a n drive t y p e t a p e r e c o r d e r C A V ( c o n s t a n t a n g u l a r

D e p t h : 0 . 1 /im

v e l o c i t y ) : rim drive t y p e t a p e r e c o r d e r .

4.

Laser b e a m is hit t h r o u g h a t r a n s p a r e n t disc layer t o read

o u t d a t a . (See Fig.

9.

1.11)

PL) (pickup) d o e s n o t c o n t a c t a disc surface b u t t r a c e s a

t r a c k m o v i n g f r o m inner radius t o outer radius.

5.

C o n s t r u c t i o n of disc. (See Fig. 1.11)

6.

Disc baseplates are usually m a d e of PC ( p o l y c a r b o n a t e ) ,

It d e p e n d s u p o n the t r a n s m i s s i o n f a c t o r , reflection f a c t o r

P M M A (acryl) is superior f o r a disc baseplate, b u t its

and double refraction.

1 0 . H o w m u c h effectively d o e s it use a laser beam?

1.5 /tm

0 . 9 - 3 . 3 nm

Protective Surface

Pit

0.4 nm

Reflecting Surface

Reproduction Light Spot

0.11 nm

1.2

mm

Transparent Plastic

Approx. 1 mm0

Objective Lens

CD System

Fig.

1.10

Laser Beam

1 mm0

1.2 mm

Disc Baseplate (Polycarbonate)

1.6 /tm

Reflecting Film (Aluminium)

Protective Film

Fig.

14

1-11

DP-1100B II

II. FUNDAMENTALS

Program

Lead in

Lead out

"(T.O.C)

Fig.

1.12

Lead In: T O C (table of c o n t e n t s ) — A b s o l u t e t i m e of t h e

h e a d i n g of m u s i c is i n c l u d e d .

Lead Out:

Used for retrieving of t h e h e a d i n g indicates of

program end.

Other — C o n t r o l Data P, Q

15

DP-1100B II

II. FUNDAMENTALS

1 2 . D o u b l e Refraction

11.

T h e rating of d o u b l e refraction is represented by a light path

difference ( m m ) . Rating: 1 0 0 m m

T h e m a i n c a u s e of d o u b l e refraction is m o l d d i s t o r t i o n . Fig.

1.14

100%

PU

Disc Surface

. Objective Lens

Absorption

Disc Baseplate

Disc

Reflection attenuation

Fig.

Reflection Film

1.13

Fig.

1.14

1 3 . CD is t o u g h a g a i n s t dusts Fig. 1.15(a) a n d (b)

Laser Beam

1 mm#

Dust

Disc Surface

1 iirr\<t>

Pits

1.5 nm<j>

(a) In a case where dusts are deposited on the disc surface

(b) In a case where dusts are attached to a reflecting film surface

Fig.

14.

Fabricating p r o c e s s of baseplate. Fig. 1.16

15.

Mastering:

Procedures for

Photo-resist c o a t i n g ,

laser

r e c o r d i n g a n d d e v e l o p m e n t are i n c l u d e d .

T h i s is c o r r e s p o n d i n g t o t h e f a b r i c a t i n g p r o

cess of a l a c q u e r disc in an a n a l o g r e c o r d

production.

16.

Molding:

Injection m o l d i n g

P h o t o Polymerization

6

1.15

0P-1100B II

II. FUNDAMENTALS

Glass Disc

Glass Disc

Photoresist

Photoresist Coating

Glass Disc

Laser R e c o r d i n g

Development

Master Disc •

Silver Mirror Ni plating

Metal Master

Ni plating

M o t h e r Disc.

Ni plating

Stamper

Molding

T r a n s p a r e n t Disc

Reflecting Film e v a p o r a t i o n

Protective file c o a t i n g

Label Printing

Finished G o o d ( C o m p a c t Disc)

Packing

Fig. 1 . 1 6 Manufacturing P r o c e s s of C D

17

DP-1100B II

II. FUNDAMENTALS

Control &

Display

Encoding

LP

Filter

Sample

& Hold

Sync.

Generation

Modulator

ADC

Ch 1

Serial

Data

Output

MUX

MUX

Audio input

Error

Correction

System

Ch 2

LP

Filter

Sample

& Hold

ADC

X-tal

Timing

ENCODING S Y S T E M

*

time multiplexer

* * Analog to Digital converter

Fig. 1 . 1 7 Encoding s y s t e m

8

DP-1100B II

II. FUNDAMENTALS

2 CODE ERROR

2-3

INTERLEAVE

Even if r e a d i n g every page of a b o o k slantwise f r o m its u p p e r

2-1

C A U S E S OF CODE ERROR

(1)

Defectives

which

are

already

left side t o l o w e r right side, y o u c a n fully recognize t h e c o n

present

on

a disc

at

text or c o n t e n t s . H o w e v e r , y o u c a n n o t recognize the c o n t e n t s

delivery:

of the b o o k if y o u are reading carefully o n e c h a r a c t e r

— Dusts a t t a c h e d t o pits d u r i n g p r o d u c t i o n of disc.

or

clause w i t h o u t r e a d i n g several t e n s of p a g e s .

— Disc m o l d i n g d i s t o r t i o n (entering of air b u b b l e s w h o s e

r e f r a c t i o n f a c t o r is n o t e q u a l . )

A n error c o l l e c t i o n c o d e is the s a m e as this, a n d c o r r e c t i o n is

easy

(2)

(3)

even w h e n

code

errors of

some

bits are

present.

Faults c r e a t e d o n h a n d l i n g of a disc: d u s t s , s c r a t c h e s ,

H o w e v e r , if m a n y , say 1000,

stains a n d f i n g e r prints.

a t i m e , it is very difficult t o c o r r e c t t h o s e errors.

