Download n `A HYDRAULIC TRANSMISSION

Transcript

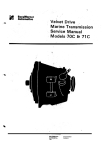

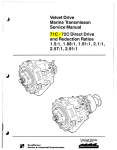

SERVICE M A N U A L n A' HYDRAULIC TRANSMISSION REDUCTION GEAR ASSEMBLY h 2.100 :1 RATIO WARNER GEAR Muncie, Indiana n P R I C E $1.50 C4 DIVISION OF BORG WARNER CORPORATION SERVICE MANUAL HYDUllUlIC TRANSMISSION REDUCTION GEAR ASSEMBLY 2.100:l RATIO S e r v i c e Manual S u p p l e m e n t for 2.100 t o 1 R e d u c t i o n U n i t s , for e i t h e r right hand o r left hand r o t a t i o n units. T h i s manual t o be used in c o n j u n c t i o n with m o d e l s 70, 71 and 72 S e r v i c e M a n u a l s w h i c h will have slight v a r i a t i o n s as noted in t h i s supplement. WARNER GEAR marine transmissions Muncie, Indiana DIVISION OF BORG WARNER CORPORATION TABLE OF CONTENTS CROSS SECTION ASSEMBLY DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 PARTS DISPLAY AND INFORMATION ............................................... 5 DESCRIPTION ............................................................. 8 DISASSEMBLY OF TRANSMISSION ................................................ 9 Removal o f reduction housing. ring gear and main shaft assembly Removal of pinion cage .............................................. 9 a s s e m b l y ........................................ 9 Removal of reduction unit adapter and sun gear assembly ...................................................... 9 Disassembly of ring gear. main shaft. coupling and bearing from reduction housing .............................................................. 9 Disassembly of Forward & Reverse Transmission .......................................................... 9 INSPECTION AND GENERAL INSTRUCTIONS .......................................... 10 ASSEMBLY OF TRANSMISSION ................................................... 10 Assembly of pinion cage & output shaft in the transmission case ....................................... 10 Selection of proper thrust washer for satisfactory end clearance ...............................................11 Assembly of s u n gear and reduction unit adapter o n forward & reverse transmission case ..................................................... 1 2 Assembly of pinion cage assembly to transmission ..........................................................12 Assembly of bearing into the reduction housing .......................................................... -13 Assembly of main shaft assembly. bearing retainer. coupling and main shaft nut in reduction housing .......................................14 Assembly of reduction housing. ring gear and main shaft assembly to the forward and reverse transmission .......................................15 BoLT TORQUE SPECIFICATIONS. ................................................. 16 GENERAL INFORMATION ....................................................... 16 I I6 Fig. I : I Cross Section o f AS3-70C Transmission Ii 1 I Fig. 2 Cross Section o f AS3-71C Transmission 3 i I Fig. 3 Fig. 4 Cross S e c t i o n o f AS13-72C Transmission Rear View o f Model 70C & 71C Transmissions Fig. 5 Rear View o f Model 72C Transmission Br Fig. 6 L L INDEX NO. PART NO. I 2 3 4 5 71-IH 4636EZ 71-140 71 -A98 120428 P a r t s D i s p l a y f o r Forward & Reverse a e c t l o n o f t h e AS3-luc ~ r a n s m i s s i o n . Only Those P a r t s D i f f e r e n t from the ASI-70C Assembly I1l u s t r a t e d . . PART NAME