Download Service Manual - Panasonic Biomedical

Transcript

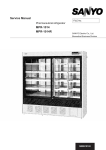

Service Manual

FILE No.

Ultra-Low Temperature Freezer

MDF-C2156VAN

MDF-C2156VANC

SANYO Electric Co., Ltd.

Biomedical Business Unit

RoHS

This product does not contain any hazardous substances prohibited by the RoHS Directive.

(You will find ‘RSF’ mark near the rating plate on the RoHS compliant product.)

WARNING

* You are requested to use RoHS compliant parts for maintenance or repair.

* You are requested to use lead-free solder.

SM9910079

Effective models

This service manual is effective following models.

Model name

MDF-C2156VAN

MDF-C2156VANC

Product code

823 189 82

823 189 83

823 189 84

823 189 87

823 189 86

Voltage and Frequency

220V

50Hz

220V

60Hz

230/240V

50Hz

220V

60Hz

220V

60Hz

Contents

㩷

Page

Features

---------------------------------------------------

Specifications

---------------------------------------------

1

2

- Structural specifications

- Control specifications

- Performance specifications

Dimensions

---------------------------------------------------------

Cooling unit parts

-------------------------------------------------

Refrigeration circuits

---------------------------------------

Refrigeration circuits welding points

Components on PCB

Electric parts

7

8

9

----------------------------------------------

11

----------------------------------------------------

12

Specifications of sensor

Wiring diagram

--------------------------

6

----------------------------------

14

------------------------------------------

16

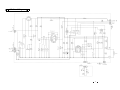

Circuit diagram for CR PCB

------------------------------------

18

Connections on PCB

-------------------------------------

20

Control specifications

---------------------------------------

21

Operation of Control Panel

Parts layout

Test data

------------------------------------

26

---------------------------------------------

31

---------------------------------------------------

33

- Pull-down data

- Pull-up data

- Temperature uniformity and variation

- Power consumption data

- Unit pressure data

- Sample load test

Instruction Manual

㩷

-------------------------------------------------

40

Features

䂓㩷 The chest type -150㷄 VIP series freezer has large effective capacity, 231L.

䂓㩷 Safety storage and security

-

New double door gasket to prevent heat leakage.

-

New VIP+ is adopted for insulation makes reduction of power consumption.

-

Notice of failure prediction by additional new status function.

-

Recording of chamber temperature and outer door open.

䂓㩷 Environmental friendly

-

2-stage mixed refrigerant system with NON-HCFC refrigerant.

䂓㩷 Optional component

zAutomatic temperature recorder + Mounting kit: MTR-155H+MDF-S30150

zInterface board: MTR-480

zLiquid N2 gas container: MDF-135N

1

Specifications

㩷

ŶStructural specifications

Item

MDF-C2156VAN

MDF-C2156VANC

Name

Ultra-Low Temperature Freezer

External dimensions

W1730 × D765 × H1010 (mm)

Internal dimensions

W760 × D495 × H615 (mm)

Effective capacity

231 L

Exterior

Painted steel

Interior

Aluminum plate

Outer lid

Painted steel

Insulation

Vacuum insulation panel + Rigid polyurethane foamed-in place

Access port

Cooling circuit

Compressor

㱢40mm, 1 place in the side table

2-stage cooling circuit and Low stage Auto cascade system

High stage side; Hermetic type, Output; 1100W

Low stage side; Hermetic type, Output; 1100W

Evaporator

High stage side; Cascade condenser type

Low stage side; Tube on sheet type

Condenser

High stage side; Fin and tube type

Low stage side; Shell and tube type, and Wire tube type

Refrigerant

H stage side; R-407D

L stage side; HFC mixed refrigerant

Refrigerating oil

Ze-NIUS32SA

Power supply

Local voltage

Battery

Weight

Voltage booster

Accessories

Lead storage battery, 6VDC, 7.2Ah x 4pcs, Auto-recharge

318 kg

325kg

None

Built-in

1 set of key for outer door latch, 1 set of key for panel door,

6 recording chart rolls, 1 dry cell

1 set connect tube for back-up system

Optional component

Automatic temperature recorder + Mounting kit (MTR-155H+MDF-S30150)

Liquid nitrogen gas container (MDF-135N)

Interface board (MTR-480)

㩷

㩷

㩷

㩷

㩷

㩷

㩷

2

ŶControl specifications

Item

Cooling performance

MDF-C2156VAN

MDF-C2156VANC

Center of the chamber; -150㷄䋨AT30㷄, No load䋩

Temp. controller

Micro-processor control system

Setting range; -125㷄䌾-155㷄䋨Unit;1㷄䋩

Non-volatile memory

Temp. sensor

Platinum resistance; Pt.1000ȍ

Temp. display

Digital display

Setting range: +5㷄~+20㷄 (Initial; +10㷄)

ALARM lamp and LCD display flashes, intermittent buzzer tone

High temp.

with 15min. delay

Remote alarm contact: Normal Open, Rating; DC30V, 2A

Remote alarm contact activates with 15min delay

Setting range: -5㷄~-20㷄 (Initial; -10㷄)

ALARM lamp and LCD display flashes, intermittent buzzer tone

Low temp.

with 15min. delay

Remote alarm contact: Normal Open, Rating; DC30V, 2A

Remote alarm contact activates with 15min delay

Alarm

When outer door is open, indication of ‘Door Open’ is shown.

Door

ALARM lamp blinks and buzzer beeps intermittently after delay

time is passed.

Filter

ALARM lamp flashes, message indication and intermittent buzzer

tone emitted

When the power to the unit is not connected or power failure,

Power failure

ALARM lamp flashes and intermittent buzzer tone emitted

Remote alarm contact activates.

Remote alarm

3P remote alarm terminal: DC30V, 2A, NC-COM, NO-COM

Temperature alarm turns on during power failure.

LCD panel

Display

Temperature display; Digital display (1㷄 increment)

Internal temperature is displayed by graphics, 24hours record can

be displayed per screen.

Lamp: BATTERY, ALARM, STANDBY

Buzzer key: BUZZER

Menu key: MENU

Control panel

Clear key: CE

Entry key: ENT

Figure input key

LCD contrast adjusting knob: CONT

Shift key:

3

㩷

Item

MDF-C2156VAN

MDF-C2156VANC

When ambient temperature is higher than approx. 35㷄 or lower

Status monitor function

than approx. 0㷄, ‘Ambient temp is abnormal ‘ is displayed on LCD.

When power supply voltage is lower than approx.170V, ‘The power

supply is abnormal’ is displayed on LCD.

zRecordable for approx. 4weeks in 12min. intervals.

zDoor delay time (more than 2min.) is recordable.

Data log function

zTemperature for cascade sensor, filter sensor and AT sensor

are recordable.

zLog

data

is

transmittable

to

PC

with

interface,

MTR-480.(Option)

In the event of any failure among temp. sensor, filter sensor and

cascade sensor;

Self diagnosis function

zError code and message are emitted.

zALARM lamp flashed, remote alarm contact turns over and

intermittent buzzer emit.

Key lock function

Key lock ‘0’: Key lock is released.

Key lock ‘1’: Key locks

When the temperature in cascade sensor is -34 㷄 or lower,

compressor (L) turns on.

L stage

When the temperature in cascade sensor is -12 㷄 or higher,

compressor (L) turns off.

Compressor

Overload relay and High pressure switch (L) are controlled.

protection

When the temperature in filter sensor is +60 㷄

H stage

or higher,

compressor (H) turns off.

When the temperature in filter sensor is 10㷄 lower than ambient

temperature, compressor (H) turns on.

zAutomatic liquid N2 injection device

zTemp. setting range;

zIndication: BACK-UP (Green)

Back-up systems

zBack-up test switch; 8R2021

zPower switch; Locker switch

zBack-up systems can be available for 48 hours by full charged

lead storage battery.