Level variations of r e p r o d u c t i o n signal (eye pattern)

T h e r e f o r e , t h e t e c h n i q u e w i t h w h i c h an o r d e r of a signal is

Because p r o t e c t i o n of o u t - o f - t r a c k i n g , Focus a n d CLV

o n c e c h a n g e d a n d t h e n r e c o r d e d a n d , after r e p r o d u c t i o n ,

are all d e p e n d i n g o n a servo s y s t e m , p o o r stability of the

bits are c o n s e c u t i v e l y w r o n g at

r e t u r n e d b a c k t o t h e original order is e m p l o y e d . This c h a n g i n g

servo leads t o increased c o d e errors.

of the order of a signal is called an " i n t e r l e a v e " , a n d the

r e t u r n i n g t o t h e original order is called a " d e i n t e r l e a v e " .

2-2

KINDS OF C O D E ERROR

(1)

R a n d o m Error:

an error w h i c h causes an error in one bit

terleave. T h e o r d e r of a signal at f a b r i c a t i o n of the disc is o u t

(2)

Burst Error: an error w h i c h c a u s e s an error in m a n y s u c

c o d e errors are d i s p e r e s e d , so t h a t o p e r a t i o n of error c o r r e c

cessive bits.

tion a n d associated j o b s are m a d e facilitative.

Fig.

2.1

is the

illustration e x p l a i n i n g the

principle

of i n

of order. T h e r e f o r e , by deinterleaving t h e s i g n a l , successive

Signal words arranged

(interleaved on a disc)

10 successive words are wrong

Signal words deinterleaved

Signal words returned to their original locations

(10 successive error words are dispersed.)

Fig.

2.1

1

•P-1100B II

II. FUNDAMENTALS

2-4

SINGLE ERASURE CORRECTING METHOD

Bill (a) as s h o w n in Fig. 2-2 indicates prices of f o u r kinds

Bill (a)

of articles A , B, C a n d D a n d t h e t o t a l . In bill (b), t h e price

of article B disappears. This calls a disappearance or

erasure. W h e n t h e total a m o u n t is k n o w n , t h e price of ar

ticle B c a n be f o u n d even if o n e figure is m i s s e d . In t h e

c o d i n g t h e o r y , w e t h e r t h e total a m o u n t is c o r r e c t in bill

+

A ¥

100

B ¥

200

C ¥

300

D ¥

400

(a) is c h e c k e d . This o p e r a t i o n is called " s y n d r o m e " .

Total P ¥ 1,000

Syndrome (Checking)

S=A+B+C+D-P=0

(2)

In bill ( b ) , t h e price of article B disappears. (It is indicated

Bill (b)

by B * . B * = 0 ) C o n d u c t i n g t h e s y n d r o m e does n o t creat

S = 0 because there is a n erasure.

However,

as t h e

n u m b e r of erasure is o n e , t h e a m o u n t of B* c a n be f o u n d

from

syndrome

S=-200.

According

t o t h e single

diserasure c o r r e c t i n g m e t h o d , o p e r a t i o n of c o r r e c t i o n is

c o n d u c t e d o n t h e a s s u m p t i o n t h a t all other data ( A ' , C

a n d D') are c o r r e c t . If there is an error f o r a n o t h e r article,

+

A'

¥

B*

¥

100

C

¥

300

D' ¥

400

?

Total P' ¥ 1,000

miscorrection happens.

Syndrome (Checking)

S = A' + B' + C' + D ' - P = 0

B = B * - S = 200

(3)

O p e r a t i n g t h e s y n d r o r m e o n bill ( c ) , zero does n o t c o m e

Bill (c)

out. T h e r e f o r e , it m a y be f o u n d t h a t s o m e t h i n g is w r o n g ,

b u t it c a n n o t be f o u n d w h i c h of A ' , B ' , C , D' a n d P' is i n

¥

100

B' ¥

300

A'

c o r r e c t . In s u c h a c a s e , c o r r e c t i o n is infeasible.

¥

300

D' ¥

400

C

+

Total P' ¥ 1,000

S = A' + B' + C' + D ' - P ' = 0

(4)

Bill (d) illustrates t h e e x a m p l e t h a t t h e location t o be cor

Bill (d)

rected is k n o w n , a n d t h e c o r r e c t i o n c a n be d o n e by t h e

s a m e m e a n s as in bill (b). T h e m e a n s t o indicate t h e loca

t i o n of error in s u c h

a w a y is called a " p o i n t e r " .

In t h e e x a m p l e s of (1) t o ( 4 ) , " T o t a l P " is used f o r c h e c k

of error or erasure of data A , B, C a n d D. A w o r d used f o r

c h e c k a n d c o r r e c t i o n besides required data is called a

+

A'

¥

100

B*

¥

300

C

¥

300

D' ¥

400

Total P' ¥ 1,000

" p a r i t y w o r d " or a " p a r i t y b i t " .

S = A' + B' + C' + D ' - P ' = 100

B = B * - S = 200

20

Disppearance

II. FUNDAMENTALS

2-5

SINGLE ERROR CORRECTION, DOUBLE E R A S U R E S

In case of (3) in 2 - 4 , c o r r e c t i o n is infeasible because the

Bill (a)

location of error is u n k n o w n . Even in s u c h a c a s e , the

w a y by w h i c h c o r r e c t i o n is feasible is a single error c o r

recting m e t h o d . In 2 - 4 , t h e r e is only o n e parity w o r d , P.

Besides t h i s , a " W e i g h t e d Total V a l u e " , Q, is u s e d .

Because t w o parity w o r d s P a n d Q are u s e d , there are

A ¥

100

B ¥

200

C ¥

300

D

400

¥

P ¥ 1,000

also t w o s y n d r o m e s S j A n d S .

2

Q ¥ 1,000

N o w s u p p o s e t h a t t h e r e is an i n c o r r e c t bill (b) in respect

P=A+B+C+D

t o a c o r r e c t bill (b) a n d t h a t the location of error (one) in

Q = 4A + 3B + 2C + D

bill (b) is u n k n o w n .