TRANSMISSION CASE NAME PLATE BAFFLE OIL STRAINER ASSEMBLY ANNULAR GASKET l",",'"," PART NO. 6 7 8 9 10 453006 71-158 or 71-15C 71 -159 71-IA2B I I I l 1 NO. REOfD PART NAME OIL DRAIN PLUG I SELECTIVE THRUST WASHER I THRUST WASHER I PlNlONCAGEd(0UTPUTSHAFTASS'Y. I . Fig. 7 I 'cEX] PART NO. I P a r t s D i s p l a y f o r Forward & Reverse S e c t i o n o f t h e AS3-71C Transmission. Only Those P a r t s D ~ f f e r e n tfrom t h e ASI-71C Assembly a r e I l l u s t r a t e d . PART NAEE TRANSM ISS I ON C A S E NAME PLATE BAFFLE O I L STRA lNER ASSEMBLY ANNULAR GASKET OIL D R A I N PLUG I ~ I~ - ~ ~ ~ 71 5 C ~ rSELECT l VE THRUST WASHER NDEX REQ'D I NO. 1 I 11 1 I I I 1 1 9 10 11 12 13 PART NO. / 71 - 159 71 -IA2B R6-177 72-A66B 72-176 NO. REO'D PART NAME I I THRUST WASHER PINION CAGE & OUTPUT SHAFTASS'Y. DOWELPIN REVERSE CLUTCH PLATE OUTER CLUTCH PLATE I I 3 2 I Fig. 8 INDEX NO. 1 2 3 4 5 6 6 PART NO. 72-1 K 4636FU 71 -A98 453006 71-1 59 72-lA28 P a r t s D i s p l a y f o r Forward & Reverse S e c t i o n o f t h e AS13-72C T r a n s m i s s i o n . Only Those P a r t s D ~ f f e r e n tf r o m t h e AS1 I- 72C Assembly a r e I l l u s t r a t e d . NO. I N D E ~ P A RT NO. REQ'D NO. TRANSMISSION CASE 71-158 1 7 or NAME PLATE I 71-15C 8 O I L STRAINER ASSEMBLY I 46228 9 O I L DRAIN PLUG I 10 72-A66B THRUST WASHER I ll 72-1 76 PlNlONCAGE&OUTPUTSHAFT I PART NI\ME PART NAME NO. REQ'D SELECTIVE THRUST WASHER I DOWEL PIN REVERSE CLUTCH PLATE OUTER CLUTCH PLATE 3 3 2 Fig. 9 INDOEX PART NO. 1 2 4775L 4547BA 3 4 4547AY 3-62 1 79860 5 6 7 8 9 10 1 03322 L4-7 L4-147 X3372 L5-I L4-146 I1 4853 lzEX PART NAME OUTPUT SHAFT NUT COUPLING FOR 70 h 71 MODELS COULING FOR 72 MODEL OIL SEAL 7 1 6-1 4x1 -1 14 HEX HEAD B LT 711 6 LOCKWASHER BEARING RETAINER BEARING RETAINER GASKET BEARING REDUCTl ON HOUS l NG REDUCCTlON HOUS l NG GASKETREAR LOCK BOLT 6 P a r t s v l s p l a y f o r 2.100 t o I PART NO. I 1 6 I I 1 6 12 13 14 15 16 17 18 , g 20 21 22 eduction b n l t d PART NAME 1 1 4607 L5-A2 L3-6 4756D L3-24 L5-IAI 50 7116 LOCKWASHER MAIN SHAFT R l NG GEAR R ING GEAR SNAP RING THRUST WASHER PLANETARY ASSEMBLY FOR AUTOMOTl VE ROTATl ON L5A-I A 1 50 PLANETARY ASSEMBLY FOR NON AUTOMOTl VE ROTATl ON L5-4 SUN GEAR L5-8 REDUCTION UN IT ADAPTER 476a SNAP RING L4-145 REDUCTION UNIT ADAPTER GASKET-FRONT -- - --- - S 6 I 1 I I I PART NO. 23 179864 24 103322 PART NAK 7116-14x1-314 HEX HEAD BOLT 711 6 LOCKWASHER NO. 2 2 DESCRIPTION T h e 2.100 t o 1 r e d u c t i o n g e a r box operates i n c o n j u n c t i o n w i t h any o f the following models: Model 70, 70R, 7 0 C , 70CR, 7 1 , 7 1 R , 7 1 C , 71CR, 7 2 , 72R, 72C, and 72CR. T h e reduction gear box consists o f a planetary gear set which is always engaged and reduces the input revolut i o n b y a 2.100 t o 1 ratio. The splined output shaft of the reduction g e a r b o x is c o a x i a l w i t h t h e i n p u t shaft o f the m a i n unit and w i t h the transmission operating in forward its direction o f rotation is the same as that o f t h e e n g i n e rotation. Lubricating oil is supplied b y the pump i n the main t r a n s m i s s i o n and is returned to the main transmission by gravity and jet flow. Location of several transmission details are shown in (Figures 10 and 11). as follows: A. Oil Filler Plug Oil outlet Opening to Cooler C. Oil Inlet Opening from Cooler D. Mountings Pads and Mounting Bolt Holes E. Shift Lever F. Oil Drain Cap G. Breather H. Drive