㩷

㩷

㩷

㩷

㩷

㩷

4

㩷

ŶPerformance specifications

Cooling performance

Center of the chamber: -150㷄䋨AT30㷄, no load䋩

Temp. control range

-125㷄䌾-150㷄䋨AT30㷄, no load䋩

Rated power consumption

Noise level

220VAC, 50Hz

220VAC, 60Hz

230VAC, 50Hz

240VAC, 50Hz

1550W

1700W

1550W

1600W

51 dB (A) (background noise; 20dB)

Maximum pressure

Usable conditions

3085 kPa

AT:5㷄䌾30㷄, less than 80䋦RH

Note: Specifications will be subject to change without notice.

5

Dimensions

6

Cooling unit parts

<MDF-C2156VAN/VANC>

Specifications

Item

H side

Compressor

220V, 60Hz

220V, 50Hz

230/240V, 50Hz

Refrigerant oil

Cooling system

L side

Type: KS370J1NS-7A

Compressor code: 7FB-0-M101-001-06

Type: KS370J1NS-4A

Compressor code: 7FB-0-M101-001-04

Type: KS370J1NS-4A1 Compressor code: 7FB-0-M101-001-05

Ze-NIUS32SA

Ze-NIUS32SA

Charged q’ty: 850cc

Charged q’ty: 850cc

Forced air cooling(partially)

Forced air cooling(partially)

Oil cooler

Oil cooler

Condenser

Type

Condenser

Pre-condenser

Frame pipe

Evaporator

Type

Capillary tube

Resistance

PSI・kg/cm2

Length (mm)

Outer diameter (mm)

Inner diameter (mm)

Refrigerant

Fin and tube

12 columns x 4 lines P6.35mm

Fin 88pcs.

W 350mm

φ6.35mm

Coil pipe

φ6.35mm x (t)0.7

ʊ

ʊ

Shell tank φ80mm

(upper)

2

Tube on sheet

(Middle) (Lower)

2

2

(Ex)

2

56 PSI/G

9.9kg/cm

11.0kg/cm

3.7kg/cm

1.9kg/cm

1300

φ2.4

φ1.2

3000

8000

3000

500

R-407D Charged q’ty: 432+/-10g

MU-N721 (HFC refrigerant)

Charged q’ty: 880g

n-Pentane

n-Pentane

Charged q’ty: 46cc (28g)

Charged q’ty: 17cc (10g)

4A-XH-9

Charged q’ty: 18g

4A-XH-6

Charged q’ty: 58g

φ230 mm、4 blades

Material: ABS

Oil additive

Dryer

Condensing fan

Condensing fan

motor

Oil separator

Type: SE4-E11L5P

ʊ

SPK-0S02S3

<Compressor terminals layout>

C

Cascade condenser

R

S

7

Refrigeration circuits

8

Refrigeration circuit welding points

<Pipe layout>

䌅䌁㩷 䌅䌇㩷

䌅䌂㩷

䌅䌃㩷

䌅䌄㩷

䌅䌆㩷

9

<Unit base Ass’y>

Pressure SW

Ex. tank (L)

䌐䌉㩷

䌅䌘䌂

䌅䌘䌁

䌅䌘䌚㩷

䌅䌘䌙㩷

䌅䌘䌗

Condenser Ass’y䌌䌄䌅㩷

䌌䌄䌃

䌅䌘䌃

䌅䌘䌄

䌅䌘䌘㩷

䌅䌘䌖

䌌䌄䌇㩷

䌌䌄䌆㩷

䌐䌏㩷

䌌䌄䌈㩷

䌌䌄䌊㩷

䌅䌘䌅㩷

䌅䌘䌕

䌅䌘䌔㩷

䌈䌄䌋

䌅䌘䌒 䌅䌘䌓

䌅䌘䌏

䌅䌘䌐

䌈䌄䌆㩷

䌈䌃䌂㩷

䌈䌃䌁㩷

Compressor (L)

䌈䌄䌇㩷

䌈䌄䌌㩷

䌅䌃䌏

䌅䌘䌑

䌅䌃䌉㩷

䌅䌘䌎

䌅䌘䌍

䌈䌄䌂

䌌䌄䌂㩷

䌌䌃䌆㩷

䌈䌃䌃㩷

䌈䌄䌁

䌌䌄䌁 䌌䌏䌁 䌌䌏䌂 䌌䌃䌇

䌈䌏䌏

䌈䌏䌉㩷

䌌䌏䌉㩷 䌌䌏䌏

䌈䌃䌇

䌌䌃䌈 䌈䌃䌈

䌈䌏䌁㩷

䌈䌏䌂㩷

䌈䌆䌉㩷

䌈䌆䌏㩷

䌌䌄䌄㩷

䌌䌄䌐㩷

Compressor(H)

䌈䌓䌃㩷

䌌䌄䌍㩷 䌌䌃䌅

䌌䌓䌄 䌌䌓䌃

䌌䌄䌌㩷

䌌䌄䌎㩷 䌌䌃䌄

䌅䌘䌌㩷

䌈䌓䌁

䌌䌓䌅

䌈䌓䌂㩷

䌏䌒㩷

䌏䌉㩷

䌌䌓䌁 䌌䌓䌂

䌏䌏㩷

䌌䌄䌋㩷

䌈䌓䌄㩷

䌌䌓䌆㩷

Capillary (H)

䌈䌄䌏㩷

䌈䌄䌉㩷

䌈䌄䌃

䌌䌃䌂㩷

䌌䌃䌁㩷

Oil separator

䌈䌄䌅

䌈䌃䌏

䌅䌘䌁㩷

10

Components on PCB

11

Electric parts

MDF-C2156VAN/2156VANC

Compressor (H), (L)

Starting relay (H), (L)

Overload relay (H), (L)

Starting capacitor (H), (L)

Running capacitor (H), (L)

Condensing fan motor

Cap.tube heater

Temp. control relay (H)

Heater relay

Temp. control relay (L)

Switching power supply

Transformer

Pressure switch

Door switch

Temp. sensor

Transformer

Battery switch

Battery

Cascade sensor

Filter sensor

AT sensor

Remote switch

Solenoid valve

Back up switch

Test switch

220V, 60Hz

Type

KS370J1NS-7A

Parts code

7FB 0 M101 001 06

Rated voltage

220V, 60Hz

Winding resistance䋨C-S)

1.64㱅

Winding resistance䋨C-R)

3.35ȍ

Type

AMVL-300A

Pick-up voltage

215~247VAC

Drop-out voltage

69~132VAC

Parts code

626 100 1503

Type

MRA999549201

Action to temp. (no current) ON:69㫧10㷄 OFF:135㫧10㷄

Action to current (AT25㷄)

29.5A

Operation time

6~16 sec.

Parts code

624 226 3173

Type

160UF, 250V

Type

25UF, 400VAC

Type

SE4-E11L5P

Rated voltage

220-240V

Parts code

624 224 0167

Rated voltage

100V, 15.7W

Resistance䋨25㷄)

638㱅

Parts code

624 030 2492

Type

G4F-11123T

Rated voltage

20A, 12VDC

Parts code

624 173 2397

Type

G2R-1A-T

Rated voltage

12V, 1-A, 250V

Parts code

624 188 9299

Type

G4F-11123T

Rated voltage

20A, 12VDC

Parts code

624 173 2397

Type

ZWS15-12/J

Rated voltage

15W, 12V

Parts code

624 227 1291

Type

ATR-C50

Rated voltage

200-240V

Parts code

624 006 0408

Type

SNS-C135Q002

Rated voltage OFF:2.75MPA ON:0.78MPA

Parts code

624 227 0959

Type

SS160-A15

Rated voltage

28V, 50MA

Parts code

624 197 1925

Type

PT-1000㱅

Type

S41-RN98PV

Rated voltage

P:100V, 9V, 0.46A

Parts code

624 227 0836

Type

SLE6A2-5

Rated voltage

4A, 250VAC

Parts code

624 213 1472

Type

LC-P067R2J

Rated voltage

6V, 7.2AH

Parts code

624 227 0843

Type

502AT

Rated voltage

5K㱅, 25㷄

Type

502AT

Rated voltage

5K㱅, 25㷄

Type

502AT

Rated voltage

5K㱅, 25㷄

Type

HLS208N

Rated voltage

250VAC, 6A

Parts code

624 169 9690

Type

X8263205LT

Rated voltage

24VDC

Parts code

624 226 8215

Type

HLS208N

Rated voltage

250VAC, 6A

Parts code

624 169 9690

Type

8R2021

Rated voltage

3A, 125VAC

Parts code

624 194 3984

12

220V, 50Hz

230/240V, 50Hz

KS370J1NS-4A

7FB 0 M101 001 04

220/230V, 50Hz

2.53ȍ

4.8ȍ

AMVL-300A

185~217VAC

60~120VAC

626 100 1503

MRA999539201

ON:69㫧10㷄 OFF:135㫧10㷄

22.5A

6~16 sec.