Syndromes

S u p p o s i n g t h a t the differences f r o m original values are

E,

A

E , E, E

B

c

Dl

E and E w i t h respect t o A ' , B', C , D ' , P'

P

e

S

1=

A + B+ C+ D-P = 0

S, = 4A + 3B + 2C + D - Q = 0

and Q ' , respectively, of bill (b) (for no error, E , to E = 0 )

A

k' = k + E

P' = P + E

Dl

B' = B + E ,

Al

C' = C + E ,

B

Q' = Q + E

Obtaining syndrome

Q

D' = D + E ,

C

D

Q

S

Bill (b)

v

5 = A ' + B' + C' + D ' - P '

A'

1

= ( A + E J + (B + E ) + (C + E ) + (D + E ) - ( P + E )

B

C

D

P

= A+B + C + D - P + E + E +Ec+E -E -E ,-(1)

yl

B

0

F

100

300

¥

300

D' ¥

C

400

i

0

¥

B' ¥

?' ¥ 1,000

= E +

E +E +E -E

A

B

C

D

Q' ¥ 2,000

P

Obtaining syndrome S

2

Syndrome

5 = 4A' + 3B' + 2C' + D ' - Q '

S ^ A ' + B' + C' + D ' - P ' ^ O O

2

= 4 A + 3 B + 2C + D - Q + (4E^ + 3 E + 2 E + E - E ) (2)

£

0

= 4E4 + 3 E + 2 E + E - E

B

C

D

C

D

Q

Q

S u p p o s i n g t h a t a c o d e error is one w o r d b e t w e e n A ' t o

P', Q'

(I)

A'wrong

S j = E^, S = 4E

(II)

B'wrong

S = E , S = 3E

B

(III)

C wrong

S = E , S = 2E

C

(IV)

D'wrong

S^E^,

(VI)

P'wrong

S^Ep, S = 0

(VII)

Q'wrong

S = 0,

2

1

1

fl

C

2

2

S =E

2

A

D

2

t

S =-E

2

e

By a m e t h o d w h e r e t w o s y n d r o m e s are i n t r o d u c e d as

m e n t i o n e d a b o v e a n d d e t e r m i n e d , w r o n g w o r d s c a n be

found and corrected.

S, = 4A' + 3B' + 2C' + D ' - Q ' = 300

DP-1100B II

II. FUNDAMENTALS

(2)

EB=100

T h e principle of d o u b l e erasure c o r r e c t i o n is described

b e l o w . In this c a s e , t h e l o c a t i o n of error is indicated w i t h

Bill (c)

a pointer. It is here k n o w n t h a t t w o w o r d s in bill (c) are

w r o n g a n d t h e r e are n o other w r o n g w o r d s .

S = A + B+ C+ D-P + E +

1

yl

E

f l

+E +E -E =200

c

D

¥

100

B' ¥

300

A'

Using e q u a t i o n (1) in p a r a g r a p h ( 1 ) ,

P

0

C

¥

400

D'

¥

400

Pointer

P' ¥ 1,000

Q' ¥ 2,000

S u p p o s i n g E = 0, E = 0 a n d E = 0

A

D

P

(3)

S = E ,+ E = 2 0 0

1

J

C

E =100

c

F r o m Equation (2) of (1

5 = A' + B * + C * + D ' - P ' = 200

1

5 = 4A' + 3B' + 2C* + D' — Q' = 500

2

S = 4 A + 3 B + 2C + D + (4E + 3 E + 2 E + E - E ) = 5 0 0

2

/4

B

c

B

Q

B* = E + E C * + = C + E

0

S = 3E

2

Where

B

J J

C

(4)

+2E =500

C

T h i s t h e o r y is t h e principle of a Reed S o l o m o n C o d e . In

Determining E

B

(3) a n d ( 4 ) ,

22

a n d E f r o m s i m u l t a n e o u s e q u a t i o n s of

c

p r a c t i c e , t h e Reed S o l o m o n Code w i t h f o u r parity w o r d s

is u s e d .

DP-1100B II

II. FUNDAMENTALS

2-6

CROSS-INTERLEAVE

Fig. 2 . 2

s h o w s a principle

of a cross-interleave.

delivered directly, b u t w o r d s f e d into N o . 2 t o N o . 4 lines

An

original series of signals is d i v i d e d into a n u m b e r

are s u b j e c t t o delay w i t h delay m e m o r i e s by o n e t o three

of

w o r d s so t h a t the w o r d o r d e r is c h a n g e d (interleaved) at

w o r d s , a n d parity w o r d s are inserted.

their respective t e r m i n a l s .

P = W

1

+ W

P = W

5

+ W

6

P = W

9

+ W

1

1

5

9

2

+ W

3

+ W

7

+

+

+ W

0

W

N

4

W

+

T h e r e is an a d d e r f o l l o w i n g the delay m e m o r i e s , w h e r e

(5)

8

W

1

a n o t h e r parity w o r d Q is c r e a t e d .

2

Q

Four original series of signals ( W

W , W

6

1 0

1 (

W , W , W ...), (W ,

5

9

1 3

2

= W

1

+ W.

Q

5

= W

5

+ W

2

+ W.

Q

9

= W

9

+ W

6

+ W

1

2

+ W.

1

3

+ W-

5

+ W .

+ W

0

8

4

+

W.

+ P .

1

5

(6)

U

+ P.?

, W , . . . ) , ( W , W , W , W , . . . ) and ( W , W ,

u

3

7

u

1 5

4

8

W , W , . . . ) a m o n g m a n y original series of signals are

1 2

1 6

a r r a n g e d f o r f o u r lines N o . 1 via N o . 4 in Fig. 2 . 2 of

In other w o r d s , t w o s y s t e m of c o d e s are used o n b o t h

these w o r d s , the w o r d s

sides of t h e delay m e m o r i e s .

passing t h r o u g h

8

7

W

1 are

1 Word

Original series of signals

,W W

No.

W

6

5

2 Words

Recorded series of signals

w

5

Q P.

t

15

W_ W .

8

5

W.