Gear I. Valve Cover J. Coupling K. Oi l Pump L. Reduction Gear Box B. c ,F CAUTION NOT1:: Either item 17 or 18 on the preceding page is used depending upon the transmission rotation. As can be seen 1;y checking the two parts in ". ure 9 t h e pinion placement is different for the two assemblies. DO NOT USE T H E WRONG ASSEMBLY Fig. 10 Left SLde o f Transmission Fig. I I Right Side, o f Transmission m DISASSEMBLY OF TRANSMISSION REMOVAL O F REDUCTION HOUSING, GEAR AND MAIN SHAFT ASSEMBLY RING 8. P l a c e t r a n s m i s s i o n r i g h t s i d e up on a c l e a n bench and loosen t h e main s h a f t nut. Remove s n a p r i n g f r o m s u n g e a r , t h e n remove s u n g e a r from r e d u c t i o n u n i t adapter. DISASSEMBLY O F R I N G GEAR, M A I N SHAFT, COUPLING AND BEARING FROM REDUCTION HOUSING Place an inch t h i c k block under the r e a r of forward and reverse transmission j u s t forward of reduction unit adapter s o that reduction unit w i l l c l e a r bench. 9. Remove m a i n s h a f t n u t a n d c o u p l i n g and s l i d e r i n g g e a r and main s h a f t from r e d u c t i o n housing. 1 0 . Remove s n a p r i n g a n d m a i n s h a f t f r o m A transmission stand similar NOTE: t o t h e o n e s h o w n i n ( F i g . 1 2 ) may b e b u i l t from one i n c h a n g l e i r o n . One p i e c e is placed t o hold t h e t r a n s m i s s i o n from s l i d i n g forward and a second angle is placed t o support t h e case j u s t forward of the reduction unit adapter. The two a n g l e s may b e w e l d e d t o a n y s u i t a b l e s u p porting pieces. Remove t h e t w o 7 / 1 6 b o l t s a n d l o c k washers which f a s t e n t h e r e d u c t i o n housing and t h e reduction adapter t o t h e forward and r e v e r s e t r a n s m i s s i o n c a s e , a n d t h e 3/8 b o l t s w h i c h f a s t e n the reduction adapter t o the reduct i o n housing. Slide the reduction housing, r i n g g e a r and main s h a f t assembly rearward off the transmission. REMOVAL O F P I N I O N CAGE ASSEMBLY ring gear. 1.1. Remove b e a r i n g r e t a i n e r a f t e r r e m o v i n g s i x hex head b o l t s and lockwashers t h a t r e t a i n it. 12. L i f t r e a r b e a r i n g cone from i t s cup. 13. T h e o u t e r r a c e a n d f r o n t c o n e c a n b e p r e s s e d from r e d u c t i o n h o u s i n g on an arbor press. P r e s s on r e a r f a c e of f r o n t bearing cone while reduct i o n housing is supported on its r e a r f a c e on a c l e a n f l a t s u r f a c e . DISASSEMBLY O F FORWARD & REVERSE TRANSMISSION 14. Follow disassembly procedures given i n S e r v i c e Manual 'Velvet D r i v e ' H y d r a u l i c T r a n s m i s s i o n e i t h e r Model 70, 71, o r 72 a s required f o r d i s assembly of forward and reverse transmission. Remove t h r u s t w a s h e r f r o m r e a r o f planet cage. S l i d e planet cage assembly rearward from u n i t . Remove t h r u s t w a s h e r from r e a r o f sun gear. REMOVAL OF REDUCTION U N I T ADAPTER AND SUN GEAR ASSEMBLY Remove s i x l o c k b o l t s a n d l o c k washers t h a t r e t a i n reduction u n i t a d a p t e r , t h e n remove a d a p t e r a n d s u n g e a r assembly from forward and r e verse transmission. Fig. 12 T r a n s m i s s i o n on s t a n d INSPECTION AND GENERAL INSTRUCTIONS 1. Cleanliness is absolutely necessary during assembly t o insure proper functioning of transmission. Transmission c a s e passages should always have p l u g s removed t o a l l o w f o r thorough c l e a n i n g . When a v a i l a b l e use compressed a i r t o d r y p a r t s before they a r e assembled. Do n o t wipe p a r t s w i t h r a g s t o c l e a n o r d r y t h e m a s l i n t f r o m t h e c l o t h may cause e r r a t i c valve action. 