624 226 3166

100UF, 250V

25UF, 400VAC

SE4-E11L5P

220-240V

624 224 0167

100V, 15.7W

638㱅

624 030 2492

G4F-11123T

20A, 12VDC

624 173 2397

G2R-1A-T

12V, 1-A, 250V

624 188 9299

G4F-11123T

20A, 12VDC

624 173 2397

ZWS15-12/J

15W, 12V

624 227 1291

ATR-C50

200-240V

624 006 0408

SNS-C135Q002

OFF:2.75MPA ON:0.78MPA

624 227 0959

SS160-A15

28V, 50MA

624 197 1925

PT-1000㱅

S41-RN98PV

P:100V, 9V, 0.46A

624 227 0836

SLE6A2-5

4A, 250VAC

624 213 1472

LC-P067R2J

6V, 7.2AH

624 227 0843

502AT

5K㱅, 25㷄

502AT

5K㱅, 25㷄

502AT

5K㱅, 25㷄

HLS208N

250VAC, 6A

624 169 9690

X8263205LT

24VDC

624 226 8215

HLS208N

250VAC, 6A

624 169 9690

8R2021

3A, 125VAC

624 194 3984

KS370J1NS-4A1

7FB 0 M101 001 05

230/240V, 50Hz

2.53ȍ

4.8ȍ

AMVL-300A

185~217VAC

60~120VAC

926 100 1504

MRA999539201

ON:69㫧10㷄 OFF:135㫧10㷄

22.5A

6~16 sec.

924 226 3167

100UF, 250V

25UF, 400VAC

SE4-E11L5P

220-240V

924 224 0168

100V, 15.7W

638㱅

924 030 2493

G4F-11123T

20A, 12VDC

924 173 2398

G2R-1A-T

12V, 1-A, 250V

924 188 9290

G4F-11123T

20A, 12VDC

924 173 2398

ZWS15-12/J

15W, 12V

924 227 1292

ATR-C50

200-240V

924 006 0409

SNS-C135Q002

OFF:2.75MPA ON:0.78MPA

924 227 0950

SS160-A15

28V, 50MA

924 197 1926

PT-1000㱅

S41-RN98PV

P:100V, 9V, 0.46A

924 227 0837

SLE6A2-5

4A, 250VAC

924 213 1473

LC-P067R2J

6V, 7.2AH

924 227 0844

502AT

5K㱅, 25㷄

502AT

5K㱅, 25㷄

502AT

5K㱅, 25㷄

HLS208N

250VAC, 6A

924 169 9691

X8263205LT

24VDC

924 226 8216

HLS208N

250VAC, 6A

924 169 9691

8R2021

3A, 125VAC

924 194 3985

MDF-C2156VAN/2156VANC

Relay

Power transformer

Back up sensor

Breaker switch

Noise filter

Time delay fuse

Breaker switch

(MDF-C2156VANC only)

Power relay

(MDF-C2156VANC only)

Boost relay

(MDF-C2156VANC only)

Power transformer

(MDF-C2156VANC only)

Power transformer

(MDF-C2156VANC only)