2

W

t

3 Words

Disc recording sequence

Adder

p =w +w +w +w

1

1

2

3

4

Q = Wj + W + W_ + W_„ + W .

t

2

5

P = W + W + W + W

S

5

6

7

5

2

Delay memories

15

8

Q = W + W + W.n + W_ + P_

5

4 Words

4

Adder

n

Fig. 2 . 2 Principle of C r o s s - I n t e r l e a v e E n c o d e r

(2)

Fig. 2 . 3 indicates relations b e t w e e n t w o parity c o d e s .

Data Word

Check Word

T h e solid lines m e a n a P's series, a n d the d o t t e d lines

m e a n a Q's series. Each of t h e m has the capability of

single erasure c o r r e c t i o n , so t h a t an error of a single

w o r d c a n be easily c o r r e c t e d of c o u r s e .

T h e s y n d r o m e of e a c h o t h e r ' s series c a n be used as a

p o i n t e r f o r p o i n t i n g o u t a l o c a t i o n of error.

Fig. 2 . 3 C o d e S e r i e s of C r o s s Interleave

(Black circules indicate errors).

P-1100B II

II. FUNDAMENTALS

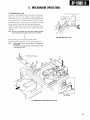

3 BRIEF EXPLANATIONS ON CD PLAYER (See

the BLOCK DIAGRAM)

3-1

3-2

PICKUP FOR C D APPLICATION

SIGNAL PROCESSING CIRCUIT

A p i c k u p p a r t c o r r e s p o n d i n g t o a c a r t r i d g e for a c o n v e n t i o n a l

A signal d e t e c t e d at a p i c k u p is delivered t o a signal process

analog

ing c i r c u i t , a n d split into t h e f o l l o w i n g three signals.

player is detailed later.

Briefly s p e a k i n g , this

part

a l l o w s the laser d i o d e t o e m i t a light b e a m ( X = 7 8 0 n m ) a n d

c o n v e r t t h e intensity of t h e reflected light f r o m disc pits into

(1)

Focus Error Signal

(2)

t r a c k i n g (Radial) Error Signal

electric signals.

(3)

Radio F r e q u e n c y (RF) S i g n a l : This signal is processed to

generate an a n a l o g signal.

3-3

3-3-1

SERVO CIRCUIT

F o c u s S e r v o Circuit

a l w a y s k e p t o n a pit surface against f l u c t u a t i o n s due t o t h e

A f o c u s error signal is f e d into a f o c u s servo c i r c u i t t o c o n t r o l a

lens s y s t e m w i t h the use of a f o c u s servo coil (like a v o i c e coil

revolutions of a disc. (The s a m e as a u t o - f o c u s i n g in an EE

of a l o u d s p e a k e r ) so t h a t t h e f o c u s s p o t of the laser b e a m is

camera)

Pickup

Disc

Lens

Focus coil

Signal

Focus Servo

Processing

Focus Coil

Driver

• Approx. 2 nm dia. Lader Spot

Fig.

3-3-2

3.1

T r a c k i n g S e r v o Circuit

Because a c o m p a c t disc has no guide g r o o v e , it is n e e d e d t o

ing servo c i r c u i t , t h e o u t p u t of w h i c h drives a t r a c k i n g servo

o p e r a t e a servo so t h a t a laser b e a m s p o t c a n a u t o m a i t c a l l y

coil t o operate t h e servo s y s t e m .

f o l l o w a signal t r a c k . A t r a c k i n g error signal is fed into a t r a c k

Laser spot (approx. 2 /tm dia.

To Tracking Coil

Pits on disc

Signal

Processing

1.6 nm

Tracking Servo

Pick Up

Fig. 3 . 2

24

Tracking

Coil Driver

DP-1100B II

II. FUNDAMENTALS

3-3-3

C L V S e r v o Circuit

C o n s t a n t linear v e l o c i t y (CLV) m e a n s t o keep a line s p e e d at a

The CLV servo c i r c u i t is t h e c i r c u i t t o s e r v o - c o n t r o l r e v o l u t i o n s

c o n s t a n t speed of a p p r o x . 1.2 m / s e c .

of the disc m o t o r t o keep c i r c u m f e r e n t i a l s p e e d of t h e disc

For this p u r p o s e disc is r o t a t e d : a p p r o x . 5 0 0 r . p . m . at inside

constant.

radios

a p p r o x . 2 0 0 r . p . m . at o u t

side radios

EFM

Signal

Bit Sync

CLV

Disc

Motor

Servo Amp.

Signal Generation

Fig. 3 . 3

3-4

EYE PATTERN

T h e RF signal is being delivered f r o m the signal processing

The w a v e f o r m is generally called " E y e P a t t e r n " .

c i r c u i t as d e s c r i b e d u n d e r 3 - 2 . T h e RF signal is vaired acord i n g t o a p p e a r a n c e or d i s a p p e a r a n c e of a pit o n a disc. This

Fig. 3 - 5 is s k e t c h e s e x p l a i n i n g c o n c e p t of t h e eye p a t t e r n .

signal c a n be displayed o n an o s c i l l o s c o p e as illustrated in the

The RF signal is c o n v e r t e d t o a digital signal c o m p o s e d of 1s

Fig. 3 - 5 .

a n d Os w i t h the aid of a c o m p a r a t o r t o g e n e r a t e an EFM

signal.

