Download Service Manual

Transcript

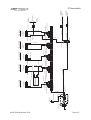

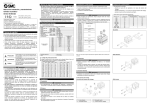

MODEL AUTOJIG 84-72 MS PARTS AND SERVICE MANUAL PART NUMBER 97.8472.0.000 AMF is trademark of AMF Group, Inc. 11/2012 LIMITED WARRANTY ON NEW AMF REECE EQUIPMENT Warranty provisions: A ninety (90) day limited service labor warranty to correct defects in installation, workmanship, or material without charge for labor. This portion of the warranty applies to machines sold as ”installed” only. A one (1) year limited material warranty on major component parts to replace materials with defects. Any new part believed defective must be returned freight prepaid to AMF Reece, Inc. for inspection. If, upon inspection, the part or material is determined to be defective, AMF Reece, Inc. will replace it without charge to the customer for parts or material. Service labor warranty period shall begin on the completed installation date. Material warranty shall begin on the date the equipment is shipped from AMF Reece, Inc. Exclusions: Excluded from both service labor warranty and material warranty are: (1) Consumable parts which would be normally considered replaceable in day-to-day operations. These include parts such as needles, knives, loopers and spreaders. (2) Normal adjustment and routine maintenance. This is the sole responsibility of the customer. (3) Cleaning and lubrication of equipment. (4) Parts found to be altered, broken or damaged due to neglect or improper installation or application. (5) Damage caused by the use of non-Genuine AMF Reece parts. (6) Shipping or delivery charges. There is no service labor warranty for machines sold as ”uninstalled”. Equipment installed without the assistance of a certified technician (either an AMF Reece Employee, a Certified Contractor, or that of an Authorized Distributor) will have the limited material warranty only. Only the defective material will be covered. Any charges associated with the use of an AMF Reece Technician or that of a Distributor to replace the defective part will be the customer’s responsibility. NO OTHER WARRANTY, EXPRESS OR IMPLIED, AS TO DESCRIPTION, QUALITY, MERCHANTABILITY, and FITNESS FOR A PARTICULAR PURPOSE, OR ANY OTHER MATTER IS GIVEN BY SELLER OR SELLER’S AGENT IN CONNECTION HEREWITH. UNDER NO CIRCUMSTANCES SHALL SELLER OR SELLER’S AGENT BE LIABLE FOR LOSS OF PROFITS OR ANY OTHER DIRECT OR INDIRECT COSTS, EXPENSES, LOSSES OR DAMAGES ARISING OUT OF DEFECTS IN OR FAILURE OF THE EQUIPMENT OR ANY PART THEREOF. WHAT TO DO IF THERE IS A QUESTION REGARDING WARRANTY If a machine is purchased through an authorized AMF Reece, Inc. distributor, warranty questions should be first directed to that distributor. However, the satisfaction and goodwill of our customers are of primary concern to AMF Reece, Inc. In the event that a warranty matter is not handled to your satisfaction, please contact AMF Reece office: Europe Prostejov, Czech Republic Phone: (+420) 582-309-286 Fax: (+420) 582-360-608 e-mail: [email protected] S-104-100 Revised 09/2004 e-mail: [email protected] ; [email protected]; website: www.amfreece.com Phones: +420 582 309 146 (Service), +420 582 309 286 (Spare Parts) ; Fax: +420 582 360 606 Warranty Registration Card (Please Fax or Mail immediately after installation) Note: All Warranty Claims Void, unless Registration Card on file at AMF Reece HQ Machine model number: (S101, S100, S104, S211, Decostitch, S4000 BH, etc) Manufacturer‘s serial or production number: Installation Site Information: Customer‘s Name: Customer‘s Mailing Address: Customer‘s Telephone Number: Supervising Mechanic‘s or Technician‘s Name: Signature of Supervising Technician: AMF Reece Technician‘s Name: AMF Reece Technician‘s Signature: Type of garment produced at this location? Average Daily Production Expected from this machine? (number of buttonholes, jackets sewn, pants produced, buttons sewn, etc) Any special requirements required at this location? What other AMF Reece Machines are at this location? How can we serve you better? Tovární 837, 796 11 Prostìjov, Czech Republic Fax: +420 582 360 606, e-mail: [email protected], website: www.amfreece.com S-104-100 Revised 09/2004 e-mail: [email protected] ; [email protected]; website: www.amfreece.com Phones: +420 582 309 146 (Service), +420 582 309 286 (Spare Parts) ; Fax: +420 582 360 606 4 Setting Procedures 4.6 Photo-Electric Switch Fig. 1 Fig. 2 .a) Hints on correct use Do not use the sensor i explosive or ignition gas. Never disassemble, repair nor taper with the sensor. Do not apply excess voltage and current over rating. Do not wire improperly such as reversing polarity. Do not short-circuit load. Do not remove protective cover from the sensor. .b) Indication In addition to the operation (orange). Sensor has indicators that denotes the level (4 green and 1 red indicators). Use them for optical axis adjustment and maintenance. .c) Sensitivity adjustment To adjusting of correctly follow those steps: aa) Put the jig with black tape under the sensor. When the black tape is under the sensor, operator indicator must not lit and one or two incident level indicators have to lit (green) see figure 1a, 1b. bb) Move the jig to the position without black tape. Here operator indicator has to lit and three or more incident indicators have to lit see figure 1d, 1e. Fig. 3 If sensor doesn´t work according points mentioned above change the position of sensitivity adjuster. Standard position for sensitivity adjuster is show in figure 2. Page 4.4 AJ84-72 M November 2012 1: VHK3-08F-01S J0A/4/400 6: KQ2L04-01S 1 3: AW20-F01CH 4: AW20P-270AS 4 2: GP46-10-01-C 7: KQ2T04-01S 18: AS1201F-M5-04 5: KQ2L06-01S 45: SS5YJ3-S41-05-M5F-Q 46: KG2H06-01S J0A/4/300 5 16: KQ2U04-00 1 3 26: KQ2L04-M5 4 20: SYJ3143-5LOU-Q 5 4 5 35: KQ2U04-00 12 2 A P1 3R J0A/4/1300 42: AS1001F-04 41: AS1001F-04 29: SYJ3143-5LOU-Q J0A/4/1400 1 3 5 40: KQ2Y04-M5 39: SYJA512-M5 44: KQ2H04-M5 43: AS1001F-04 J5A/4/600 31: KQ2L04-01S 54: KQ2S04-M5 2 4 53: KQ2S04-M5 37: KQ2T04-00 2 52: KQ2S04-M5 1 3 33: GKM8-16 34: C85C25 32: C85N20-40 YV5 - KNIFE 30: KQ2L04-01S 25: AS1201F-M5-04 38: KQ2L04-M5 24: SYJ3143-5LOU-Q 51: KQ2S04-M5 56: KQ2S04-M5 1 3 2 21: KQ2P-04 22: AS1201F-M5-04 50: KQ2S04-M5 49: KQ2S04-M5 2 15: KQ2U04-00 19: KQ2P-04 48: KQ2S04-M5 55: KQ2S04-M5 2 4 11: SYJ3143-5LOU-Q 5 1 3 4 47: KQ2S04-M5 17: AS1201F-M5-04 ROTARY ACTUATOR (FESTO DSR-25180-P) 9: AS1211F-M5-04 14: KQ2H04-M5 23: CJ2B10-30S J4A/4/1000 13: KQ2H04-M5 J2A/4/800 J2A/4/1150 27: C85N12-10 28: KJ6D J4B/4/1000 12: CQ2B20-20D J2B/4/800 J2B/4/1150 YV4 - JIG DRIVE J3A/4/950 YV3 - JIG