Type

Rated voltage

Parts code

Type

Rated voltage

Parts code

Type

Type

Rated voltage

Parts code

Type

Rated voltage

Parts code

Type

Rated voltage

Parts code

Type

Rated voltage

Parts code

Type

Rated voltage

Parts code

Type

Rated voltage

Parts code

Type

Rated voltage

Parts code

Type

Rated voltage

Parts code

220V, 60Hz

220V, 50Hz

230/240V, 50Hz

G4F-1123T

1C, 15A, 24VDC

624 001 4586

ATR-K285T

P:100V, 115V, 230V

624 227 0850

PT-1000ȍ

BAM215171

250V, 15A

624 226 3623

ZAC2220-11

250VAC, 20A

624 204 3294

SD4 UL E39265

250V, 0.5A

423 018 2109

IR11A2E201R

250VAC, 20A

624 225 9589

G7L-1A-TUB

30A, 220V, 24VDC

624 208 1043

G7L-1A-TUB

30A, 220V, 24VDC

624 208 1043

ATR-HJ61TC-1

200, 225, 240V

624 226 7614

ATR-D35003

P:208V, S:230V

624 226 7621

G4F-1123T

1C, 15A, 24VDC

624 001 4586

ATR-K285T

P:100V, 115V, 230V

624 227 0850

PT-1000ȍ

BAM215171

250V, 15A

624 226 3623

ZAC2220-11

250VAC, 20A

624 204 3294

SD4 UL E39265

250V, 0.5A

423 018 2109

G4F-1123T

1C, 15A, 24VDC

924 001 4587

ATR-K285T

P:100V, 115V, 230V

924 227 0851

PT-1000ȍ

BAM215171

250V, 15A

924 226 3624

ZAC2220-11

250VAC, 20A

924 204 3295

SD4 UL E39265

250V, 0.5A

323 018 2102

13

Specification of sensor

1. Following shows temperature and resistance values in thermistor sensor (502AT-1).

㷄

kȍ

㷄

kȍ

㷄

kȍ

㷄

kȍ

䋭50

154.5

䋭36

71.80

䋭22

35.65

0

13.29

䋭49

145.9

䋭35

68.15

䋭21

33.99

5

10.80

䋭48

137.8

䋭34

64.71

䋭20

32.43

10

8.84

䋭47

130.2

䋭33

61.48

䋭19

30.92

15

7.20

䋭46

123.1

䋭32

58.43

䋭18

29.50

20

6.01

䋭45

116.5

䋭31

55.55

䋭17

28.14

25

5.00

䋭44

110.2

䋭30

52.84

䋭16

26.87

30

4.17

䋭43

104.4

䋭29

50.23

䋭15

25.65

35

3.50

䋭42

98.87

䋭28

47.77

䋭14

24.51

40

2.96

䋭41

93.70

䋭27

45.45

䋭13

23.42

45

2.51

䋭40

88.85

䋭26

43.26

䋭12

22.39

50

2.13

䋭39

84.18

䋭25

41.19

䋭11

21.41

55

1.82

䋭38

79.80

䋭24

39.24

䋭10

20.48

60

1.56

䋭37

75.67

䋭23

37.39

䋭5

16.43

65

1.35

2. Following shows temperature㩷 䋨-170㷄䌾0㷄䋩㩷 and resistance values in temp. sensor (Pt1000ȍ).

䋨㷄䋩

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-170

330.4

326.2

322.1

318.0

313.8

309.7

305.5

301.4

297.3

293.1

-160

371.4

367.3

363.2

359.1

355.0

350.9

346.8

342.7

338.6

334.5

-150

412.2

408.2

404.1

400.0

395.9

391.9

387.8

383.7

379.6

375.5

-140

452.8

448.7

444.7

440.6

436.5

432.5

428.5

424.4

420.4

416.3

-130

493.0

489.0

485.0

481.0

477.0

472.9

468.9

464.9

460.8

456.8

-120

533.1

529.1

525.1

521.1

517.1

513.1

509.1

505.1

501.1

497.1

-110

572.9

569.0

565.0

561.0

557.0

553.0

549.1

545.1

541.1

537.1

-100

612.6

608.6

604.6

600.7

596.7

592.8

588.8

584.8

580.9

576.9

-90

652.0

648.1

644.1

640.2

636.2

632.3

628.4

624.4

620.5

616.5

-80

691.3

687.3

683.4

679.5

675.6

671.6

667.7

663.8

659.9

655.9

-70

730.3

726.4

722.5

718.6

714.7

710.8

706.9

703.0

699.1

695.2

-60

769.3

765.4

761.5

757.6

753.7

749.8

745.9

742.0

738.1

734.2

-50

808.1

804.2

800.3

796.4

792.6

788.7

784.8

780.9

777.0

773.2

-40

846.7

842.8

839.0

835.1

831.3

827.4

823.5

819.7

815.8

811.9

-30

885.2

881.4

877.6

873.7

869.8

866.0

862.1

858.3

854.4

850.6

-20

923.6

919.8

915.9

912.1

908.3

904.4

900.6

896.7

892.9

889.1

-10

961.9

958.0

954.2

950.4

946.6

942.7

938.9

935.1

931.3

927.4

0

1000.0

996.2

992.4

988.6

984.8

980.9

977.1

973.3

969.5

965.7

14

2. Following shows temperature㩷 䋨0㷄䌾100㷄䋩㩷 and resistance values in temp. sensor (Pt1000ȍ).

䋨㷄䋩

0

1

2

3

4

5

6

7

8

9

0

1000.0

1003.8

1007.6

1011.4

1015.2

1019.0

1022.8

1026.6

1030.4

1034.2

10

1038.0

1041.8

1045.6

1049.4

1053.2

1057.0

1060.8

1064.6

1068.4

1072.2

20

1076.0

1079.7

1083.5

1087.3

1091.1

1094.9

1098.7

1102.4

1106.2

1110.0

30

1113.8

1117.5

1121.3

1125.1

1128.8

1132.6

1136.4

1140.1

1143.9

1147.7

40

1151.4

1155.2

1159.0

1162.7

1166.5

1170.2

1174.0

1177.7

1181.5

1185.2

50

1189.0

1192.7

1196.5

1200.2

1204.0

1207.7

1211.5

1215.2

1219.0

1222.7

60

1226.4

1230.2

1233.9

1237.6

1241.4

1245.1

1248.8

1252.6

1256.3

1260.0

70

1263.8

1267.5

1271.2

1274.9

1278.7

1282.4

1286.1

1289.8

1293.5

1297.2

80

1301.0

1304.7

1308.4

1312.1

1315.8

1319.5

1323.2

1326.9

1330.6

1334.3

90

1338.0

1341.7

1345.4

1349.1

1352.8

1356.5

1360.2

1363.9

1367.6

1371.3

100

1375.0

1378.7

1382.4

1386.1

1389.8

1393.4

1397.1

1400.8

1404.5

1408.2

15

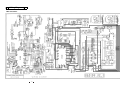

Wiring Diagram

<MDF-C2156VAN>

16

<MDF-C2156VANC>

17

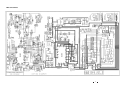

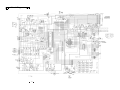

Circuit Diagram

18

CR Circuit Diagram

19

Connections on PCB

* Following are explanation of connections on the Main PCB.

Connector

Connects to

Usage

CN1

Switching power supply

To supply the power to PCB.

CN2

LCD module

To connect with LCD.

CN3

Control Board (CN5)

#1-#2: Battery switch

CN4

#3-#4: Transformer(100V, 9V)

To connect with LCD contrast adjusting

knob.

To supply the power to Main PCB #1-#2: 24V

during power failure.

To detect abnormal low voltage.

CN5

Main PCB (CN3)

CN6

Main PCB (CN18)

CN7

MTR-480 (Option)

To connect with interface.

CN8

#1-#2: Buzzer PCB

To connect with buzzer.

CN9

#1-#2: Temp. control relay H

#3-#4: Temp. control relay L

#5-#6: Heater relay

To control compressor H.

To control internal temperature.

To supply the power to cap. tube heater.

CN10

#3-#4: Door switch

To control digital lock (Option).

CN11

Remote alarm terminal

Remote switch

To output remote alarm

#1-#2: AT sensor

#3-#4: Filter sensor

CN12

Voltage

#1: 12V

#1: 5V

#1: 12V

#2: 5V

#1: COM

#2: N.C.

#3: N.O.

To detect ambient temperature.

To detect temperature at condenser

outlet pipe.

To detect temperature at cascade.

To control door switch.

CN13

#5-#6: Cascade sensor

#9-#10: Door switch

Unused

CN14

LCD module

CN15

Main PCB (CN8)

CN16

Unused

CN17

#1-#2: Switching power supply

#3-#4: Lock

To supply the power to digital lock.

CN18

Control board (CN6)

To connect with each keys.

CN19

#3-#4: Back up PCB

To connect with back-up system.

CN20

#1-#3: Temp. sensor

To detect internal temperature.

CN21

#3-#4: Analog terminal

To output analog.

To supply the power to back lamp for

LCD.

20

#1: 24V

#3: 24V

* Following are explanation of connectors on the Back-up PCB.

Connector

Connects to

Usage

S1

Back-up sensor

To detect internal temperature.

S2

#1-#2: Solenoid valve

#3-#4: Power transformer

To supply the power to solenoid valve.

To supply the main power

S3

#1-#2: Test switch

To test back-up system.

S4

Temperature control knob

To set temperature for back-up.

S5

Battery LED

To light LED when low battery.

S6

Temperature control dial

21

Voltage

24V

Control specifications

1.

Temperature control range

Settable temperature: -125㷄 ~ -155㷄

Internal temperature display range: -180㷄 ~ +50㷄

Setting method: In ‘TopScreen’, press MENU key and step into temperature setting mode

with Shift key (upward, downward, rightward, leftward), then set your

desired value with Figure Input key. Press MENU/OK to store the value.

2.

Alarm and safety functions

(1) Error code

E01: Temp. sensor is open circuited.

When temperature in temp. sensor is equal or higher than -180㷄, ‘E01’ is

displayed in ‘TopScreen’, the basic screen.

E02: Temp. sensor is short circuited.

When temperature in temp. sensor is equal or lower than +50㷄, ‘E02’ is

displayed in ‘TopScreen’, the basic screen.

E03:

E04:

E05:

E06:

E07:

E08:

Cascade sensor is open circuited.

When temperature in cascade sensor is equal or lower than -70㷄, ‘E03’ is

displayed in ‘TopScreen’, the basic screen.

Cascade sensor is short circuited.

When temperature in cascade sensor is equal or higher than +100㷄, ‘E04’ is

displayed in ‘TopScreen’, the basic screen.

Filter sensor is open circuited.

When temperature in filter sensor is equal or lower than -70㷄, ‘E05’ is

displayed in ‘TopScreen’, the basic screen.

Filter sensor is short circuited.

When temperature in filter sensor is equal or higher than +100㷄, ‘E06’ is

displayed in ‘TopScreen’, the basic screen.

AT sensor is open circuited.

When temperature in AT sensor is equal or lower than -70㷄, ‘E07’ is displayed

in ‘TopScreen’, the basic screen.

AT sensor is short circuited.

When temperature in AT sensor is equal or higher than +100㷄,’E08’ is

displayed in ‘TopScreen’, the basic screen.

E09:

When Alarm test is performed with battery uncharged or battery switch is OFF

position, ‘E09’ is displayed in ‘TopScreen’, the basic screen.

E10:

When temperature in filter sensor is equal or higher than +60㷄,’E10’ is

displayed in ‘TopScreen’, the basic screen, and Compressor H is ceased.