1 V/div

0.5 /ts/div

Fig. 3 . 5

25

DP-1100B II

II. FUNDAMENTALS

4 SEMICONDUCTOR LASER (LASER DIODE)

4-2 L A S E R DIODE

4-1

t e r m s of r e c o m b i n a t i o n l u m i n e s c e n c e of carriers, b u t different

A laser d i o d e , as m e n t i o n e d 4 - 1 , is t h e s a m e as an LED in

PRINCIPLE O F L E D LUMINESCENCE

A LED is f o r m e d w i t h a P-N j u n c t i o n c o m p o s e d of an n-type

in t h a t t h e light e m i t t e d is a c o h e r e n t laser light, t h e phase of

s e m i c o n d u c t o r w h i c h a l l o w s electric c o n d u c t i o n w i t h elec

w h i c h is u n i f o r m (single w a v e l e n g t h ) .

t r o n s a n d p-type s e m i c o n d u c t o r in w h i c h holes serves electric

c o n d u c t i o n . A p p l y i n g a v o l t a g e in t h e f o r w a r d d i r e c t i o n , elec

4-3 PROPERTIES REQUIRED FOR A L A S E R DIODE

t r o n s in t h e n-type s e m i c o n d u c t o r are i n j e c t e d into t h e p-type

s e m i c o n d u c t o r , a n d holes in t h e p- t y p e s e m i c o n d u c t o r are

(1)

Oscillation W a v e l e n g t h

A c c o r d i n g t o a C D ' s p r o p o s a l , t h e r e s h o u l d be t h e f o l l o w

i n j e c t e d into t h e n-type s e m i c o n d u c t o r . Red l u m i n e s c e n c e is

e m i t t e d w h e n e l e c t r o n s i n j e c t e d into t h e p-type s e m i c o n d u c

ing relaiton b e t w e e n a w a v e l e n g t h of a laser d i o d e a n d

t o r c o m b i n e w i t h holes.

t h e n u m b e r of a p e r t u r e of lens N A :

Green l u m i n e s c e n c e is e m i t t e d w h e n holes injected into t h e

X / N A = 1 . 7 5 jim

n-type s e m i c o n d u c t o r c o m b i n e w i t h e l e c t r o n s .

A s l o n g as t o d a y ' s G a A I A s material is u s e d , it is difficult

t o m a k e a laser d i o d e h a v i n g a w a v e l e n g t h shorter t h a n

Conduction band

Electrons

apporx.

Light

7 6 0 n m , b u t a laser d i o d e w i t h

higher

than

7 8 0 n m c a n be m a d e in mass p r o d u c t i o n .

Valence Band

T h e r e f o r e , N A = X / 1 . 7 5 /*m = 0 . 4 4 6

Holes

N-Type Region

A s t h e result, t h e o b j e c t i v e lens in t h e p i c k u p used in DP-

P-Type Region

1 1 0 0 B / I I has been d e s i g n e d for a p p r o x .

NA = 0 . 4 7 ± 0 . 0 1

PN Junciton

(2)

Fig. 4.1

Operating Current

A n laser d i o d e has a t h r e s h o l d c u r r e n t I, w i t h

which

oscillation starts, a n d w i t h a c u r r e n t larger t h a n

this

t h r e s h o l d level, a light p o w e r P increases linearly w i t h i n

crease of a c u r r e n t I. F u r t h e r m o r e , if k e e p i n g drive at a

fixed c u r r e n t , t h e light o u t p o u t is greatly varied d u e t o

t e m p e r a t u r e i n c r e a s e . T h e r e f o r e , c o n t r o l is a l w a y s d o n e

Light Output

so t h a t t h e light o u t p u t is kept c o n s t a n t .

T,<T

2

I, (30mA)

Current

Fig. 4 . 2 Oscillating C h a r a c t e r i s t i c of a L a s e r Diode

26

•P-1100B II

II. FUNDAMENTALS

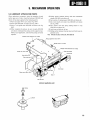

5 PICK-UP (PU) AND PU SERVO

The light reflected f r o m a disc passes again t h r o u g h t h e o b

jective lens a n d f o l l o w s t h e s a m e path as the f o r w a r d path t o

5-1

the polarizing f i l m . By t h e effect of the q u a r t e r - w a v e plate, the

S T R U C T U R E OF A PICKUP

light i n c o m i n g into the polarizing f i l m is c h a n g e d so t h a t its

Light b e a m s e m i t t e d f r o m a s e m i c o n d u c t o r laser are c h a n g e d

polarizing d i r e c t i o n is p e r p e n d i c u l a r t o the polarizing d i r e c t i o n

t o parallel light ralys by a c o l l i m a t o r lens system a n d enter a

polarization p r i s m . Since the s e m i c o n d u c t o r laser b e a m s are

in t h e f o r w a r d p a t h . T h e r e f o r e , the light t r a n s m i t s t h e polariz

linear-polarized in t h e d i r e c t i o n vertical t o the plane of in

ing f i l m a n d d o e s n o t g o b a c k t o t h e s e m i c o n d u c t o r raSer.

c i d e n c e , t h e b e a m s are reflected by the polarizing f i l m . T h e

Next, t h e light i n c o m i n g into a critical angle prism for d e t e c

light b e a m s reflected f r o m a n o t h e r plane of the polarization

t i o n of a f o u c s p o i n t is reflected t h r e e t i m e s inside the prism

prism pass t h r o u g h a q u a r t e r - w a v e plate, a n d t h e n are c o n

a n d t h e n f e d into 4 - d i v i d e d p h o t o d i o d e s . T h e o u t p u t of these

v e r g e d t o a s p o t of nearly 1.5 /im in d i a m e t e r w i t h the aid of

p h o t o d i o d e s are used f o r c o n t r o l i n g a t r a c k i n g servo coil a n d

an o b j e c t i v e lens.

a f o c u s servo coil t o o b t a i n an o p t i m u m f o c u s i n g of the abjec

tive lens o n pits of the disc.

Disc

4-divided photodiodes

Objective

lens

Laser diode

Monitor photodiode

Critical angle prism

Tracking

servo

coil

Focus

servo

coil

Polarizing prism

Collimator lens

1/4 wavelength plate

Polarization

film

4-divided

photodiodes'

Critical angle prism

Collimator lens

Laser

diodes

Polarized prism

Objective lens

Fig.

5.1

27

DP-1100B II

II. FUNDAMENTALS

(1)

C o l l i m a t o r Lens

5-2

Diffused light b e a m s are c h a n g e d t o parallel light b e a m s .