EJECT 15A/4/900 10: CJPB10-5 J1A/4/1400 8: SYJ3143-5LOU-Q J0A/6/400 J5A/4/50 WASTE BLOWING WASTE BLOWING BLOWING THE PRESSURE FOOT BLOWING THE PRESSURE FOOT 36: KQ2S04-M5 4/200 YV2 - JIG TURN J0A/4/100 J5B/4/1100 AJ84-72 M November 2012 4/180 YV1 - JIG FLAP 5 Pneumatics 2 1 Page 6.2 Programs manufacturer setting Program 1 1 2 8 9 10 11 12 13 14 15 16 17 18 19 20 Fast Sew Double Jig Knife delay START Knife delay END Dense into Corner Start dense time End dense time Set DENSE speed SLOW sew speed NEEDLE DOWN sped MAX sewing speed Jig Flap Action Speed to Corner Auxillary drive Ph-cell Retry QTY Program 2 ON OFF OFF OFF OFF Delay 1,0 sec Delay 1,0 sec Speed 4 Speed 6 Speed 6 Speed 11 ON Speed 11 OFF 30 1 2 8 9 10 11 12 13 14 15 16 17 18 19 20 Program 3 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Fast Sew Double Jig 1st Jig Corner 2nd Jig Corner 3nd Jig Corner 4th Jig Corner Stepback trimming Knife delay START Knife delay END Dense into Corner Start dense time End dense time Set DENSE speed SLOW sew speed NEEDLE DOWN speed MAX sewing speed Jig Flap Action Speed to Corner Auxillary drive Ph-cell Retry QTY Fast Sew Double Jig 1st Jig Corner 2nd Jig Corner 3nd Jig Corner 4th Jig Corner Stepback trimming Knife delay START Knife delay END Dense into Corner Start dense time End dense time Set DENSE speed SLOW sew speed NEEDLE DOWN speed MAX sewing speed Jig Flap Action Speed to Corner Auxillary drive Ph-cell Retry QTY AJ84-72 M November 2012 ON OFF OFF OFF OFF Delay 1,0 sec Delay 1,0 sec Speed 4 Speed 6 Speed 6 Speed 11 ON Speed 11 OFF 30 Program 4 OFF OFF Needle down Needle down Cycle End? Cycle End? OFF OFF OFF OFF Delay 1,0 sec Delay 1,0 sec Speed 4 Speed 6 Speed 6 Speed 11 ON Speed 11 OFF 30 1 2 3 3a 4 4a 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Program 5 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Fast Sew Double Jig Knife delay START Knife delay END Dense into Corner Start dense time End dense time Set DENSE speed SLOW sew speed NEEDLE DOWN sped MAX sewing speed Jig Flap Action Speed to Corner Auxillary drive Ph-cell Retry QTY Fast Sew Double Jig 1st Jig Corner 1st Corner slow 2nd Jig Corner 2nd Corner slow 3nd Jig Corner 4th Jig Corner Stepback trimming Knife delay START Knife delay END Dense into Corner Start dense time End dense time Set DENSE speed SLOW sew speed NEEDLE DOWN speed MAX sewing speed Jig Flap Action Speed to Corner Auxillary drive Ph-cell Retry QTY OFF OFF Slow sew Speed 0 Slow sew Speed 0 Cycle End? Cycle End? OFF OFF OFF OFF Delay 1,0 sec Delay 1,0 sec Speed 4 Speed 6 Speed 6 Speed 11 ON Speed 11 OFF 30 Program 6 OFF OFF Needle down Cycle End? Cycle End? Cycle End? OFF OFF OFF OFF Delay 1,0 sec Delay 1,0 sec Speed 4 Speed 6 Speed 6 Speed 11 ON Speed 11 OFF 30 1 2 3 3a 4 5 6 7 8 8a 9 10 11 12 13 14 15 16 17 18 19 20 Fast Sew Double Jig 1st Jig Corner 1st Corner slow 2nd Jig Corner 3nd Jig Corner 4nd Jig Corner Stepback trimming Knife delay START Tape OFF Knife delay END Dense into Corner Start dense time End dense time Set DENSE speed SLOW sew speed NEEDLE DOWN speed MAX sewing speed Jig Flap Action Speed to Corner Auxillary drive Ph-cell Retry QTY OFF OFF Slow sew Speed 0 Cycle End? Cycle End? Cycle End? OFF ON OFF ON OFF Delay 1,0 sec Delay 1,0 sec Speed 4 Speed 6 Speed 6 Speed 11 ON Speed 11 OFF 30 Page 8.B