22

(2)

High temp. alarm

When internal temperature is higher than high temperature alarm setting value, alarm

lamp flashes, intermittent buzzer beeps with 15 minutes of delay and remote alarm

activates.

Press BUZZER key to stop buzzer beeping. However, buzzer beeps again after Ring

Back time is passed. Remote alarm is still activated during this period.

High temp. alarm setting range: SV+5㷄 ~ +20㷄 (Initial: +10㷄)

Ring Back time setting range: 1 ~ 99 minutes (Initial: 30 minutes)

* 0 minutes = Alarm does not recover.

* Note) During pull-down, both buzzer and remote alarm don’t activate.

(3)

Low temp. alarm

When internal temperature is lower than low temperature alarm setting value, alarm

lamp flashes, intermittent buzzer beeps with 15 minutes of delay and remote alarm

activates.

Press BUZZER key to stop buzzer beeping, however, buzzer beeps again after Ring

Back time is passed. Remote alarm is still activated during this period.

Low temp. alarm setting range: SV-5㷄 ~ -20㷄 (Initial: -10㷄)

Ring Back time setting range: 1 ~ 99 minutes (Initial: 30 minutes)

* 0 minutes = Alarm does not recover.

* Note) During pull-down, both buzzer and remote alarm don’t activate.

(4)

Door alarm

When door is open, intermittent buzzer beeps and ‘DOOR’ at ‘TopScreen’ flashes.

Shut door or press BUZZER key to stop buzzer beeping. Remote alarm does not

activate during this period.

Door alarm setting range: 1 ~ 15 minutes (Initial: 2 minutes)

(5)

Filter alarm

When temperature in filter sensor is equal or higher than +48.0㷄, intermittent buzzer

beeps and ‘FILTER’ at ‘TopScreen’ flashes. Remote alarm does not activate.

Press BUZZER key to stop buzzer beeping. (Buzzer does not recover automatically)

When temperature in filter sensor is equal or lower than +43.0㷄, buzzer stops beeping

and indication is disappeared.

If you set buzzer does not activate, buzzer does not beep.

(6)

Remote alarm

Remote alarm is output from the terminal.

Contact status ‘Normal’: ‘Open’ between COM. and N.O.

‘Close’ between COM. and N.C.

Contact status ‘Abnormal’: ‘Open’ between COM. and N.C.

‘Close’ between COM. and N.O.

*Note) When remote alarm is OFF position at Default setting screen, remote alarm

does not activate. (Initial: 1 (=ON))

23

3.

Buzzer Auto-recovery (Ring Back function)

You can stop buzzer beeping temporary with BUZZER key pressed. Remote alarm

contact does not activate at the time.

Ring Back setting time: 1 ~ 99 minutes

* 0 minute = Buzzer does not recover if BUZZER key pressed once.

4.

ON/OFF control for Compressor H

Start-up: Compressor H turns on with 2 minutes of delay after the power is supplied.

Compressor H starts with designed delay time after the power failure.

Protection: Compressor H is forcibly turned off when temperature in filter sensor is equal or

higher than +60㷄.

Recovery: Compressor H is turned on when temperature in filter sensor is equal or lower

than AT + 10㷄 and also compressor delay time is passed.

5.

ON/OFF control for Compressor L

ON: When cascade temperature is equal or lower than -34㷄, Compressor L is turned on.

OFF: When cascade temperature is equal or higher than -12㷄, Compressor L is turned off.

Differential: When compressor delay timer is set at ‘0’ and controlled temperature is higher

than SV+0.5㷄, Compressor L is turned on.

When controlled temperature is SV-0.5㷄, Compressor L is turned off.

6.

Monitor of freezer status

(1) Abnormal ambient temperature

When ambient temperature is equal or lower than 0㷄, or equal or higher than +35㷄,

‘Status-1’ is displayed.

(2) Voltage decline

When the voltage decreases in about 170V, ‘Status-2’ is displayed.

When the unit detects above abnormal status, the Status indication flashes on the basic

screen with massage indication.

(3) Compressor running rate

You can see compressor running rate in the indication of MENU/Svc – Status in the

screen of ‘Hardware Status’.

* Running rate of Compressor L

= {Compressor ON time / (Compressor ON time + Compressor OFF time)} x 100 (%)

7.

Control of Cap. tube heater

Cap. tube heater is permitted to turn on once every 18 hours.

Cap. tube heater is forcibly turned on for 8 minutes after compressor L is turned off and

8.

MENU screen

In MENU is displayed on the basic screen, MENU is automatically disappeared if there is not

any key inputs for 1 minute.

In MENU is not displayed on the basic screen, the screen is changed for renewal once every

hours.

24

9.

Operation in power failure

Unit checks power failure by the port for detecting power failure in every 0.42 seconds.

Operation in power failure;

- All ports for controlling compressor, cap. tube heater, LCD back lamp, signal lines and

digital lock turn off and unit operates to the mode in low power consumption.

- LCD is turned off and intermittent buzzer beeps.

- If you press BUZZER key, buzzer stops beeping, LCD back lamp is lit for 5 seconds

and you can check the time when power failure was occurred. However, buzzer beeps

again after buzzer resume time is passed.

- Log data is stored.

10.

Auto Return

Display changes to the basic screen if there are any key inputs for 90 seconds.

11.

Notice of parts replacement

- Battery replacement: When battery accumulating time is over than 2.8 years,

‘Please exchange batteries’ is indicated.

- Fan motor replacement: When fan motor accumulating time is over than 5.6 years,

‘Please exchange fan motor’ is indicated.

12.

Warning message

Y

13.

M

D

H

M

S

High temp. alarm:

‘ High Temp Warning 20XX/XX/XX XX:XX:XX ‘

Low temp. alarm:

‘ Low Temp Warning 20XX/XX/XX XX:XX:XX ‘

Power failure alarm: ‘ Power failure Warning 20XX/XX/XX XX:XX:XX ‘

Filter alarm: ‘ Please check a condenser filter ‘

Setting specifications

Internal temperature

High temp. alarm

Low temp. alarm

Alarm delay time

Compressor L ON/OFF

Cycle of Cap. tube heater ON

Differential of Compressor L

Filter alarm operation

Auto Return

Key lock password

-155㷄~-125㷄

(Initial: -150㷄)

+5㷄~+20㷄

(Initial: +10㷄)

-5㷄~-20㷄

(Initial: -10㷄)

15 min.

ON: -34㷄

OFF: -12㷄

Ring Back

Door delay time

Log record time

Compressor L delay time

Compressor delay time after

power failure

Every 18hrs.

Cap. tube heater ON time

+/- 0.5㷄

Compressor H protection

Message

Buzzer:ON/OFF

(Initial: ON)

90 sec.

Initial: 0000

25

1~99 min.

0: OFF

(Initial: 30 min.)

1~15 min.

(Initial: 2 min.)

2~30 min.

(Initial: 15 min.)

2 min.

2~15 min.

(Initial: 15 min.)

6~15 min.

(Initial: 8 min.)

OFF: +60㷄 up

ON: AT+10㷄

Internal temp. offset

-4.0㷄

Auto MENU OFF

60 sec.

㩷

Operation of Control Panel

㩷

Note: For the operations of ‘Basic Screen’, ‘Function’, ‘Key Lock function’, ‘Display of Log’,

‘Various Setting’, ‘Initialization’ ‘Setting of date, time, log interval’ and ‘Key Lock

Password’, please refer to P.15~P.22 in the Instruction Manual.

1䋮Buzzer

・Buzzer for Temperature Alarm (Intermittent tone)

Buzzer beeps intermittently after 15 minutes has passed since the unit was detected High Temp. alarm or

Low Temp. alarm. Press BUZZER key to stop buzzer beeping.

Buzzer beeps again if the unit still keeps alarming condition even after Ring Back time has passed.

zIntermittent buzzer tone and message indication emitted even after Auto Recovery.

zPress BUZZER key to erase message and buzzer tone.