T o read tiny pits ( w i d t h : 0 . 5 / i m , length 0 . 9 # 3 . 2 / * m )

F O C U S ERROR AND TRACKING ERROR

Light b e a m s d i s t r i b u t e d in oval pattern is c h a n g e d t o a p

disc by m e a n s of a laser s p o t , t h e l o c a t i o n m u s t be precisely

prox. circular distributions.

c o n t r o l l e d t o f o l l o w surface a n d axial d e v i a t i o n s of t h e disc

on a

c a u s e d by r o t a t i n g t h e disc f o r p l a y b a c k . For this p u r p o s e ,

(2)

(3)

Polarized Prism

Light polarized in parallel t o a surface is r e f l e c t e d , a n d

(1)

Focus error

light polarized in vertical is passed t h r o u g h t h e p r i s m .

(2)

T r a c k i n g error

114 W a v e l e n g t h Plate

m u s t be d e t e c t e d . T h e d e t e c t i o n m u t h o d s for b o t h errors w i l l

and

be given b e l o w .

5-2-1

F o c u s Error Detection

W h e n a light b e a m is passed f r o m a high refraction material t o

a l o w r e f r a c t i o n m a t e r i a l , a r e l a i o n , as s h o w n in Fig. 5 . 2 , is

existed b e t w e e n t h e i n c i d e n t angle a n d refleciton ratio at t h e

b o u n d a r y of t h e materials. A s c a n be seen f r o m t h e g r a p h s ,

t h e reflection ratio will c h a n g e rapidly as t h e i n c i d e n t light

angle c h a n g e s in t h e area w h e r e t h e i n c i d e n t angle is slightly

less t h a n t h e critical a n g l e .

Reflection Surface

(4)

Objective Lens

NA

0.47

S

P

o

l

a

""1L,

g

h

t

NA = Sin0

1.5/xm

WD

Strength

of

Reflection

(Rp-Rs)

Disc

Critical Angle

(41.8°)

Pit surface

Incident light angle 0

(5)

4-divided photodiodes

C o n v e r t s light into an electrical signal

28

Fig. 5 . 2

Refleciton c h a n g e s rapidly at angles d o s e

to critical angle.

QP-1100B II

II. FUNDAMENTALS

In Fig. 5 . 3 , t h e a n g l e of t h e critical p r i s m has been a d j u s t e d

D i s c too c l o s e

so t h a t t h e i n c i d e n t light angle is j u s t e q u a l t o t h e critical angle

for

a center

light b e a m

of i n c i d e n t

light. A c c o r d i n g l y ,

Objective lens

if

parallel light b e a m s are i m p i n g e d , t h e i n c i d e n t light angle is

Divergent

e q u a l t o critical angle f o r all light b e a m s a n d all light b e a m s

(Go through)

Light axi

Light

are r e f l e c t e d , g i v i n g e q u a l light a m o u n t t o e a c h e l e m e n t of

beam

4 - d i v i d e d p h o t o - d i o d e s (PDa, PDb, PDc a n d PDd). If diffused

or d i v e r g e n t light is i m p i n g e d , reflection s t r e n g t h at a left half

Reflected beam

of t h e p r i s m l o w e r s a n d light a m o u n t r e c e i v e d by t h e p h o t o

d i o d e s PDa a n d PDb w i l l be d e c r e a s e d . On t h e c o n t r a r y , if

Prism

Disc

c o n v e r g e n t light is i m p i n g e d , light a m o u n t received by PDc

4-divided

a n d PDd is r e d u c e d . By utilizing this p h e n o m e n o n , t h e p h o t o

photodiodes

d i o d e s c o n v e r t light received into f o u r electrical signals a n d

the signals are p r o c e s s e d w i t h a differential amplifier t o p r o

vide a f o c u s error signal in t e r m s of (A + A ) — ( A + A ) .

t

(A

1 (

A , A , and A

2

3

4

2

3

4

A r e electrical signals d e v e l o p e d by PDa,

P D b , PDc a n d P D d , respectively.)

Disc Focused

Objective lens

^Critical angle prism

Reflection surface

Light axi

4-divided photodiode

(Go through)

Convergent

light

Focus Error Signal

(A! + A ) - ( A + A )

2

A + A

3

3

-Ai + A

2

A + A

2

A + A

4

A + A

4

3

4

t

3

4

Criticl angle

Disc too close (point A) (divergent light beams....)

Focus point (point B) (parallel light....)

Disc too far (point C) (convergent light beams....)

D i s c too far

Parallel

-light beams

3

2

PDc

PDb

PDd

PDa

4

1

Prism

4-Divided Photodiode

Fig. 5 . 4

Fig. 5 . 3

F o c u s error detection by using a critical prism

F o c u s error detection m e t h o d using a critical

angla prism

29

DP-1100B II

II. FUNDAMENTALS

5 - 2 - 2 T r a c k i n g Error Detection

T r a c k i n g error is a d e v i a t i o n of the r e a d i n g light s p o t f r o m the

In this

pits (track) t o be t r a c e d .

4 - d i v i d e d p h o t o d i o d e is a s s u m e d as A , A , A

Pickup

a

each

electrical

signal

x

A + A

3

A + A

3

t

In the

system,

method

called

"heterodyne

system"

is

a d o p t e d t o d e t e c t t h e s p o t d e v i a t i o n f r o m a pit.

t

converted

2

3

by

the

A n d A , and

4

a n d A + A A r e e v a l u a t e d . N a m e l y , b o t h phases f o r

2

and

A + A

2

4

are the

same

when

the

tracking

is

established, w h i l e phase difference will be c a u s e d w h e n the

s p o t deviates f r o m a pit.

T h e h e t e r o d y n e s y s t e m is based u p o n the distribution of the

reflected light d i f f r a c t e d f r o m a pit d e p e n d s u p o n a relative

l o c a t i o n of t h e pit a n d s p o t .

