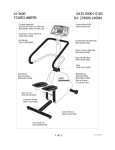

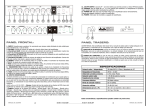

Download Independent Stairclimbers® SC95, SC91, SC85, S9I, 95Si, 93Si

Transcript