・Buzzer for Door Alarm (Intermittent tone)

Buzzer beeps intermittently after delay time has passed since door was open.

Shut door or press BUZZER key to stop buzzer beeping.

zRemote alarm does not activate.

・Buzzer for Filter Alarm (Intermittent tone)

Buzzer beeps intermittently when temperature in filter sensor is equal or higher than +48.0℃

Buzzer stops beeping when temperature in filter sensor is equal or lower than +43.0℃.

zRemote alarm does not activate.

0

1

Screen of High Temp. alarm

0

2

1

1

1

2

1

3

1

4

o

C

T e mp

2

3

5

Hi g h

- 1 5 0

T e mp

Screen

of power 1failure

0

1 1 1

2

1

2

3

4

o

C

2

0

2

1

2

2

2

3

1

5

1

6

T e mp

2

3

- 1 5 0

5

P o we r

Screen of filter alarm

0

2

1

1

1

2

1

3

1

4

o

C

1

7

T e mp

- 1 5 0

1

8

1

9

2

0

1

5

1

6

1

7

1

8

1

9

2

0

c h e c k

2

9

3

0

3

1

3

2

a

3

3

3

4

3

5

3

6

3

7

3

8

Al a r m

St a t us 䋺

St a nd- by

Do o r 䋺

Cl o s e d

3

9

4

0

0 3 䋺 1 5 䋺 3 0

1 2 : 0 0 : 0 0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3

8

A l a r m䋺

N o r ma l

St a t us 䋺

St a nd- by

Do o r 䋺

Cl o s e d

3

9

4

0

0 3 䋺 1 5 䋺 3 0

1 2 : 0 0 : 0 0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3

8

Sc r e e n

−150℃

Pl e a s e

2

8

Sc r e e n

To p

1

2

7

A l a r m䋺

2 0 0 6 / 0 7 / 0 1

0

1

2

6

Wa r n i n g 2 0 0 6 / 0 7 / 0 1

f a i l ur e

6

2

5

2 0 0 6 / 0 7 / 0 1

−150℃

4

2

4

Sc r e e n

To p

1

6

1

9

2 0 0 6 / 0 7 / 0 1

0

1

5

1

8

Wa r n i n g

6

4

1

7

−150℃

4

3

1

6

To p

1

2

1

5

A l a r m䋺

Fi l t e r

St a t us 䋺

St a nd- by

Do o r 䋺

Cl o s e d

c onde ns e r

2 0 0 6 / 0 7 / 0 1

f i l t e r .

1 2 : 0 0 : 0 0

26

3

9

4

0

2-1. MENU/Tools – Select Tools Svc

Temperature calibration, Service function - Secret function for Customers

0

1

Top Screen

0

2

1

1

1

2

1

3

1

4

1

5

1

6

1

7

To p

1

T e mp

2

3

- 1 5 0

o

1

8

1

9

2

0

2

1

5

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3

8

3

9

4

0

0

1

St a t us 䋺

Do o r 䋺

0

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

3

3

4

For

3

5

3

6

3

7

3

8

3

9

Se r v i c e

Da t e

5

Ke y

0

8

0

9

1

0

1

1

1

2

1

3

1

4

Tool s

Tool s

Status indication

0

3

0

4

0

5

0

6

0

7

0

8

0 1

9 0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

H a r d wa r e

St a t us

T e mp

- 1 5 0 . 0 㫦C

SV

T e mp

1

9

2

0

T e mp

2 5 . 0 㫦C

Ca s

T e mp

- 3 5 . 0 㫦C

㩷 Fi l

T e mp

3 5 . 0 㫦C

Ca p i . H

OF F

2

2

2

3

2

4

2

5

C o mp

- 1 5 0 . 0 㫦C

PV

A mb

2

1

2

6

2

7

2

8

2

9

SV

C o mp

3

0

3

1

3

2

3

3

3

4

PV

3

6

3

7

3

8

3

9

6 䋯

6 6 %

PW

Lo c k

Calibration 2

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1 1

8 9

2

0

1 da y

1 da y

1

Ca l i b r a t i o n

3

Ca p i

H . T i me r

8

Ca p i

H. St a r t

0

4

L . C o mp

5

E_ L oc k

㩷

6

Mo d e l

2

Op t i o n

Co d e

Fun c t i on

2

1

2

2

2

3

2

4

2

5

L . C o mp

2

6

2

7

2

8

2

9

3

0

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3

8

3

9

4

0

M ENU

Sv c

Ca nc e l

Se t t i ng

Se t t i ng

0

2

0 0

3 4

0

5

0

6

0

7

0

8

0

9

1

0

1

1

1

2

1

3

1 5 0 0

3

1

3

2

3

3

3

4

3

5

3

6

3

7

Ca l i b r a t i o n

1

4

Ca l i b r a t i o n

2

5

Te s t

6

F l a s h 䋯W r i t e

0

1

Tool s

0

M ENU

6 - 1 5 mi n )

OK

( 0 . Au t o 1 . ON)

Ca n c e l

( 0 . Au t o 1 . ON)

1

( 0 . OF F

2

( 1 . 1 1 5 6

2 . 2 1 5 6 )

0

( 4 0 9 . BC

4 1 9 . F C)

1

7

1

8

0

2

0

3

Calibration 1

0

4

0

5

0

6

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

3

2 0

9

3

1

3

2

3

3

V e r . 㪁㩷 㪅㩷 㪁㩷 㪁㩷 㪯㩷

Sv c

3

4

3

5

3

6

3

7

3 3

8 9

4

0

M ENU

OK

Ca n c e l

Da t a

0 0

7 8

0

9

1

0

1

1

1

2

1

3

Ca l i b r a t i o n

3

C h a mb e r

5

1

6

Pr ogr a m

1

6

3 3

8 9

1

5

St a t us

㩷

OF F

1

4

Se l e c t

3

Indication for Internal temp, Ambient temp, Cascade

temp, Filter temp, Power supply voltage, Compressor

status, Compressor running rate, Battery accumulating

time, Fan motor accumulating time and battery life

0

1

1

9

Se t t i ng

3

4

F AN

ON

1

8

M DF - 2 1 5 6

1

4

0

1 0 0 %

Ba t t e r y

H . C o mp

3

5

O N 䋯O F F

9 0 %

P o we r

1

7

OK

I n i t i a l i z e

6

0

2

1

6

Select Tools for service

Ca n c e l

P a ss wo r d

0

1

1

5

T i me

Loc k

0

1

OK

4

5

0

7

㩷 㩷 㩷 㩷

4

4

0

M ENU

2

3

0

6

6

P as s wo r d

1

0

5

De f a u l t

1 2 : 0 0 : 0 0

Password (for service): 384

0

4

Se l e c t

㩷

2 0 0 6 / 0 7 / 0 1

6

0

3

3 㩷 㩷

Se t

N o r ma l

Lo g

St a nd- by

To ol s

Cl o s e d

A l a r m䋺

Select Tools㩷 㩷 (* Lock Setting is option)

0

2

1

M ENU

C

−150℃

4

2

2

Sc r e e n

Pr ogr a m

1

4

T e mp

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

- 1 5 2 . 5

o

C

C

1

0 . 0

A mb l e n t

T e mp

0 . 0

2 5 . 0

o

Ca s c a d e

T e mp

0 . 0

- 3 5 . 0

o

C

Fi l t e r

T e mp

0 . 0

3 5 . 0

o

C

Po we r

An a l o g

Suppl y

5 0 0

T e mp

5 0 0

3

2

3

3

3

4

3

5

3

6

3

7

3

8

3

9

4

0

M ENU

0 . 0

OK

0 . 0

Ca n c e l

0 . 0

0 . 0

1 0 0%

Calibration for Intermal temp, Ambient temp, Cascade

temp and Filter temp

4

0

Function #

0

101

102

( 0 . OF F

1 . ON)

103

104

Capi H.Timer: Cap. tube heater ON time

㩷

Setting range: 6䌾15min. (Initial: 8min.)