Inside of

the track

On a track

Outside of

the track

On a track

Inside or outside

of the track

Sum signal

Inside of

the track

Difference

Signal

Outside or

the track

Pit Section

Fig. 5 . 5

5-3

Time elapsed

P I C K U P Radial Signal Sampling T h e o r y (Pit depth X/4)

RF SIGNAL

W h e n the LDC g o e s t o L level, the o u t p u t of T A 7 5 4 5 8 ( 1 / 2 )

4

c h a n g e s t o n e g a t i v e , a n d this a l l o w s bias c u r r e n t of Q 1 0 9 to

d e v e l o p e d b y the 4 - d i v i d e d p h o t o d i o d e (refer to 3 - 5 ) . T h e RF

f l o w f r o m its e m i t t e r t o the base, t h u s Q 1 0 9 is t u r n e d o n a n d

signal is t h e n p r o c e s s e d t o provide EFM signal. T h e EFM

the Laser d i o d e e m i t s infrared light ( 8 1 0 m m ) .

A RF signal is a s u m of e a c h electrical signal A , A , A a n d A

x

2

signal is t h e n c o n v e r t e d into an a n a l o g signal in

3

passing

t h r o u g h a D-A c o n v e r t o r after d e m o d u l a t e d .

W h e n light e m i t t e d f r o m the laser d i o d e is i m p i n g e d t o the pin

5-4

f r o m a n o d e to c a t h o d e of the d i o d e . W i t h the strength of the

d i o d e , a c u r r e n t p r o p o r t i o n a l t o s t r e n g t h of the light f l o w s

LIGHT EMISSION F R O M L A S E R DIODE

TA75458(Q108)

light i n c r e a s e d , a v o l t a g e d e v e l o p e d across R 1 1 3 also i n

b e c o m e s positive as s h o w n in the s c h e m a t i c d i a g r a m , A n d a

creases a n d m a k e s n o n - i n v e r t e d ( + ) t e r m i n a l of the o p e r a

current

tional

When

the

LDC

flowing

goes

H,

through

the

output

R145,

of

D102,

And

D104

turns

Q 1 0 9 c u t off, t h e r e b y stops the oscillation of the Laser D i o d e .

amplifier

positive.

As

the

c u r r e n t f l o w i n g into the laser d i o d e .

30

result,

the

operational

amplifier o u t p u t also increases in positive, t h u s r e d u c i n g the

DP-1100B II

II. FUNDAMENTALS

6. GENERAL DESCRIPTION ON MICROPROCESSOR

6-1

A d d r e s s D a t a (Q Signal)

1)

A d d r e s s Data (Q Signal) Reading S e c t i o n

R-Channel....&

In t h e CD system s p e c i f i c a t i o n s , o n e s y m b o l c o n s i s t i n g

Q-Channel is used f o r address data a n d o n e a d d r e s s data

W-Channel.

the

is c o m p r i z e d

PCM data is called C O N T R O L & DISPLAY S Y M B O L , a n d

s h o w s this c o n f i g u r a t i o n of the C O N T R O L &

each

symbol data.

8

bits

Frame Synchronization Signal

is

called

P-Channel,

Frame Synchronization Signal

Q-Channel,

Frame Synchronization Signal

Frame Synchronization Signal

Frame Synchronization Signal

User's bit

After conversion of 8 bits to 14 bits

CONTROL DISPLAY Symbol

Fig. 6-1

Q-Channel

eight

of 8 bits a n d l o c a t e d after f r a m e s y n c h r o n i z a t i o n signal of

of

of 9 8 f r a m e

Of

data.

channels,

Fig.

5.6

DISPLAY

DP-1100B II

II. FUNDAMENTALS

A d d r e s s data f o r m a t (outside lead-in area) are as f o l l o w s :

SO, S 1 :

2 bits address signal sync p a t t e r n .

CONTROL:

4 bits c o n t r o l d a t a , M S B indicates p r e - e m p h a s i s o n or off, a n d LSB indicates 4 C H / 2 C H .

1: Pre-emphasis ON

0: Pre-emphasis O F F

1: 4 CH

0: 2 C H

ADR:

4 bit m o d e data

M O D E 1 (1 in BCD): A d r e s s m o d e

M O D E 2 (2 in BCD): Disc c a t a l o g n u m b e r m o d e

M O D E 3 (3 in BCD): Special i n f o r m a t i o n m o d e ( r e c o r d e d by a l p h a n u m e r i c c o d e 0 # 9 , A # Z )

MNR:

P r o g r a m n u m b e r expressed by BCD in 2 digits (8 bits)

X:

Index f o r e a c h p r o g r a m expressed by BCD in 2 digits (8 bits)

MIN:

Elapsed t i m e ( m i n u t e ) f o r e a c h p r o g r a m expressed by BCD in 2 digits (8 bits)

FRAME:

Elapsed t i m e f o r e a c h p r o g r a m expressed by BCD in 2 digits (8 gits) ( F r a m e , 1 f r a m e = 1/75 sec)

ZERO:

N o t used (8 bits <£data)

A MIN:

Elapsed t i m e (sec) f o r disc expressed by BCD in 2 digits (8 bits)

A SEC:

Elapsed t i m e (sec) f o r a disc expressed by BCD in 2 digits (8 bits)

A FRAME:

Elapsed t i m e f o r a disc expressed by BCD in 2 digits (8 bits) ( f r a m e ) .

CRC:

16 bit CRC c o d e data c a l c u l a t e d f o r data C O N T R O L # A FRAME.

Fig. 6-2

S h o w s the a d d r e s s d a t a configuration.

Each f i g u r e u n d e r a c o d e s h o w s bit n u m b e r required f o r the c o d e .

s

0

>

2

S

i

CONTROL

A D R

4

4

M N

8

R

X

8

M

I

8

N

S E C

FRAME

ZERO

AMIN

ASEC

8

8

8

8

8

Fig. 6 - 2 A d d r e s s D a t a configuration

32

AFRAME

8

C R C

16

SQISI

DP-1100B II

1. CIRCUIT DESCRIPTION

H e a d a m p " , t h e servo PCB a n d t h e

w h e n play m o d e is e n t e r e d f r o m s t o p m o d e . It c h e c k s t h e

p r o c e s s PCB are d e s c r i b e d in o r d e r a l o n g the RF signal f l o w .

n u m b e r of data errors to c o n t r o l c o n t r o l i n p u t s A , B, C a n d

1-1

playback.