2. I n s p e c t a l l p a r t s f o r damage o r wear. Replace defective parts. 3. A l l g a s k e t s , o i l s e a l s and r u b b e r sealing r i n g s should be replaced e x c e p t i n r e l a t i v e l y new u n i t s . Judgement s h o u l d t h e n be e x e r c i s e d a s t o t h e need f o r r e p l a c i n g t h e s e parts. 4. O i l s e a l s and b e a r i n g s a r e b e s t i n s t a l l e d by u s i n g an a r b o r p r e s s , s u i t a b l e f i x t u r e s , and t o o l s t o p r o p e r l y a l i g n p a r t s being assembled. Hammering s e a l s and b e a r i n g s i n t o p o s i t i o n c a n s e v e r l y damage parts. 5. Automatic transmission f l u i d type 'A' s u f f i x 'A' should be used t o l u b r i c a t e p a r t s a s t h e y a r e assembled. P e t r o l e u m j e l l y may b e u s e d on g a s k e t s o r o t h e r p a r t s t h a t must b e held i n p o s i t i o n during assembly. A l l r u b b e r p a r t s w i l l s l i d e moreL freely i f lubricated. 6. T i g h t e n a l l b o l t s a n d s c r e w s e v e n l 1. t o t h e recommended t o r q u e . ( s e e page 16). 7. A l l p i n i o n cage s e r v i c e i n s t r u c t i o n s a r e c o v e r e d i n t h e S e r v i c e Manual 'Velvet Drive' Hydraulic Transm i s s i o n u n d e r P i n i o n Cage S e r v i c e Instruction sheets. ASSEMBLY OF TRANSMISSION ASSEMBLY OF PINION CAGE & OUTPUT SHAFT I N THE TRANSMISSION CASE i t i o n e d i n c a s e g r o o v e a s shown i n ' (Fig. 1 3 ) . 1 d P l a c e t h e r e d u c t i o n housing on i t s forward f a c e , and then s e t t h e transmission case s o t h a t i t s r e a r f a c e i s s u p p o r t e d on t h e r e a r f a c e of t h e reduction housing. This w i l l provide proper support f o r the t r a n s m i s s i o n c a s e d u r i n g t h e assemb l y o f t h e forward and r e v e r s e u n i t when t h e p i n i o n c a g e a n d o u t p u t s h a f t assembly p r o t r u d e s from t h e r e a r of t h e case. 2. Coat s t e e l back of t h r u s t washer with petroleum jelly. Install t h r u s t w a s h e r on i n s i d e t h r u s t s u r f a c e of c a s e w i t h washer t a n g pos- 3 . I n s t a l l p i n i o n c a g e and o u t p u t s h a f t f l u s h a g a i n s t t h r u s t w a s h e r a s shown i n (Fig. 14). Avoid r o t a t i o n o f p i n i o n c a g e and o u t p u t s h a f t d u r i n g assembly a s it tends t o unseat washer t a n g from i t s g r o o v e . NOTE: P i n i o n c a g e a n d o u t p u t s h a f t a s s e m b l y ( 7 2 - 1 A 2 B ) i s now b e i n g supplied with three o i l grooves around t h e l a r g e s h a f t diameter a s shown i n ( F i g . 1 5 ) . T h i s new s h a f t can be used t o replace e a r l i e r shafts. However t h e e a r l i e r s h a f t s w i t h o u t t h e g r o o v e s must n o t b e u s e w i t h t h e l a t e s t f o r w a r d and r e v e r s e . 9 transmission cases supplied without 71-28R b u s h i n g s . 