Capi H.Start: Operation of Cap. tube heater

0: ON every 18hrs.

1: Forcibly ON

2: OFF

E_Lock Option: Usage of Digital Lock (Option)

0: Unused㩷

1: Used

Model Code: Products model code

1: MDF-1156ATN

2: MDF-C2156VAN

Function:

㩷 Indications of Key lock Password and Master ID

Password

Reset for battery and fan motor accumulating

time, Memory initialization

27

105

409

419

925

Function

Mode for shipment

Key lock Password is indicated forcibly

Master ID and Password are indicated

forcibly

Log indication

(Cascade temp, Ambient temp)

Log Address is indicated during data

ransmission to PC

Digital Lock Password is indicated

during data transmission to PC

Reset battery replacement

Reset fan motor replacement

Non-volatile memory initialization

Set ‘925’ and perform ‘MENU/Tools Svc - Initialize All Data’ to initialize

value. Repower unit to set initial value.

Function # automatically reverts to ‘0’

after initialization done.

<Note> You should perform Temp.

Calibration because temp. calibration

value is also initialized.

2-2. MENU/Tools – Select Tools Svc

Maintenance function – Secret function for Customers

Top Screen

0

1

0

2

1

1

1

2

1

3

1

4

1

5

1

6

1

7

To p

1

T e mp

2

3

- 1 5 0

o

1

8

1

9

2

0

2

1

2

3

2

4

2

5

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

1

0

1

1

1

2

1

3

2

7

2

8

2

9

3

0

1

4

1

5

1

6

3

1

3

2

3

3

1

7

St a t us 䋺

1

9

2

0

2

1

2

2

2

3

3

5

3

6

3

7

3

8

3

9

4

0

2

4

2

5

䋺

0

1

0

2

Select Tools㩷 㩷 (* Lock Setting is option)

0

3

2

8

2

9

3

0

0

6

0

7

0

8

0

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

Too l s

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

3

Da t e

5

Ke y

3

6

3

7

3

8

3

9

Se t t i ng

Sv c

Lo c k 䋮

PW

Ca n c e l

Se t t i ng

Se t t i ng

6

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3

8

3

9

0

1

4

0

M ENU

OK

Ca n c e l

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

Select Tools for service

1

Se l e c t

3

St a t us

4

1

Ca l i b r a t i o n

2

2

2

2

3

2

4

2

5

2

6

2

7

2

8

M

OK

Ca

3

0

U

el

2

9

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3

8

3

9

4

0

M ENU

OK

Ca nc e l

Pr og r a m

I n i t i a l i z e

Da t a

F l a s h 䋯W r i t e

6

2

1

V e r . 㪁㩷 㪅㩷 㪁㩷 㪁㩷 㪯㩷

Sv c

Ca l i b r a t i o n

Te s t

5

To ol s

2

0

Pr ogr a m

㩷

Test Run

Program version Renewal

㩷

㩷

㩷 For Facotry test

㩷

Delete data

Reboot program

㩷

㩷

㩷

Repower unit after reboot is done

Please refer to <Note!>

should use this function only when non-volatile

㩷 You

memory initialization

㩷

㩷 <Note!>㩷

1. Initialization for Calibration data and all accumulating data

(1) Set Function # ‘925’ at screen of ‘Calibration 2’.

Erase all data at screen of ‘Initialize All Data MENU/OK’.

㩷 (2)

(3) Cut the power off and repower unit.

㩷 2. Flash memory reboot

0

1

0

2

0

3

0 0

4 5

1 Te s t

o

2 C

0

6

0

7

0

8

0

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

Pr ogr a m

r un

1

8

1

9

2

0

2

1

2

2

2

3

Cy c

2

4

2

5

2

6

2

7

2

8

2

9

1 / 1

3

0

3

1

3

2

3

3

De c

3

4

3

5

3

6

3

7

3

8

3

9

4

0

M ENU

3

8 6 : 0 0

6 T e mp

- 15 0

- 1 6 0

0

1

0

2

0

3

0

4

- 1 6 0

0

5

0

6

0

7

0

8

0

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

Al l

Us e r

s ur e

Ar e

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3

8

3

9

d e l e t e

4

0

1

a nd

0

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

3

y ou

s ur e

3

4

3

5

3

6

3

7

M ENU

t o

Ca n c e l

Wr i t e

a nd

M e mo r y

?

0

2

0 0

3 4

0

5

0

6

0

7

0

8

0

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3 3

8 9

3

Ca n c e l

P r o g r am s

Re b o o t

a f t e r

p r ogr a mi ng.

5

㩷

6

㩷

㩷

3 3

8 9

OK

1

OK

4

N a me s

0

8

Fl a s h

4

0

M ENU

t o

0

7

6

2

y ou

0

6

㩷

C on f i r ma t i o n

Ar e

0

5

C o n f i r ma t i o n

5

4 : 0 0

5

0 0

3 4

4

4

3

0

2

3

Ca n c e l

1

0

1

1

St a r t

5 T i me 2 4 : 0 0

4

0

M ENU

T i me

Loc k

3

5

OK

De f a u l t

4

3

4

M DF - 2 1 5 6

㩷 㩷 㩷 㩷

㩷

2

7

0

5

3 㩷 㩷

0 0 : 0 0

2

6

0

4

Se l e c t

1

Se t

N o r ma l

Lo g

St a nd- by

To ol s

Cl o s e d

A l a r m䋺

1

8

3

4

M ENU

Do o r

㩷5

㩷

2 0 0 6 / 0 7 / 0 1

1 2 :

6

㩷

㩷 Password (for service): 384

㩷 1 P as s wo r d

㩷2

Fo r

Se r v i c e T o o l s

3

㩷4

㩷 5 P a ss wo r d

㩷

6

㩷

0

1

2

6

C

−150℃

4

2

2

Sc r e e n

6

㩷

Interface board, MTR-480 (option) and communication cable for RS232C are necessary to reboot

memory.

28

4

0

4

0

㩷

㩷

㩷

㩷

㩷

1

㩷2

㩷3

㩷 45

㩷

㩷6

㩷

㩷

㩷

㩷1

㩷2

㩷3

4

㩷5

㩷

6

㩷

㩷

㩷

㩷

1

㩷2

㩷3

㩷4

5

㩷

㩷6

㩷

㩷

㩷

㩷1

2

㩷3

㩷4

㩷5

㩷6

㩷

㩷

㩷

㩷

㩷

㩷 1

㩷 2

3

㩷 4

㩷 5

㩷

6

㩷

㩷

3-1 Digital Lock – Unlock

Locked

0

1

0

1

0

1

0

2

1

1

1

2

1

3

1

4

1

5

o

C

1

6

1

7

1

8

To p

T e mp

- 1 5 0

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

Sc r e e n

3

3

3

4

3

5

3

6

3

7

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

To p

T e mp

- 1 5 0

o

1

9

2

0

St a t us 䋺

St a nd- by

Loc k e d

2

1

2

2

1

1

1

2

1

3

- 1 5 0

o

1

4

1

5

1

6

1

7

1

8

1

2

1

3

1

4

o

- 1 5 0

1

9

2

0

2

1

1

5

1

6

1

7

1

8

Password

1

2

- 1 5 0

3

2

3

3

3

4

3

5

3

6

3

7

3

8

3

9

4

0

Input ID and Password without pressing ENTER

key to indicate digits one by one. Press ENTER key

after all 7 digits are input.

(Ex. ID 123, Password * * * *)

N o r ma l

St a nd- by

Do o r 䋺

Loc k e d

Note) If you don’t press ENTER key within 30

seconds since you input 1st digit of ID, buzzer

beeps to revert to STANDBY automatically.

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

3

3

4

3

5

3 3

6 7

3

8

3

9

4

0

Buzzer beeps with unlocked after ID and

Password input correctly.