Subsequent to " 1 - 2

INH of Q 1 0 2 o n t h e m e c h a n i s m PCB t o o b t a i n t h e o p t i m u m

Head amplifier

T h e f o u r signals f r o m t h e p i c k u p are i n p u t t o preamplifier IC

T h e internal block d i a g r a m a n d t r u t h table of Q 1 0 2 is s h o w n

in Fig 2-1 C a n d D of s e c t i o n 2 - 1 - 2 . Inputs A , B, C a n d I N H ,

( Q 1 0 3 ) o n the m e c h a n i s m PCB.

d e t e r m i n e w h i c h o u t p u t 0 t o 7 (bilateral s w i t c h s h o u l d be i n

1- 1-1

ternally c o n n e c t e d w i t h C O M ) .

F o c u s b a l a n c e a n d S V C operation circuit ( Q 1 0 3 )

T h e internal b l o c k d i a g r a m of Q 1 0 3

is s h o w n in section

2 - 1 - 1 . T h r o u g h t h e resistors, c o n n e c t e d b e t w e e n pins 1 a n d

1-1-4

A P C (laser p o w e r control) circuit ( Q 1 0 5 , Q 1 0 6 a n d

Q107)

2 a n d b e t w e e n pins 15 a n d 16 of Q 1 0 3 ( T A 7 7 3 1 P ) , f o c u s

b a l a n c e a n d SVC o p e r a t i o n (described later) are p e r f o r m e d .

Q 1 0 5 , w h i c h is the laser O N / O F F s w i t c h , t u r n s O N w i t h " L "

W e a k signal is a m p l i f i e d a n d o u t p u t t o servo PCB as S1 a n d

signal LDC (J8-3P) f r o m the m i c r o p r o c e s s o r so t h a t t h e laser

d i o d e e m i t s light. T h i s laser d i o d e i n c o r p o r a t e s a light e m i s

S2.

sion m o n i t o r d i o d e . T h e n , APC o p e r a t i o n is p e r f o r m e d by us

1-1-2

F o c u s error signal generation circuit ( Q 1 0 1 and Q 1 0 4 )

ing t h e m o n i t o r o u t p u t as t h e APC c o n t r o l i n p u t .

T h e FE amplifier a n d peak d e t e c t o r , c o n s i s t i n g of Q 1 0 1 a n d

Q 1 0 4 , is a c i r c u i t t o g e n e r a t e t h e f o c u s error signal. Peak

1-1-5

d e t e c t i o n is m a d e w i t h t h e B-E d i o d e characteristic of Q 1 0 4

FG signal is p r o d u c e d by Q 1 0 1 , Q 1 0 8 a n d Q 1 0 9 t o m o n i t o r

F G amplifier circuit ( Q 1 0 1 ( 2 / 2 ) , Q 1 0 8 a n d Q 1 0 9 )

a n d t h e CR t i m e c o n s t a n t of its e m i t t e r . T h e f o c u s error signal

t h e rotation of t h e disc m o t o r . Q 1 0 1 p e r f o r m s a m p l i f i c a t i o n

is o b t a i n e d f r o m (C + D) - (A + B) o p e r a t i o n of the p i c k e d - u p

a n d Q 1 0 8 , Q 1 0 9 a n d D 1 0 4 p e r f o r m w a v e f o r m s h a p i n g . For

f o u r signals f r o m t h e p i c k u p by Q 1 0 1 .

a d j u s t m e n t of e a c h t r i m m i n g p o t e n t i o m e t e r , refer t o " A d j u s t

m e n t " o n page 1 6 5 .

1-1-3

S V C circuit operation ( Q 1 0 2 )

T h e servo c o n t r o l (SVC) is p e r f o r m e d by processor IC12 o n

the p r o c e s s PCB ( X 3 2 - 1 0 1 0 ) , w h e n t h e disc is e x c h a n g e d or

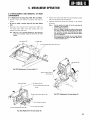

Fig. 1 - 1 - 3

S V C Circuit Operation

33

DP-11D0BII

1. CIRCUIT DESCRIPTION

1-2 Servo circuits

1-2-3

1-2-1

Pits are m a d e o n a disc in s u c h a w a y t h a t the s u m of " H "

F o c u s s e r v o circuit

D S V circuit ( I C 8 ( 1 / 2 ) a n d I C 1 5 D L S 1 a n d 2)

T h e f o c u s error (FE) s i g n a l , g e n e r a t e d in t h e m e c h a n i s m PCB,

d u r a t i o n s is equal t o t h a t of " L " d u r a t i o n s i.e. DSV (Digital

is f e d into pin 8 of C N 6 o n t h e servo PCB, T h i s signal is used

S u m Value) is z e r o . T h u s , this c i r c u i t c o n t r o l s the amplifier

in m a k i n g signal DOK w h i c h t h e p r e s e n c e or a b s e n c e of t h e

bias so t h a t t h e data o n the disc is identical t o t h a t read by t h e

disc is j u d g e d w h e n t h e tray is c l o s e d .

player, t h e r e b y d e c r e a s i n g error.

W i t h a disc present, " L " signal DOK is o u t p u t f r o m pin 1 of

C N 2 t o pin 2 7 of IC15 o n t h e p r o c e s s PCB ( X 3 2 ) .

1 -2-4

On t h e o t h e r h a n d , w h e n t h e RF signal f r o m the p i c k u p is i n

T h e signal f r o m pin 4 of IC6 is f u r t h e r a m p l i f i e d a n d applied t o

p u t t o pin 2 0 of I C 1 5 , pin 1 2 (FOK) of IC16 is at - 1 2 V a n d

the base of Q 2 1 . T h e variation in a m p l i t u d e of the DC c o m p o

Q2 turns

OFF. Signal

adjustment

nent, t h a t is e q u i v a l e n t t o t h e a m p l i t u d e of the EFM signal