4. Complete forward and r e v e r s e t r a n s mission assembly by following instruct.ions given i n e i t h e r Service Manual f o r Model 7 0 , 7 1 , o r 7 2 'Velvet D r i v e V y d r a u l i c Transmission a s required. SELECTION OF PROPER THRUST WASHER FOR SATISFACTORY END CLEARANCE 5. 6. Forward and r e v e r s e u n i t end c l e a r ance should b e checked by p l a c i n g a n i n d i c a t o r on e i t h e r i n p u t s h a f t o r o u t p u t s h a f t a s shown i n ( F i g . 16). Shove a l l p a r t s t o f r o n t o f c a s e , s e t i n d i c a t o r on z e r o , and t h e n move a l l p a r t s t o r e a r o f c a s e by pushing on d r i v e g e a r . End c l e a r a n c e should read between .004 and .043 i n c h . Fig. 14 I n s t a l l i n g P i n i o n Cage and Output Shaft W SHAFT /' Replace s e l e c t i v e t h r u s t washer i f necessary t o b r i n g end play within above l i m i t s . NOTE: End p l a y c h e c k e d d u r i n g d i s assembly permits selection of c o r r e c t washer during reassembly. .. , Fig. Fig. 13 T h r u s t Washer w i t h Tang and Groove A l i gned 15 Fig. L a t e and E a r l y Model P i n i o n Cage and O u t p u t S h a f t s 16 C h e c k i n g End P l a y 9. S l i d e sun g e a r s p l i n e s i n t o reduction unit adapter splines until gear b o t t o m s on s h o u l d e r o f a d a p t e r . 10. S u p p o r t r e d u c t i o n u n i t a d a p t e r and s u n g e a r on r e a r f a c e o f s u n g e a r and i n s t a l l snap r i n g f i r m l y i n t o i t s g r o o v e a s shown i n ( F i g . 1 8 ) . 11. I n s t a l l a d a p t e r a n d s u n g e a r o v e r t h e t r a n s m i s s i o n o u t p u t s h a f t and locate p i l o t of adapter into bore provided i n r e a r of transmission case. 12. A s s e m b l e t h e two 7 / 1 6 - 1 4 X 1 - 3 / 4 h e x head b o l t s t o i n s u r e c o r r e c t a l i g n ment, b u t do not t i g h t e n . 13. I n s t a l l s i x NEW 7 / 1 6 - 1 4 X 1 n y l o c k b o l t s and e x t e r n a l t o o t h l o c k w a s h e r s Tighten bolts shown i n ( F i g . 1 9 ) . e v e n l y a n d t o r q u e t o 4 2 - 5 0 poundsfeet. l KANSM l SS l ON Fig. 17 ction Unit , . I n s t a l 1 i n,~ gRedu naaprer G a s ~ e r - F r o n t . > - _ l . ASSEMBLY OF SUN GEAR AND REDUCTION UNIT ADAPTER ON FORWARD & REVERSE TRANSMISSION CASE. 7. 8. Support Forward and Reverse t r a n s m i s s i o n on i t s f r o n t f a c e o r p l a c e i t upright on bench with an inch block under back of t r a n s m i s s i o n t o g i v e c l e a r a n c e needed f o r assembling A transreduction unit parts. m i s s i o n s t a n d may a l s o b e u s e d a s described i n the disassembly section of t h i s manual. Coat r e a r f a c e of c a s e w i t h p e t r o l eum j e l l y a n d i n s t a l l r e d u c t i o n u n i t a d a p t e r g a s k e t - f r o n t on r e a r f a c e o f t r a n s m i s s i o n c a s e a s shown i n (Fig. 17). - 1 4 . Remove t h e t w o 7 / 1 6 - 1 4 X 1 - 3 / 4 h e x head b o l t s , which were i n s t a l l e d i n s t e p (6). AZSEMBLY OF PINION CAGE ASSEMBLY TO TRANSMISSION 15. I n s t a l l t h e t h r u s t w a s h e r o n h u b o f s u n g e a r a s shown i n (Fig. 20). 16. E n g a g e p i n i o n g e a r s w i t h s u n g e a r t e e t h a s planet cage assembly is slowly rotated t o align pinion cage splines with output shaft splines, then bottom cage against t h r u s t washer on r e a r of sun gear. SNAP RING REDUCT l ON UNIT ADAPTER Fig. 18 I n s t a l l i n g Sun Gear Snap Ring Fig. 19 1 Removing t h e Two 7 16 I n c h Bolts After T ~ g h t e n i n gt e 6 Nylock Bolts , I CAUTION: T w o p l a n e t a r y c a g e and pinion sub-assemblies are available for the 2 . 