L oc k - Fr e e

A l a r m䋺

N o r ma l

St a t us 䋺

St a n d- b y

Do o r 䋺

Cl o s e d

1

9

Note) If you don’t open door within 30 seconds

since unlocked, buzzer beeps to lock again.

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3

8

3

9

4

0

L oc k - Fr e e

The screen shows unlocked and door open.

Note) You cannot input ID and Password at the

time.

C

1

3

1

4

1

5

1

6

1

7

To p

T e mp

3

1

1 2 3 - 䋪䋪䋪䋪

Sc r e e n

Digital Lock is unused

1

1

3

0

St a t us 䋺

A l a r m䋺

N o r ma l

St a t us 䋺

St a nd- by

Do o r 䋺

Op e n

2 0 0 6 / 0 7 / 0 1

0

2

2

9

1 2 : 0 0 : 0 0

−150℃

0

1

2

8

C

To p

T e mp

2

7

Sc r e e n

Unlocked and door open

1

1

2

6

A l a r m䋺

2 0 0 6 / 0 7 / 0 1

0

2

2

5

1 2 : 0 0 : 0 0

−150℃

0

1

2

4

C

To p

T e mp

2

3

Sc r e e n

2 0 0 6 / 0 7 / 0 1

0

2

䊶Door is closed with locked (Solenoid OFF)

1 2 : 0 0 : 0 0

−150℃

Unlocked

4

0

N o r ma l

ID

Input ID and Password

3

9

Do o r 䋺

2 0 0 6 / 0 7 / 0 1

0

2

3

8

S T ANDBY

A l a r m䋺

−150℃

3

2

o

1

8

1

9

1 2 : 0 0 : 0 0

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

Sc r e e n

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3

8

3

9

E L - OF F

The screen shows Digital Lock is unused when

you set ‘0’ (Disable) in Lock Setting screen.

C

−150℃

2 0 0 6 / 0 7 / 0 1

4

0

A l a r m䋺

N o r ma l

St a t us 䋺

St a nd- by

Do o r 䋺

Cl o s e d

1 2 : 0 0 : 0 0

29

㩷

㩷

3-2.

Digital Lock -㩷 MENU/Tools - Lock Setting㩷

㩷

㩷 Top Screen

Select Tools

Se l e c t

Tool

To p Sc r e e n

㩷1

1

M ENU

㩷 㩷

㩷 㩷 㩷 㩷

T e mp - 1 5 0 C

3

2

㩷

Se t

De f a u l t

Se t

A l a r m䋺

N o r ma l

3

Lo g

㩷4

S

D

a

t

e

T

i

m

e

t

a

t

u

s

S

t

a

n

d

b

y

䋺

4

℃

To ol s

0

1

0

2

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3

8

3

9

0

1

4

0

0

2

0 0

3 4

0

5

0 0

6 7

0

8

0

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

s

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

3

㩷

5

Do o r 䋺

Cl o s e d

Ke y

5

㩷

2 0 0 6 / 0 7 / 0 1

6

1 2 : 0 0 : 0 0

Master ID and Password input

0

1

0

2

1

0

3

0

4

0

5

0

6

0

7

0

8

0

9

1

0

1

1

Ma s t e r

I D

Ma s t e r

I D

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

L oc k

Loc k

t i n g

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3

8

3

9

Lock Setting screen

4

0

0

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

Loc k

3

Sa v e

4

4

De l e t e

h i s t or y

5

5

De l e t e

a

De l e t e

a l l Us e r

0 0 0 䋪䋪䋪䋪

6

Initial setting: Master ID ‘000’㩷 Password ‘0000’

Secondary Master ID ‘384Ĺ’㩷 Password ‘384ĸ’

0

2

0

3

0

4

0

5

0

6

0

7

Sa v e

1

0

8

0

9

1

0

1

1

1

2

Us e r

1

3

1

4

1

5

I D

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

Ca n c e l

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3

8

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

Us e r

U se r

I D

3

9

0

2

Us e r

ma s t e r

I D

3

PW

4

4

5

5

6

6

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

De l et e

1

1

0

1

1

1

2

1

3

1

4

Us e r

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3

8

3

9

I D

I D

I D

1

PW

+

4

0

HI S

PC

I D

3

9

4

0

3

9

4

0

I D

0

3

0

4

0

5

0

6

0

7

0

8

0

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

4

4

5

5

6

6

Input specified ID and Password then press ENTER

key. Input ID and Password again for confirmation

and press ENTER key again to delete specified ID

and Password.

Note) In case your input ID and Password are not

saved or not matched, they are cleared to standby.

3

3

Ar e

y ou

Al l

Us e r

3

4

3

5

3

6

3

7

3

8

M ENU

s ur e

t o

de l e t e

OK

?

Ca n c e l

Hi s t o r y

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

C o n f i r ma t i o n

Ar e

y ou

Al l

Us e r

s ur e

I D

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3

8

M ENU

2

U se r

3

9

Ca nc e l

Delete all ID and Password

0

1

4

0

2

3

3

8

History opened by Master ID is not deleted.

Input desired ID and Password then press ENTER

key. Input ID and Password again for confirmation and

press ENTER key again to save ID and Password.

Note) In case your input ID and Password are already

saved or not matched, they are cleared to standby.

0

1

3

7

PC

C o n f i r ma t i o n

1

Delete specified ID and Password

3

6

OK

Delete all history of door open-and-shut

0

1

4

0

a s

+

3

5

M aE bN lU e 䋩

1 . En

䋨 0 . Di s a b l e

I D

2

Ne w

3

4

Lock setting: 0: Disable 1䋺Able

2

3

3

3

i ng

1

a

Sa v e

6

Saving of ID and Password

4

0

Se t t i ng

2

0

1

3 3

8 9

6

2

PW

3

7

Sv c

Se t t i ng

L o c k. S e t t

+

3

6

OK

1

3

3

5

M ENU

o

−150

3

4

M DF - 2 1 5 6

t o

de l e t e

?

OK

Ca n c e l

?

All saved ID and Password is deleted.

Saving of Master ID and Password

0

1

1

0

2

0

3

0

4

0

5

0

6

Sa v e

0

7

0

8

0

9

1

0

1

1

1

2

1

3

Ma s t e r

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3

8

3

9

4

0

Input desired Master ID and Password and press

ENTER key. Input master ID and Password again for

conformation and press ENTER key again to save

Master ID and Password.

I D

2

3

Ne w

Ma s t e r

I D

+

PW

4

5

Initial setting: Master ID ‘000’ Password ‘0000’

6

30

Parts layout

䋼Control panel䋾

Digital temperature indicator

Communication box cover

Back-up

test

switch

Remote alarm switch

Back-up

switch

Analog output terminal

Remote alarm terminal

AT sensor

Temp. control knob Battery switch

<Grille>

Power supply switch

Exhaust air vent

31

䋼Control BOX䋾

Main PCB

䋼Electric BOX䋾

12P terminal

Noise filter

Running capacitor

Starting

Capacitor

Compressor H

Fan motor

Filter sensor

Compressor L

32

Test Data

0

-10

-20

-30

-40

Chamber temp. (℃)

-50

-60

-70

-80

-90

-100

-110

-120

-130

-140

-150

-160

0

1

2

3

4

5

6

7

Time scale (hour)

8

9

10

11

12

Pull-up data(AT30℃)

40

20

0

Chamber temp.(℃)

-20

-40

1/2air temp.

-60

-80

-100

-120

-140

-160

0

1

2

3

4

5

6

7

8

9

10

11

12

Time scale (hour)

13

14

Pull-down data ( Φ3, 50Hz AT30℃ )

33

15

16

17

18

19

20

㩷

㩷

㩷

㩷

㩷 㩷 㩷 㩷 㩷 㩷 * Temperature uniformity for MDF-C2156VAN

Conditions: (chamber air temp. 㱢3, 50Hz , AT30㷄)

䋭147㷄

䋭146㷄

䋭149㷄

䋭149㷄

䋭150㷄

䋭150㷄