1 0 0 -1 ratio reduction units. Selection o f proper s u b assembly is dictated by direction of transmission rotation. Part numbers and matching direction o f rotation are shown in (Fig. 9 ) . Correct cage assembly must be used at all times. The pinions are located differently in the two assemblies. Install thrust washer on the hub of pinion c a g e as s h o w n in (Fig.21). THRUST ~ I AUSF RI , ~ ,P~ I,N'I ,1 O N CAGE ASSEMBLY OF RING GEAR TO MAIN SHAFT F i g . 21 18. Install mainshaft into r i n g gear. b REDUCTION UNIT MAIN SHAFT ASSEMBLY 19. Assemble snap ring firmly into ring gear groove as shown in (Fig. I n s t a l l i n g P i n i o n Cage T h r u s t Washer 22). I4-4 20. A s s e m b l e r i n g g e a r and m a i n s h a f t over pinion carrier rotating the ring gear to properly align gear teeth as the ring gear slides onto the pinion gears. gc I -8 1 -p 8, SNAP RING * I ASSEMBLY OF BEARING INTO THE REDIICTION HOUSING *' 21. P l a c e the r e d u c t i o n housing o n a n arbor press, resting the front face on a clean flat surface. 22. I n s t a l l t h e f i r s t r o w o f t a p e r e d bearing s o that inner ring rests against the shoulder in the reduction housing. T h e r e l a t i o n s h i p o f the bearing parts are shown in (Fig. 23). KlNti/ GEAR Fig. 2 2 Assembl i n g Snap R i n g + BEAR l NG a d " f 69 i' * % REDUCTIUN n u u h l n b F i g . 20 I n s t a l l i n g Sun Gear T h r u s t Washer Fig. 23 Assemb! i n g B e a r i n g i n t o t h e Reduct on Hous ~ n g I NOTE: B e a r i n g s a r e received i n matched s e t s and match marks s h o u l d check. One b e a r i n g c o n e w i l l h a v e a number w i t h a n ' A ' s u f f i x , t h e o t h e r w i l l have t h e same number w i t h o u t the 'A' suffix. The o u t e r r a c e w i l l h a v e t h e same number w i t h t h e s u f f i x ' A ' o n o n e e n d a n d n o n u m b e r on t h e o t h e r end. T h e p a r t s w i t h t h e 3' s u f f i x s h o u l d be p l a c e d t o g e t h e r and t h e e n d o f t h e o u t e r r a c e w i t h no number s h o u l d b e p l a c e d w i t h t h e b e a r i n g cone without t h e 'A' s u f f i x . RING ER F - 23. 3 . 24 I n s t a l l ing Outer 1 Race RING\ Lubricate the outer diameter of the outer race with automatic transmission f l u i d , then using a suitable t o o l a s shown i n ( F i g . 2 4 ) p r e s s r a c e i n u n t i l it is f i r m l y s e a t e d against shoulder i n the reduction housing. 24. I n s t a l l t h e r e a r b e a r i n g c o n e i n t o t h e o u t e r r a c e a s shown i n ( F i g . 2 5 ) . ASSEMBLY OF M A I N SHAFT ASSEMBLY, BEARING RETAINER, COUPLING AND M A I N S H A F T NUT I N REDUCTION HOUSING R E D U C T I O N HOUSING 1. 2 5 25. P l a c e b e a r i n g r e t a i n e r g a s k e t o n reduction housing, a l i g n i n g t h e s l o t w i t h t h e p a s s a g e s a s shown i n ( F i g . 26). G a s k e t may b e c o a t e d w i t h petroleum j e l l y f o r e a s i e r assembly. I n s t a l l ing Rear Inner Bearing Race 26. I n s p e c t r u b b e r l i p o f t h e o i l s e a l f o r c u t s , c r a c k s o r o t h e r damage which might cause leakage and replace i f necessary. Oil seal is pressed i n flush with the rear retainer face. Assemble t h e b e a r i n g retainer onto reduction housing a l i g n i n g t h e o i l p a s s a g e s a s shown i n (Fig. 26). 27. I n s t a l l t h e s i x 7/16 - 14 X 1 - 1 / 4 hex head b o l t s and lockwashers and t o r q u e t o 4 2 - 5 0 p o u n d s f e e t a s shown i n (Fig. 27). Fig. 2 6 I n s t a l l i n g Bearing Retainer and Gasket ASSEMBLY OF REDUCTION HOUSING, RING GEAR AND MAIN SHAFT ASSEMBLY TO THE FORWARD AND REVERSE T R A N S M I S S I O N 28. Use petroleum j e l l y to hold reduction housing gasket-rear in position as shown in (Fig. 28). lssemble reduction housing and bearing assembly over output s h a f t and position it against rear face of the reduction adapter. 30. Install the s i x 3/8-16 X 1-1/8 hex head bolts and lockwashers and the two 7 / 1 6 -1 4 X 1-3/4 hex head bolts a n d l o c k w a s h e r s as s h o w n in (Fig. 29). Torque the 7/16 bolts to 4 2 -5 0 p o u n d s f e e t a n d t h e 3/8 b o l t s t o 27-32 pounds feet. I Fig. 28 I n s t a l l i n g t h e R e d u c t i o n Housing Gasket- Rear 31. Inspect coupling sealing diameter to make sure that there are no burrs or s h a r p e d g e s w h i c h might d a m a g e the oil seal or prevent proper sealing, replace i f damaged. L u b r i c a t e t h e s e a l i n g d i a m e t e r and internal splines with automatic transmission fluid. Align splines of coupling to t h o s e o f t h e m a i n s h a f t and p r e s s coupling down until contact with bearing inner race is made. 32. Assemble main shaft nut as shown in (Fig. 30) a n d t i g h t e n t o 1 0 0 - 2 0 0 pounds feet. I BEAR I NC RETAdNE Fig. 27 Fig. 29 I n s t a l ! i n g Reduction Housing R e t a i n ~ n gB o l t s - 7 1 1 6- 1 4 l ~ 1 14 BOLTS AND LOCKWASHERS I n s t a l l i n g t h e S i x 7 / 1 6 Hex Head B o l t s and Lockwashers F i g . 30 I n s t a l l i n g Output S h a f t Nut TORQUE SPECIFICATIONS PART NUMBER DESCRIPTION APPLICATION 179840 3/8-16 X 1-1/4 HEX HEAD BOLT REDUCTION ADAPTER TO REDUCTION HOUSING 179860 7/16-14 X 1-1/4 HEX HEAD BOLT BEARING RETAINER TO REDUCTION HOUSING 179864 7/16-14 X 1-3/4 HEX HEAD BOLT REDUCTION HOUSING AND ADAPTER TO CASE 4853 7/16-14 X 1 HEX HEAD BOLT, LOCKING REDUCTION ADAPTER TO CASE 4775L 1-20 NUT OUTPUT SHAFT NUT 100-200 GENERAL INFORMATION MODEL WEIGHT, LBS. EMPTY 1 r TRANSMISSION OIL CAPACITY (QUARTS) lSO INCLINED LEVEL AS3-70C or CR 143 2.5 2.7 AS3-71C or CR 143 2.5 2.7 AS13-72C or CR 153.5 2.7 2.8 NOTE: OIL CAPACITY DOES NOT INCLUDE CAPACITY NEEDED FOR TRANSMISSION COOLER AND OIL LINES. C MARINE TRANSMISSION STANDARD WARRANTY TO ENGINE MANUFACTURERS S e l l e r guarantees its products against defective material o r w o r k m a n s h i p f o r a p e r i o d o f 1 2 m o n t h s o r 400 h o u r s w h i c h e v e r o c c u r s f i r s t from d a t e of d e l i v e r y t o t h e f i r s t owneroperator. S e l l e r ' s o b l i g a t i o n under t h i s g u a r a n t e e i s l i m i t e d t o r e p l a c e m e n t o r r e p a i r o f a n y d e f e c t i v e m a t e r i a l when r e turned f.o.b. S e l l e r ' s f a c t o r y a t Muncie, I n d i a n a and s h a l l b e subject t o Seller's i n s p e c t i o n and v e r i f i c a t i o n o f claim. Purchasers of engines o r boats using our products should follow t h e procedure d e s i g n a t e d i n t h e warranty policy supplied by t h e company from whom t h e p r o d u c t was p u r c h a s e d . WARNER GEAR Division of Borg-Warner Corporation Muncie, I n d i a n a DIVISION OF BORG-WARNER CORPORATION FORM 108A